Fracture of the workpiece is a frequent subject of concern during large deformation cold and warm forming processes. Damage factor, as suggested by Cockcroft and Latham, can be used to predict fracture in cold forming operations. A number of Damage factors have been investigated by researchers, with the Cockcroft-Latham Damage Factor demonstrating good correlation with experimental data when the fracture occurs in a predominately tensile state of stress.

Read More

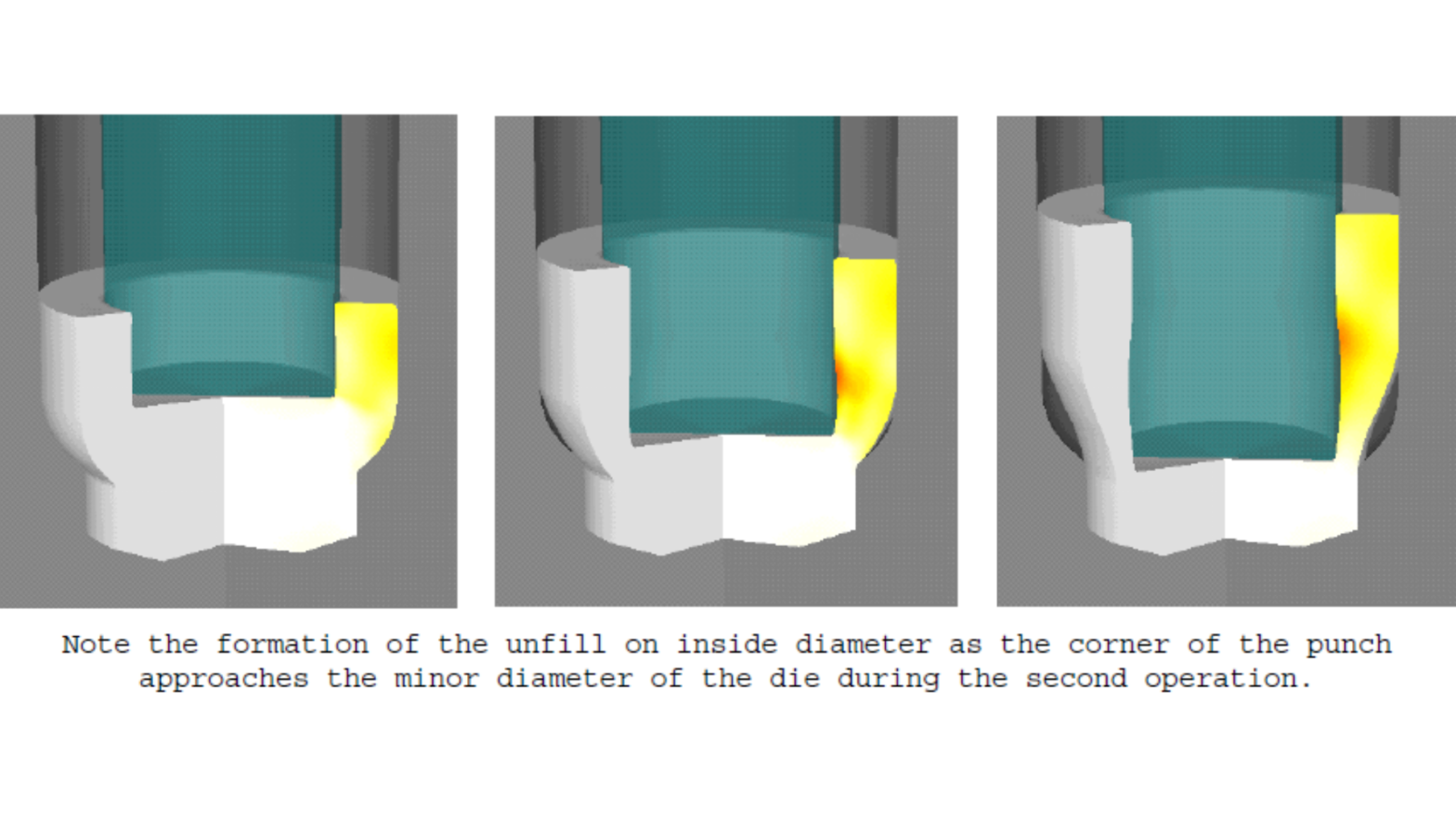

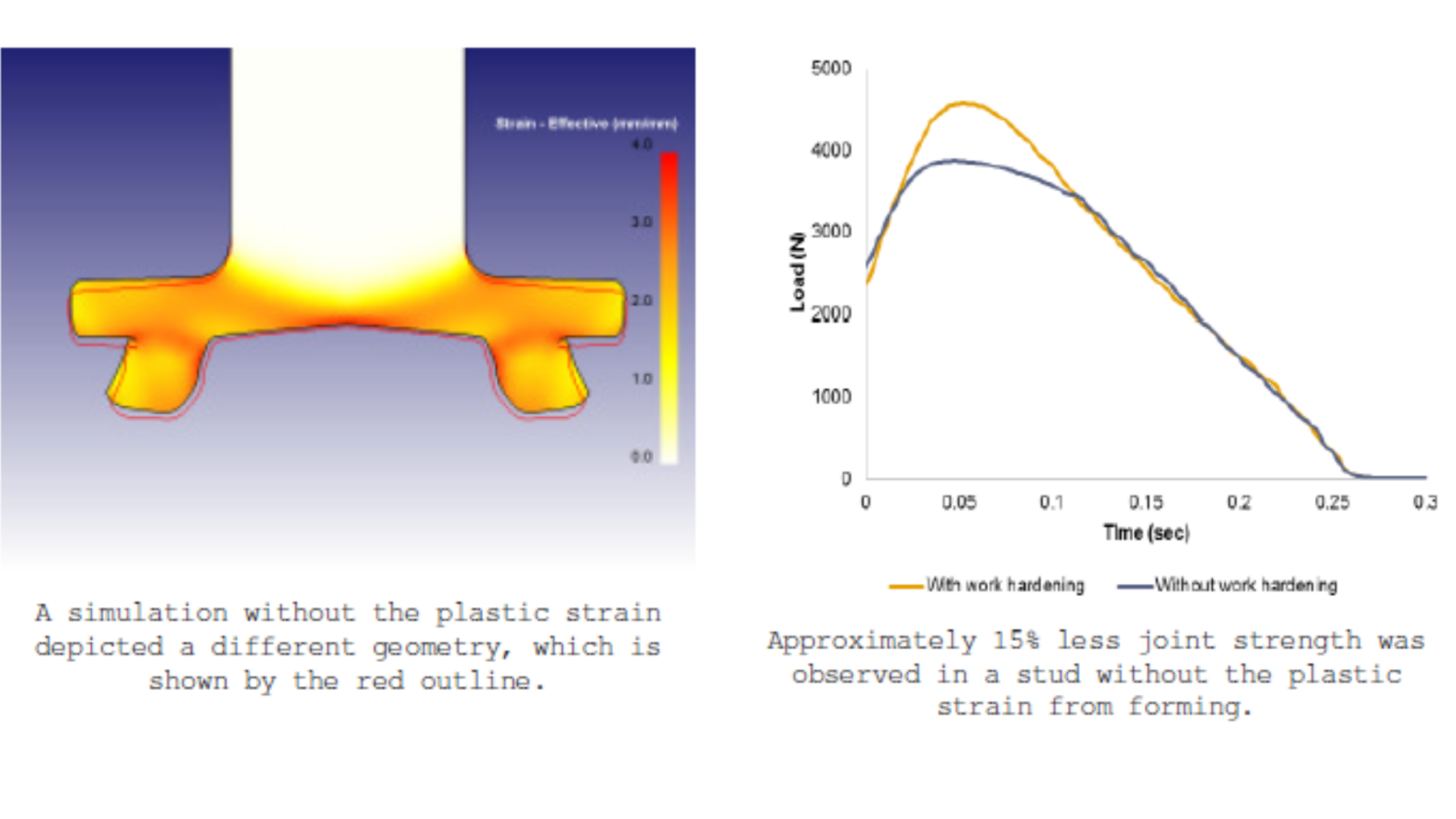

The Fabristeel Corporation of Taylor, Michigan used computer simulation to develop their self-piercing mechanically staked fasteners for sheet metal parts.

The patented drawform stud was fully developed using simulation. The development process included cold forming the stud, an installation process and a

pullout test. The entire manufacturing process was developed with the aid of process simulation. Based on damage values in the sheet, the original design

was modified to prevent fracture in the panel.

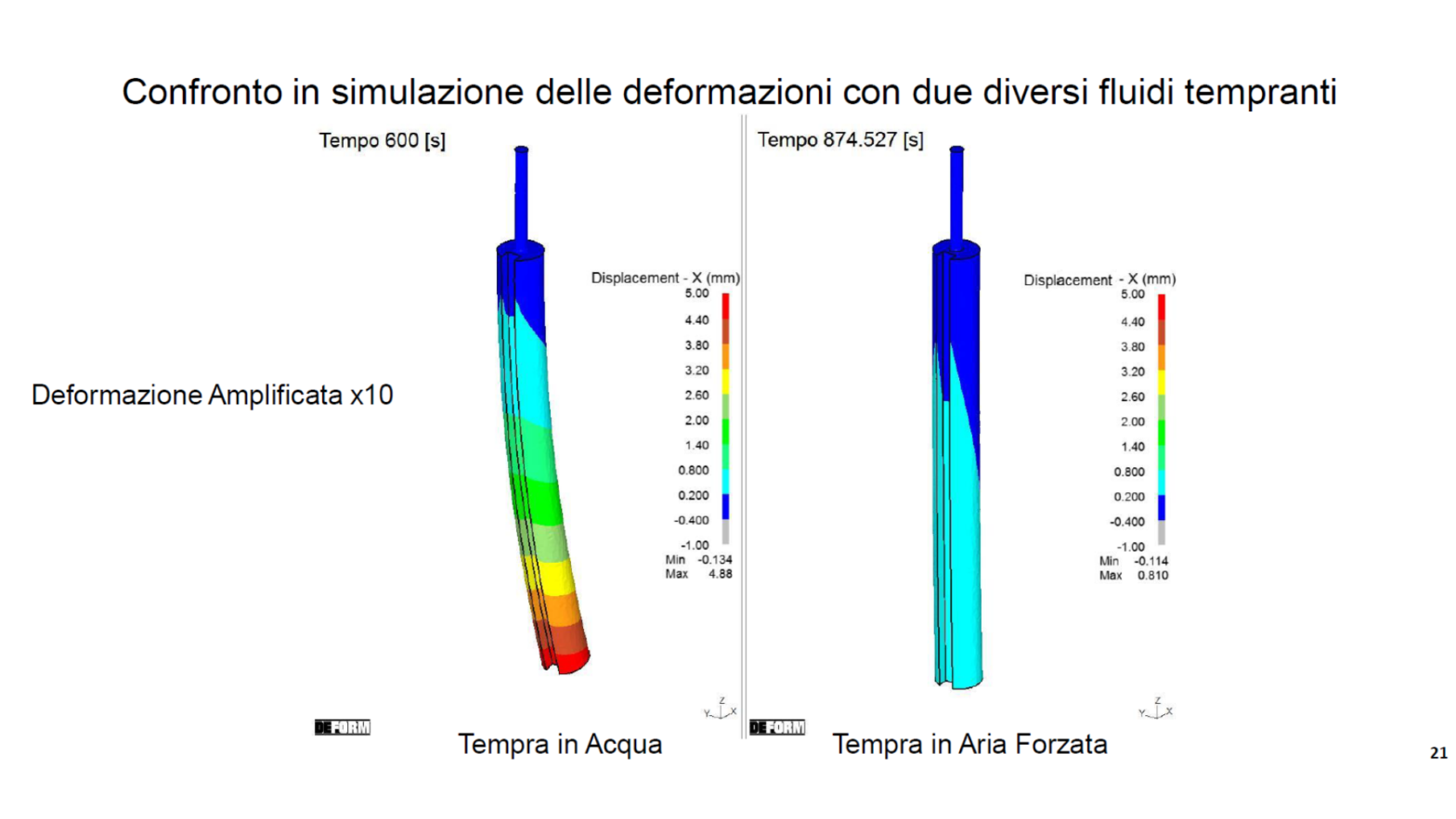

1. The simulation software must virtualize the microstructure of the material and the metallurgy of the heat treatment cycle. 2. Objective of the heat treatment: to achieve the required microstructure and mechanical performance, guaranteeing dimensions and residual stresses in the component 3. Possible problems of the hardening heat treatment: deformations and microstructures that do not comply with the regulations 4. With the DEFORM software it is possible to predict microstructure and deformations of the piece during heat treatment.

Read More

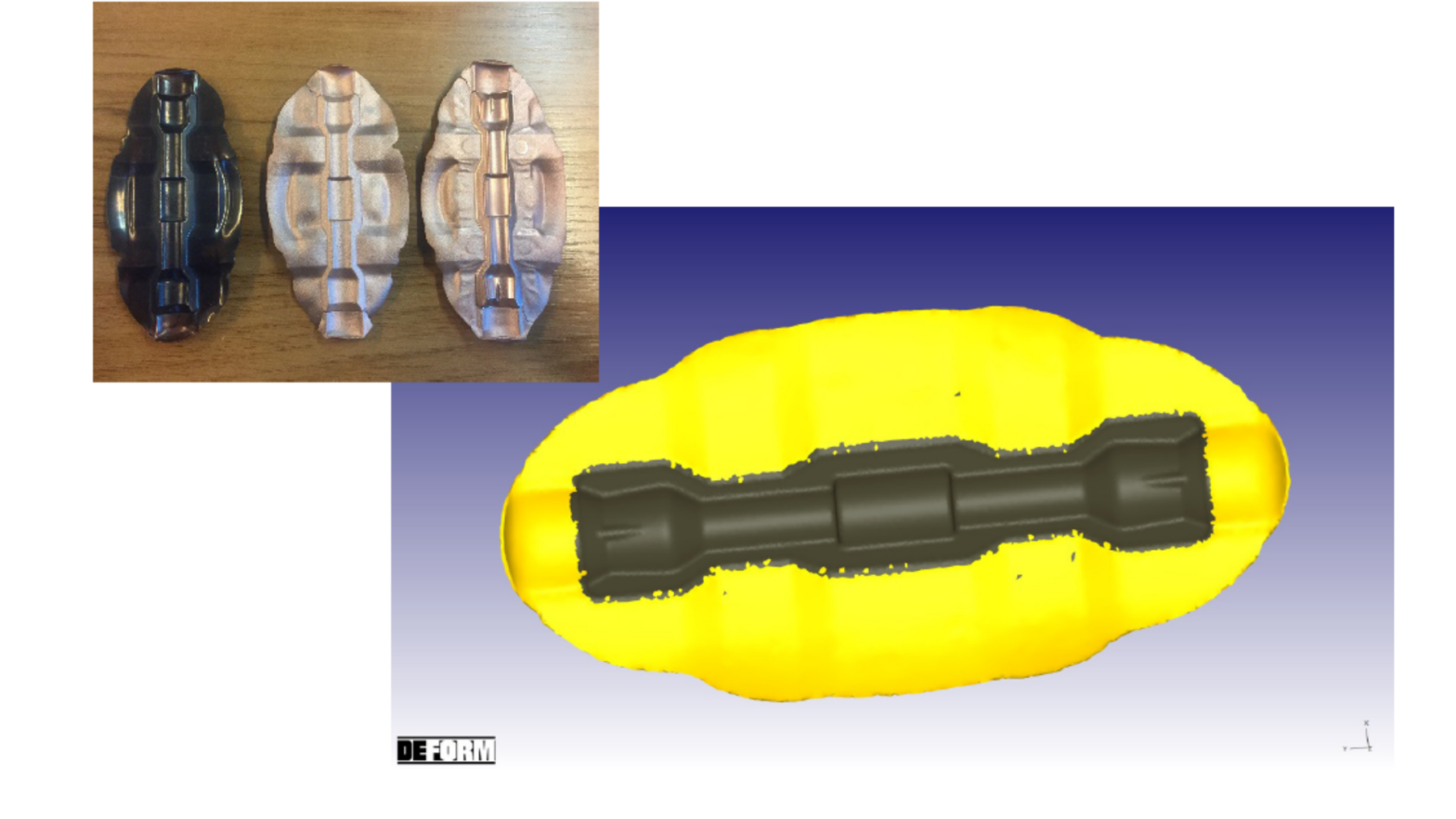

This case study

illustrates how DEFORM is highly

beneficial in dimensional control and

cost reduction tasks.

Tight schedules are the order of

the day in the competitive forging

industry. Very few manufacturers

have the luxury of an increased

selling price to compensate for

the added costs associated with

conservative material sizing, die

rework or expensive shop trials.

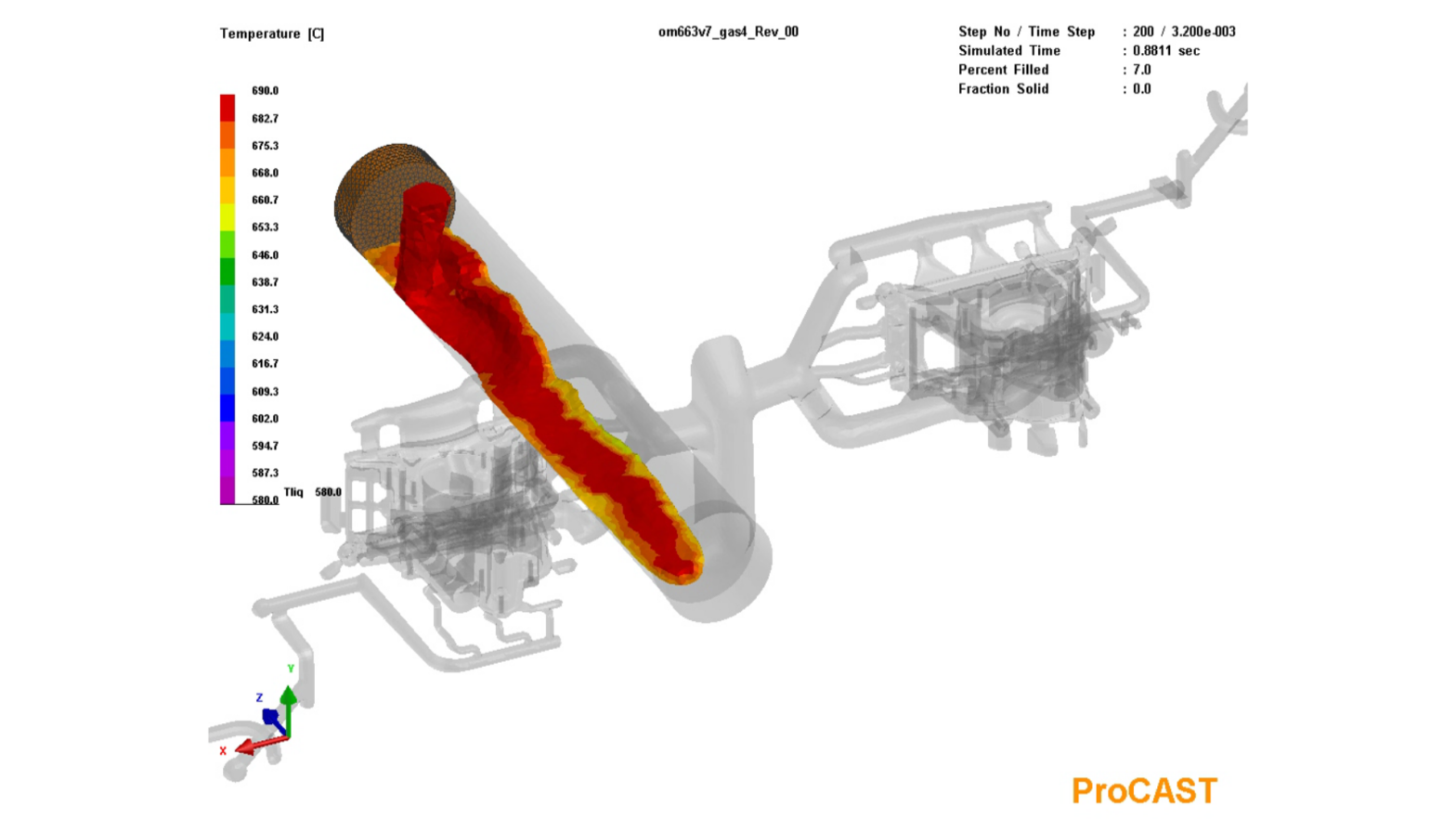

Case 1 Die casting simulation is finally complete with ProCAST. Virtualization of the diecasting machine The occurrence of cases of mismatch between simulation and reality led Ecotre to activate a project in which over 900 diecasting simulations were analyzed over a period of 3 years. It was evaluated how correctly the casting simulation software predicted the way to fill the mold cavity and the gas porosities in the piece ....

Read More

Ecotre Valente from Brescia distributes simulation software. Growing more than 20% annually in the last 5 years

It is a matter of time. The simulation software for casting, forging, rolling, heat treatment and machining allow to expand or compress it: ingots of tons that take days, to give just one example, can be reduced and evaluated in a few minutes; conversely, steps of a few thousandths can be analyzed in hundreds of seconds. But the time factor today is also the key to the diffusion process of these virtualization programs of the production cycle. "It's only a matter of time: even in the world of steel, the tools that allow the virtual reality of production processes will be widespread."

Article in Italian

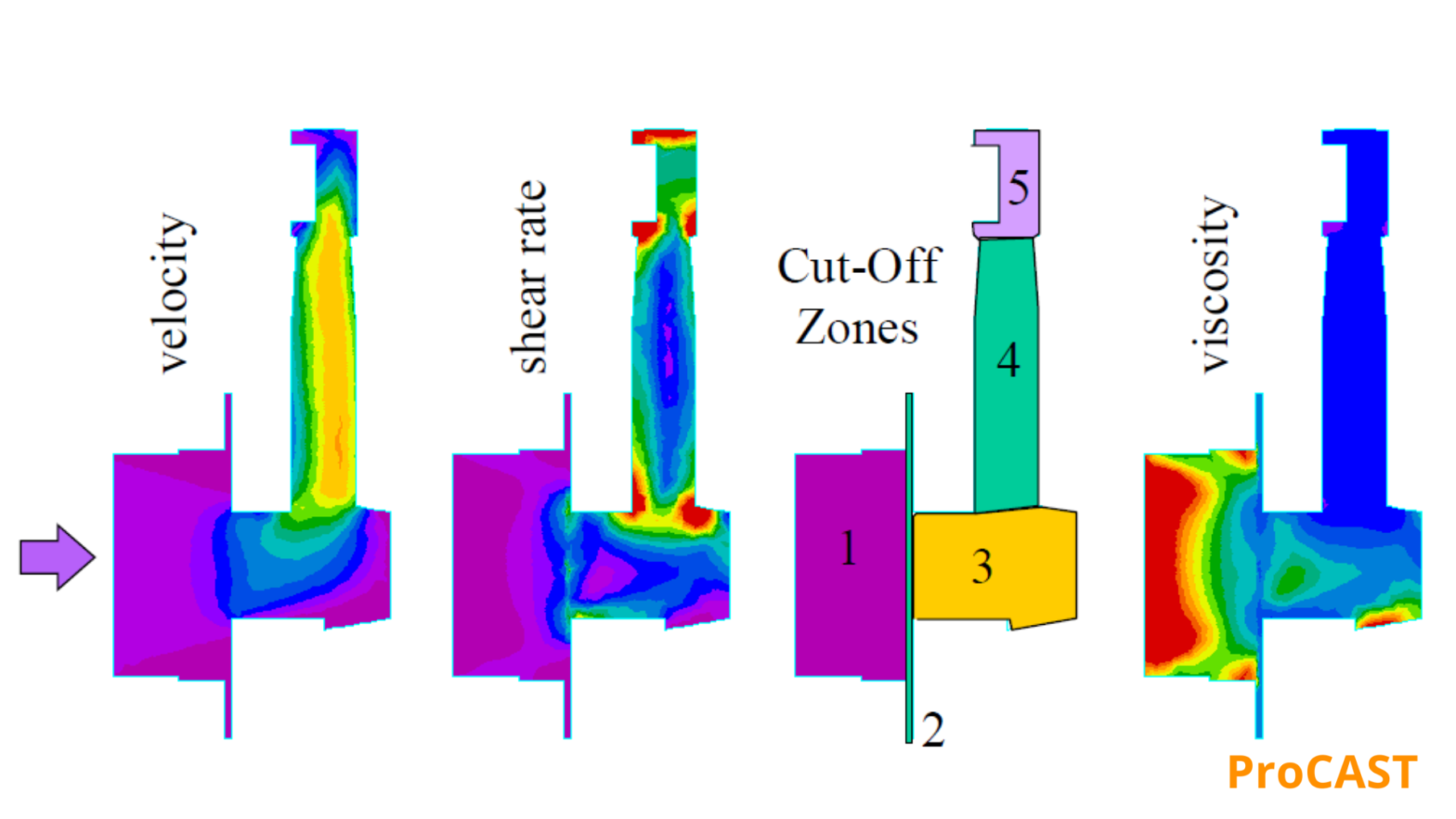

ESI ProCAST 2016 is the introduction of the machine selection workflow that draws on a dedicated database for High Pressure Die Casting (HPDC) machines, including the Colosio machines.

The new functionality enables the user to define the operating point and operating zone for any machine, using the Pressure (P)- Flow Rate(Q)² graph. This information is linked to ProCAST’s solver to achieve virtual piston control in real time.

Introduction Thixoforming process Physical phenomena Process Simulation Validation Applications / examples

Read More

Elimination of scraps and defects with the DEFORM simulation software

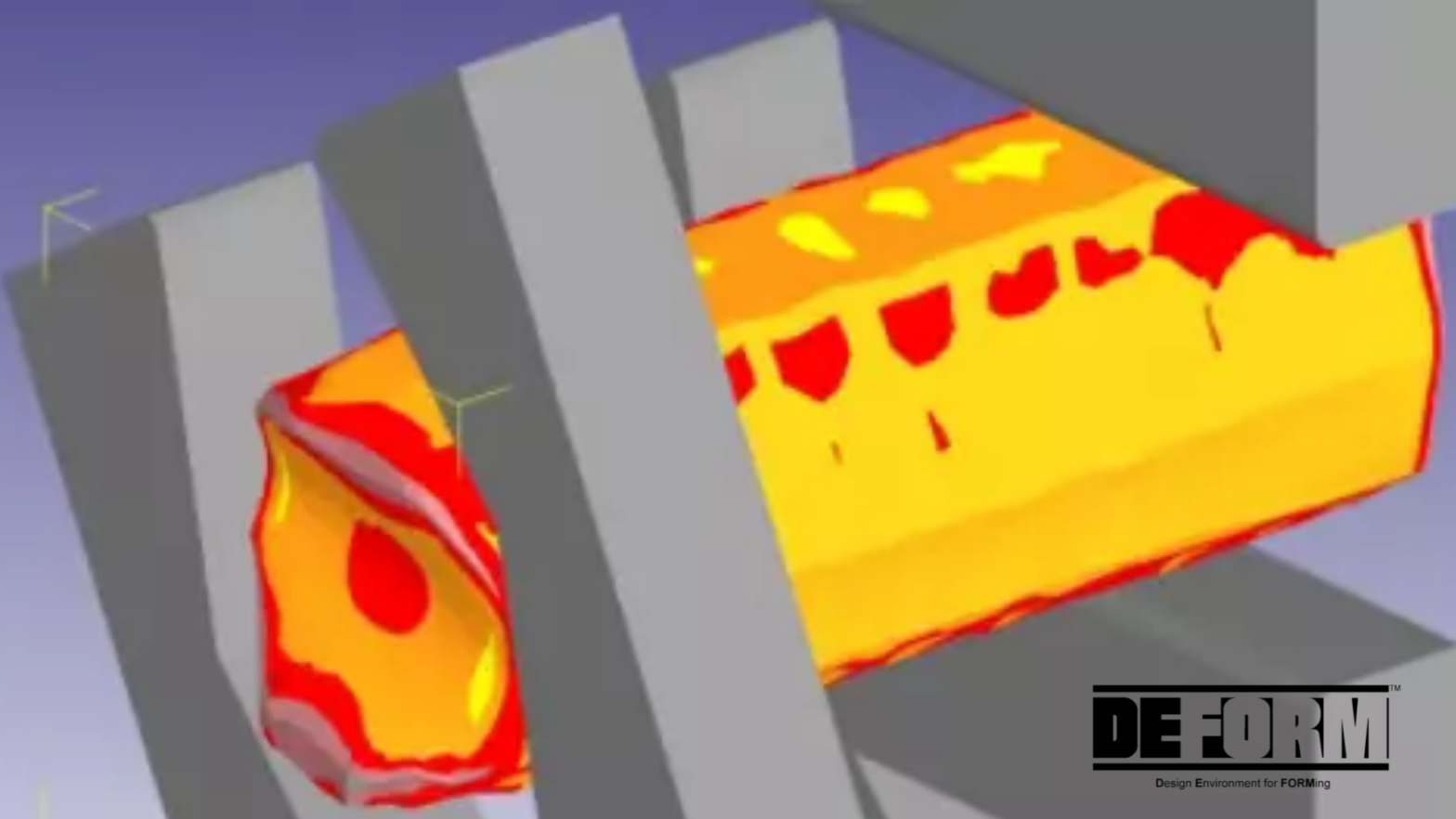

The webinar dedicated to the novelties in Simulation of Hot and Cold Forming, Coining, Drawing, Rolling, Forging, Shape Rolling, Extrusion, Sheet Metal Forming, Shearing, Welding, Additive Manufacturing, Heat Treatments was held on Thursday 1 July 2021 and Machining with the new DEFORM 2021 Software and organized by the Brescia-based Ecotre Valente. The wide participation of the experts gave rise to an afternoon of meeting and exchange on the state of the art of metallurgical process simulation, on the criticalities encountered during production and on the prediction and resolution of defects thanks to computer simulation to obtain a high metallurgical quality.

This year Ecotre, for the "Simulation and Innovation" award, has decided to reward those companies that have distinguished themselves for their ability to innovate in the sector of presses, machines and systems. Among the 4 awarded companies: PRIMETALS TECHNOLOGIES ITALY

Lorenzo Valente, CEO of Ecotre Valente, concluded the day with these words: “We are in a moment in which the need to obtain components without defects is essential, while at the same time reducing production times and costs. The DEFORM metallurgical process simulation software is able to predict a priori the behavior of the metal during the process, evaluating defects on the product and equipment, with the aim of obtaining the maximum in terms of machine and process efficiency. ".

Elimination of scraps and defects with the DEFORM simulation software

The webinar dedicated to the novelties in Simulation of Hot and Cold Forming, Coining, Drawing, Rolling, Forging, Shape Rolling, Extrusion, Sheet Metal Forming, Shearing, Welding, Additive Manufacturing, Heat Treatments was held on Thursday 1 July 2021 and Machining with the new DEFORM 2021 Software and organized by the Brescia-based Ecotre Valente. The wide participation of the experts gave rise to an afternoon of meeting and exchange on the state of the art of metallurgical process simulation, on the criticalities encountered during production and on the prediction and resolution of defects thanks to computer simulation to obtain a high metallurgical quality.

This year Ecotre, for the "Simulation and Innovation" award, has decided to reward those companies that have distinguished themselves for their ability to innovate in the sector of presses, machines and systems. Among the 4 awarded companies: AUTOMAZIONI INDUSTRIALI SRL.

Lorenzo Valente, CEO of Ecotre Valente, concluded the day with these words: “We are in a moment in which the need to obtain components without defects is essential, while at the same time reducing production times and costs. The DEFORM metallurgical process simulation software is able to predict a priori the behavior of the metal during the process, evaluating defects on the product and equipment, with the aim of obtaining the maximum in terms of machine and process efficiency. ".

Elimination of scraps and defects with the DEFORM simulation software

The webinar dedicated to the novelties in Simulation of Hot and Cold Forming, Coining, Drawing, Rolling, Forging, Shape Rolling, Extrusion, Sheet Metal Forming, Shearing, Welding, Additive Manufacturing, Heat Treatments was held on Thursday 1 July 2021 and Machining with the new DEFORM 2021 Software and organized by the Brescia-based Ecotre Valente. The wide participation of the experts gave rise to an afternoon of meeting and exchange on the state of the art of metallurgical process simulation, on the criticalities encountered during production and on the prediction and resolution of defects thanks to computer simulation to obtain a high metallurgical quality.

This year Ecotre, for the "Simulation and Innovation" award, has decided to reward those companies that have distinguished themselves for their ability to innovate in the sector of presses, machines and systems. Among the 4 awarded companies: MECOLPRESS SPA.

Lorenzo Valente, CEO of Ecotre Valente, concluded the day with these words: “We are in a moment in which the need to obtain components without defects is essential, while at the same time reducing production times and costs. The DEFORM metallurgical process simulation software is able to predict a priori the behavior of the metal during the process, evaluating defects on the product and equipment, with the aim of obtaining the maximum in terms of machine and process efficiency. ".

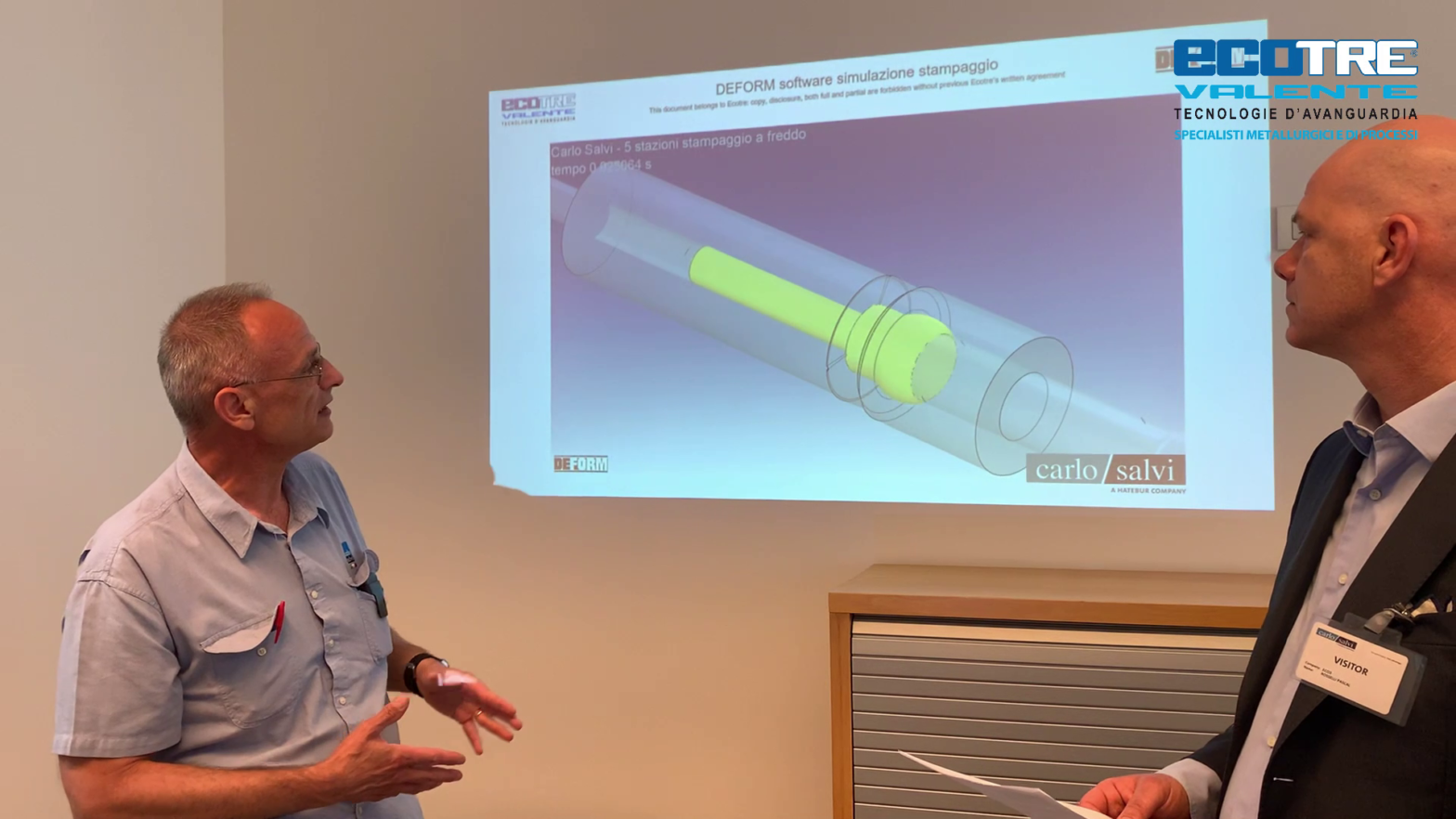

Elimination of scraps and defects with the DEFORM simulation software

The webinar dedicated to the novelties in Simulation of Hot and Cold Forming, Coining, Drawing, Rolling, Forging, Shape Rolling, Extrusion, Sheet Metal Forming, Shearing, Welding, Additive Manufacturing, Heat Treatments was held on Thursday 1 July 2021 and Machining with the new DEFORM 2021 Software and organized by the Brescia-based Ecotre Valente. The wide participation of the experts gave rise to an afternoon of meeting and exchange on the state of the art of metallurgical process simulation, on the criticalities encountered during production and on the prediction and resolution of defects thanks to computer simulation to obtain a high metallurgical quality.

This year Ecotre, for the "Simulation and Innovation" award, has decided to reward those companies that have distinguished themselves for their ability to innovate in the sector of presses, machines and systems. Among the 4 awarded companies: CARLO SALVI SPA.

Lorenzo Valente, CEO of Ecotre Valente, concluded the day with these words: “We are in a moment in which the need to obtain components without defects is essential, while at the same time reducing production times and costs. The DEFORM metallurgical process simulation software is able to predict a priori the behavior of the metal during the process, evaluating defects on the product and equipment, with the aim of obtaining the maximum in terms of machine and process efficiency. ".