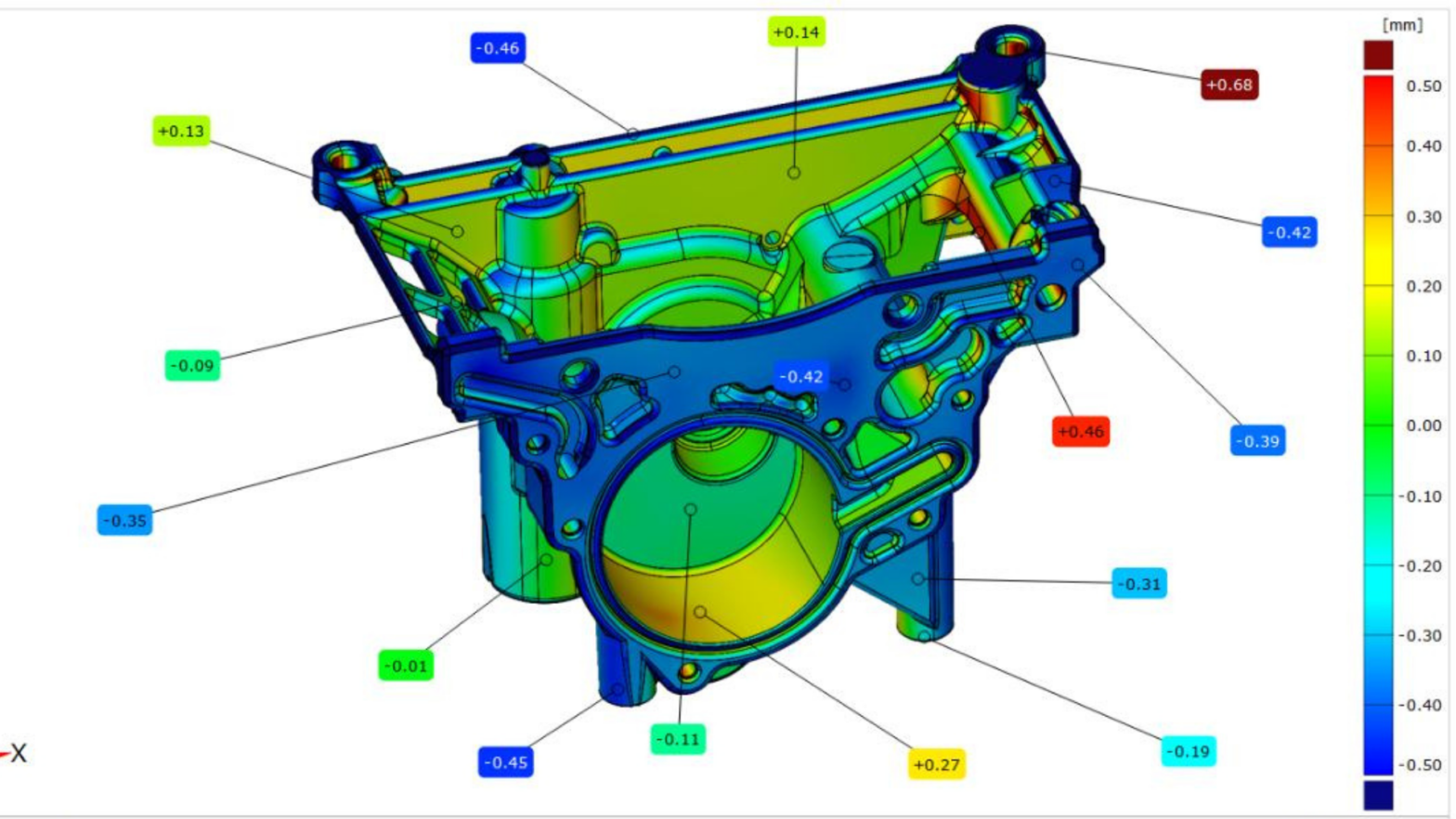

Simulation software programs for casting identify metallurgical defectiveness, mechanical properties and deformations of parts, and are fundamental for operating in a market that requires the rapid manufacture of difficult pieces, and which leaves no room for mistakes, testing or re-sampling. ECOTRE Valente, specialists in the simulation of metallurgical processes, use GOM Inspect Professional for the dimensional analysis of virtual pieces, in order to predict and rectify the onset of problems linked to shrinkage and warpage.

Read More

Thanks to the casting simulation software, it is possible to design without shrinkage cavities and increase the performance of diecastings.

Casting simulation is now widely used in various foundry applications and is essential in production as it reduces time, development costs and product cycle.

BRESCIA. The first Central European was born for the virtual foundry 4.0, thanks to Ecotre Valente Cutting-edge technologies in direct collaboration with Esi Group Germany, colossus of the software. Article in Italian

Read More

ESI Group, specialist in material physics, has developed a unique proficiency in helping industrial manufacturers replace physical prototypes by virtually replicating the fabrication, assembly and testing of products in different environments.

Today, coupled with Virtual Reality, animated by systems models, and benefiting from data analytics, Virtual Prototyping becomes immersive and interactive: ESI’s clients can bring their products to life, ensuring reliable performance, serviceability and maintainability.

Simone Gentiletti, technical sales engineering of M.C.S. Facchetti, in this interview, addresses various issues related to the diecasting sector and its operating dynamics, in light of the current situation and its developments Article in Italian

Read More

As you know the University, that of Brescia in particular, for years has been offering a teaching service aimed at what are the realities of our territory so there are courses on foundry, in particular on diecasting, courses on non-ferrous metals with particular attention to 'aluminum and zinc alloys together with foundry and metallurgy laboratories Article in Italian

Read More

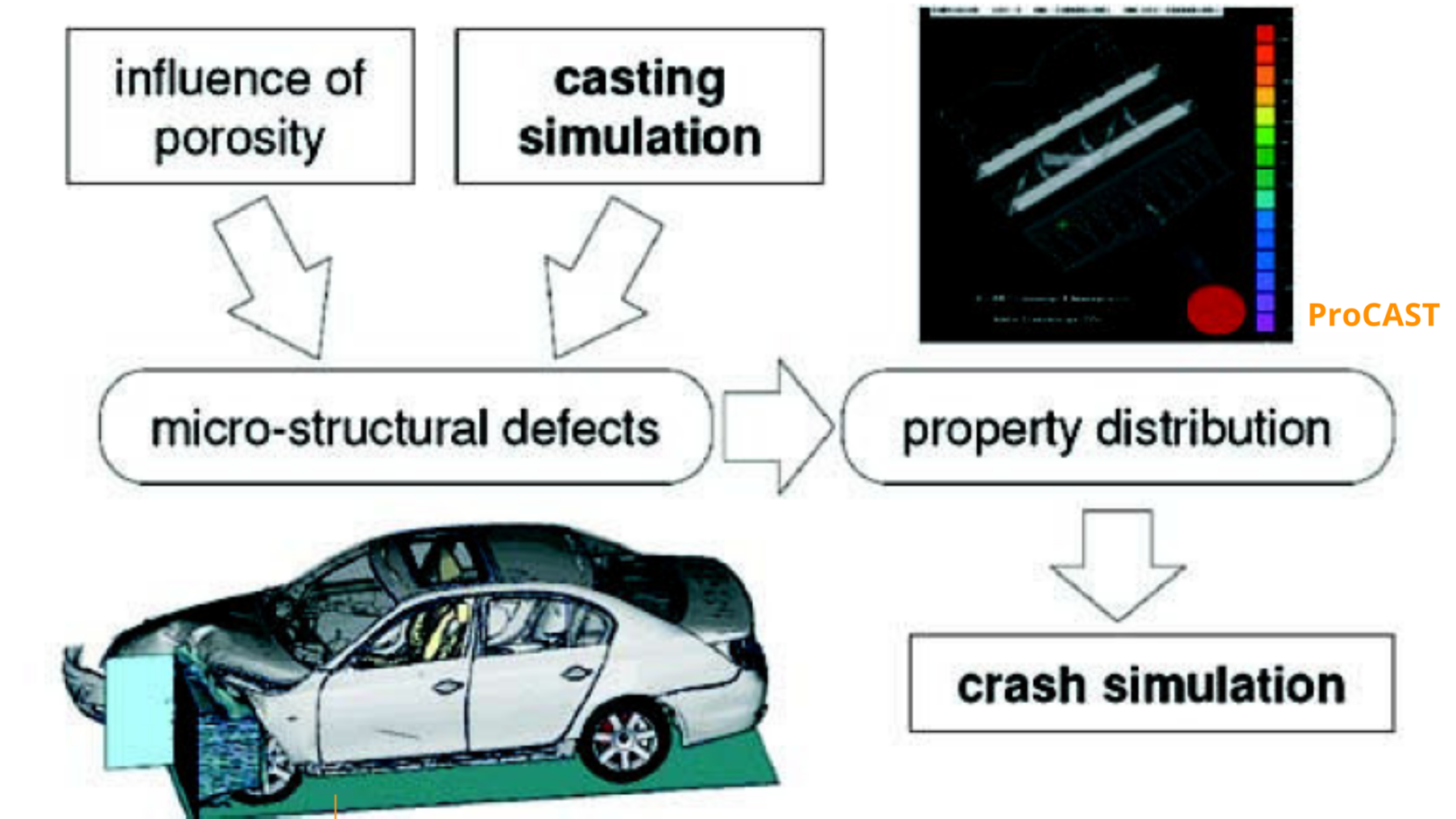

Alcan, BMW and ESI Group have successfully validated the potential benefits of a coupled product/process engineering approach based on crash and cast coupling with correlation of simulation and experimental results.

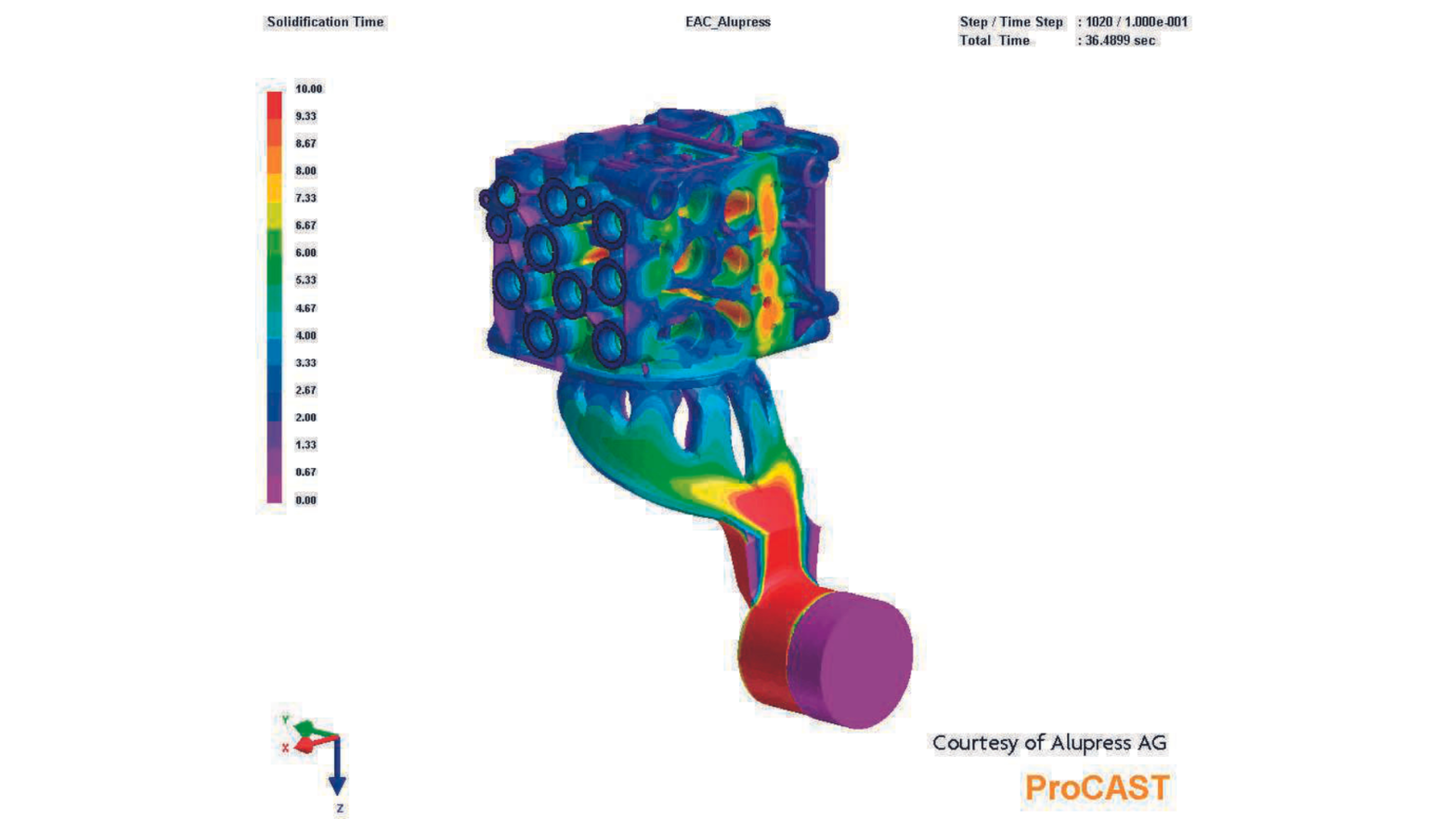

Casting Process Simulation

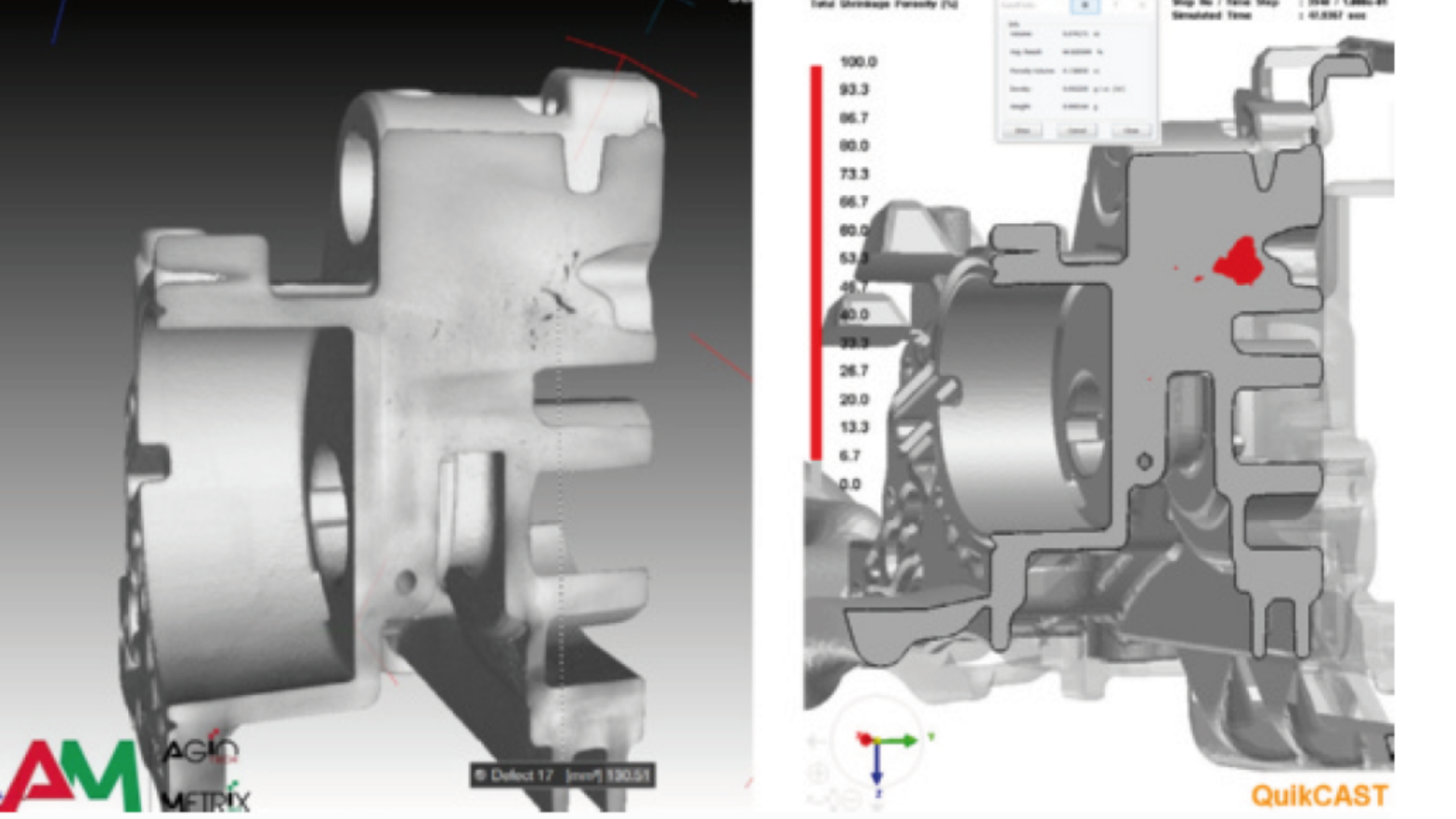

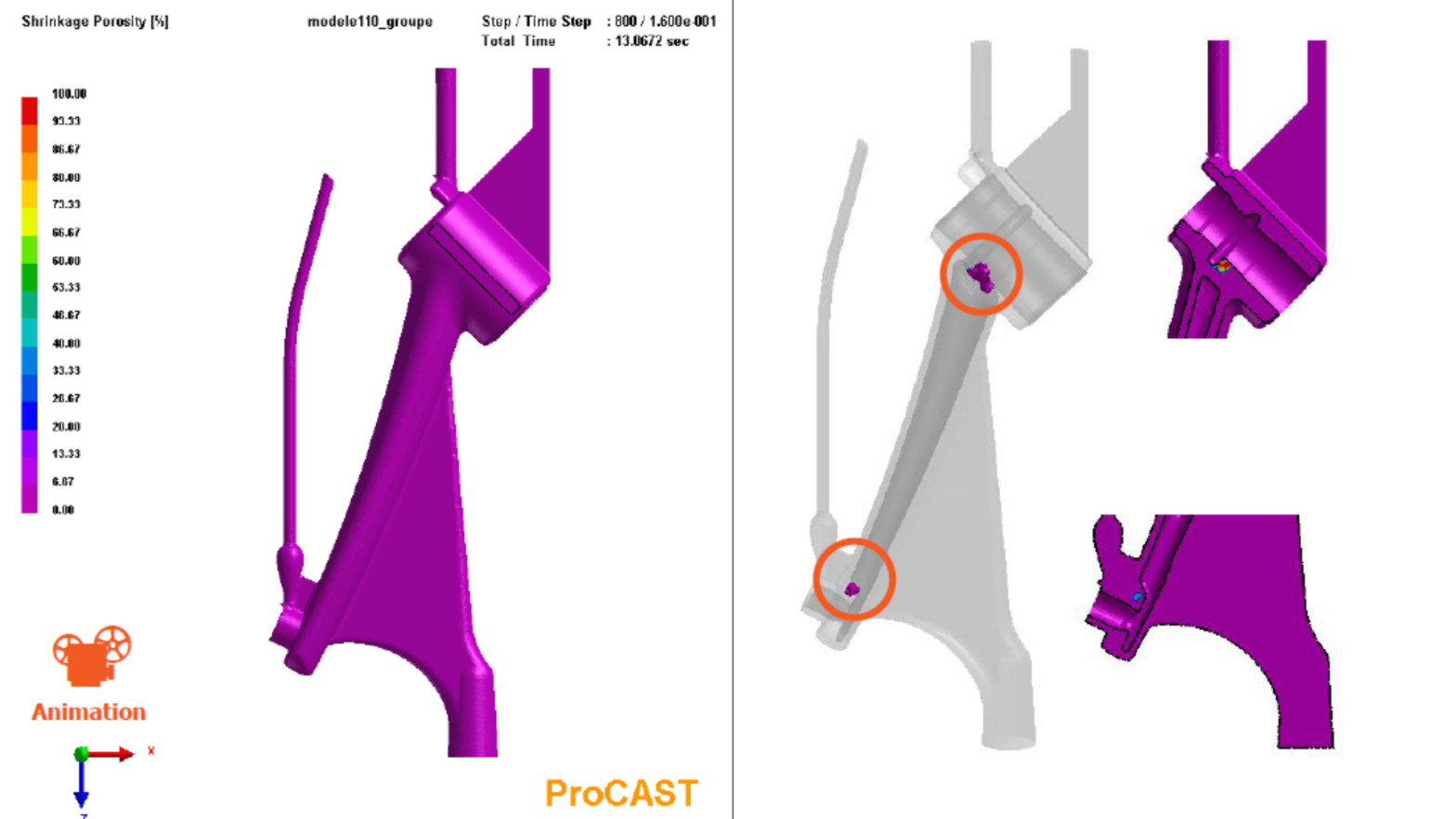

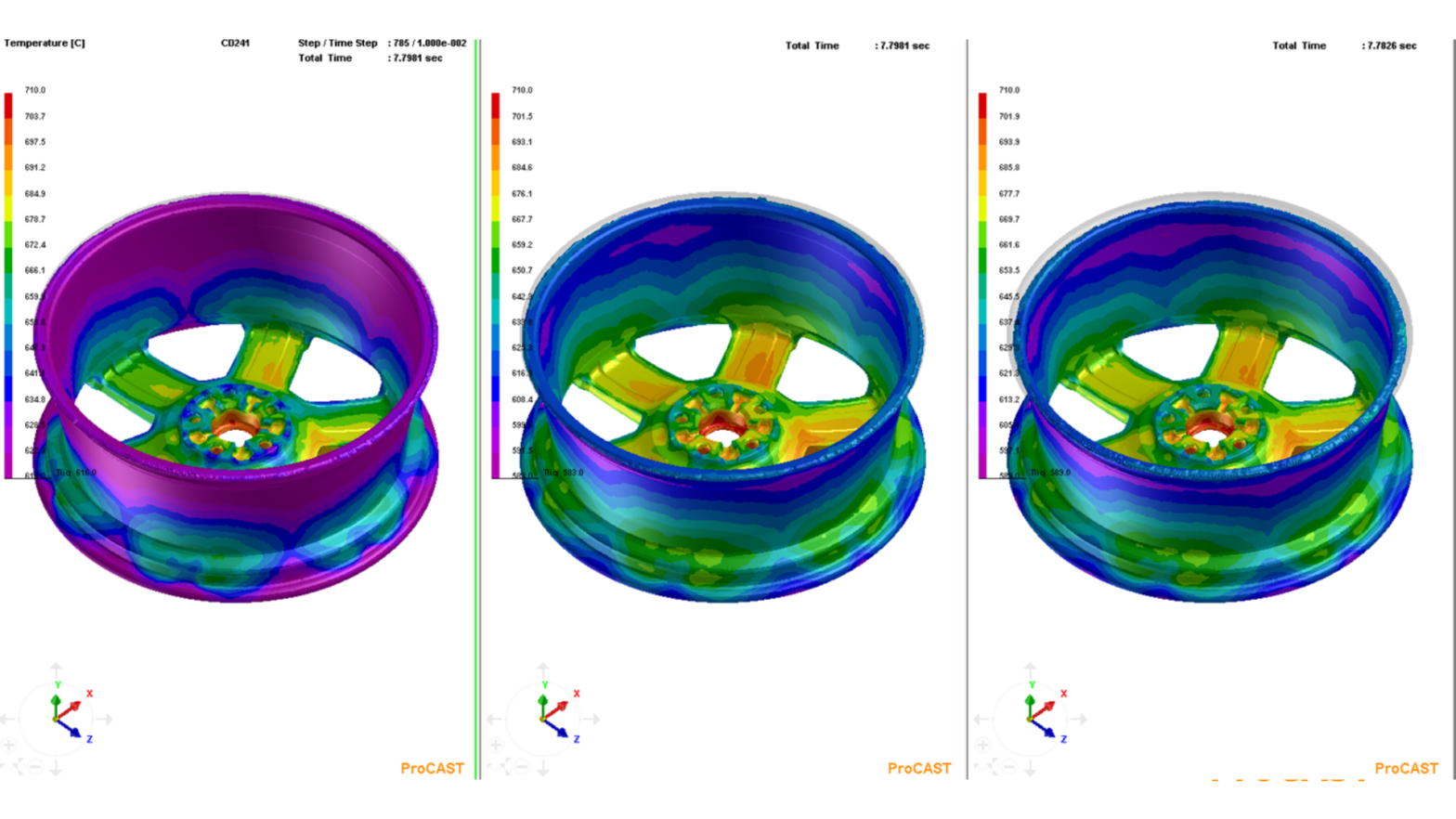

To account for the effects of the production process, the first step in the current approach is a casting process simulation in order to predict the uneven distribution of mechanical properties, and particularly the porosity distribution within a given aluminum die cast part. Comparison of numerical porosity predictions (obtained with ProCAST) with CTscans and micrographs show a good match.

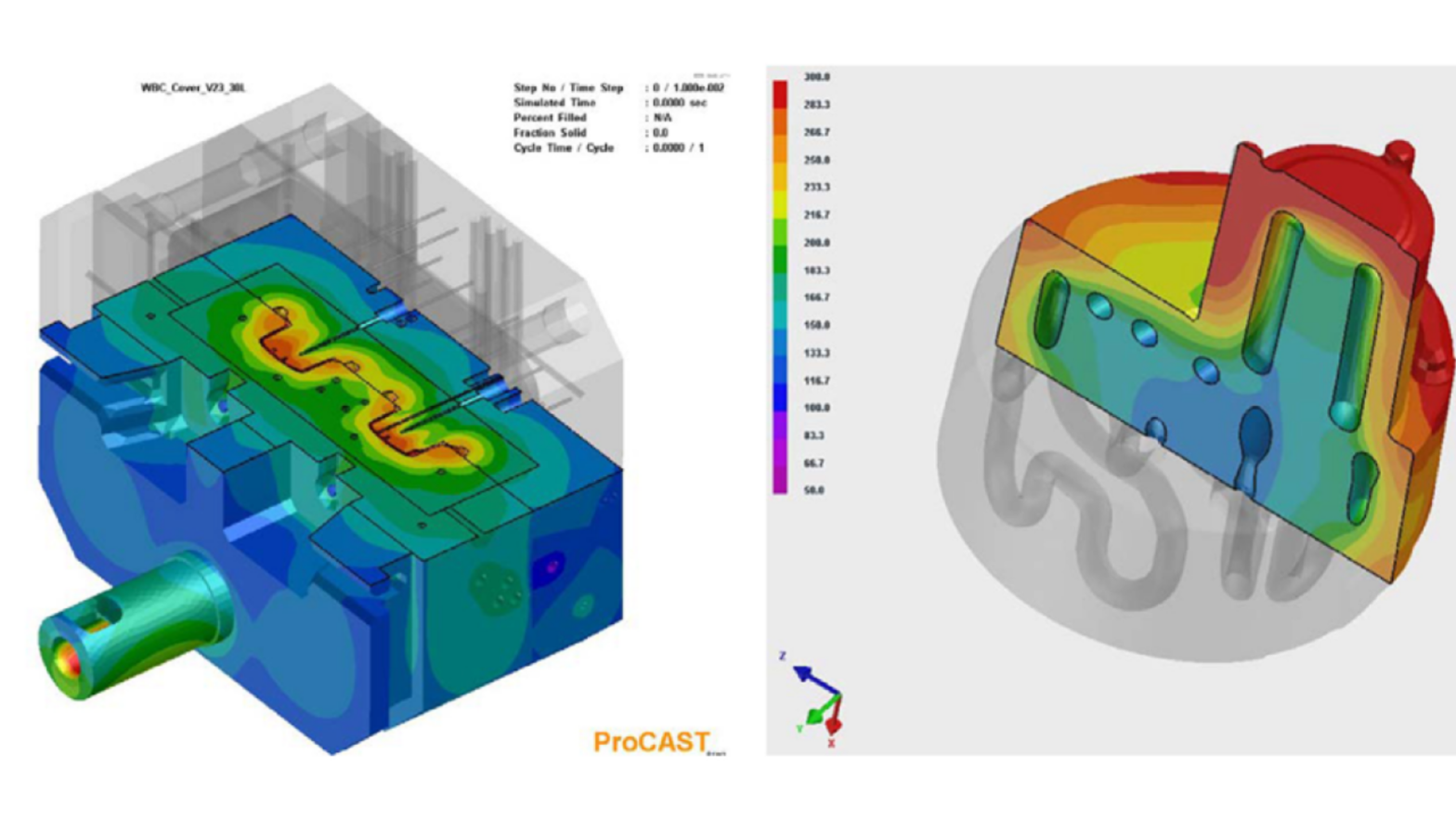

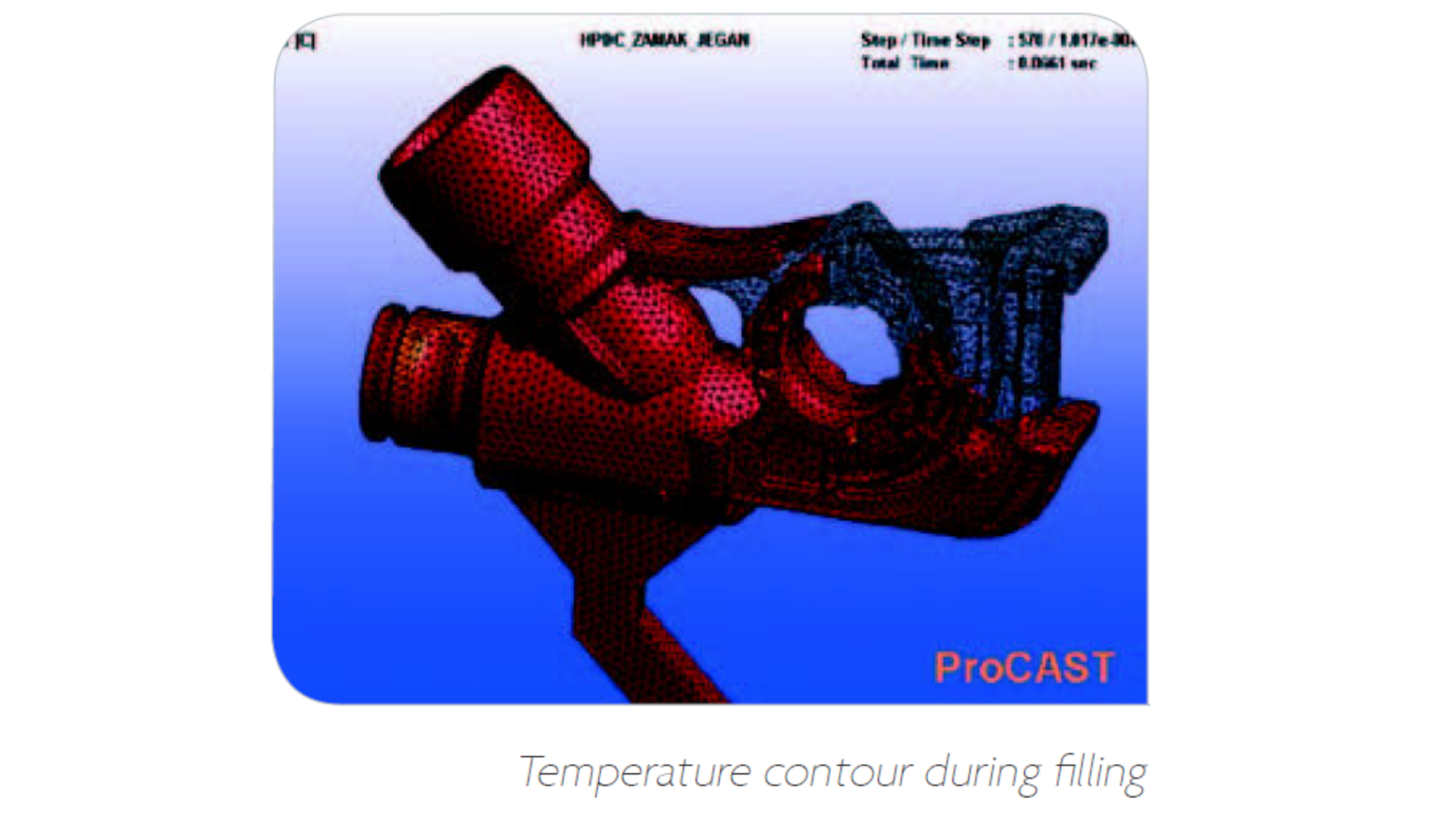

"ProCAST and QuikCAST give us the ability to see the injection as if we were inside the die. With ProCAST we have been able to reduce the number of physical tests, which means a reduction in time and costs."

Bart Goes

Director of Jegan

Defects? No thank you. Probably the flaw is a feature of the real world, as opposed to everything that is ideal and, consequently, perfect. However, there is a but: if the defect exists and cannot be completely eliminated, it is also true that it can be contained and reduced to acceptable values. Therefore, the primary objective of each foundry is to produce castings consistent with specifications, free from defects. Article in Italian

Read More

The aim of the project is to produce automotive structural components with thicknesses reduced from 4 to 2 mm through the use of innovative LPDC and gravity casting systems and vacuum dies, real-time monitoring and closed-loop logic management.

Read More

Similor Kugler Faucet was able to solve shrinkage porosities thanks to simulation with ProCAST

Read More

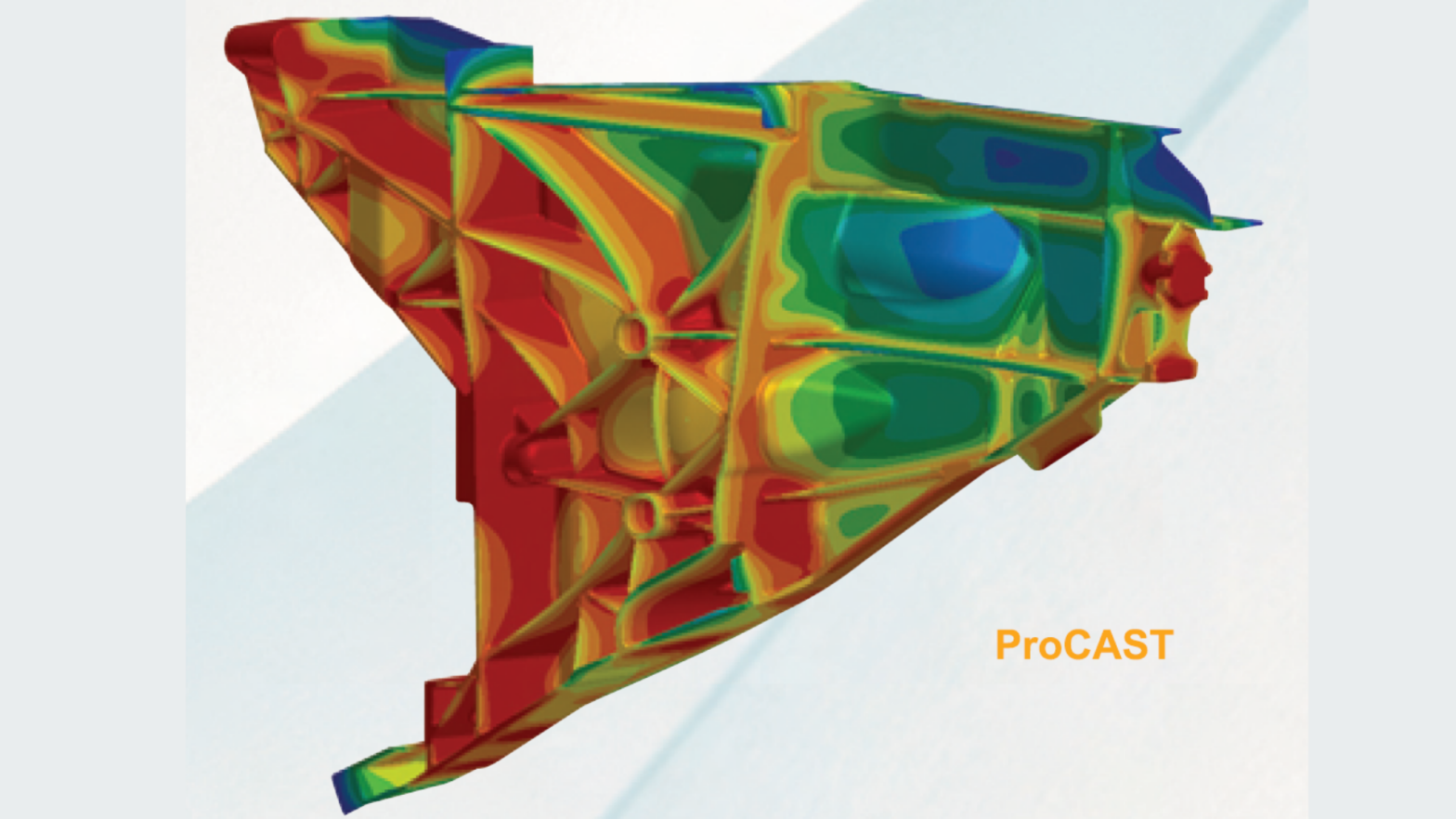

The mesh, to Finite Elements, it is automatic and, in a few minutes, it allows the operator to set the foundry parameters. It is important to underline that ProCAST is based on technology constructive to the Elements finished. Indeed, this technique is the only one that guarantees the best accuracy and correspondence between the foundry and the simulation.

Read More