DEFORM Benefits:

- Quality improvement

- Optimization and saving in the design

- Improvement of production

- Enhanced precision

- Flexibility of use

- Reduction of calculation times

- Reduction of production rejects

- Saves money

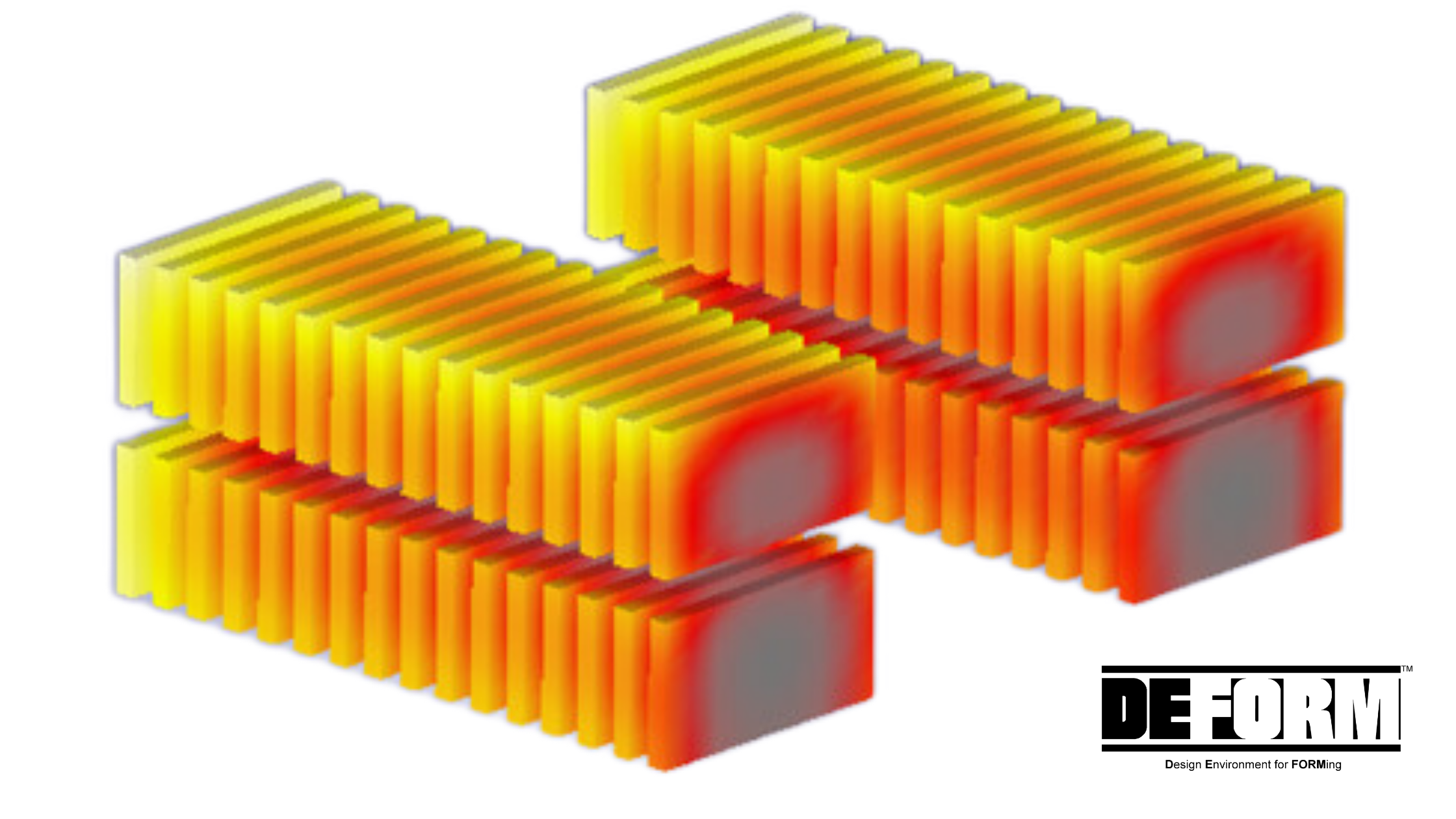

Furnaces Simulation: What and how it works

A heating furnace must therefore guarantee, in addition to excellent production, ideal heating quality and ever less energy consumption and emissions for lower environmental impact. At the same time it needs to maintain competitive capital and operational costs.

Simulation of heating furnace, single or multiple load furnace. Shorter loading times, less stresses, very slow transformations, steady-state furnaces, less transients.

In order to achieve all of these goals, for comprehensive optimisation of the furnace and reduction of energy consumption, the 3D computational thermal-fluid-dynamic simulation of the complete furnace comes into play.

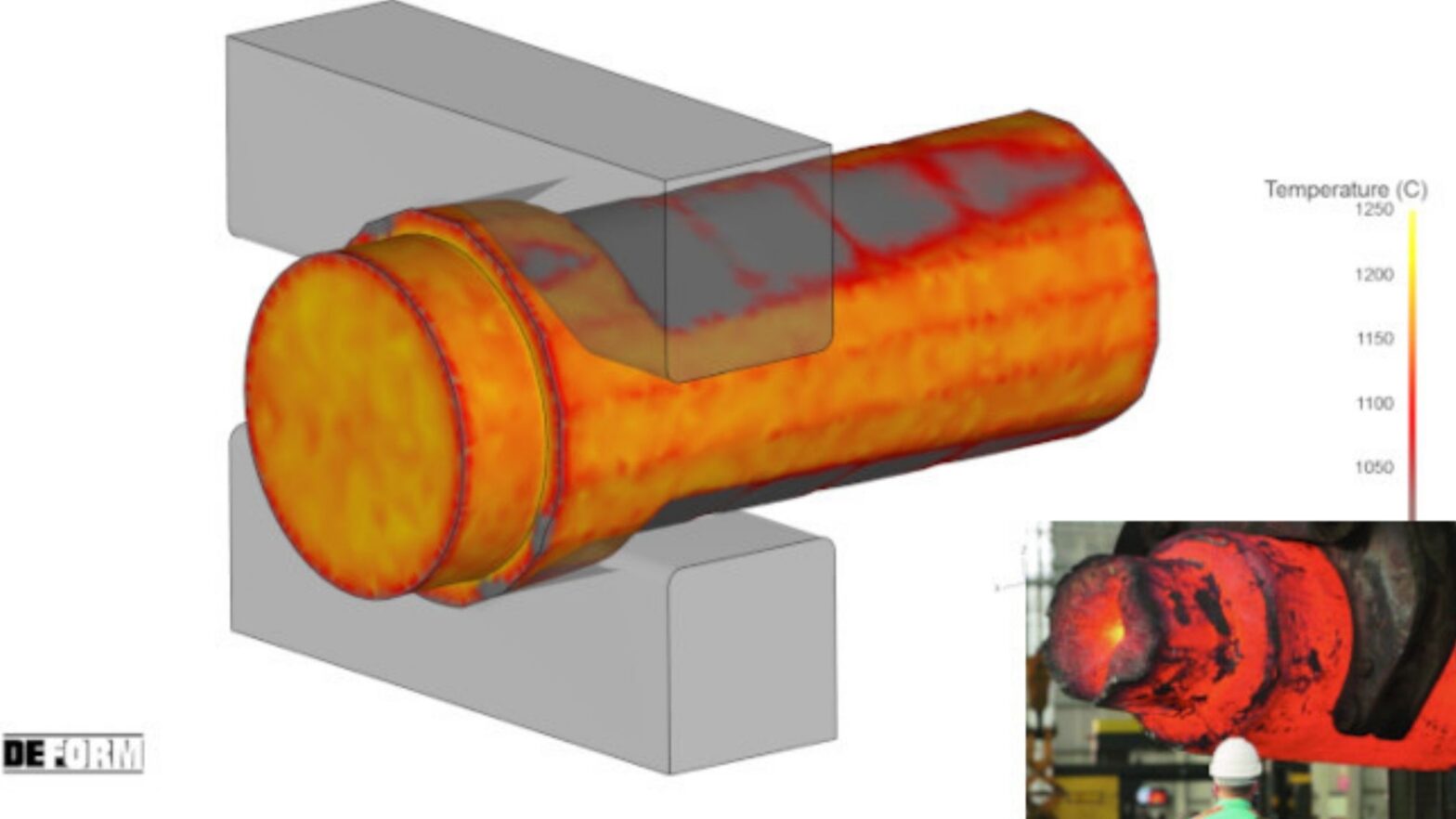

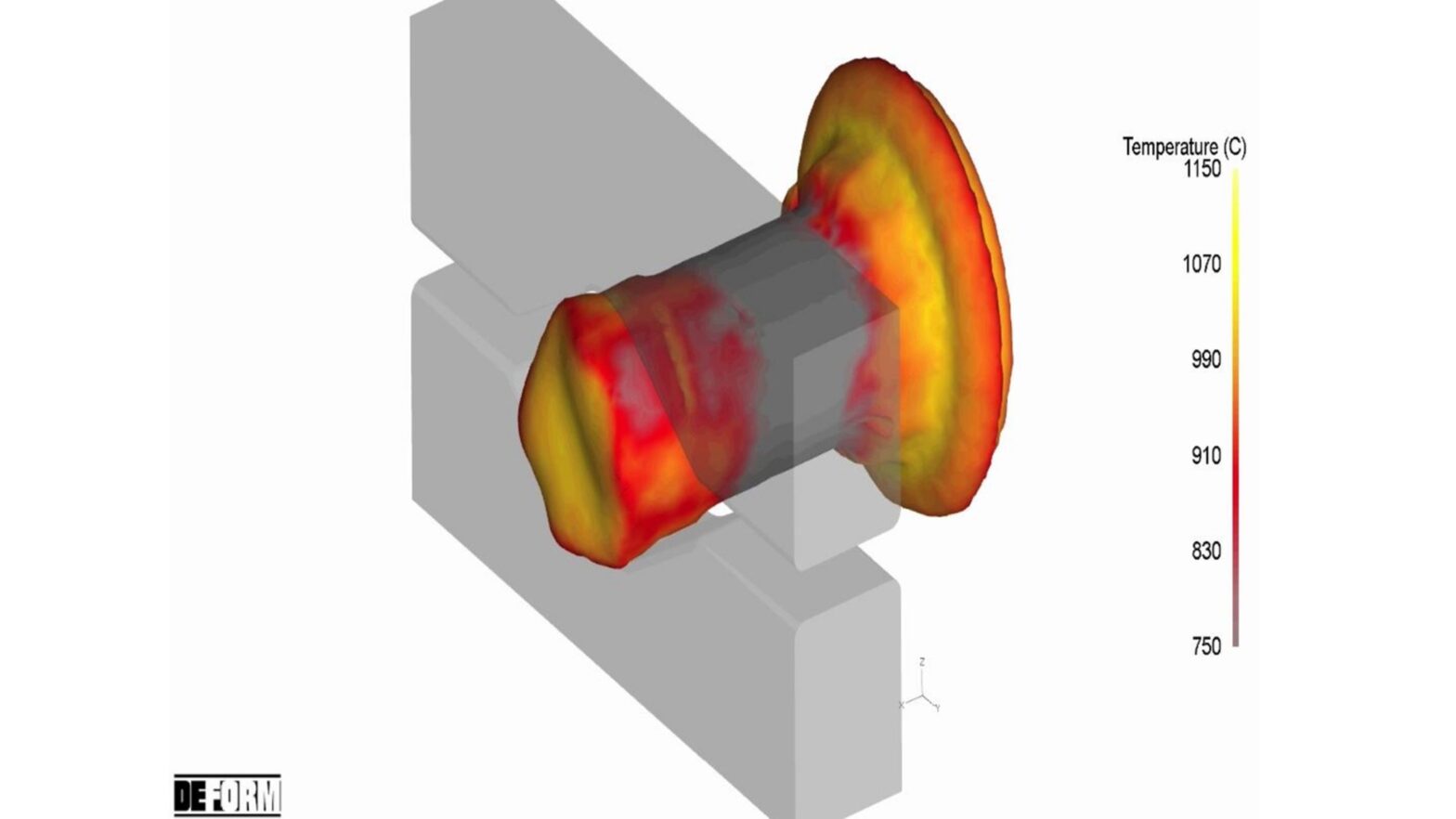

Through geometrical changes and changes to the combustion system, simulation of the heating furnaces makes it possible to analyse thermofluidodynamic details of the gases inside the furnace and to compute the comprehensive energy balance and heating curve of the load. The simulation also allows you to analyse in detail the fluidodynamic features of the gases, the effectiveness of the combustion blend, the thermal distribution on the walls and the temperature and thermal flow on the load.

The ProCAST and DEFORM heating furnaces simulation software programs reproduce the heating furnaces/complete treatment while considering movement of the load in the furnace.

The software output includes graphs, images, tables, animations and STL shapes, and the material database includes a wide range of steel, aluminum, alloys, titanium, copper and other materials.

What customers say about DEFORM:

DEFORM furnaces simulation software is American and has been optimised to be reliable, quick and easy.

- EXCELLENT AGREEMENT OF “SOFTWARE RESULTS” WITH “REALITY”DEFORM is the most widely used cold forming simulation software in the world

- SAMPLING IMMEDIATELY POSITIVEThe simulation makes it possible to identify defects obtained during forming, to understand their causes and therefore to undertake the right corrective actions

For the purchase, hire or a DEMO of the software or if you want to take advantage of a simulation service specially-made by our technical department, write or call us at +39 030 3365383