Vehicles lightening is a common goal to all car manufacturers, with the aim to improve fuel economy and

reduce CO2 emissions.

It is not always easy, however, to reconcile the use of light alloys and conventional

forming or casting technologies with the need to manufacture structural or engine components, with thin

walls, complex shapes and adequate mechanical properties.

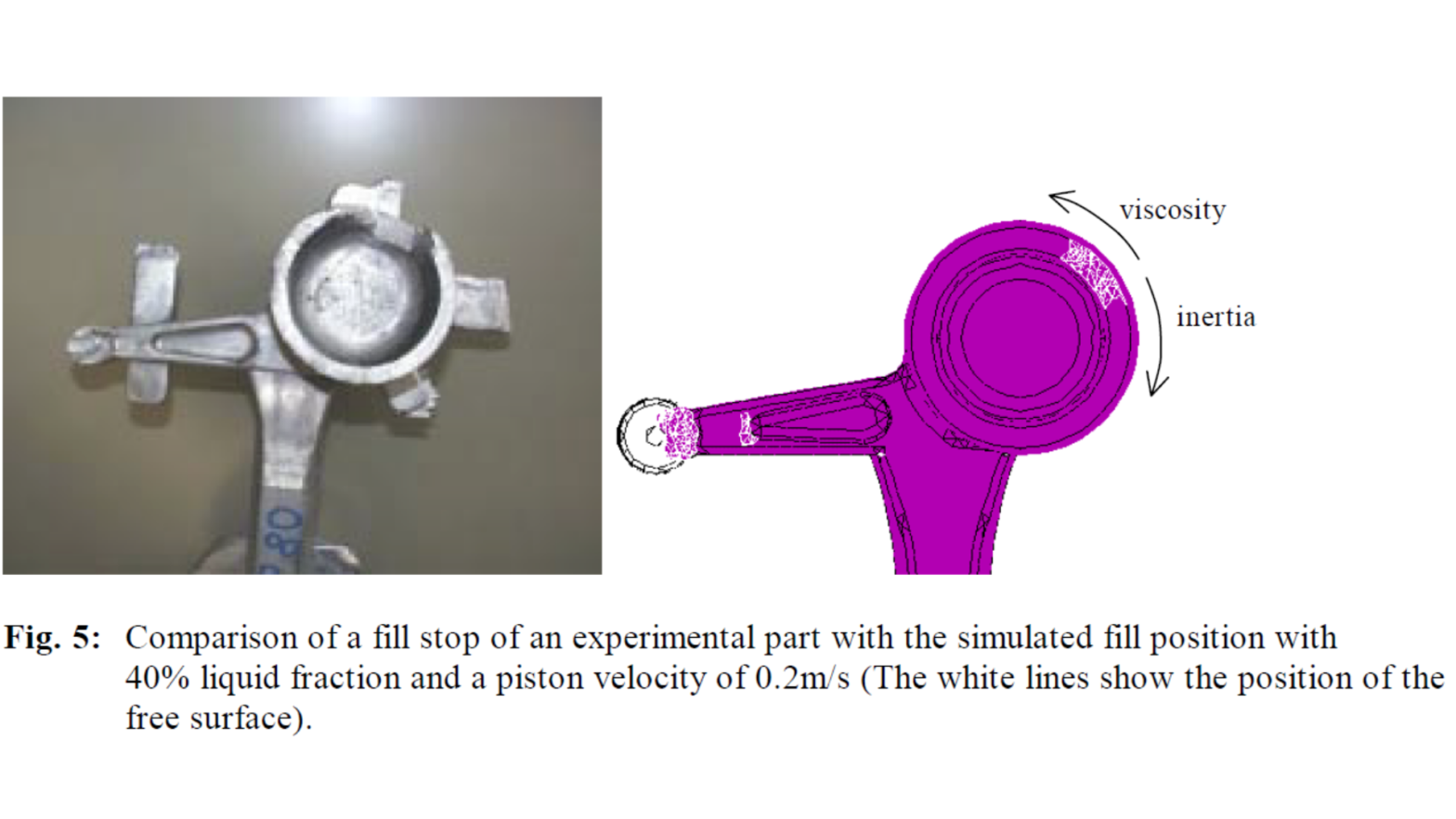

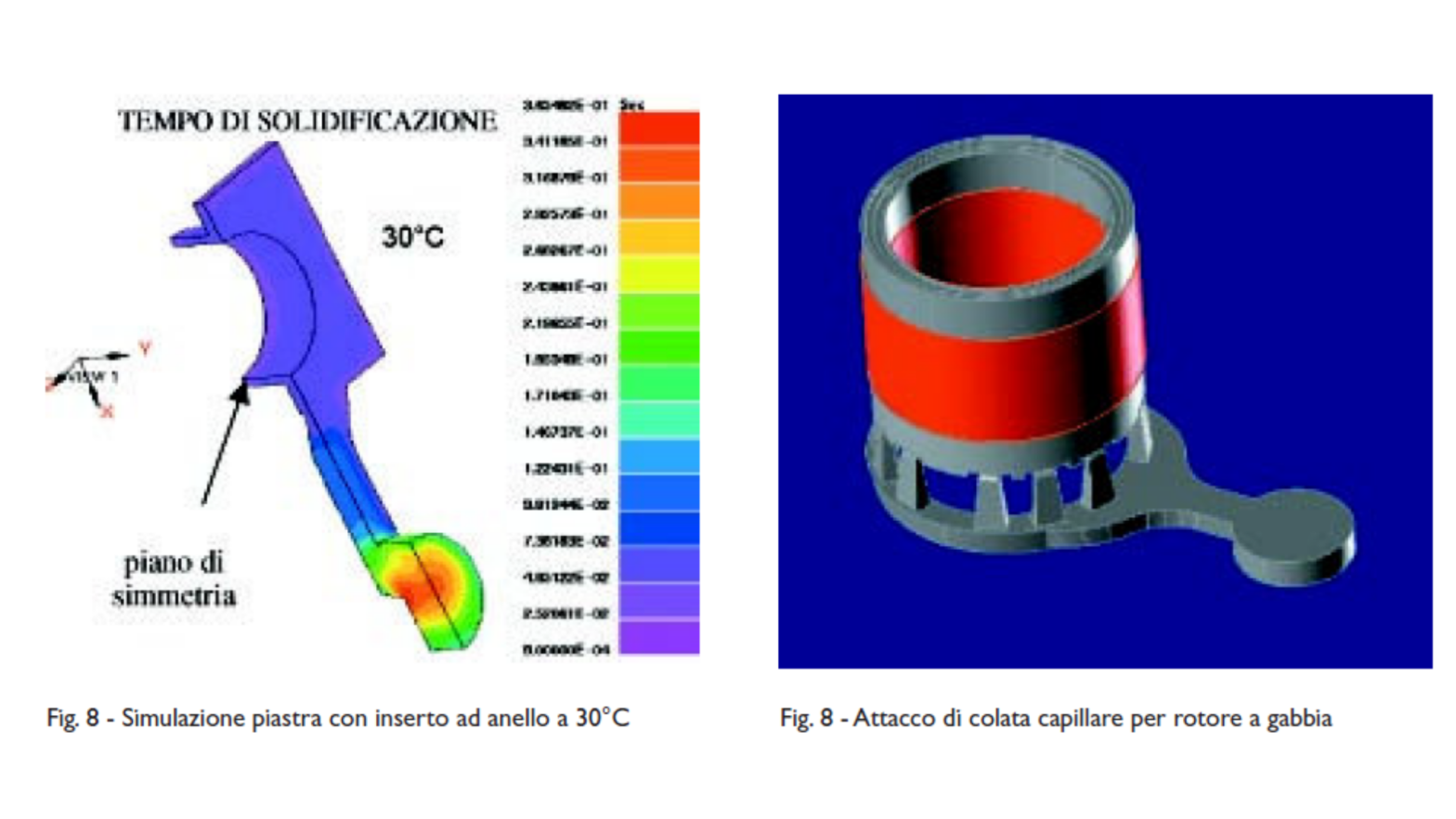

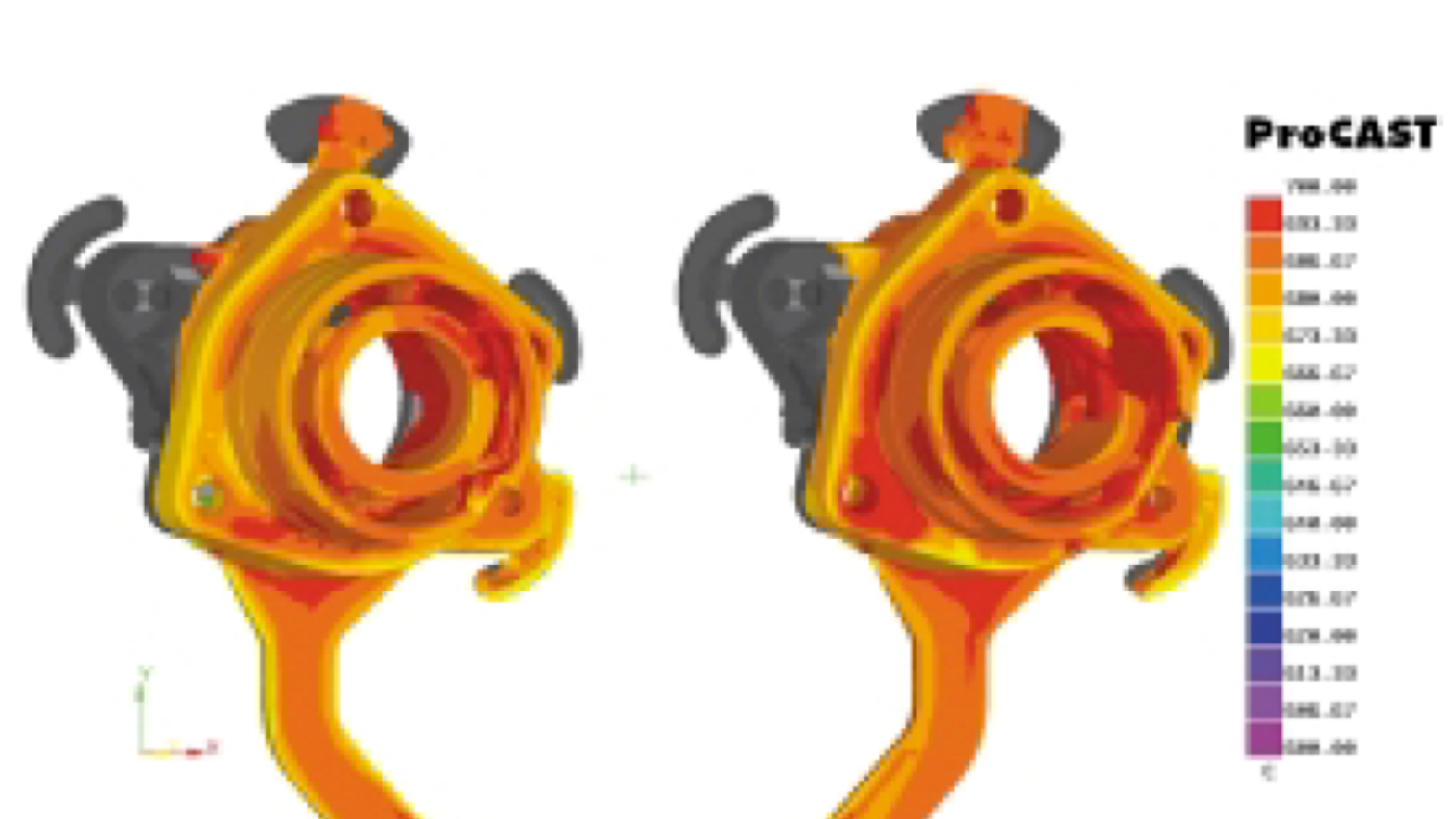

Numerical modelling of mould filling and of solidification has been used for the optimisation of thixoforming production moulds. Rheological data and boundary conditions for the modelling were deduced from several sets of instrumented experiments. The simulation results could be correlated with several types of known defects. Using this simulation tool for the identification of potential defects, the geometries of gates, parts, overflows and vents have been optimised.

Read More

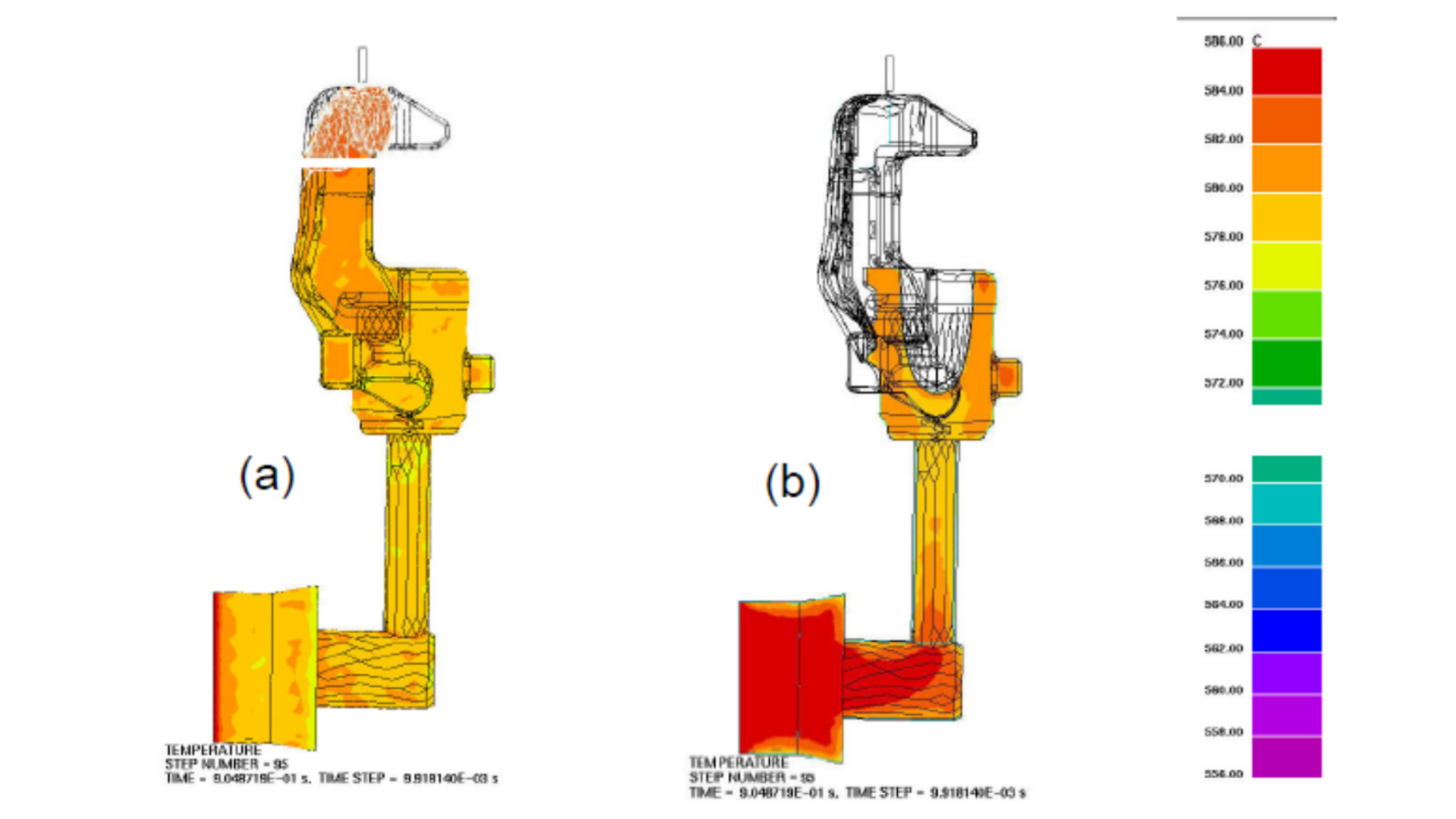

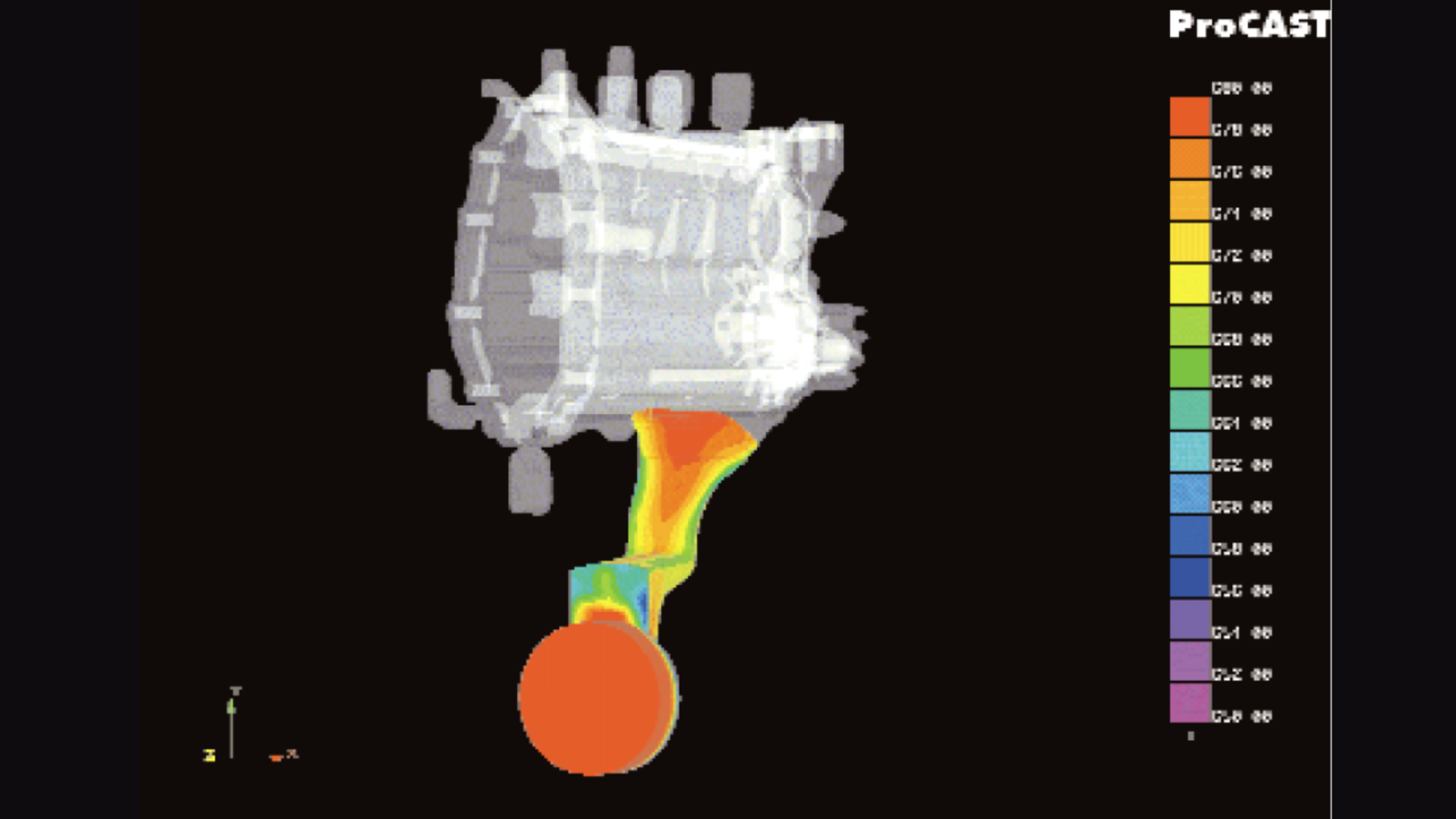

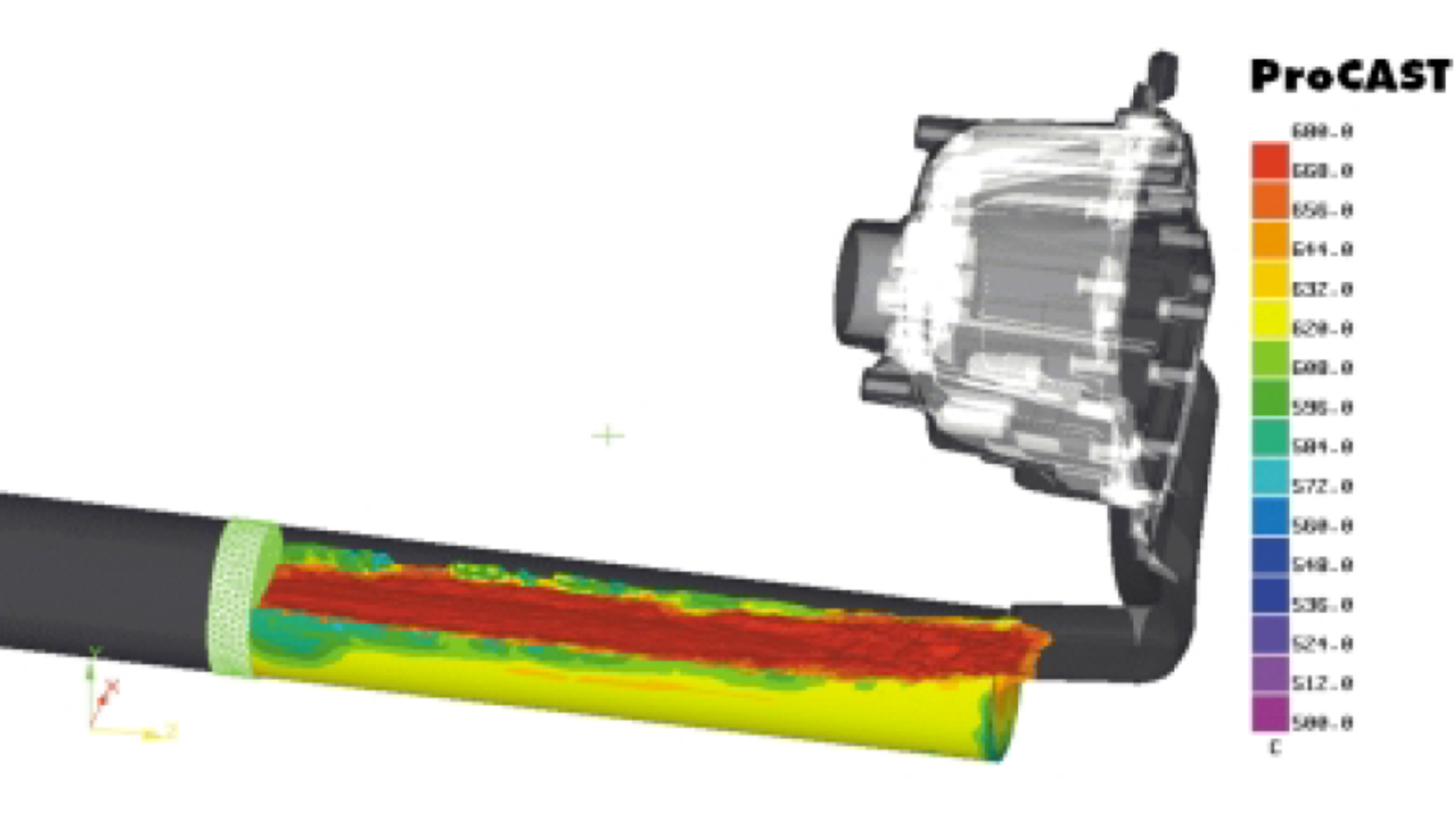

Numerical modeling has been used successfully as an efficient tool for converting a gravity-cast brake caliper into a thixocasting process. Procast's thixo module was used for the modeling process to achieve optimal processing parameters. The jet results show excellent correlation with the fluid dynamics and flow pattern of the model. The level and position of porosities, revealed by non-destructive X-ray and microscopic analyzes, showed a good correlation with model prediction

Read More

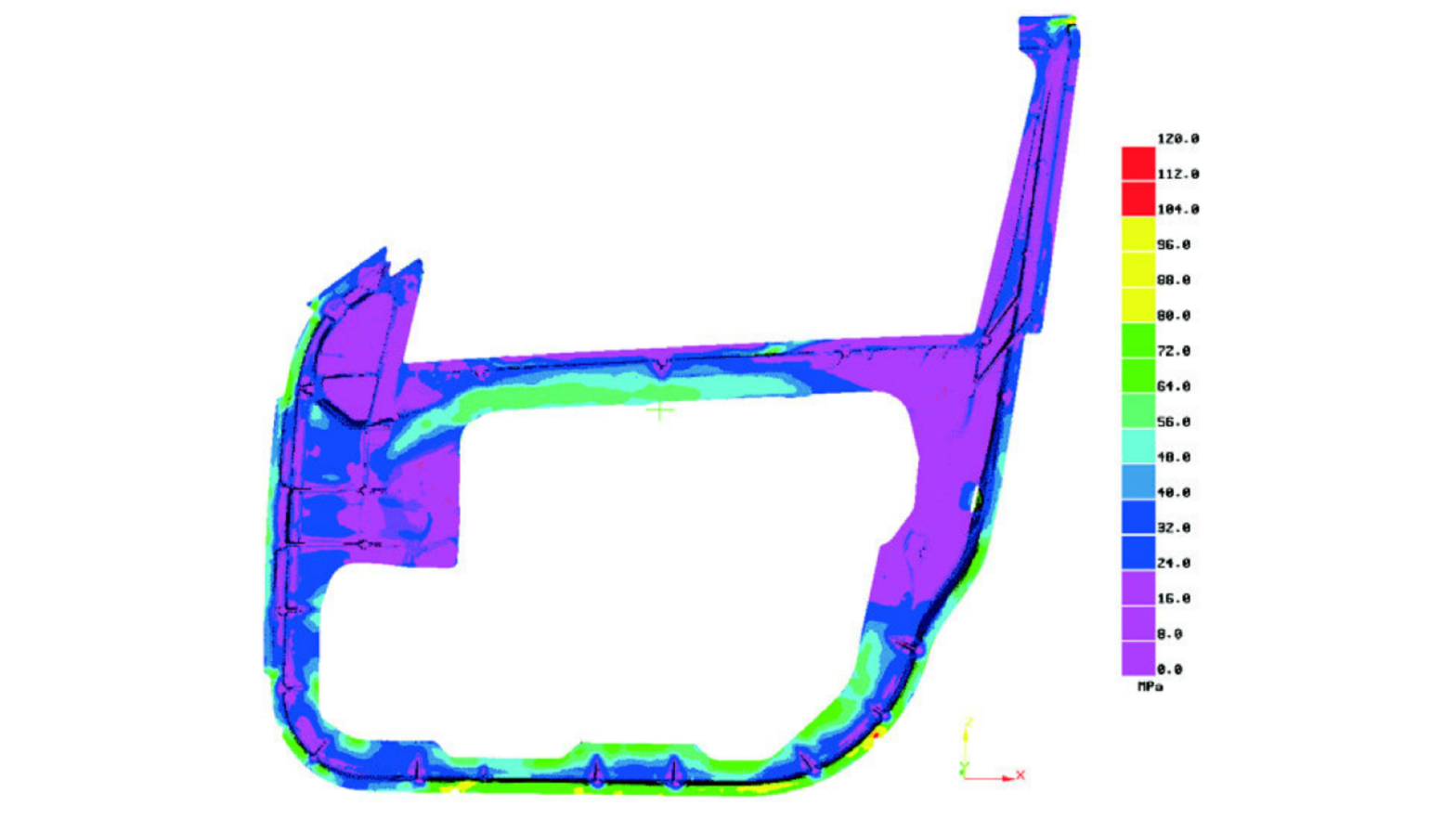

High Pressure Die Casting (HPDC) enables manufacturing of large thin-walled light-weight structural components.

To remain competitive in the new global marketplace, component manufacturers in the automotive and aeronautic industries are constantly being asked to increase efficency while lowering production costs and shortening delivery times. This request from OEMs for product solutions with low energy consumption, in tandem with new requirements by the government for increase full efficency, can be satisfied using light metals such as aluminum and magnesium.

It is now common practice in the design of aluminum components produced by die casting to provide for the use of inserts of different material than the cast alloy.

This research was conducted with the aid of simulation software supplied to the research group. In this way it was possible to observe the progress of the filling of the impression as well as the solidification of the casting.

Article in Italian

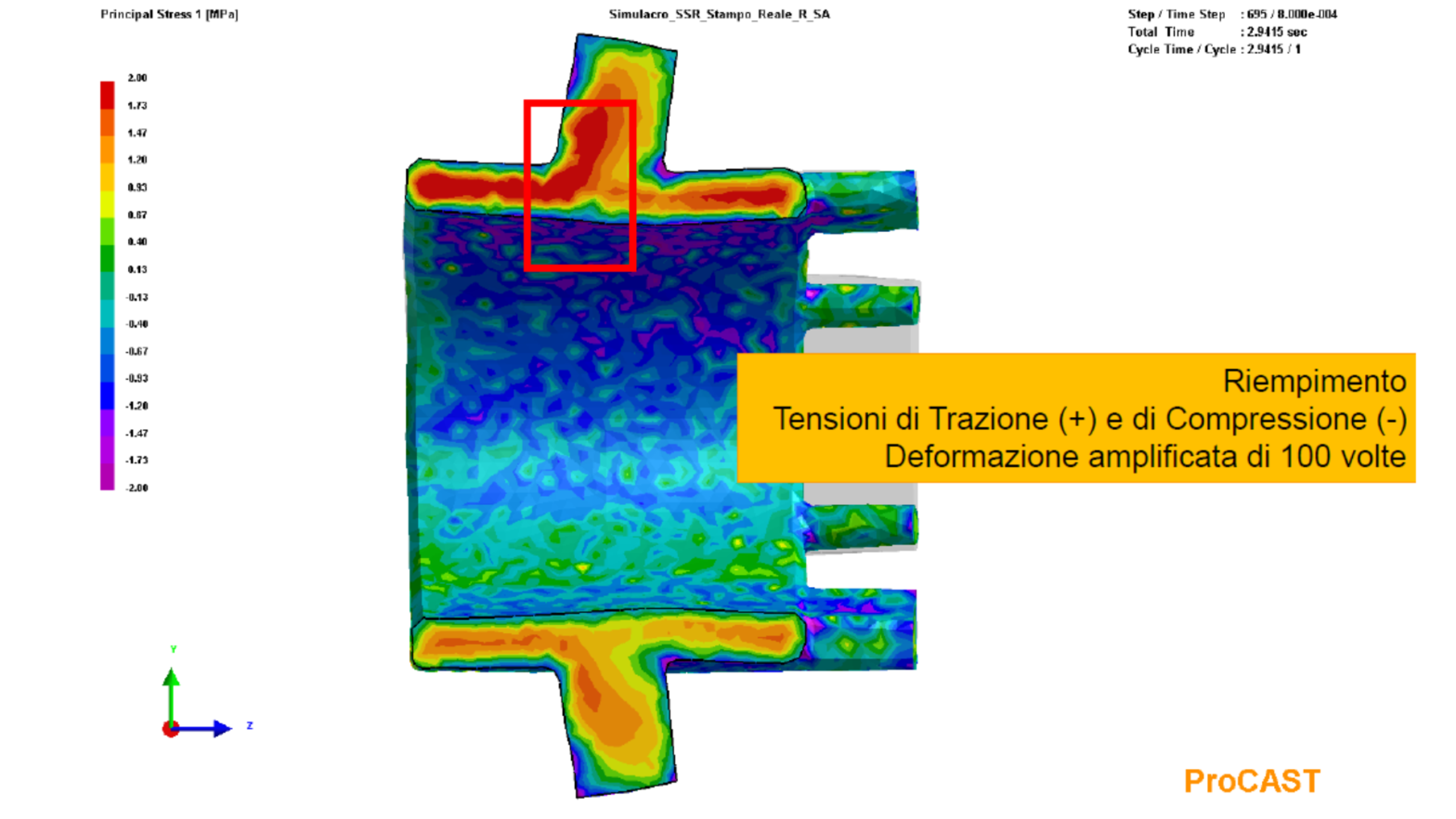

After 5 years of concentrated and profitable use of ProCAST, ZML manages the simulation of filling and solidification as any other company activity, perfectly integrated in the cycle of products and dies development.

Moreover, thanks to this user-friendly software and to its calculation rapidity, we can evaluate in details all the small particulars which could escape through a traditional approach.

This analytic care in designing and engineering allowed ZML to broaden business horizons supplying systems for European automotive industry.

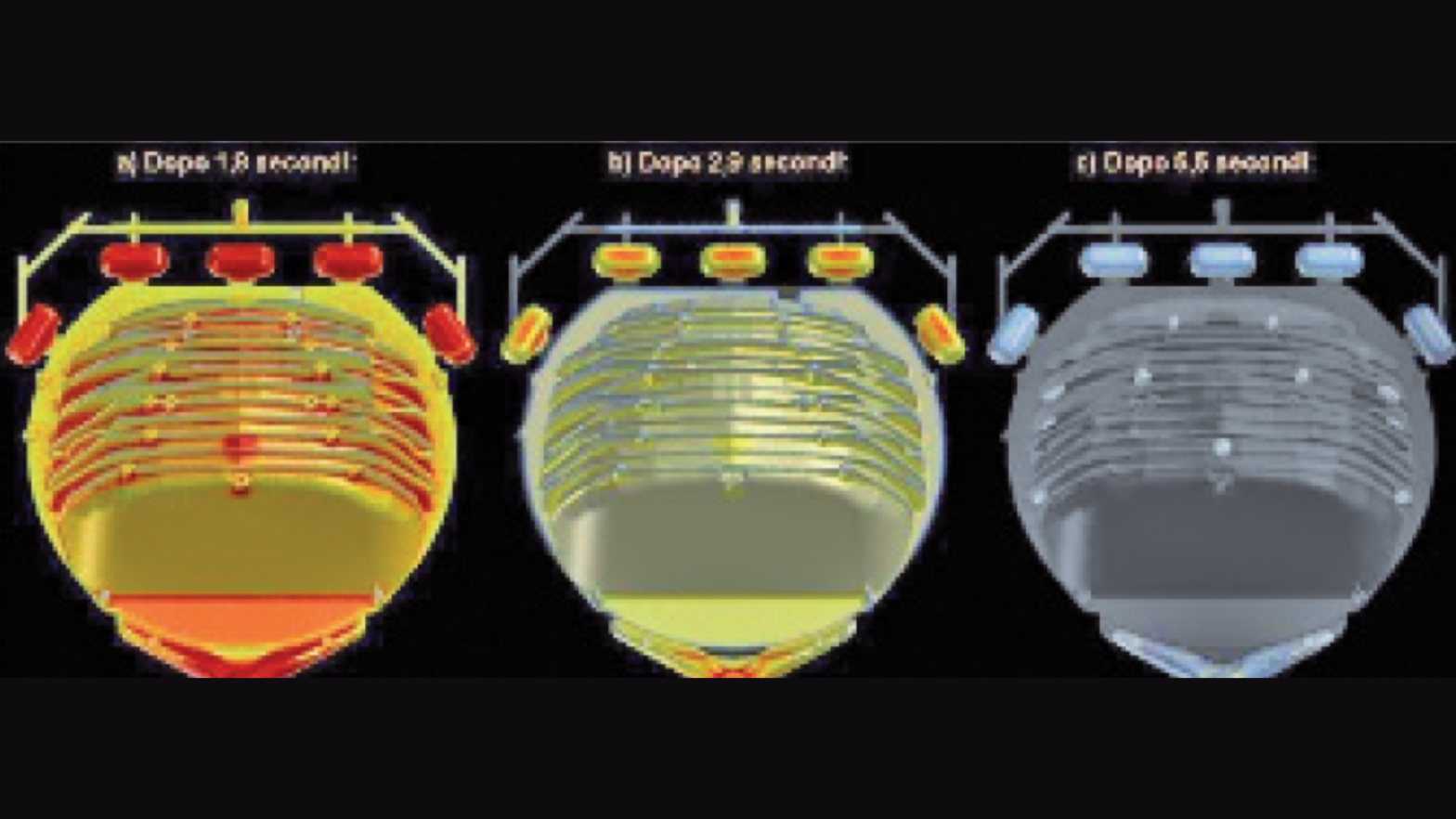

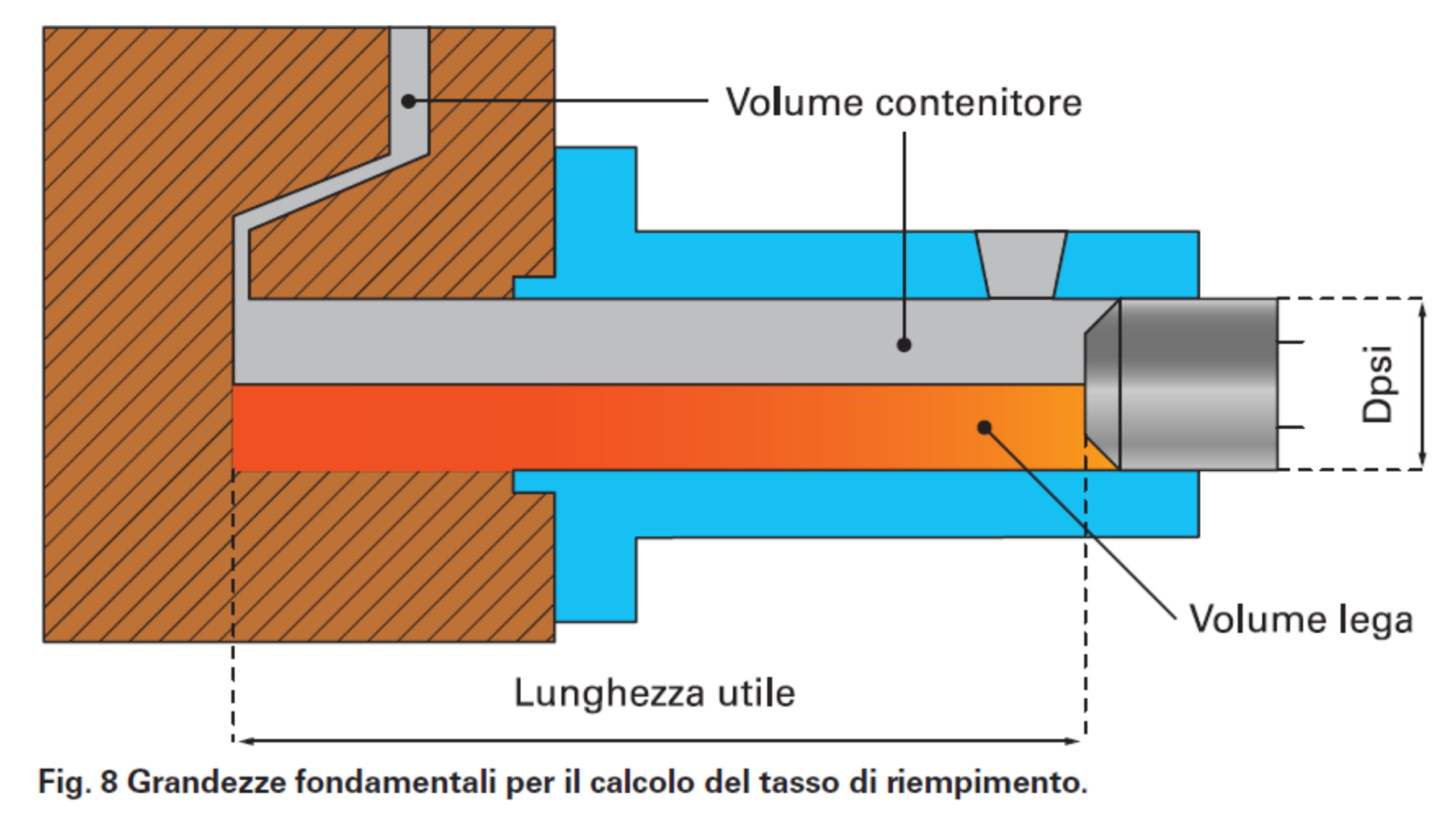

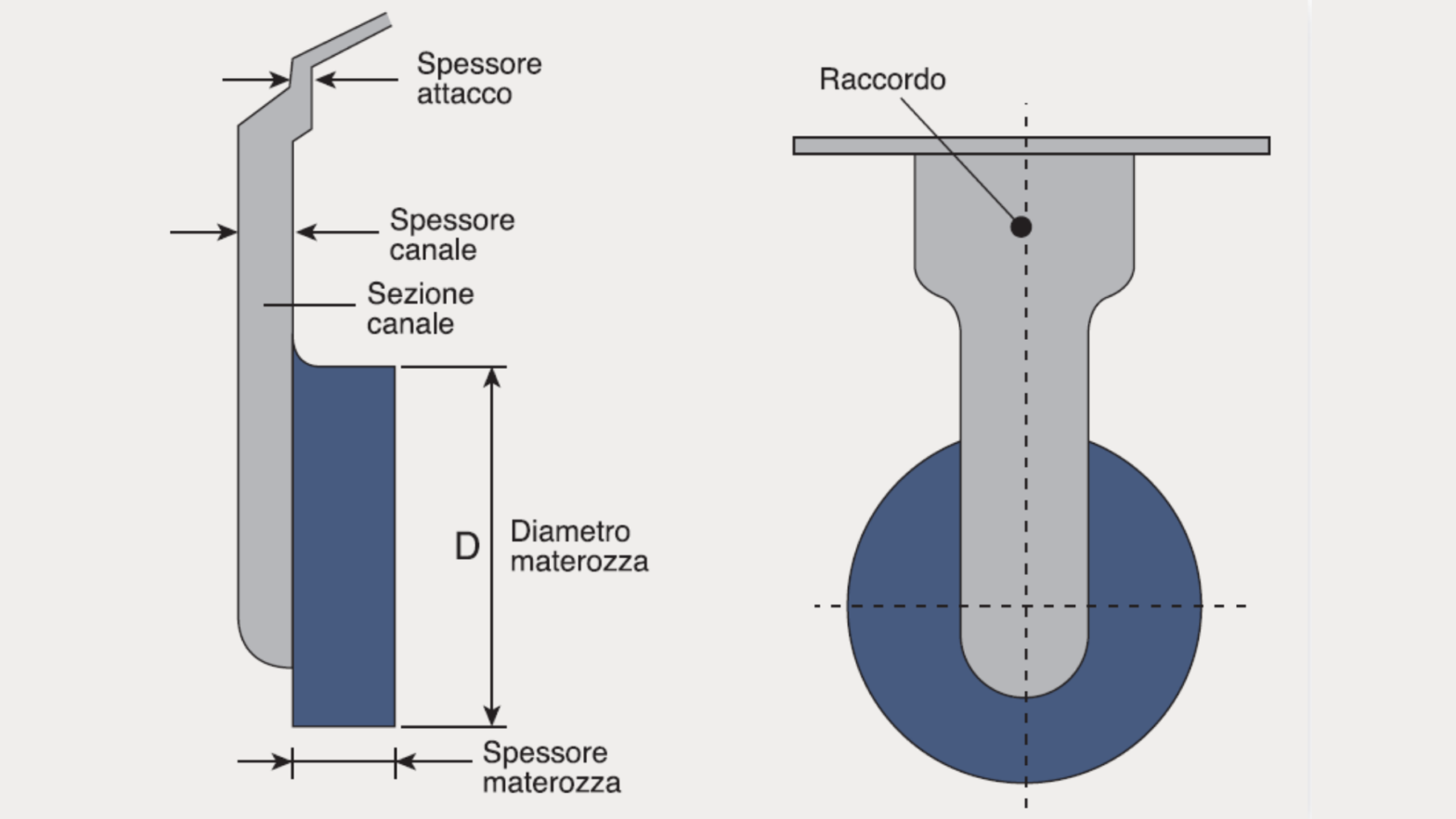

The design of a casting device by integrating traditional sizing and process simulation. Below is an application example of general design guidelines that can be shared for the realization of a technologically and therefore economically valid product.

Solidification analysis of the casting.

Article in Italian

The design of a casting device by integrating traditional sizing and process simulation. Below is an application example of general design guidelines that can be shared for the realization of a technologically and therefore economically valid product.

Filling analysis as the injection curve changes.

Article in Italian

The design of a casting device by integrating traditional sizing and process simulation. Below is an application example of general design guidelines that can be shared for the realization of a technologically and therefore economically valid product.

Article in Italian

GHIAL of Castegnato, Brescia, a well-known foundry in the field of die casting and gravity casting of aluminum alloy castings for the automotive sector, has been using a casting simulator since 2000.

The first important characteristic, ProCAST’s 2006 novelty, is the importation of the .model and .catpart native files from CAD CATIA.

Lastly, GHIAL in the first place and all the foundries, die constructors and design engineers using CATIA will no longer encounter the typical problems associated with exporting geometries, from Iges, with its special tolerance, to STL which must in all cases be solid.

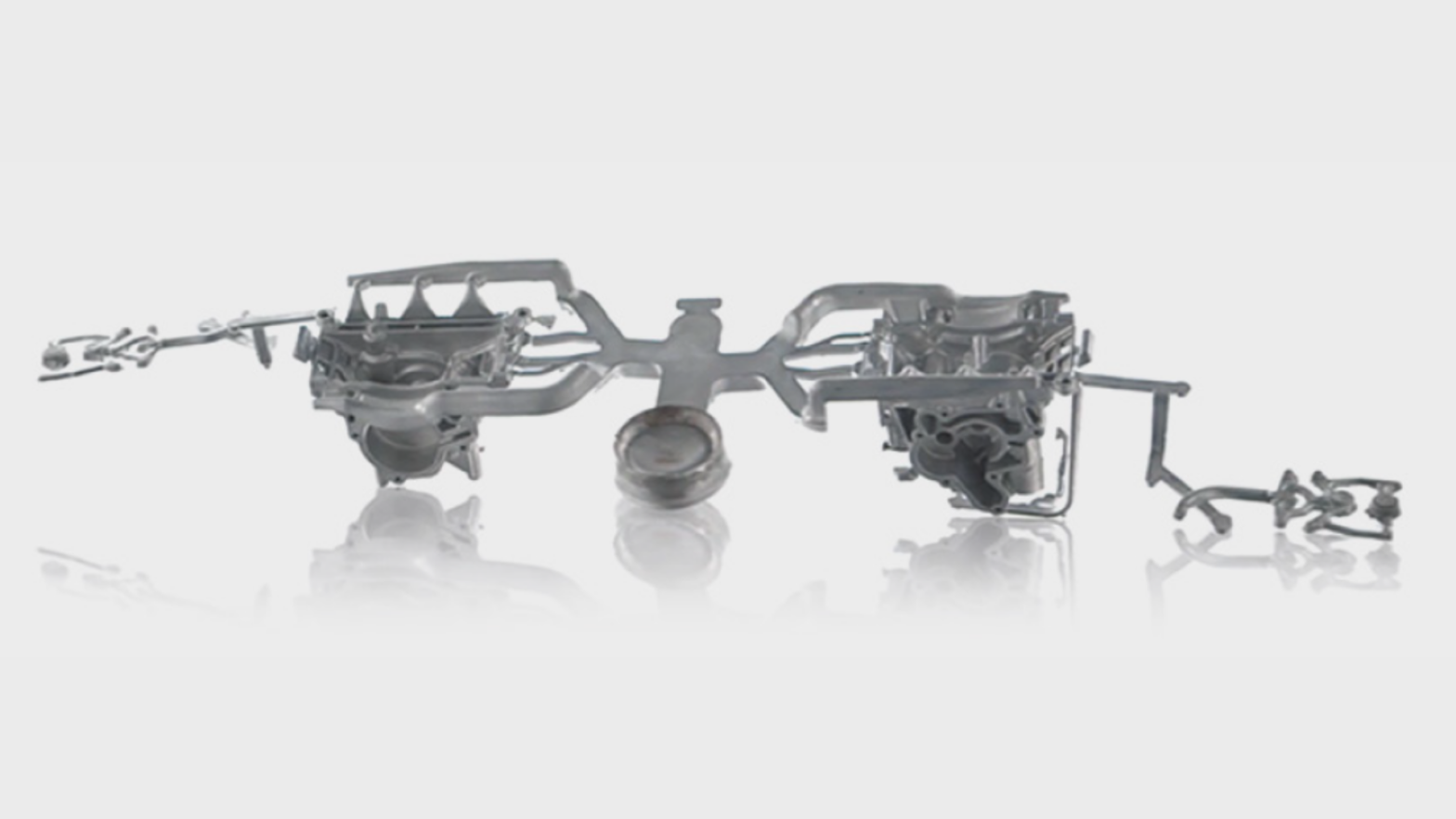

Used by Fomt for the design and production of core boxes for the distribution body of a braking system consisting of seventeen cores,

FOMT of Grugliasco, Turin, the foundry which has always been willing to invest in innovative technologies, is using the ProCAST casting simulator to its great satisfaction. The ease of use, the speed of calculation and the correspondence between the simulation and the foundry process have made it possible to achieve superior levels of quality and productivity, involving personnel – who now consider simulation to be normal activity but vital and rich in satisfaction.

New functionality within ESI ProCAST allows simulation to account for DCM characteristics. FAR successfully switched from one to two high-quality cavities and engineered a new die design for the right die casting machine at a minimum cost.

Read More