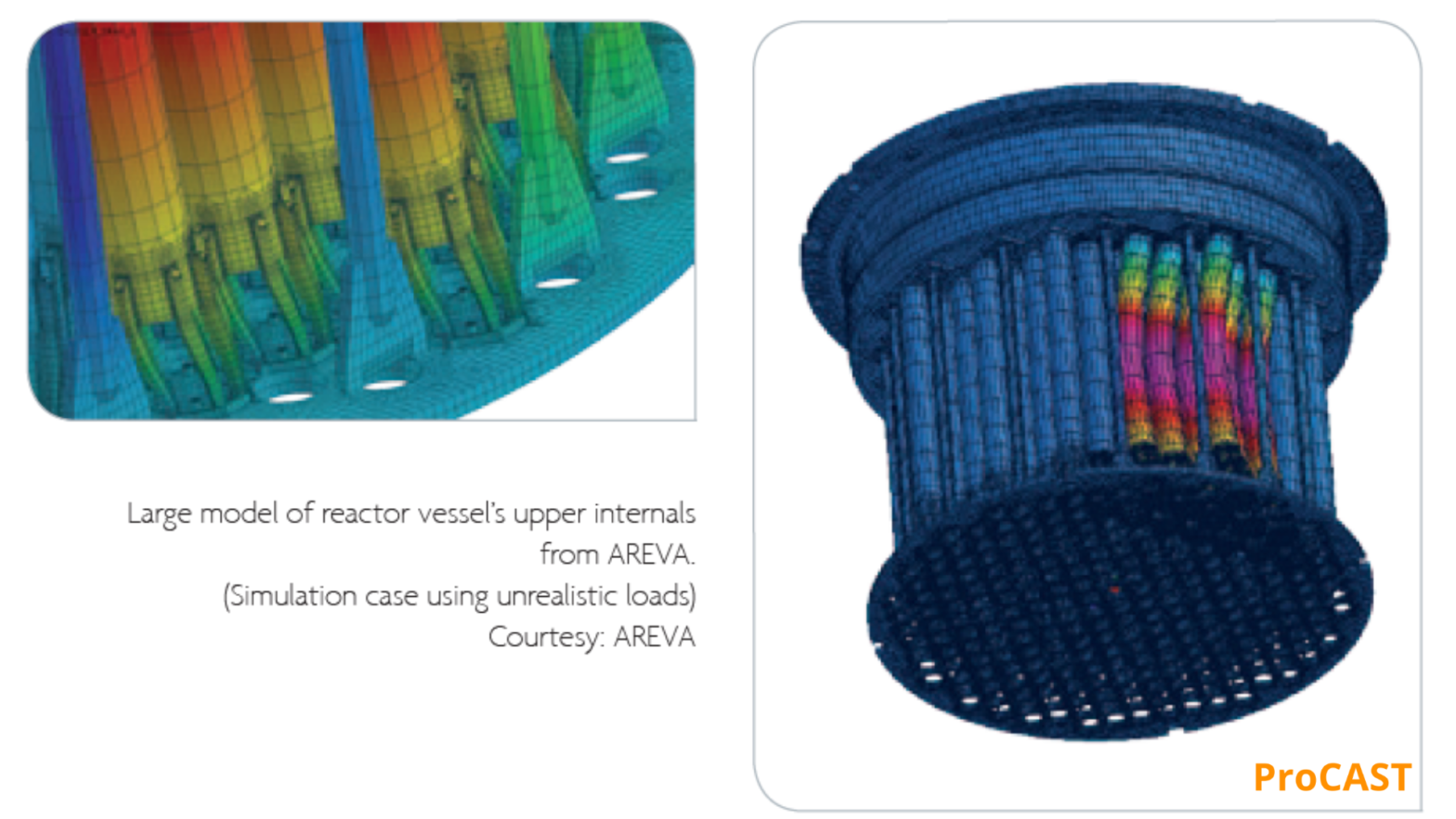

. Ever-enhanced safety: simulate

completely and accurately large

nuclear components

. Optimal quality and applicability

of simulation for leaders in nuclear

power

. Hardware solutions with the most

computational power ever on

the market at affordable cost of

ownership

. Precise and efficient dimensioning

analyses and behavior simulations

Using ESI QuikCAST virtual casting solution, Epcor was ableto evaluate alternative die designs at a fraction of the standard development time and cost to deliver higher quality parts to their customer, and be faster than the competition. They successfully achieved a 98% first time through put for the initial parts.

Read More

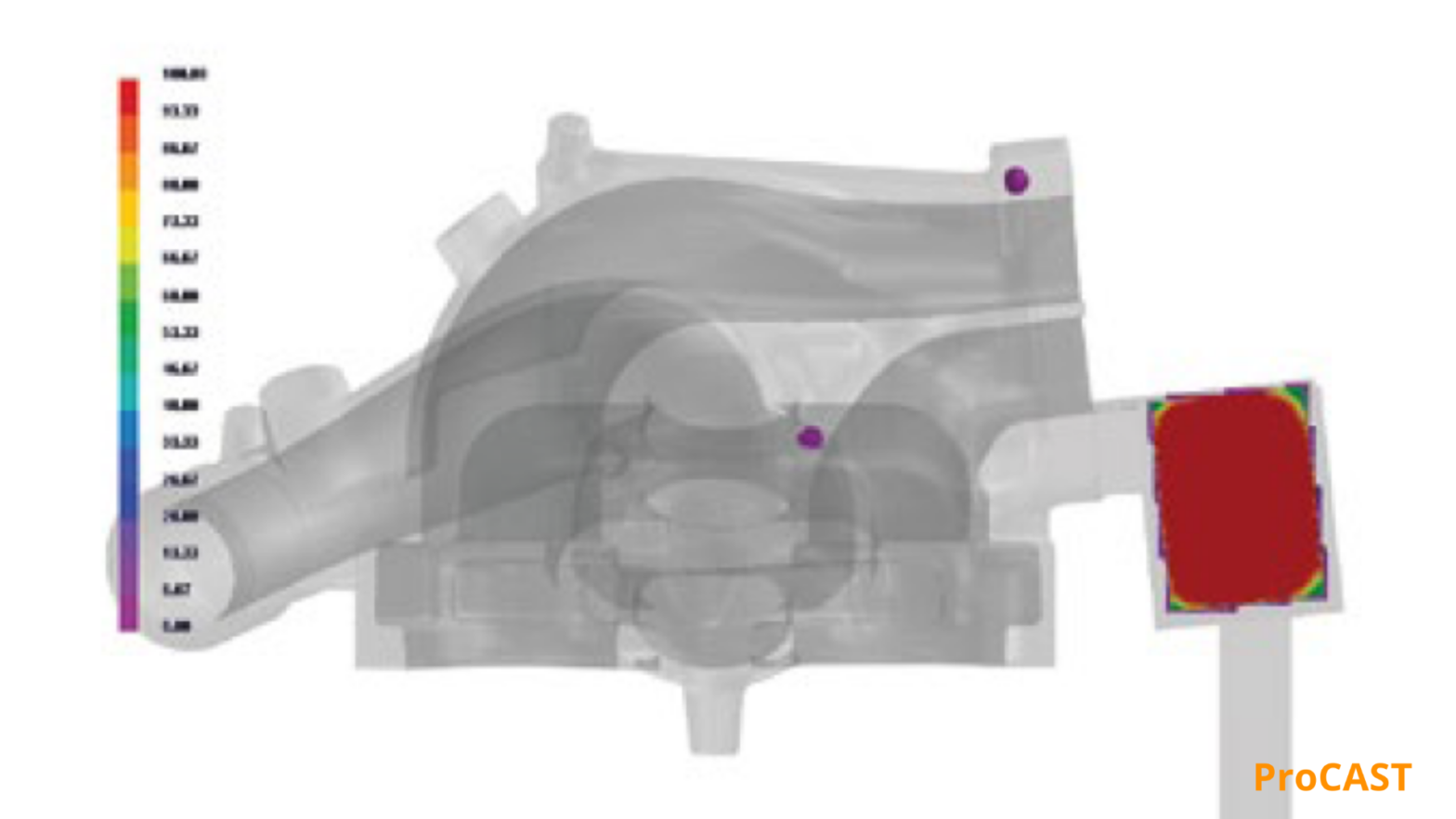

Sand Casting – Aluminium Helicopter Transmission Case Filling - Solidification - Stresses - Deformations

Read More

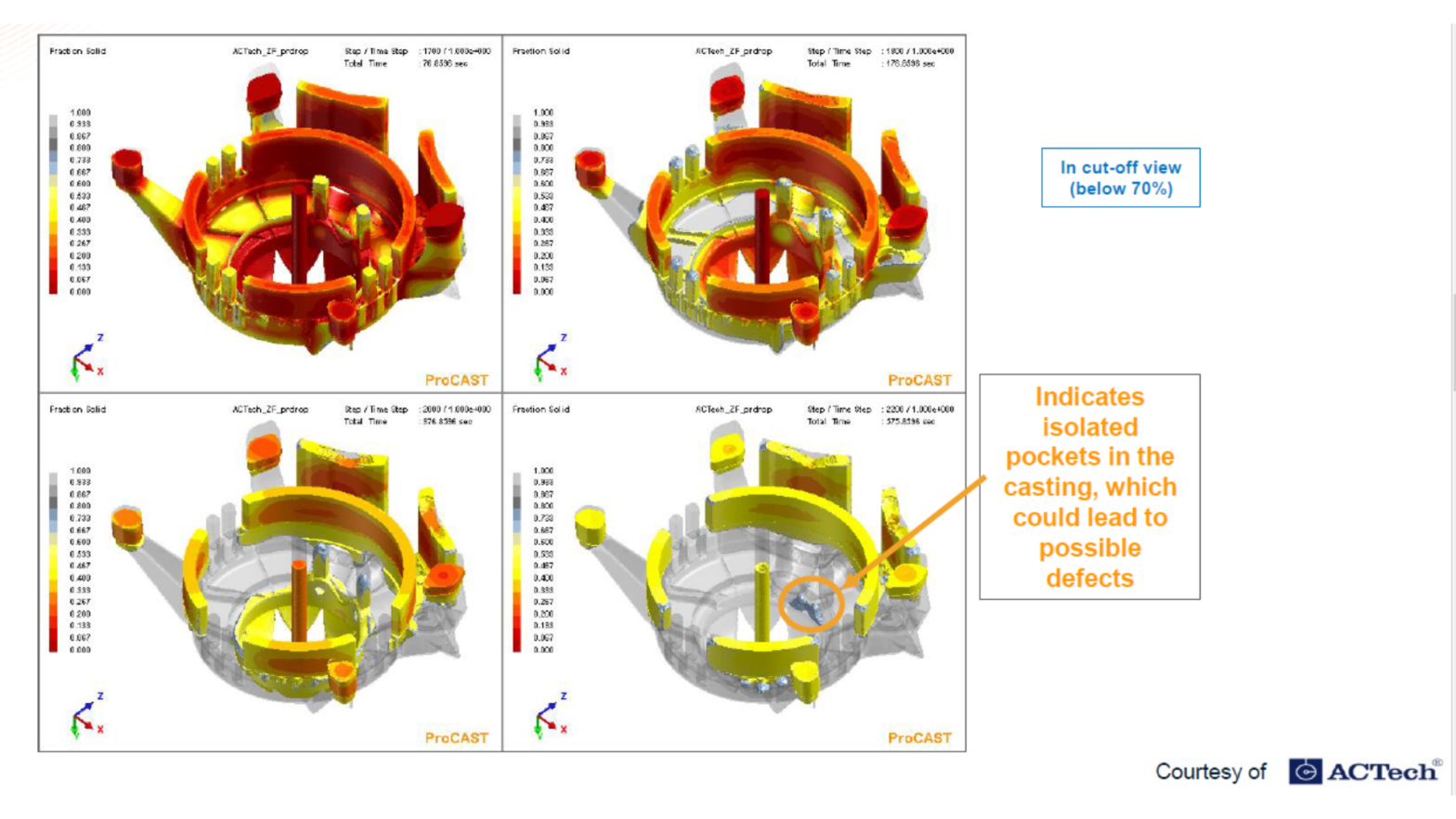

1. The Italia castings are characterized by very high quality and have extreme supply specifications 2. The time available is minimal and it is not allowed to make a mistake in the merger 3. It is possible to meet these requirements, with these times and minimize costs by giving the great experience and knowledge of the Foundry the Virtual Sampling of the casting simulation software. Excellent alignment “ProCAST Software Results” with “Reality” 4. Co design and definition of the casting system and uprights guided by the simulation of casting on the piece alone Article in Italian

Read More

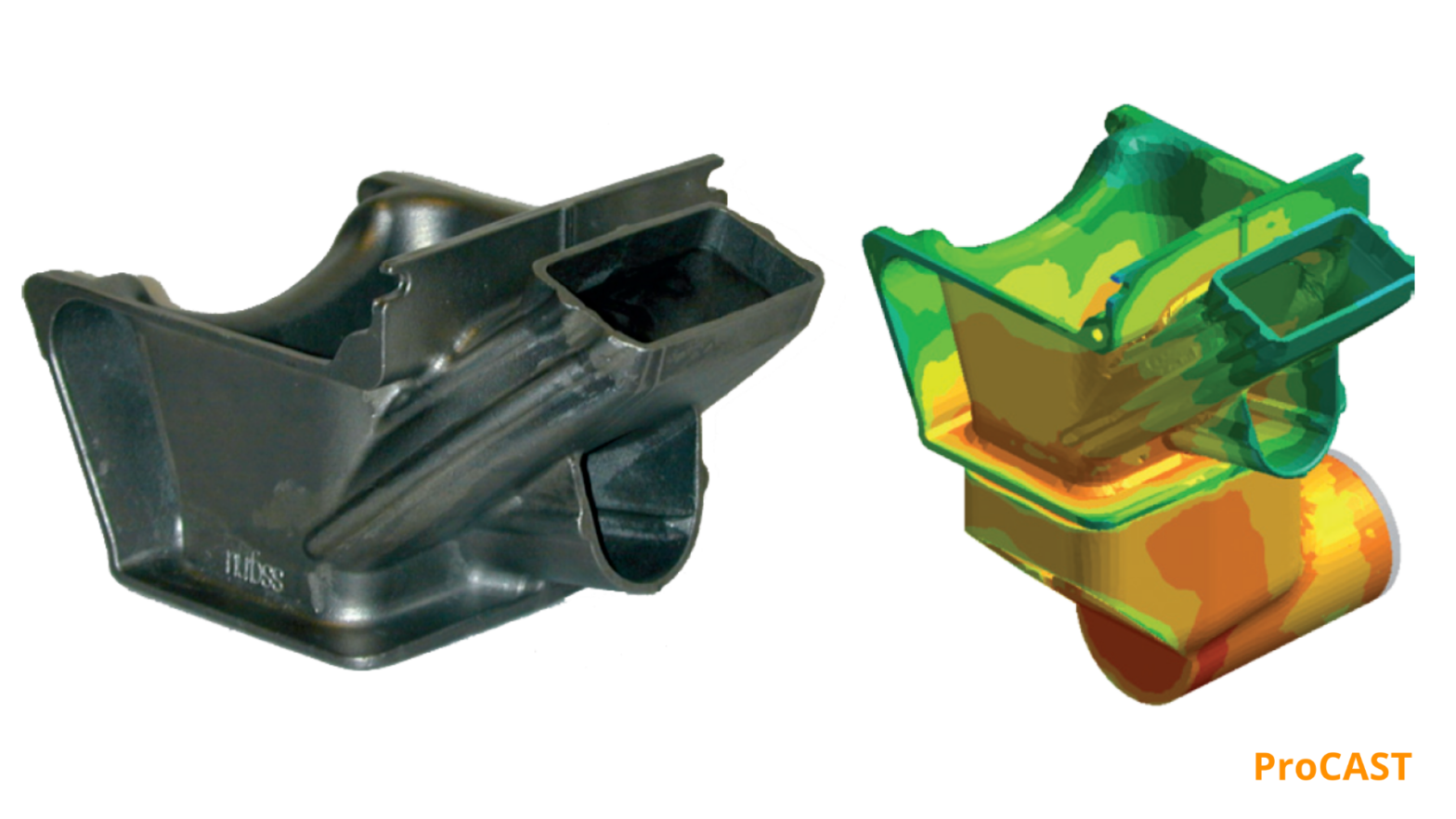

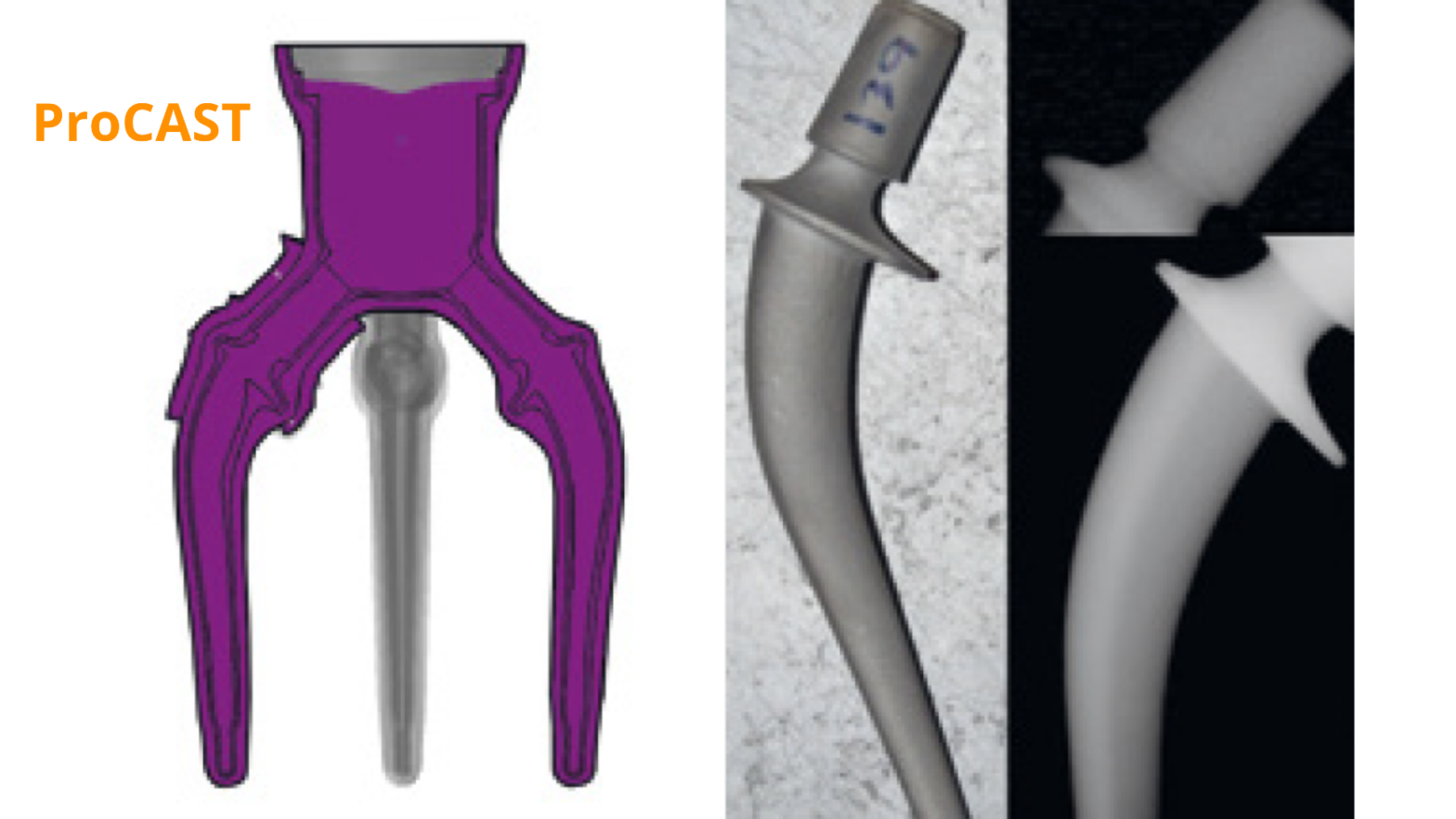

THE BENEFITS:

Validate the manufacturing tool of a foundry component and successfully move to production

Investigate the feasibility of a difficult thin-walled component while ensuring in-service performance of the product

Cost savings for tool development and production Allow decision-making early in the design phase

THE BENEFITS:

• The component wall thickness was reduced from 6mm to 3.5mm

• Casting weight was reduced significantly.

• 30% reduction in the total production cost

"During this project we used ProCAST software and that gave us the possibility to simulate & optimize thin-walled steel castings. ProCAST is a very competent software, when it comes to simulate thinwalled geometries"

Per Ytterell,

Managing Director (participant in the project, supplier of this steel component),

Smålands Stålgjuteri AB, Sweden

“The objective of DSB EURO is to satisfy

the requirements of our customers

regarding the quality of our products at

the highest level.

ProCAST helps us not only to enhance

the quality of our castings but also to

ensure a better competitiveness. Using

ProCAST enables us to deliver castings

on time and to cut back unnecessary

and repeated rework operations.

Finally, thanks to ProCAST we received

the “European Quality Award” in 2008

which opens up opportunities for new

cooperation.”

Ing. Pavel Veselý

Production Director, DSB EURO s.r.o.

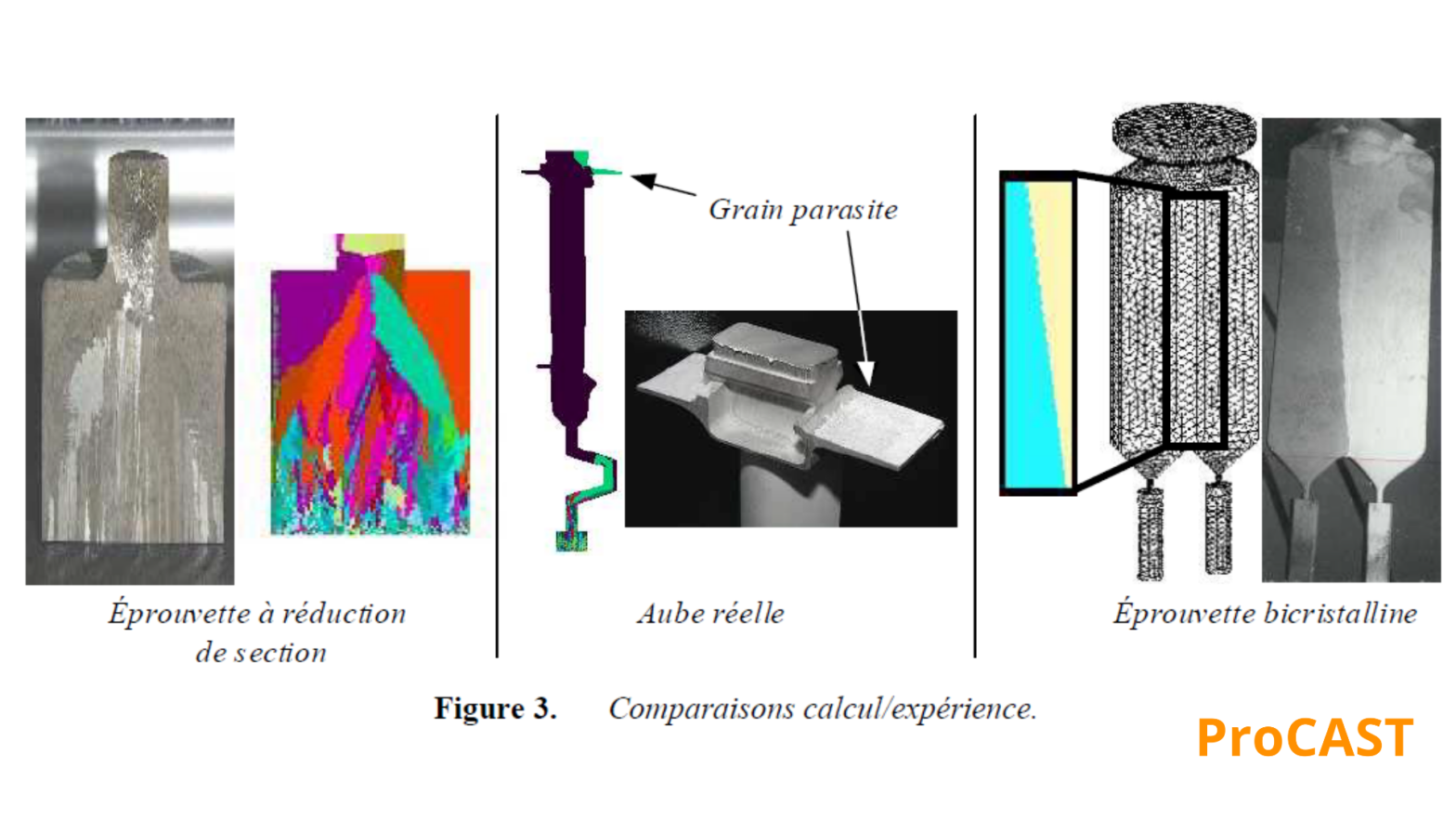

The C.A.F.E module for metal simulation foresees the germination and therefore the growth of the grains and, allows to obtain a high sensitivity of the prediction of grain defects in solidification. Article in French

Read More

THE CHALLENGE

Metalcast is casting increasingly complex parts in alloys that are difficult to cast. Yet Metalcast's customers expect them to continually meet their strict quality specifications and at the same time maintain or reduce product development time and expenses.

THE BENEFITS

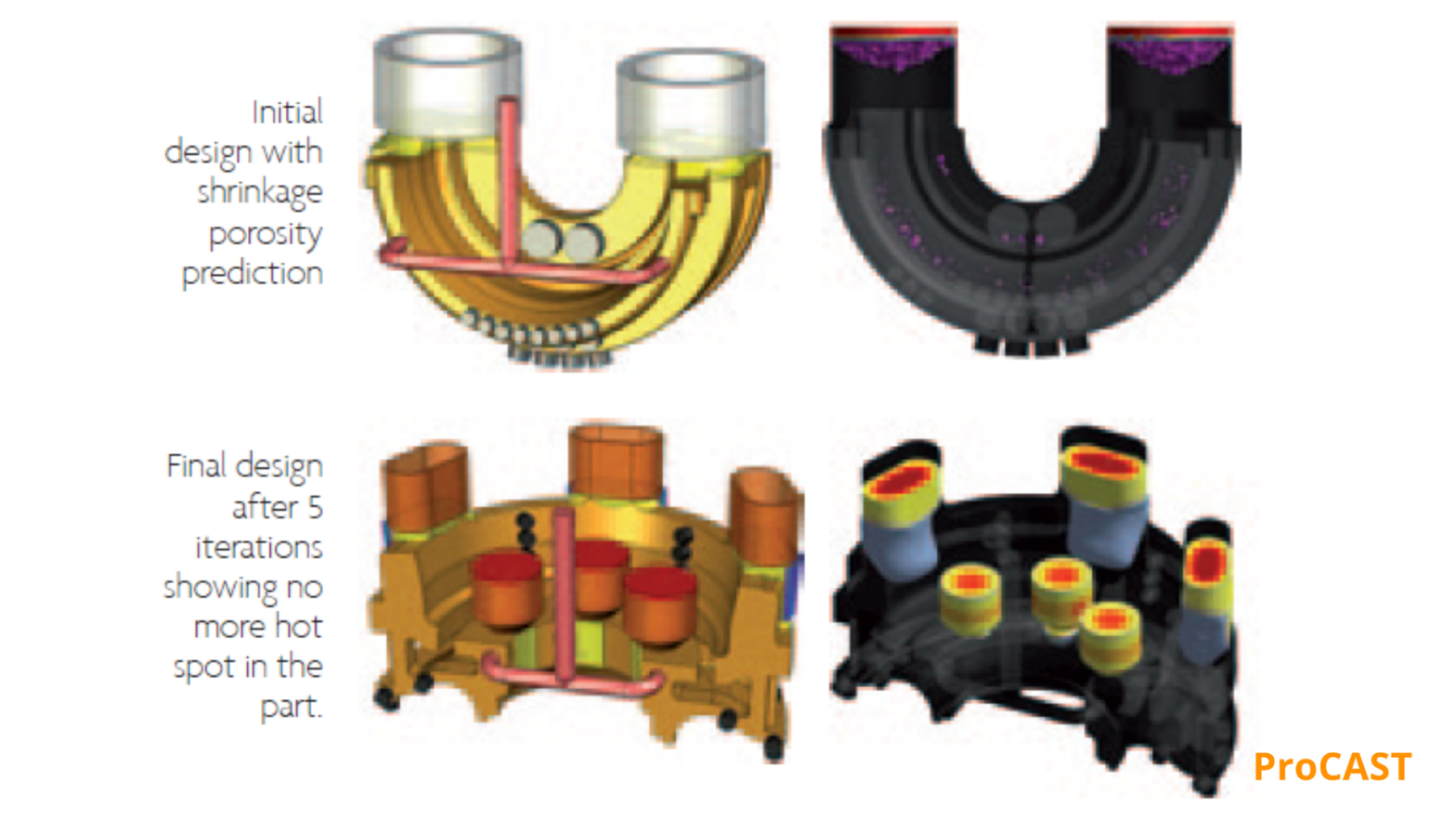

. Multiple design iterations via simulation to reach an optimal design thereby reducing shop floor trials;

. Reduction in product development times;

. Rejections reduced from 25% to 3% on a valve body casting part.

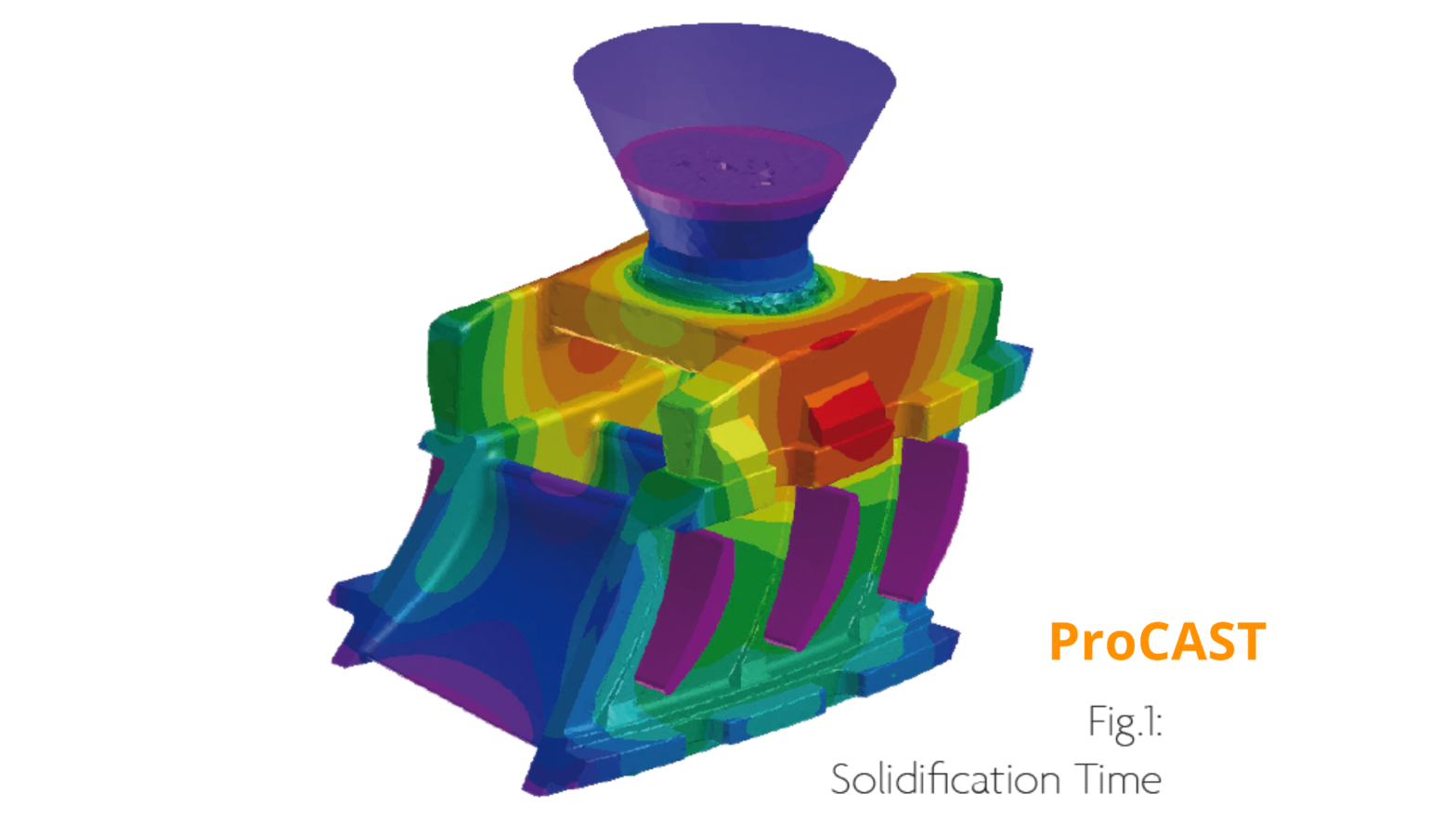

Thanks to the development of dedicated techniques over the last two decades, investment casting modeling with ESI’s software has become reliable and efficient to optimize safety components such as turbine blades for jet engines. The solution includes dedicated superalloy material databases and ceramics characterization allowing very accurate predictions.

Read More

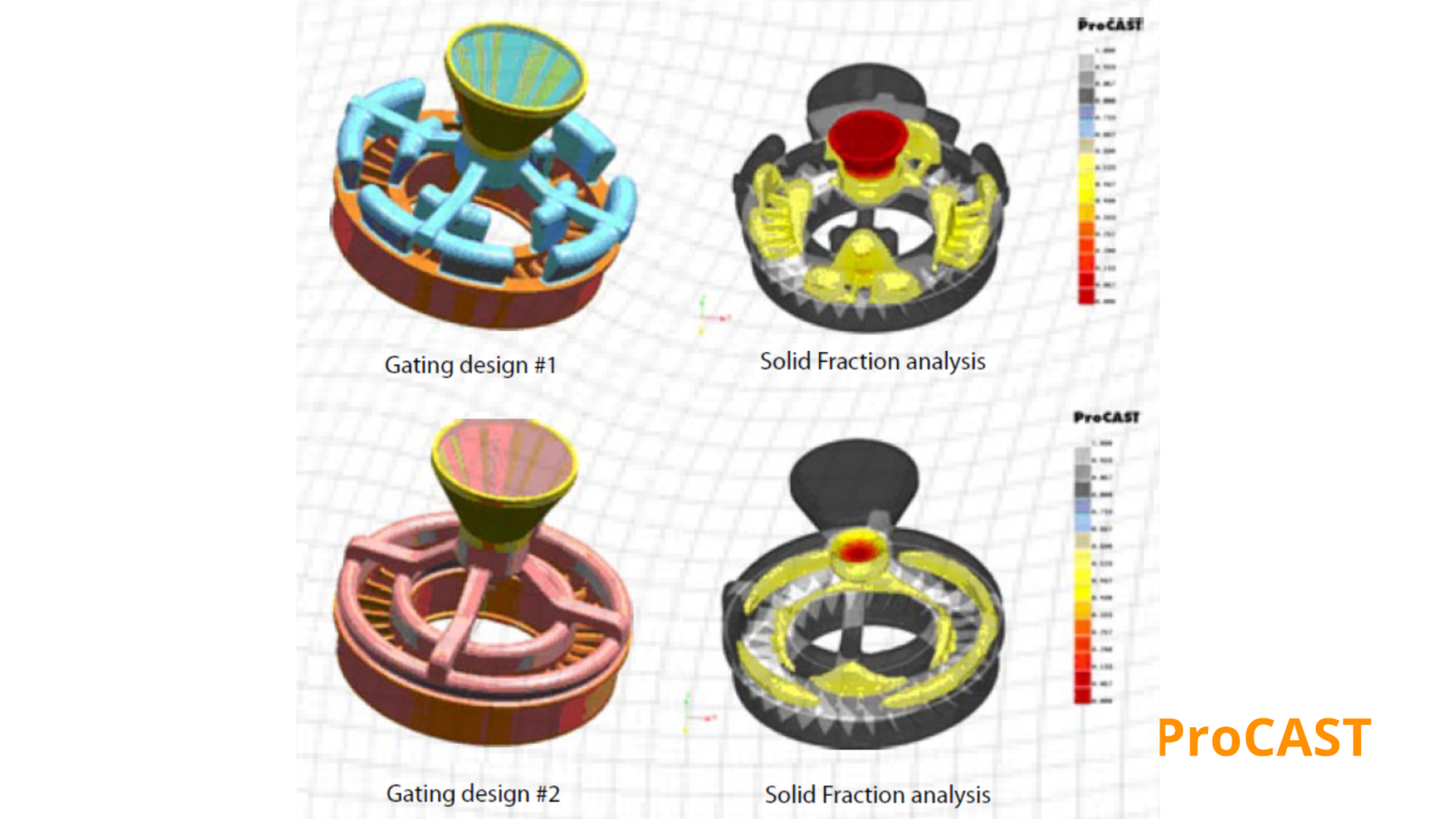

Reduce part development lead-times by a better knowledge of process and an early confi rmation of metallurgical capabilities is one of the main topics for investment casting technology.

Numerical simulation is one of the major tools which can be used to face this goal. This e-tip illustrates a simulation methodology usable to optimize a casting design in an efficient and rapid way.

“Scientific methods can always save us time and cost. ProCAST is just that tool helping foundry men find the right solutions.

For investment casting process, ProCAST can generate different layers of shells and with wrapping outside. This helps predict the temperature field more precisely.”

Nannan Song,

Senior Researcher

Advanced Foundry and Rapid Prototyping Technologies, Inegi