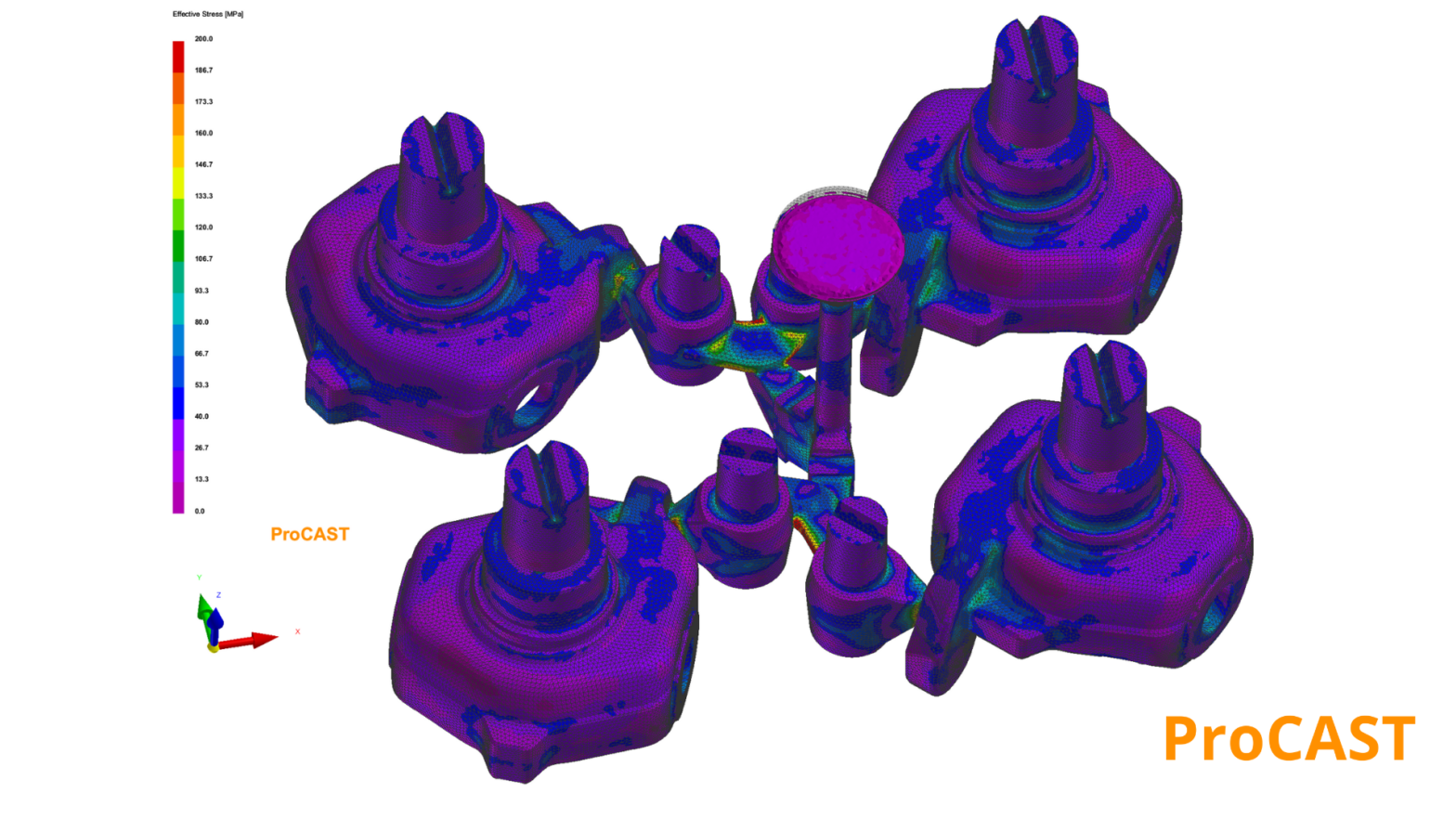

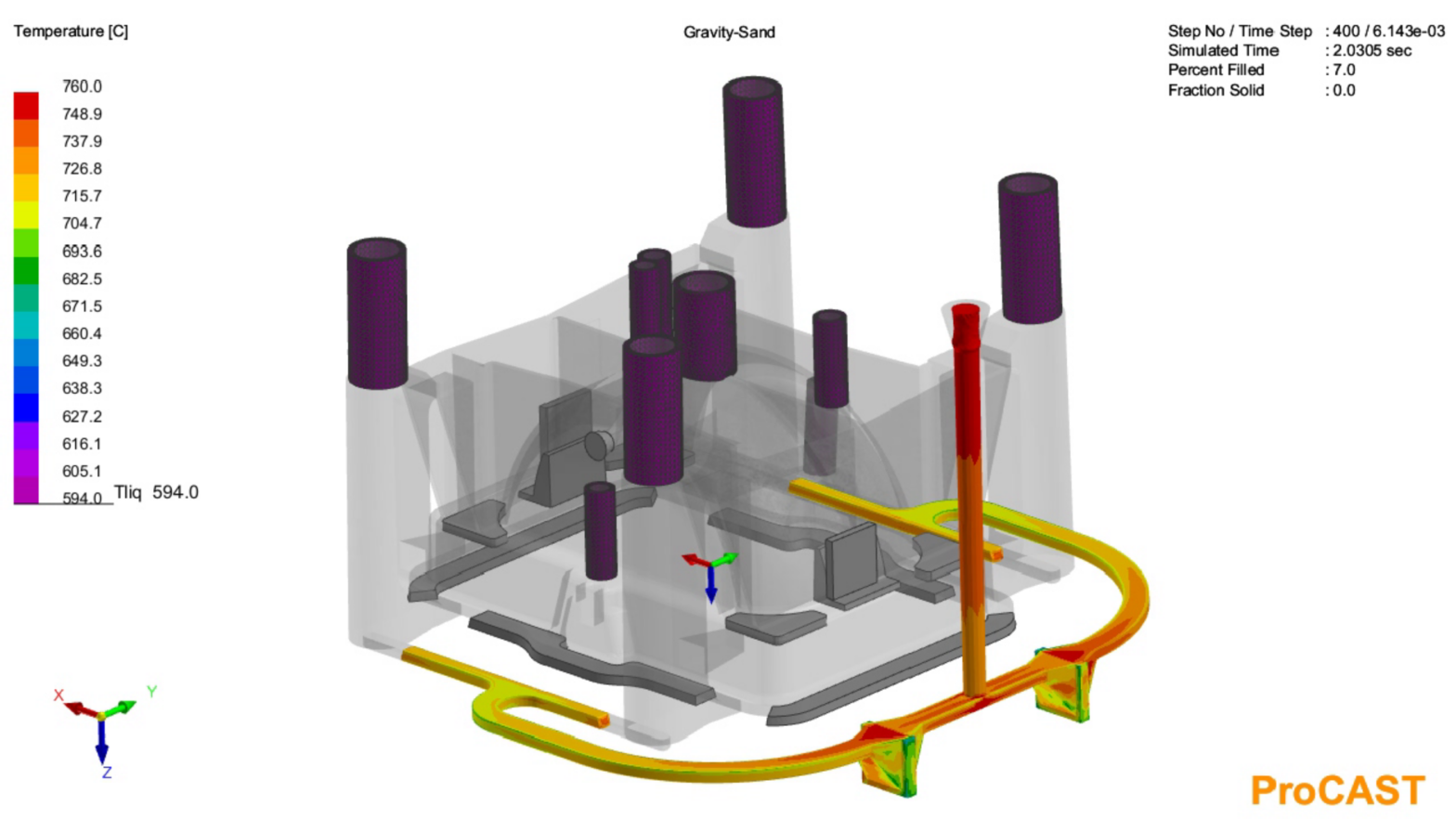

QuickCast and ProCast are the predictive software tools used by Pialorsi Stampi in the creation of an electric motor for e-bikes for Polini Motori.

The product and process simulations offered by both software tools made it possible to transform an ambitious and innovative project for the construction of aluminium supports to connect the electric motor to the bike frame into reality.

The aim of the project was to make two non-porous parts using an alloy with sufficient mechanical properties to withstand the stresses of off-road use.

The technical challenge during the production phase was to create the best conditions for the welding and subsequent heat treatment of the components.

QuickCast and ProCast software were used to simulate three different possible settings for the mould with a view to choosing the most functional solution. The results of the simulations were gradually analysed and the right adjustments made it possible to eliminate any flaws highlighted by the predictive programmes during the design phase, resulting in a functioning end product with all the specifications required by the customer.

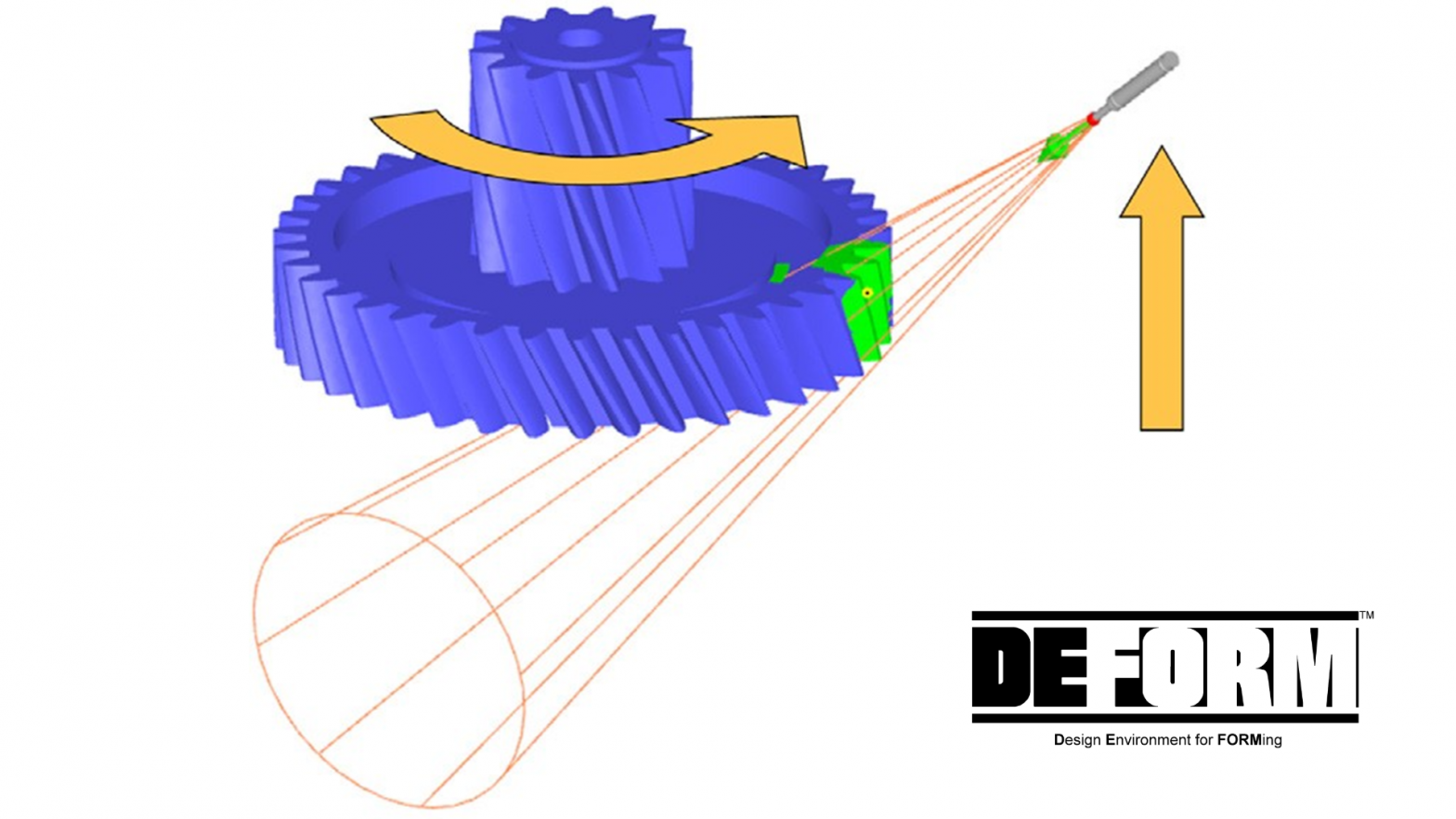

SFTC recently took part in a research project to develop modeling methods for shot peening processes. A deliverable from this work was the new Shot Peening Template, which streamlines the setup and simulation of this complicated process.

Shot peening is a beneficial surface treatment used in a wide range of industries. It induces a compressive residual stress on the surface of a metal component via cold working. This is accomplished by firing spherical shot onto a part at high velocity. The resulting compressive stress state counteracts tensile stresses experienced during inservice operation. This can greatly increase a part’s fatigue resistance.

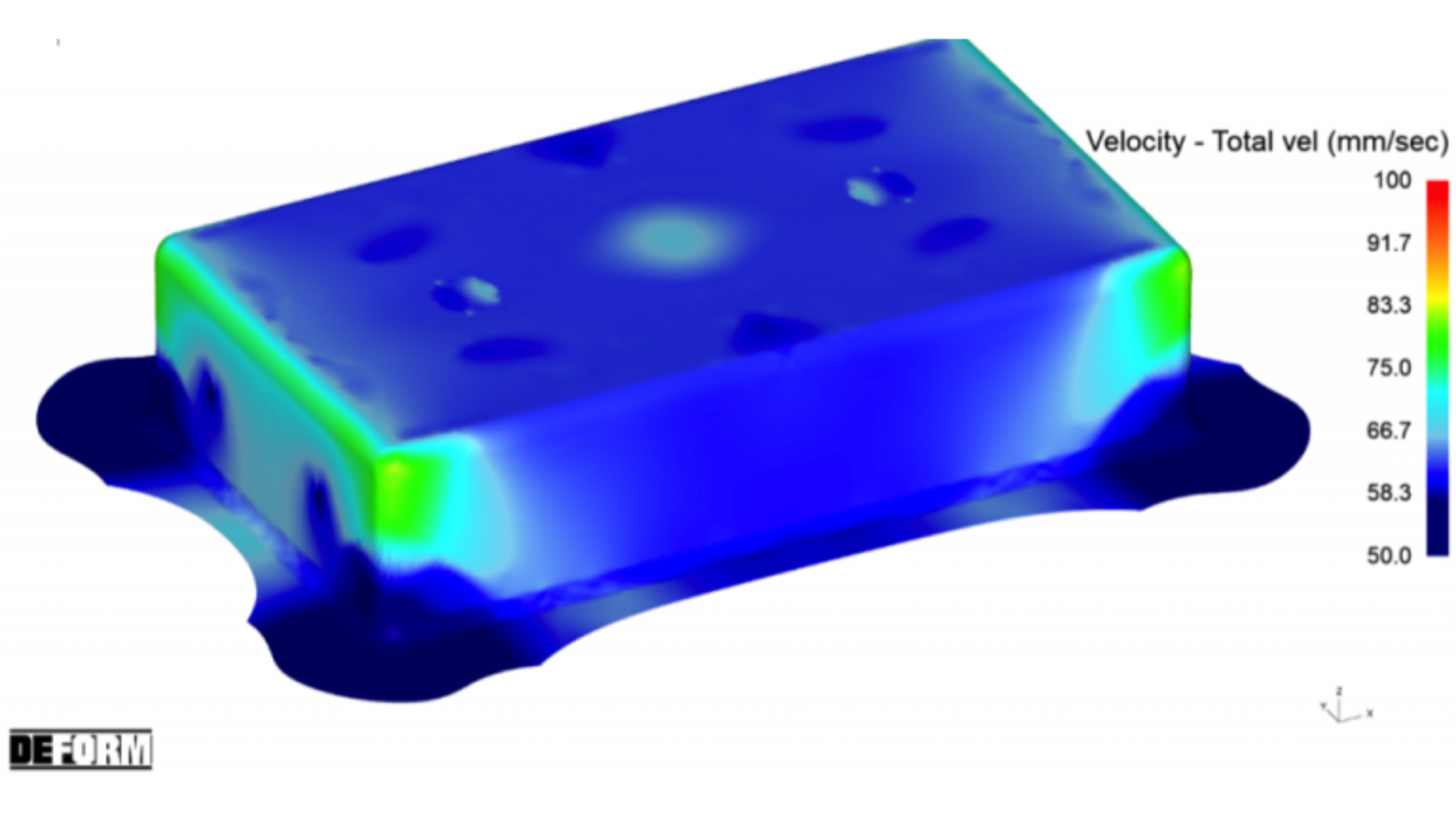

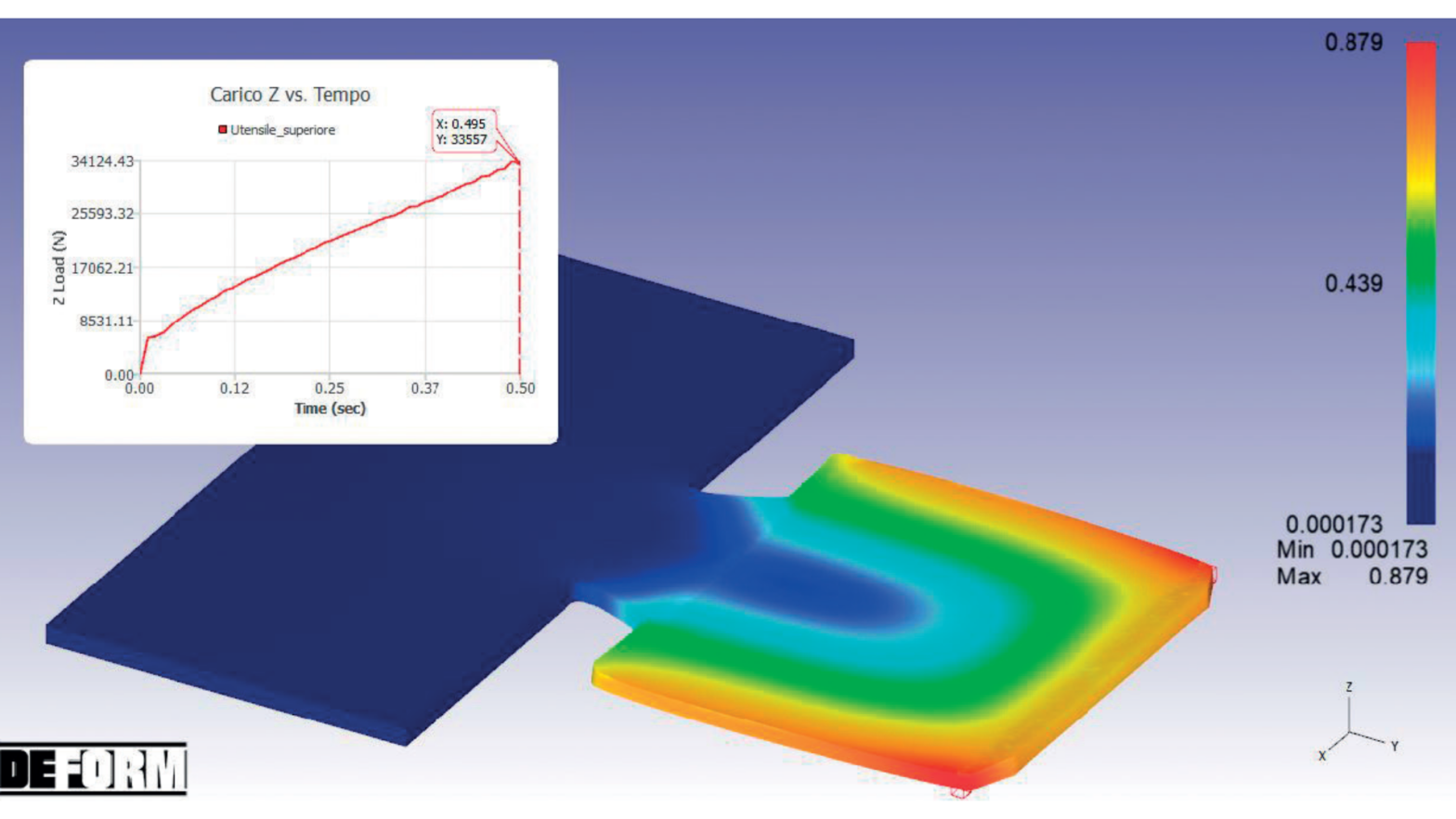

Mori 2A in collaboration with ECOTRE VALENTE carried out a deep drawing simulation of a sink. This analysis allows you to thoroughly examine all the phenomena that come into action during the drawing process, virtually sample and have all the information for setting up a compliant and optimal work cycle.

Thanks to the deep drawing tests carried out in DEFORM, Mori 2A can produce its sinks on the computer and know their performance and quality: required tons, shape, defects, wrinkles, cracks and elastic return.

Article in Italian

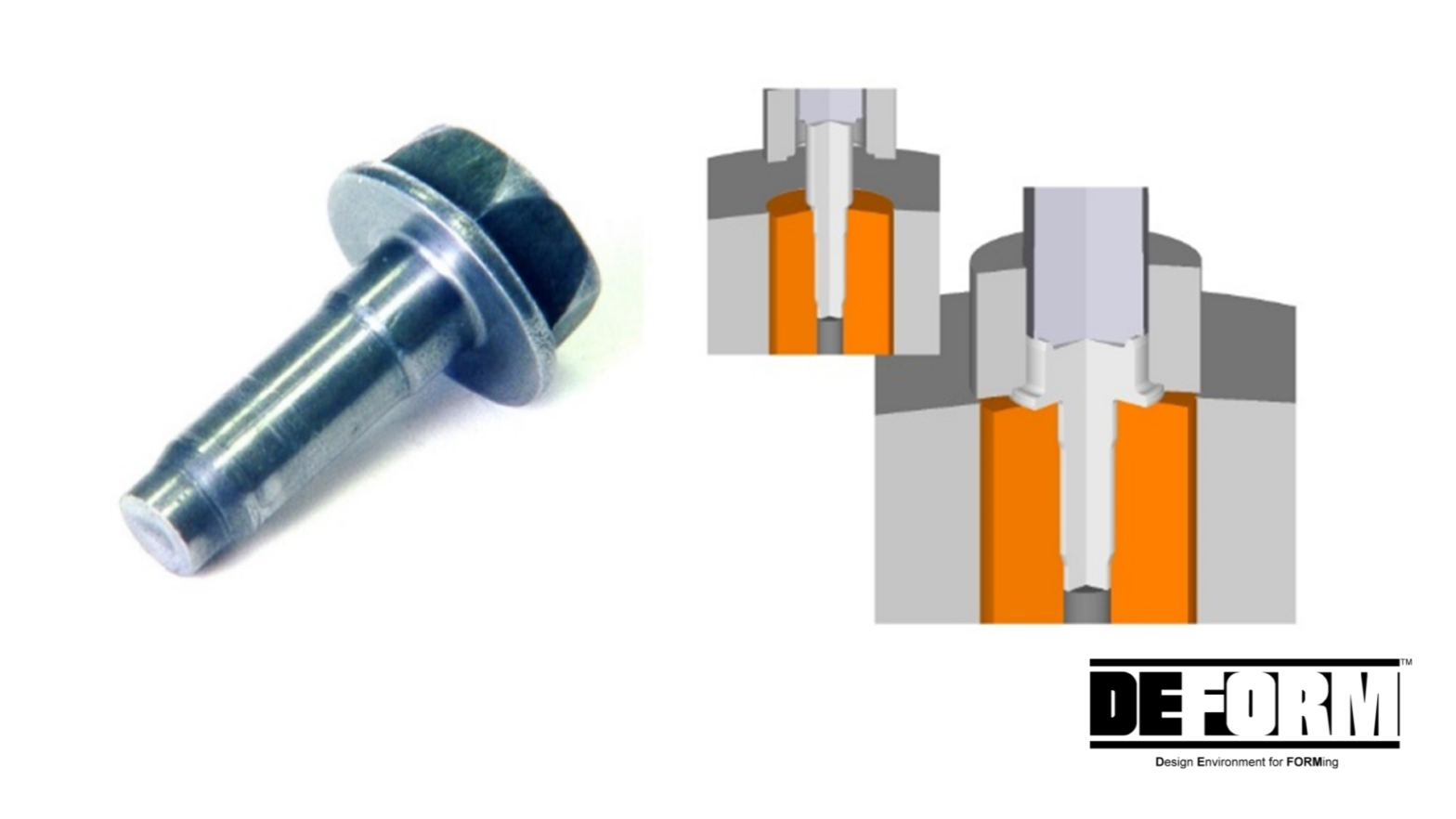

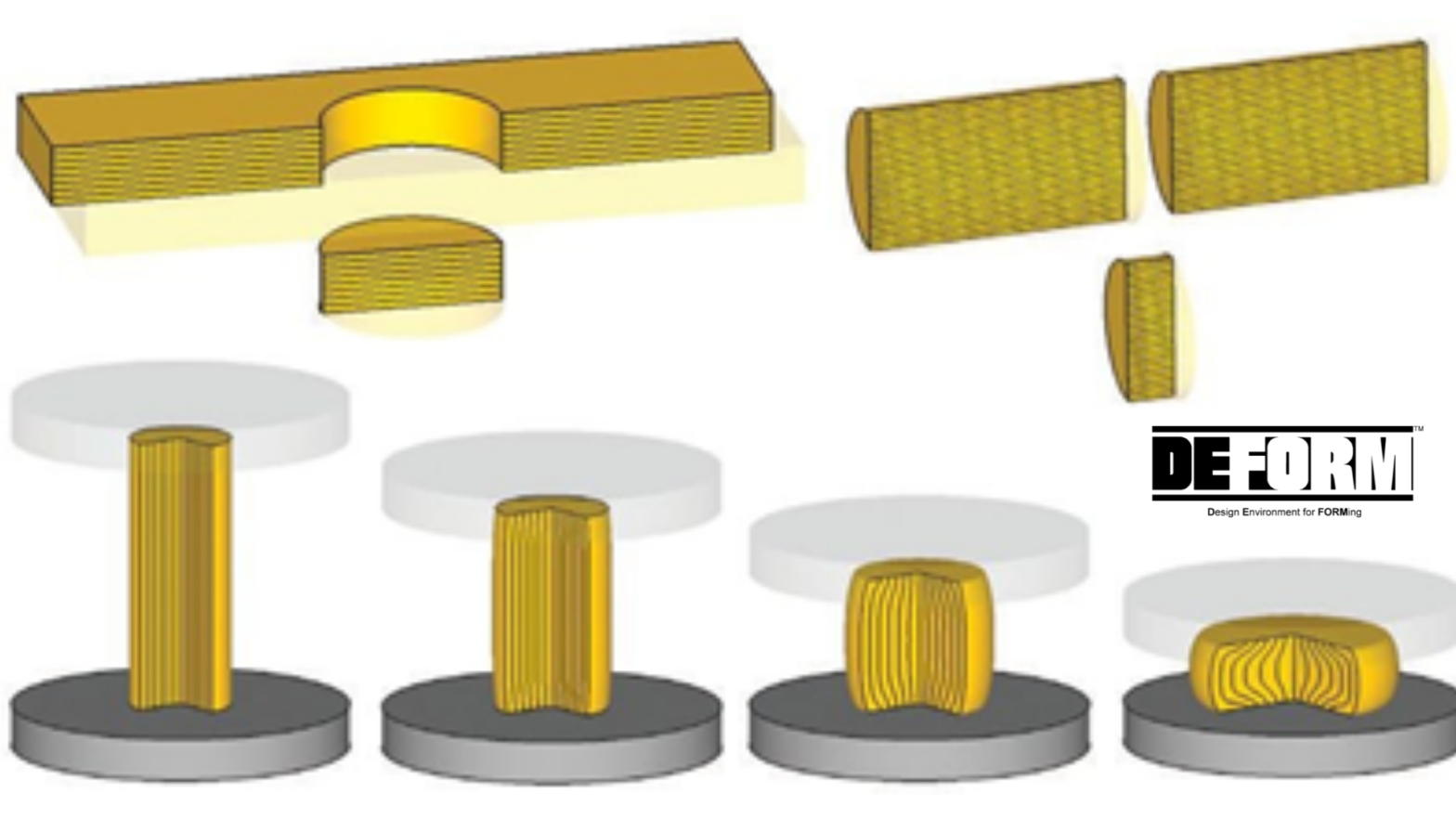

DEFORM was used to simulate the forming of the hex-head flange screw blank.

The stresses during forming were subsequently used to predict the effort and deflection of the equipment components. To study the matrix effectively, it is necessary to include the interaction between the matrix and the keying. The original matrix consisted of a hard metal insert and jacket.

DEFORM was used to perform a subsequent matrix stress analysis at the stage where the highest load was observed.

Ecotre Valente from Brescia proposes DEFORM to optimize costs through process simulations

Not only reductions in shiftwork and production in the lower cost ranges, energy savings can also come from a simple one

software.

A popular saying goes that "necessity sharpens the wits", meaning that when you are in critical conditions it is a process of nature

find new solutions to problems, and in this case to costs.

Precisely in the face of the expensive energy Ecotre Valente, it has decided to offer its customers a new weapon represented by the software

DEFORM for the simulation of energy consumption in furnaces...

Article in Talian

THE CHALLENGE

Produce a knuckle in GJS 500-7 with a weight of 41,5 kg. The dimensions of the flask are 1100 x 900 x 700 mm.

Meet the customer’s quality standard by delivering high excellent casts, with complex geometry and tight tolerance.

Ironcastings aim to precisely solve residual stress problems predicting and optimizing microstructure, mechanical properties and porosity formation along with maximum efficiency during foundry process (metal yield maximization) leading to production cost reduction, for example reducing weight of cores.

All these goals have been reached without modify the part geometry.

FONDERIA MORINI - Leader in Europe in the foundry sector, specializes in the production of aluminum and aluminum alloy castings with sand casting technology, alongside the Gravity Die Casting Foundry Division. Co-design and definition of the casting system and uprights guided by the simulation of casting on the single piece Article in Italian

Read More

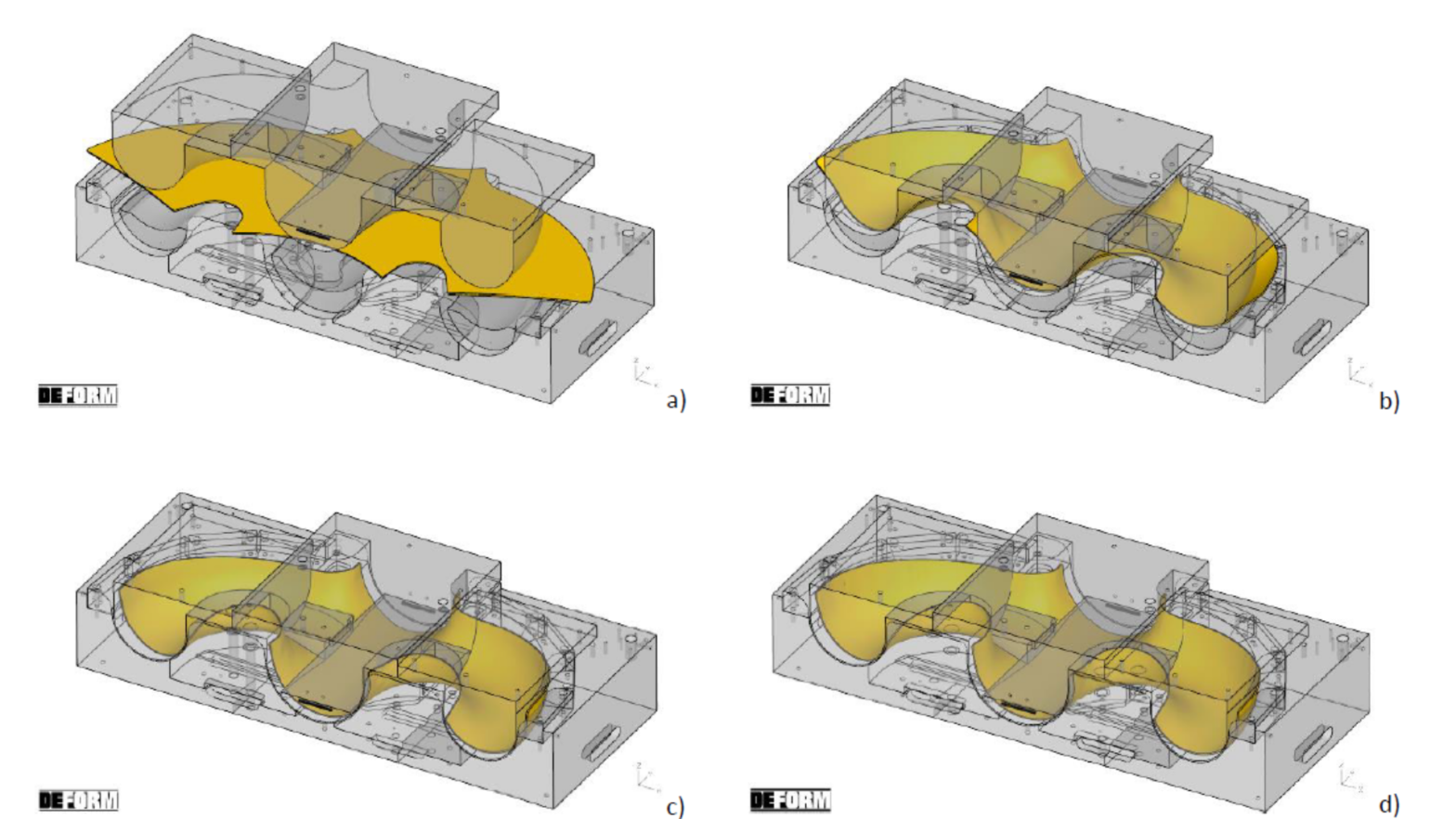

PentaP supports die makers through the service of

virtualization of the forming process, or the

FEM simulation through the use of software

DEFORM, distributed exclusively in Italy by Ecotre

Valente of Brescia. “The results obtained are a lot

interesting and allow our customers to evaluate

immediately what are the intrinsic problems

of a forming, with a very high reliability, the results

they are close to reality ”, underlines the owner.

Ecotre Valente offers solutions to metallurgical and quality problems with the partner PentaP Srl of Bergamo: www.pentap.it

This study illustrated how DEFORM-3D predicted the influence of process parameters and geometric features on final product quality. The redevelopment project achieved the following objectives that led to reduced production costs.

• Cracking was eliminated and wrinkles were avoided in the final product.

• The robust design allowed for less stringent material requirements on the Alloy 601 sheet stock.

• Use of standard sheet stock increased flexibility in production scheduling and reduced costs, since the standard material was often on hand.

• The number of stamping operations was reduced from three to two, which shortened the production cycle time.

• Continuous processing eliminated the need for in-process inventory.

• Machine tooling and setup time were reduced.

• Overall delivery time was improved.

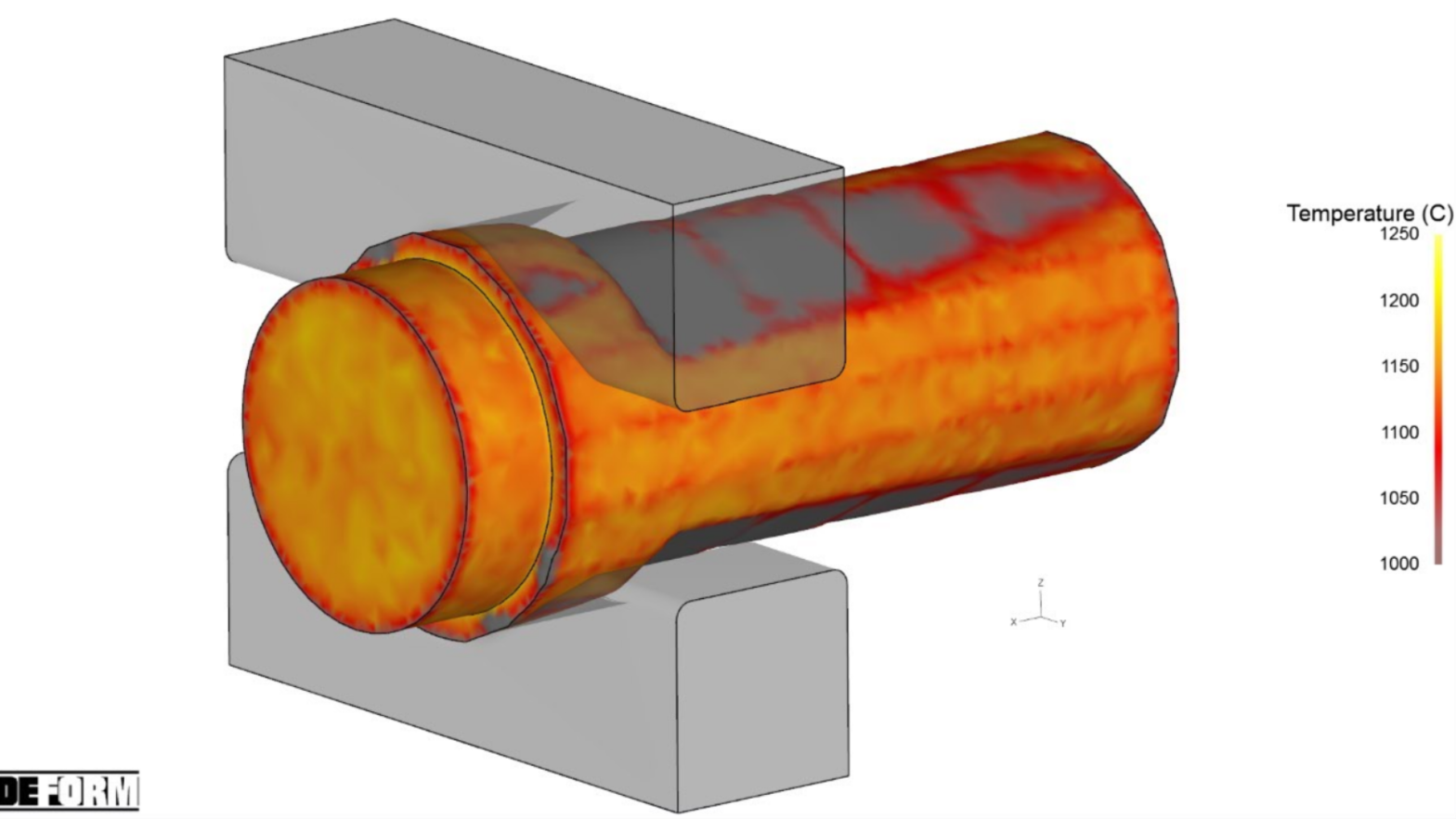

The webinar dedicated to the novelties in the simulation of hot and cold forming, coining, drawing, shearing, rolling, forging, drawing, extrusion, welding with the new software DEFORM 2021 and organized by the Brescia-based company will be held on Thursday 1 July 2021. Article in Italian

Read More

Our main focus was on closed die forging for the previous items in this series. In this, however, we will consider preforms and large components, which are often produced by open molding.

Read More

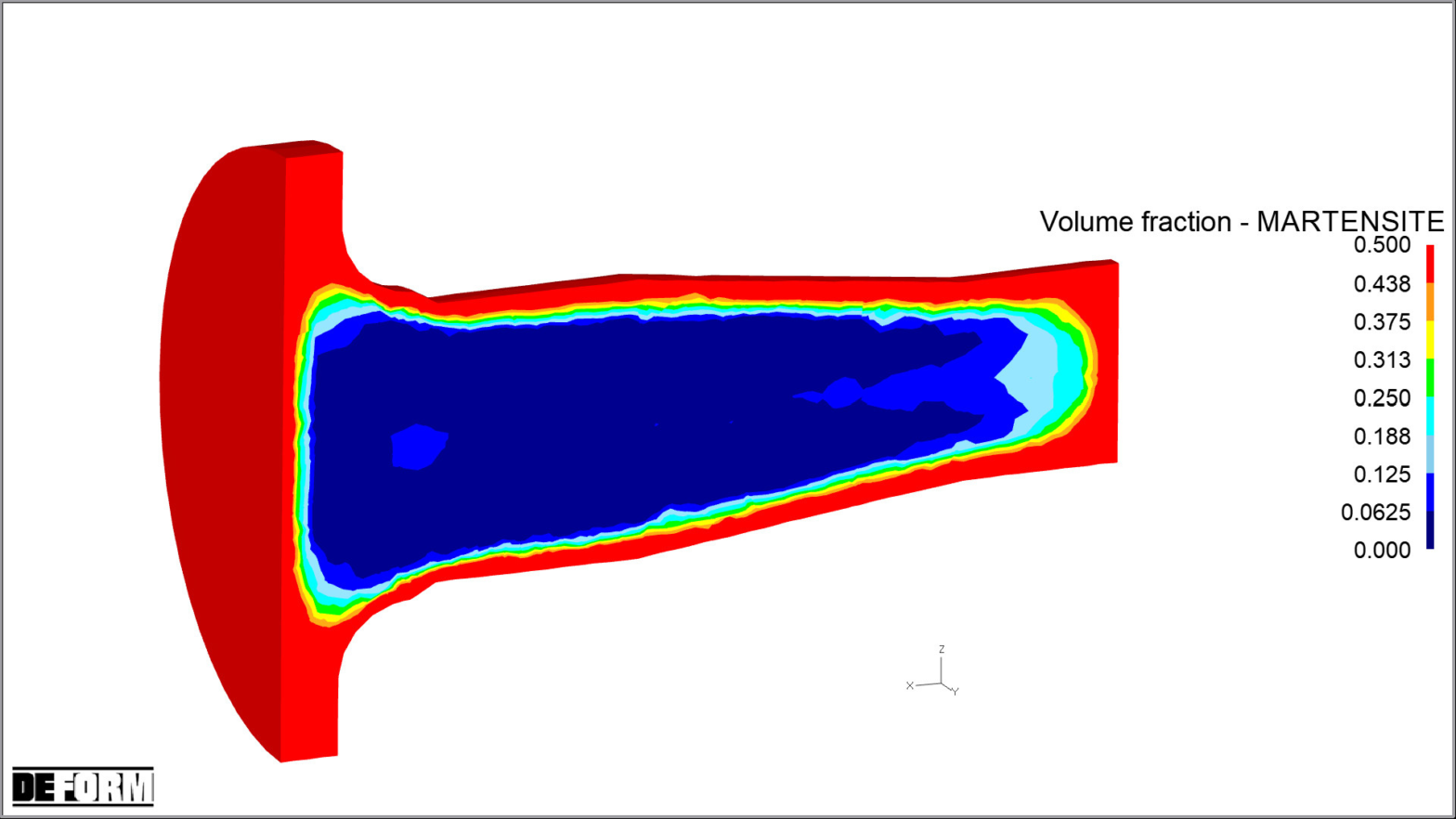

The metallurgical sector is experiencing a time of change with the demand for increasingly complex components, light, performing and high performance. The new software QuikCAST Light, QuikCAST, ProCAST 2021 and DEFORM 12.1 support steel mills, forgers, calibrators, foundries, die makers, metallurgists and designers, as they virtualize their own process and create a virtual department in which to try in advance the equipment, the production cycle and execute a preview of the quality control on the product. up to to any heat treatment and mechanical processing final providing information related to quality, properties mechanical and structural features of the product.

Read More