DEFORM Benefits

- High quality forming products

- Elimination of rejects and reduction of defects

- Elimination of samplings

- Improved mechanical features of the workpiece

- Greater strength of the workpiece

- Reduced 3D printing times

- Reduced 3D printing costs

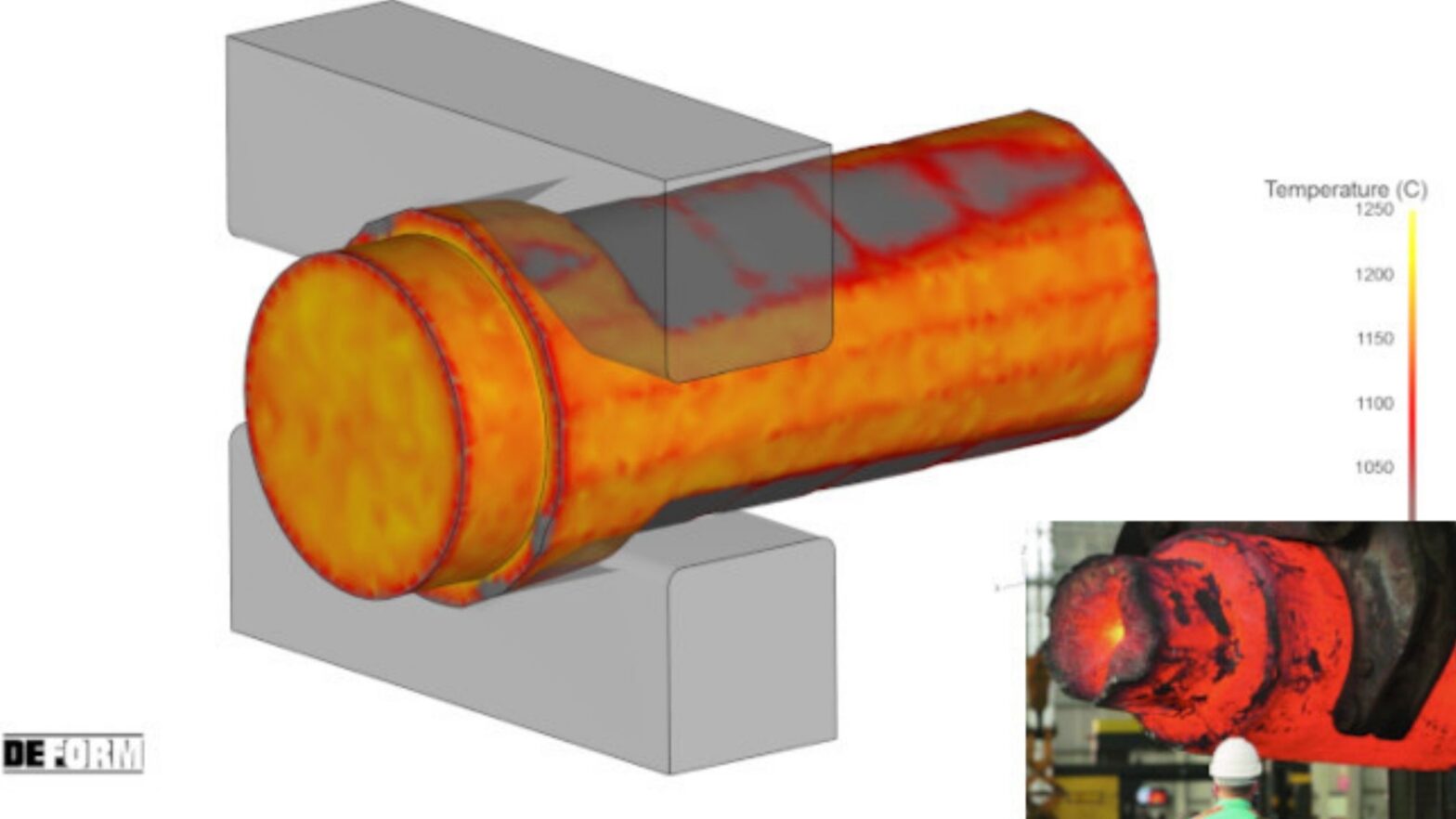

Metal Binder Jetting Simulation: What it is and how it works

The Metal Binder Jetting is used for 3D printing and the production of sand moulds and cores for foundries. This consists in a liquid binding agent which is selectively deposited on a layer of metal dust, after which the final object is formed layer by layer.

The process starts from the design of the component using a CAD and the resulting file is sent to a 3D printer that produces the object, divided into layers.

After the 3D printing stage, the produced object is a layer with poor mechanical properties and high porosity. This makes the post-process treatments of infiltration and/or debinding and sintering necessary so as to densify the printed component, enhancing its mechanical properties.

This system can make complex metal components suited for the majority of foundry materials, getting them directly from CAD files in 3D, without creating models and milling processes and thus saving time and money.

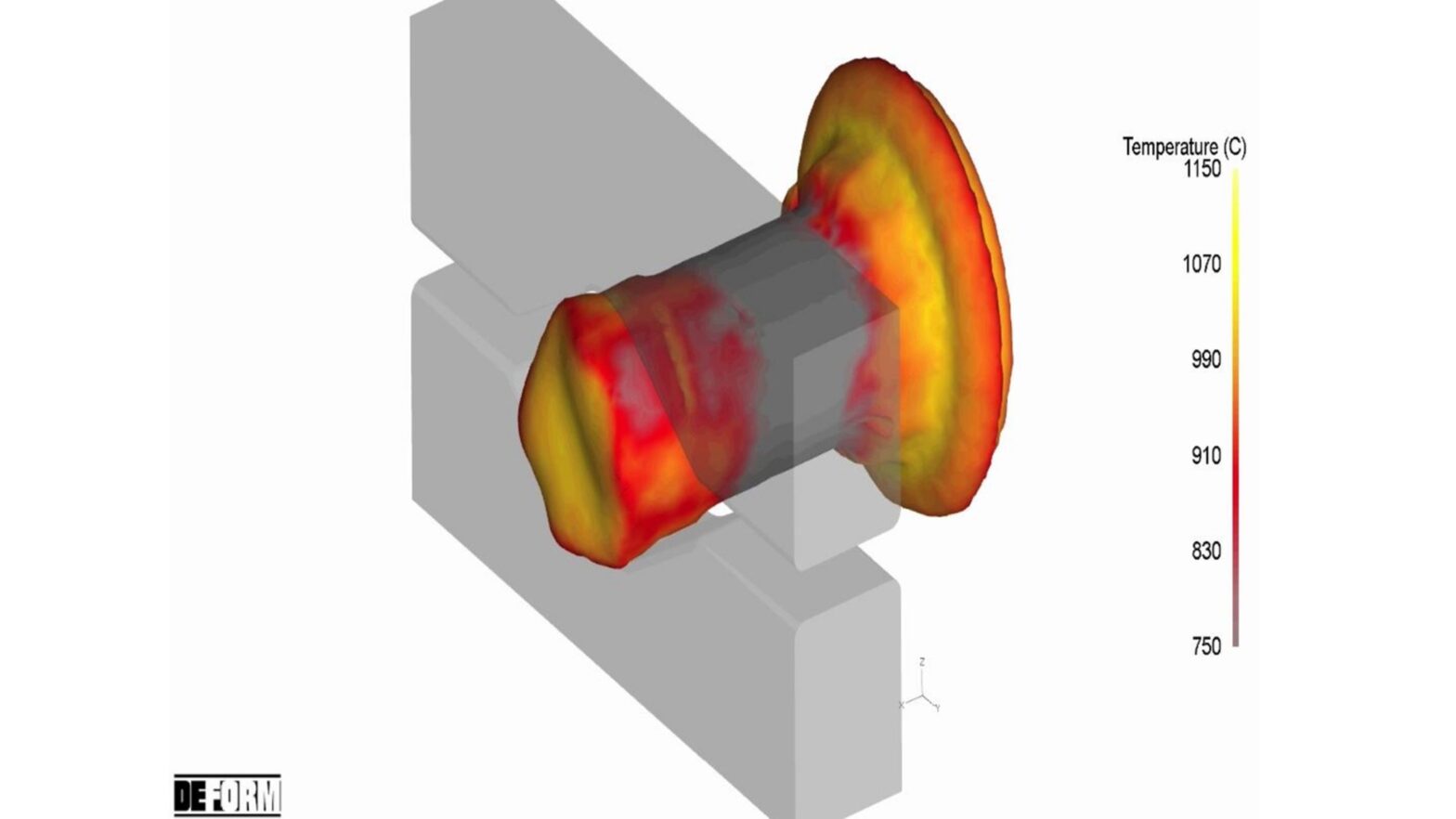

DEFORM, simulation software owned by the American SFTC, is the international reference in Metal Binder Jetting simulation. Thanks to this simulation software, technicians are able to preemptively analyse forming, compacting, mechanical properties and porosity which will occur during the 3D printing phase and after sintering. This reduces times and processes, with optimal production performance and a clear improvement of the entire design phase.

What customers say about DEFORM:

DEFORM Metal Binder Jetting simulation software is American and has been optimised to be reliable, quick and easy.

- EXCELLENT AGREEMENT OF “SOFTWARE RESULTS” WITH “REALITY” DEFORM is the most widely used cold forming simulation software in the world

- SAMPLING IMMEDIATELY POSITIVEThe simulation makes it possible to identify defects obtained during forming, to understand their causes and therefore to undertake the right corrective actions

- STARTING TIMES REDUCED TO A MINIMUM The press setting was already tested in simulation. The real sampling will dispose of the machine setup card already defined.

For the purchase, hire or a DEMO of the software or if you want to take advantage of a simulation service specially-made by our technical department, write or call us at +39 030 3365383