Presentation of a Technological Hub for MIM and sintering applications

Fill in the form to register

for the event

Following the huge success of the first edition held last 23 May, which was completely sold out, Ecotre Valente, Arburg and iHR are proud to repeat the presentation of a new project that will completely change the approach to MIM for metallurgical companies.

Next 27 June in the prestigious location of Agriturismo Quattro Terre Via Risorgimento, 11, Corte Franca (BS), the technical team of Ecotre Valente, Arburg and iHR will be hosting a meeting focused on injection moulding using MIM technology.

Parts using MIM technology are widely used in various sectors, ranging from biomedical to automotive, marine, electronics and many more. This technology, which offers numerous benefits in the production of pieces with complex geometries and high quality, with details down to the micrometre, is also gaining ground in the world of fashion, expanding rapidly.

Luxury brands are increasingly adopting this technology not only for its extreme precision, but also for its benefits in terms of sustainability. No solvents or other harmful chemicals are used in the production process, and the residues produced are fully recyclable, contributing to a greener and more responsible approach.

During the meeting, Lorenzo Valente, CEO of Ecotre, and Raffaele Abbruzzetti, Managing Director of ARBURG Srl, a pioneering company in metal injection moulding technology, will be presenting the project for the Technological Hub for MIM and sintering applications, a consulting service to ensure that customers are able to produce parts using MIM without running the risk of falling into the typical pitfalls encountered when starting out on a new path with MIM and sintering.

Ecotre, a leader in the Digital Manufacturing of metallurgical processes, is the only company to possess a complete platform for MIM which enables the digitisation of the entire manufacturing process (injection and sintering).

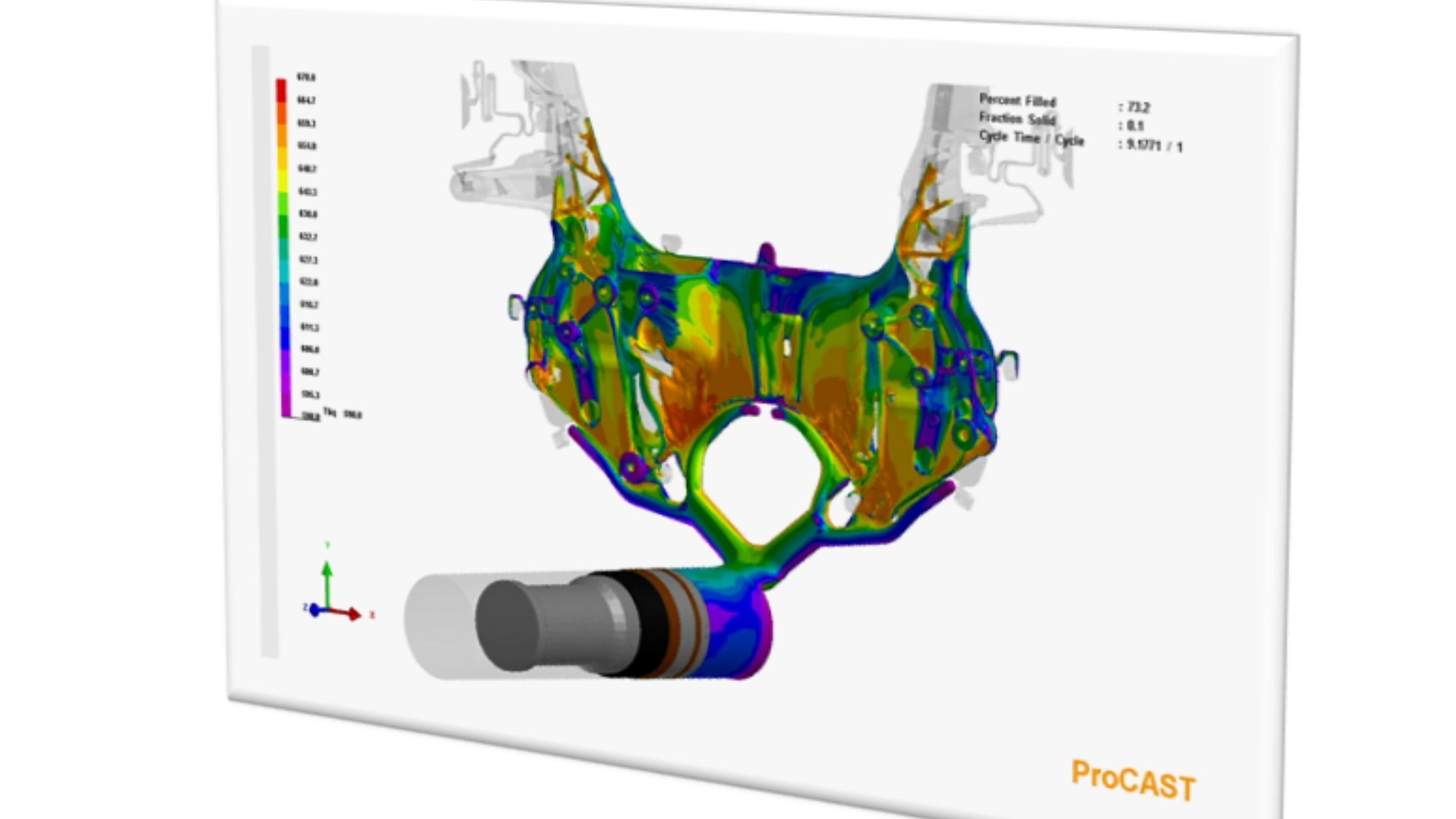

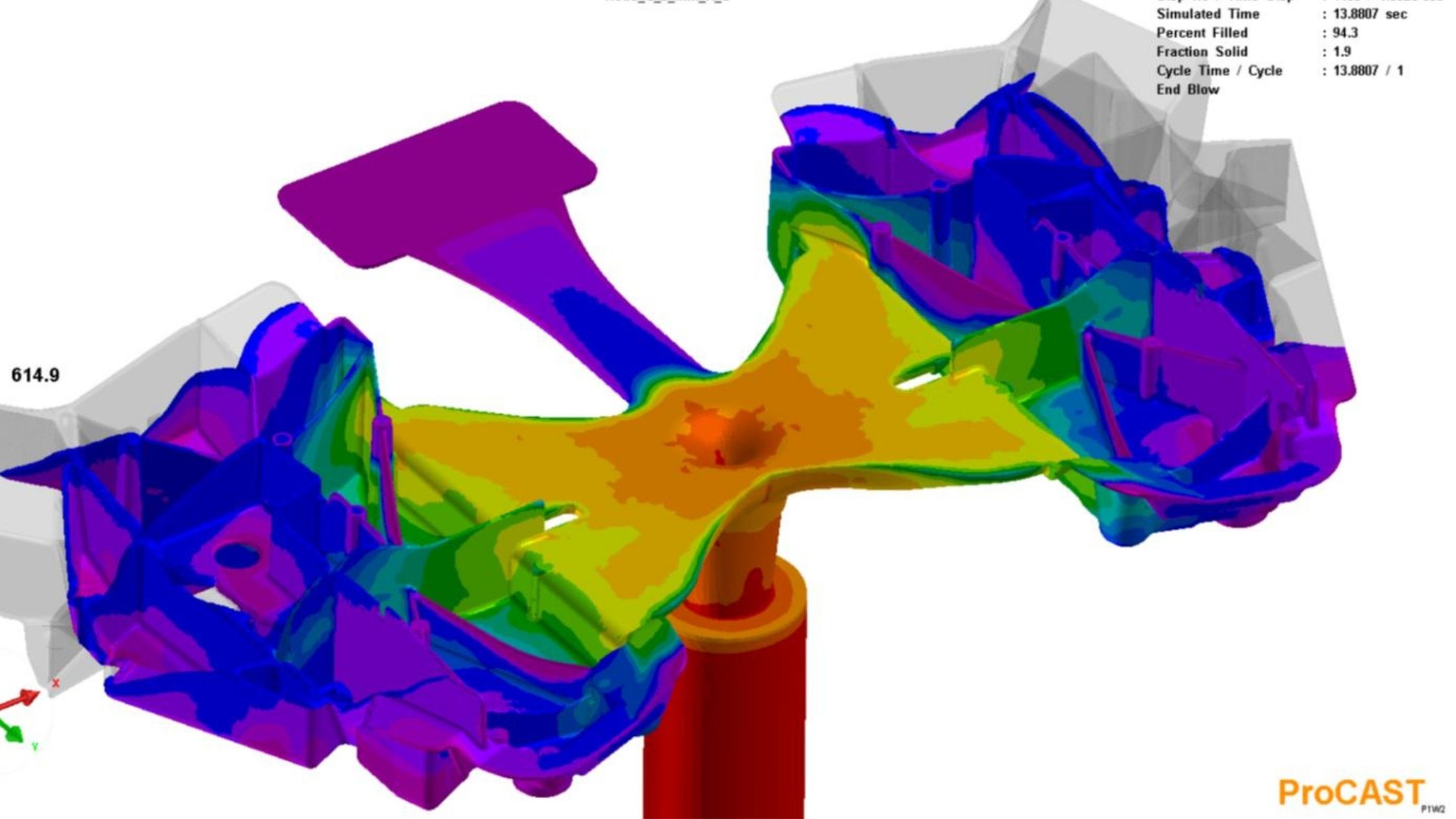

MIM using ProCAST software allows us to demonstrate, predict and therefore optimise mould heat and part quality, eliminating surface staining defects, caused by separation of the metal from the plastic carrier, on the part.

Thanks to DEFORM software, we can predict the sintering cycle to know how much the part will shrink and know if and how it will become deformed, enabling us to understand how to position the parts in the sintering furnace and avoid the presence of expensive supports.

Ecotre’s technical team has developed an innovative application called SINTRE to define the geometry to be printed to obtain a perfectly formed sintered.

The programme for the day is currently being finalised and will feature talks by industry experts representing leading companies in the field of MIM for metallurgical companies.

FILL IN THE FORM ABOVE TO REGISTER FOR THE NEXT EDITION ON 27 JUNE.

Programme

09.00 Welcome coffee

10.00 Presentation “MIM Italia: Arburg, Ecotre, iHR Project”. Raffaele Abbruzzetti, Valente Lorenzo, Michele Ranco

10.25 Presses for MIM. Arburg, Luca Adessa

10.50 Digital manufacturing for MIM and sintering: fault prediction. Ecotre, Cristian Viscardi

11.15 MIM equipment. iHR , Michele Ranco

11.40 Testimonial. VISOTTICA, CEO

12.00 MIM Package Proposal. Arburg, Ecotre and iHR

12.30 Lunch

- Target audience: Moulders, Die-makers and Designers

- Speakers: Ecotre Technical Department

- Duration: Starts Wednesday 20 September 2023 – Ends Thursday 16 November 2023

20-21 September: joint course

28 September, 5-12-19-26 October and 7-9-16 November: individual meeting slots lasting one hour - Time: From 8 a.m. to 12 noon and from 1 p.m. to 4 p.m.

- Material: DEFORM software for the duration of two months, Course notes in pdf format and Attendance Certificate

- Venue: BACCADEMY Srl – Via Industriale, 106 – 25065 Lumezzane (BS)

FILL IN THE FORM FOR FURTHER INFORMATION

Benefits

- Integrated Design and Optimization

- Enables better design choices

- Improved part moulding

- Fewer defects and better cost control