Webinar – Digital Green Foundry: Materials and Implications in Casting

Webinar – Digital Green Foundry: Materials and Implications in Casting

Online - 4 PM - 5 PM

This webinar, organised by ExOne and Corsa3D in collaboration with Resand and ECOTRE, is the continuation of the “Digital Green Foundry” conference held on 15 May 2025.

It is designed to delve deeper into the technical challenges and practical solutions driving the digital transformation of foundries. Topics will include additive manufacturing applied to casting, reclaimed and regenerated materials, predictive simulation, and circular economy strategies — illustrating how these technologies are shaping the sustainable future of metal foundries. The free online event will take place on Thursday, 25 September, from 16:00 to 17:00 (CET).

Target audience of the Webinar – Digital Green Foundry: Materials and Implications in Casting

- Target audience: Moulders, Die-makers and Designers

- Speakers: Ecotre Technical Department

- Duration: Starts Wednesday 20 September 2023 – Ends Thursday 16 November 2023

20-21 September: joint course

28 September, 5-12-19-26 October and 7-9-16 November: individual meeting slots lasting one hour - Time: From 8 a.m. to 12 noon and from 1 p.m. to 4 p.m.

- Material: DEFORM software for the duration of two months, Course notes in pdf format and Attendance Certificate

- Venue: BACCADEMY Srl – Via Industriale, 106 – 25065 Lumezzane (BS)

FILL IN THE FORM FOR FURTHER INFORMATION

The webinar is designed for foundry owners, production managers, process engineers, and technical specialists, particularly those involved in casting, additive manufacturing, and materials management. It offers a valuable opportunity both for those looking to reduce defects and production costs, and for professionals aiming to integrate sustainability and innovation strategies into their manufacturing processes.

Programme of Presentations and ECOTRE’s Technical Contribution

Binder Jetting Technology – ExOne

A presentation on how sand 3D printers (S-Max) and reclaimed sand are transforming traditional foundry processes into modern, efficient, and low-impact production solutions.

Silica Sand Regeneration – Resand

An in-depth look at how natural sand regeneration reduces raw material consumption, lowers environmental impact, and cuts fixed costs — delivering a more sustainable production model.

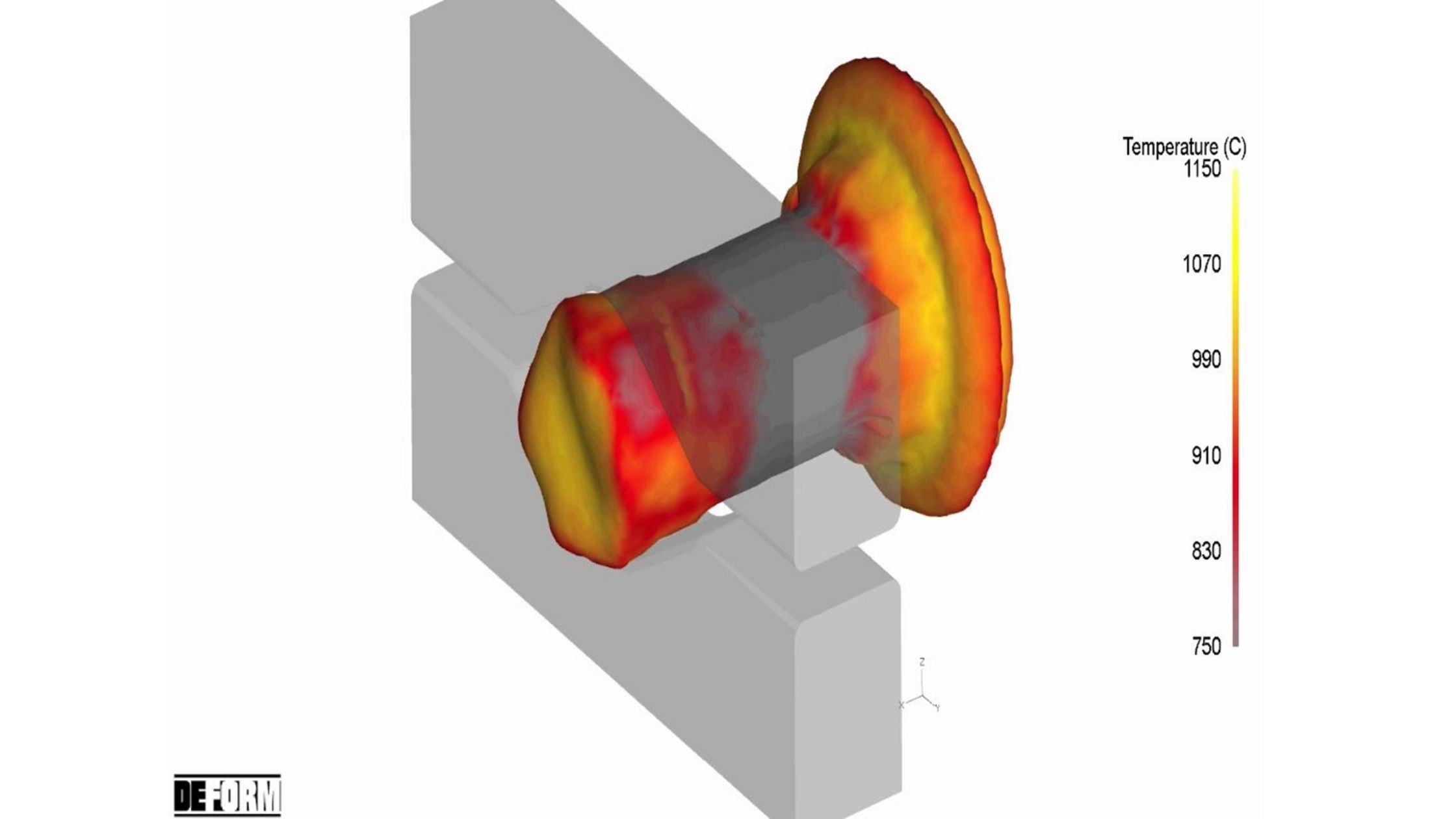

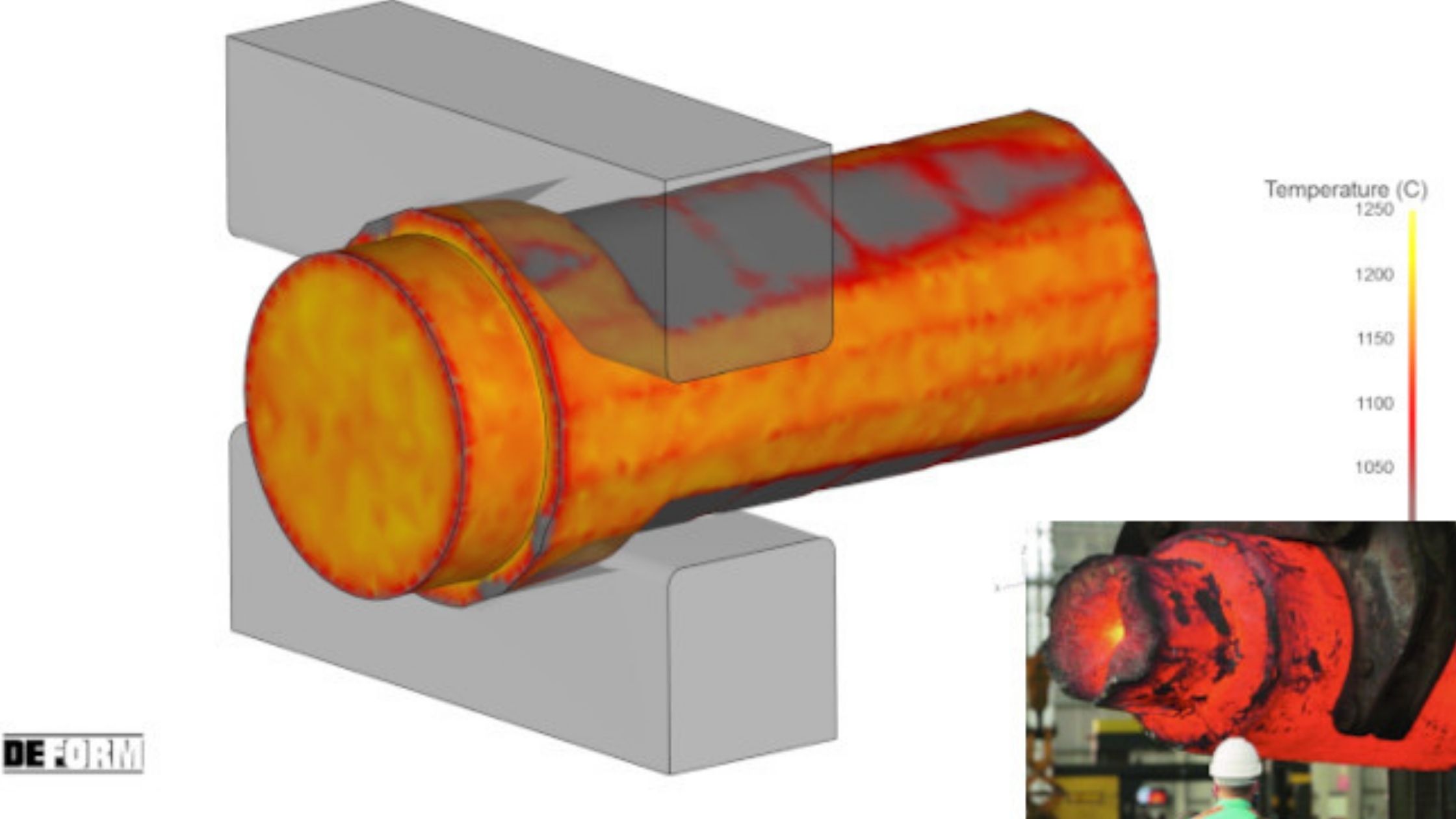

Predictive Casting Simulation – ECOTRE (presentation by Lorenzo Valente, CEO)

An exploration of how advanced simulation systems, supported by high-precision material databases, enable castings that are up to 99% identical to real-world trials, significantly reducing errors, waste, and physical testing cycles.

Digital Transformation and Sustainability have become cornerstones of the modern foundry. Don’t miss this unique opportunity to gain insight from leading experts who are already shaping the future of Italian foundries.

Register for the “DIGITAL GREEN FOUNDRY” Webinar and join leading experts in metallurgical manufacturing.

Thursday, 25 September, from 16:00 to 17:00 (CET). This FREE online event has limited availability.

Benefits

- Integrated Design and Optimization

- Enables better design choices

- Improved part moulding

- Fewer defects and better cost control