Solidification Course 2026 – The new edition by Ecotre

Champéry (Svizzera) – Hotel Suisse

Read more

ECOTRE Valente and CORSA 3D at MECSPE 2026: Digitalization of foundry and metallurgical processes for the manufacturing industry

BolognaFiere – Hall 36, Booth D70

Read more

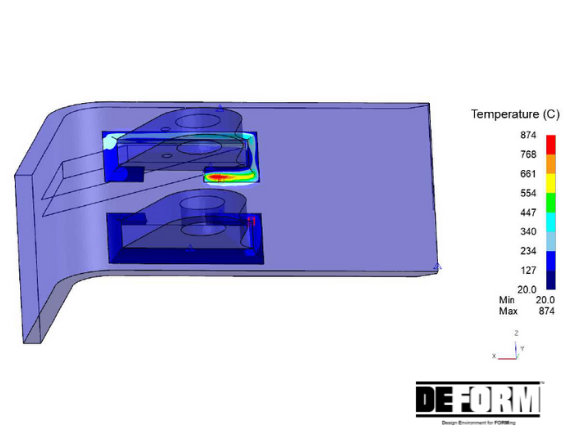

ProCAST & QuikCAST in Practice: the invisible limits of simulation with previous versions

Online

Read more

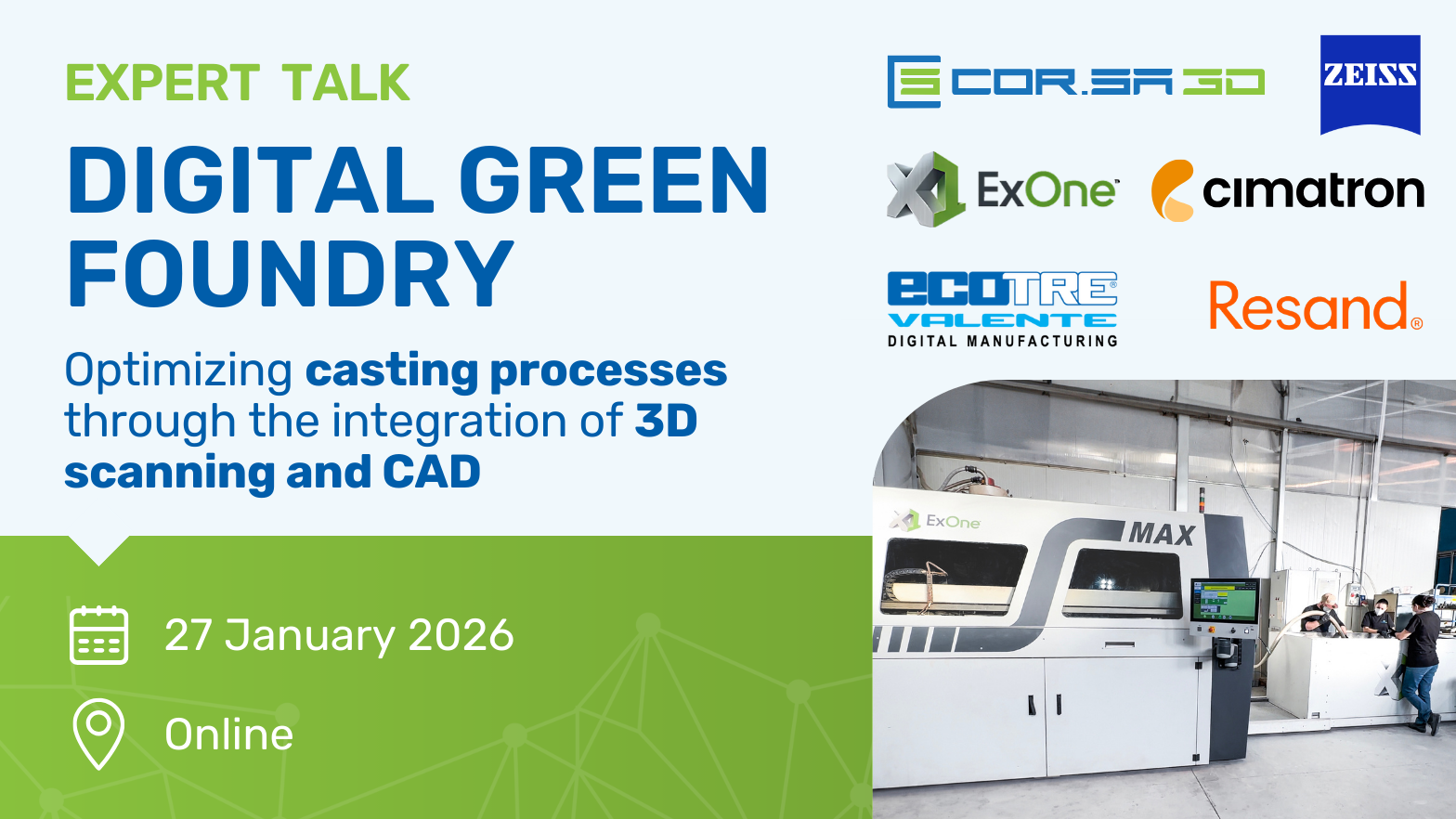

Digital Green Foundry: Optimizing the Casting Process through the Integration of 3D Scanning and CAD

Online – Live from the ZEISS headquarters in Novara

Read more

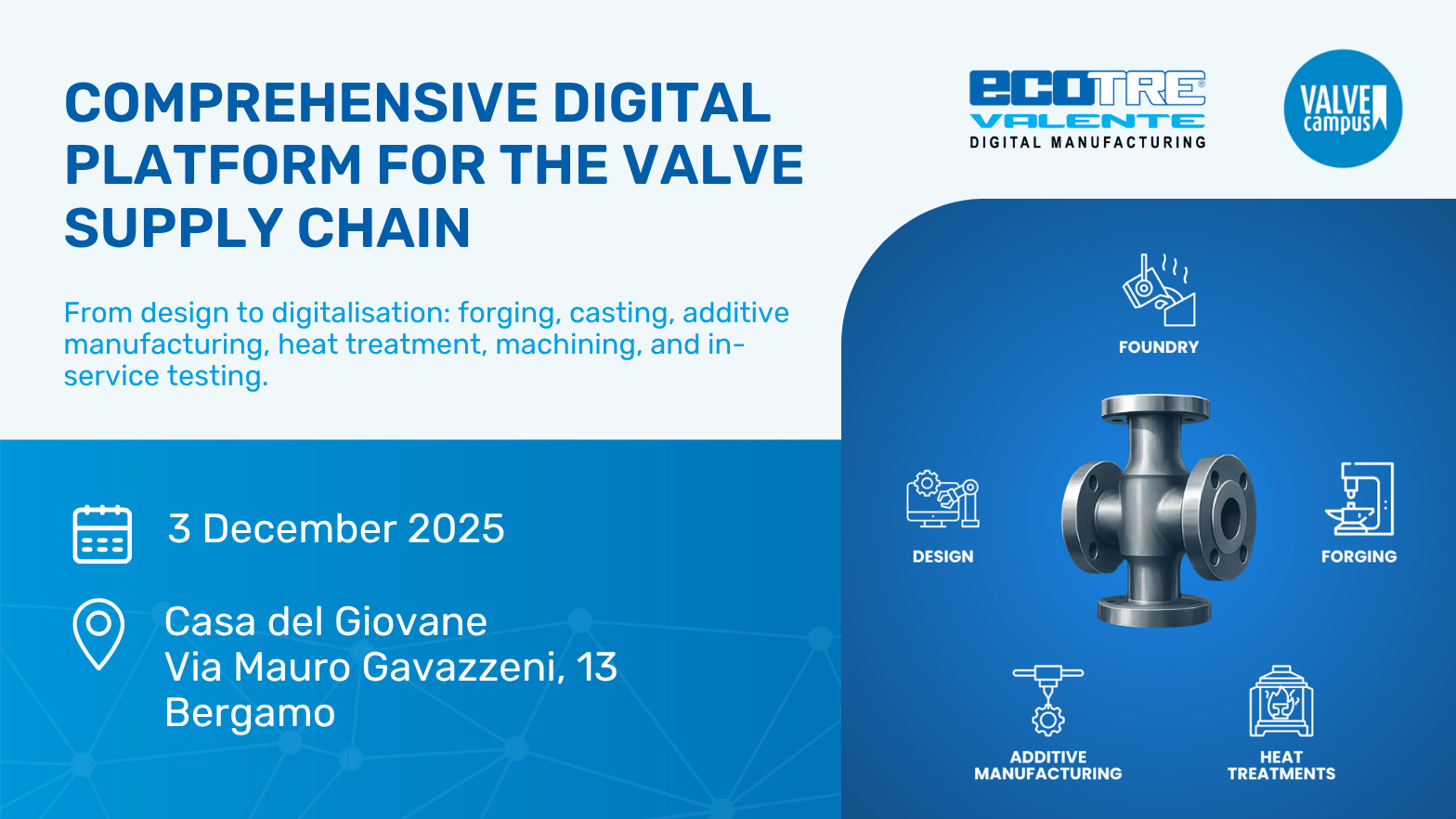

Comprehensive digital platform for the valve supply chain

Casa del Giovane – Sala Nembrini, Via Mauro Gavazzeni 13, Bergamo, Italy

Read more

Ecotre Valente at DTMI 2025

Congress Center Giovanni XXIII, Viale Papa Giovanni XXIII 106, Bergamo, Italy

Read more