Comprehensive digital platform for the valve supply chain

Comprehensive digital platform for the valve supply chain

Casa del Giovane – Sala Nembrini, Via Mauro Gavazzeni 13, Bergamo, Italy

The digital transformation is redefining the way design, production, and validation of metallic components are approached. In the valve sector, characterised by complex geometries, stringent performance requirements, and intricate production cycles, the integration of predictive tools has become a key accelerator for competitiveness and reliability.

This course, developed by ECOTRE Valente, presents a digital platform capable of supporting the entire valve development cycle: from design definition to production process validation, up to final performance verification.

It is a technical training day dedicated to industry professionals, aiming to provide a clear and practical understanding of how simulation technologies can reduce costs, lead times, and process waste, while improving the quality of the finished product.

The course will be held in person on Wednesday, 3 December 2025, from 10:30 to 16:30, at Casa del Giovane – Sala Nembrini, Via Mauro Gavazzeni 13, Bergamo.

Digital Manufacturing for the Valve Supply Chain

- Target audience: Moulders, Die-makers and Designers

- Speakers: Ecotre Technical Department

- Duration: Starts Wednesday 20 September 2023 – Ends Thursday 16 November 2023

20-21 September: joint course

28 September, 5-12-19-26 October and 7-9-16 November: individual meeting slots lasting one hour - Time: From 8 a.m. to 12 noon and from 1 p.m. to 4 p.m.

- Material: DEFORM software for the duration of two months, Course notes in pdf format and Attendance Certificate

- Venue: BACCADEMY Srl – Via Industriale, 106 – 25065 Lumezzane (BS)

FILL IN THE FORM FOR FURTHER INFORMATION

The course is led by Cristian Viscardi, Technical Director and R&D Manager at ECOTRE Valente. For over four decades, ECOTRE has supported the metal components industry in selecting, training, and applying the most advanced simulation technologies for: foundry, forging, additive manufacturing, heat treatments, machining, and structural and performance testing. By integrating these technologies, the digital platform enables the optimization of every stage of the production process.

Course Goals

The course provides a structured overview of digitalization technologies applied to the valve supply chain, showing how each tool contributes to creating a more reliable and efficient production process.

Participants will gain an integrated view of the main digital disciplines:

- – Computational Fluid Dynamics (CFD) for performance analysis

- – Structural Analysis (CAE) for mechanical and regulatory verification

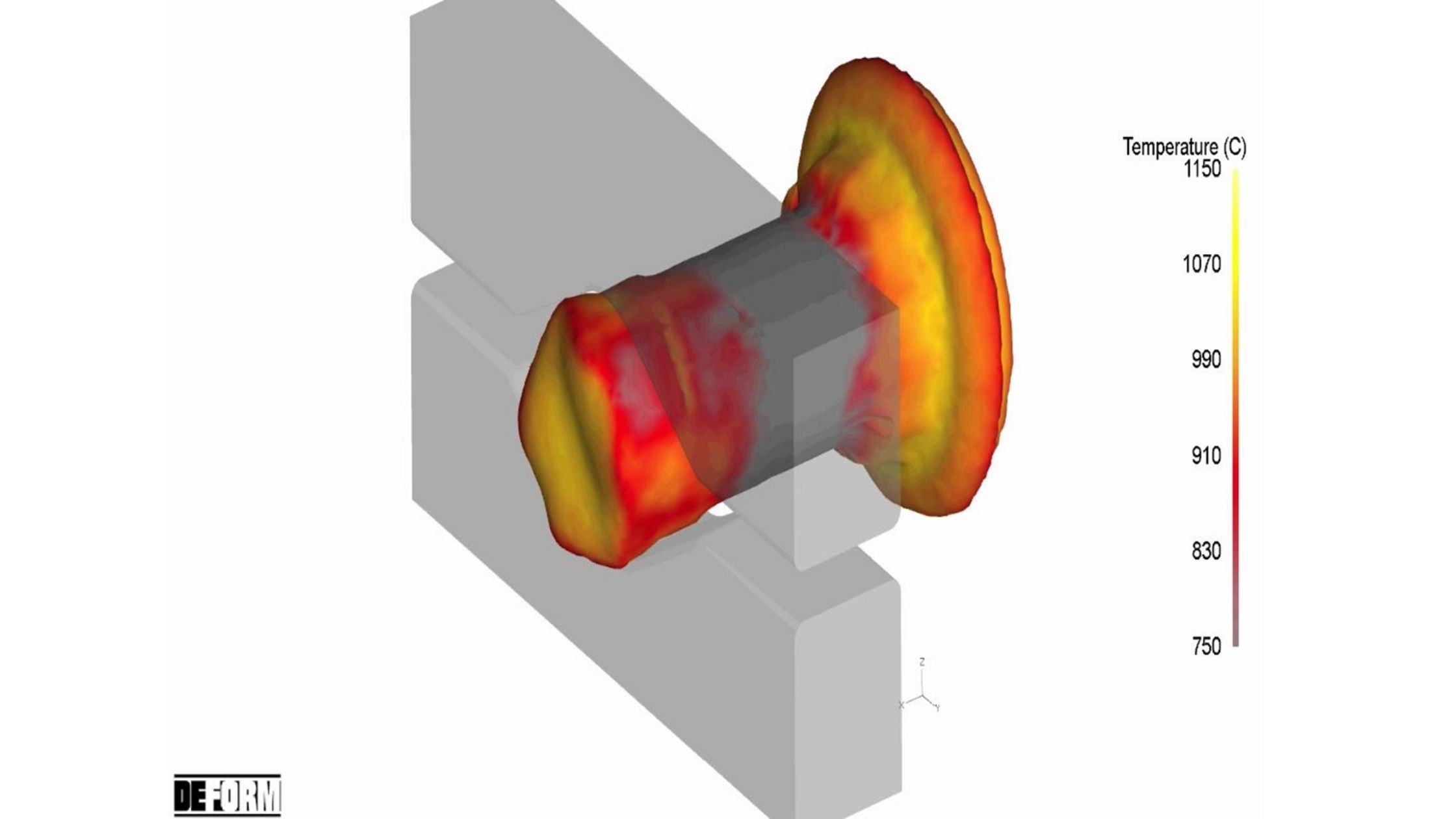

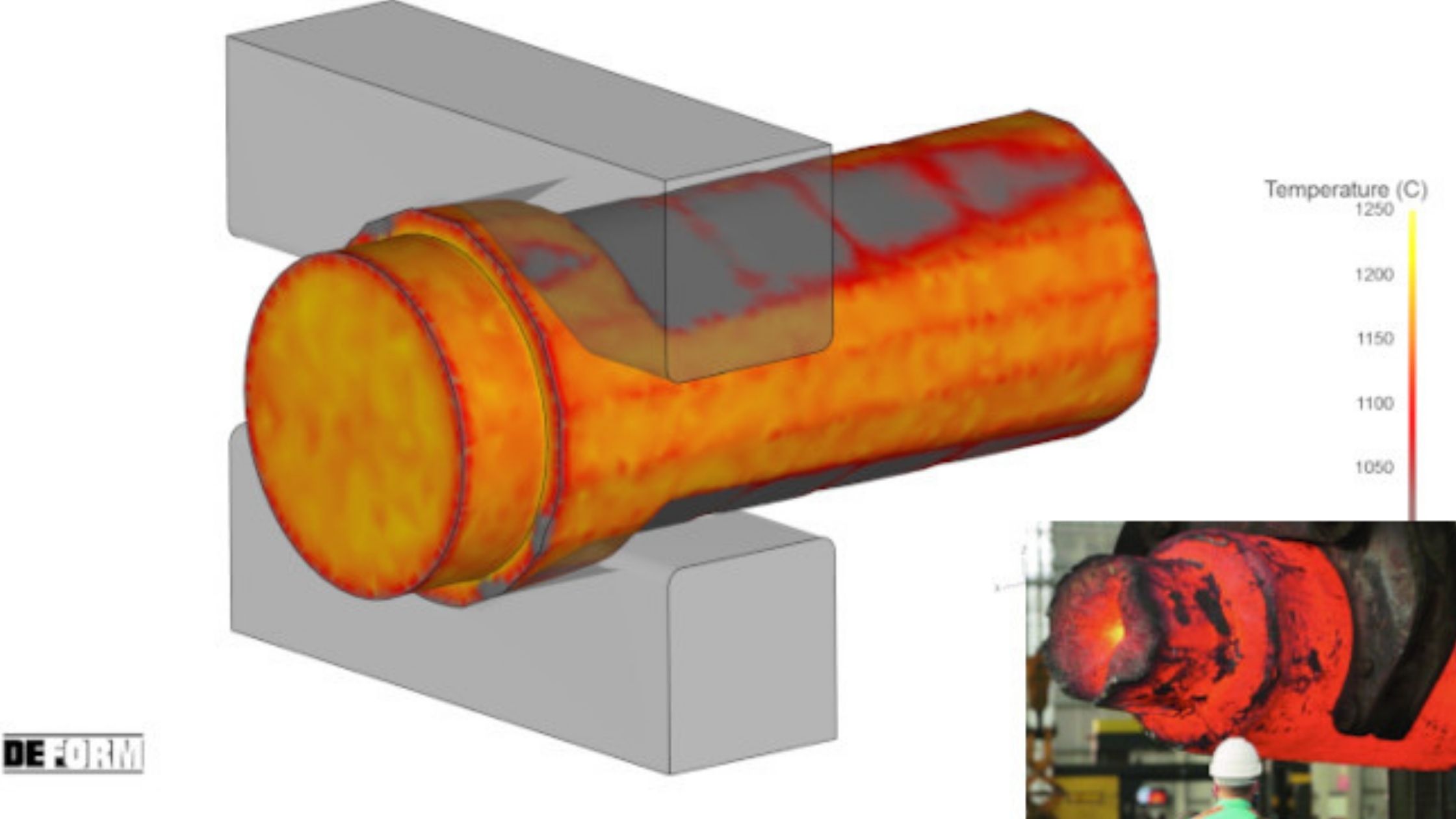

- – Simulation of production processes (foundry, forging, additive manufacturing)

- – Heat treatments and their effects on final properties

- – Analysis of machining processes

- – In-service testing

The objective is to demonstrate how simulation, applied sequentially and consistently throughout the entire supply chain, can reduce development time and costs while ensuring higher quality and traceability of the final product.

Target audience of the Comprehensive digital platform for the valve supply chain

- – Designers, engineers, and R&D managers

- – Process and production managers

- – Foundry, forging, and heat treatment technicians

- – Quality and testing managers

- – Application engineers and product managers

- – SMEs and large companies in the Oil & Gas, Power, Water, Chemical, Automotive, and Industrial Valve sectors

The course promotes a cross-functional vision that links design, manufacturing, and performance verification.

Programme of journey

- 10:30 – 10:45 Introduction to performance and manufacturing simulation for valves

L. Valente – CEO, ECOTRE Valente - 10:45 – 11:15 Valve development based on required fluid-dynamic performance using CFD simulation

Paolo C. – CFD Expert, ECOTRE Valente - 11:15 – 11:45 Structural sizing of the valve using CAE simulation

Salvatore LG. – Structural Analysis Expert, ECOTRE Valente - 11:45 – 12:15 Definition of the valve production cycle

C. Viscardi – Digital Manufacturing Expert, ECOTRE Valente - 12:15 – 12:45 Production simulation through foundry processes

C. Viscardi - 12:45 – 14:15 Lunch Break

- 14:15 – 15:15 Production simulation through hot stamping and forging

C. Viscardi - 15:15 – 15:45 Heat treatment of valves analyzed via simulation

C. Viscardi - 15:45 – 16:00 Analysis of mechanical machining using simulation

Stefano B. – ECOTRE Valente - 16:00 – 16:15 CAE evaluation of valve performance after the production cycle

Salvatore LG. - 16:15 – 16:30 Conclusions and Q&A

ECOTRE Valente Technical Team

Register for the course: Comprehensive digital platform for the valve supply chain

3 December 2025

Casa del Giovane – Sala Nembrini, in Via Mauro Gavazzeni 13, Bergamo, Italy. Limited spots available.

Benefits

- Integrated Design and Optimization

- Enables better design choices

- Improved part moulding

- Fewer defects and better cost control