Ecotre at ESTAD 2025 – Simulation Technologies for the Steel Industry of the Future

Ecotre at ESTAD 2025 – Simulation Technologies for the Steel Industry of the Future

Stand 31 – Palaexpo, Veronafiere

Ecotre Valente is proud to participate in the 7th edition of ESTAD – European Steel Technology & Application Days, Europe’s leading technical forum for innovation in steelmaking processes.

Organised by AIM in association with Siderweb, the congress will convene from 6 to 9 October in Verona, drawing engineers, researchers and industry specialists from across Europe to exchange insights on the digital and ecological transformation of metallurgical production.

Design, predict, optimise: simulation technologies for the steel value chain

- Target audience: Moulders, Die-makers and Designers

- Speakers: Ecotre Technical Department

- Duration: Starts Wednesday 20 September 2023 – Ends Thursday 16 November 2023

20-21 September: joint course

28 September, 5-12-19-26 October and 7-9-16 November: individual meeting slots lasting one hour - Time: From 8 a.m. to 12 noon and from 1 p.m. to 4 p.m.

- Material: DEFORM software for the duration of two months, Course notes in pdf format and Attendance Certificate

- Venue: BACCADEMY Srl – Via Industriale, 106 – 25065 Lumezzane (BS)

FILL IN THE FORM FOR FURTHER INFORMATION

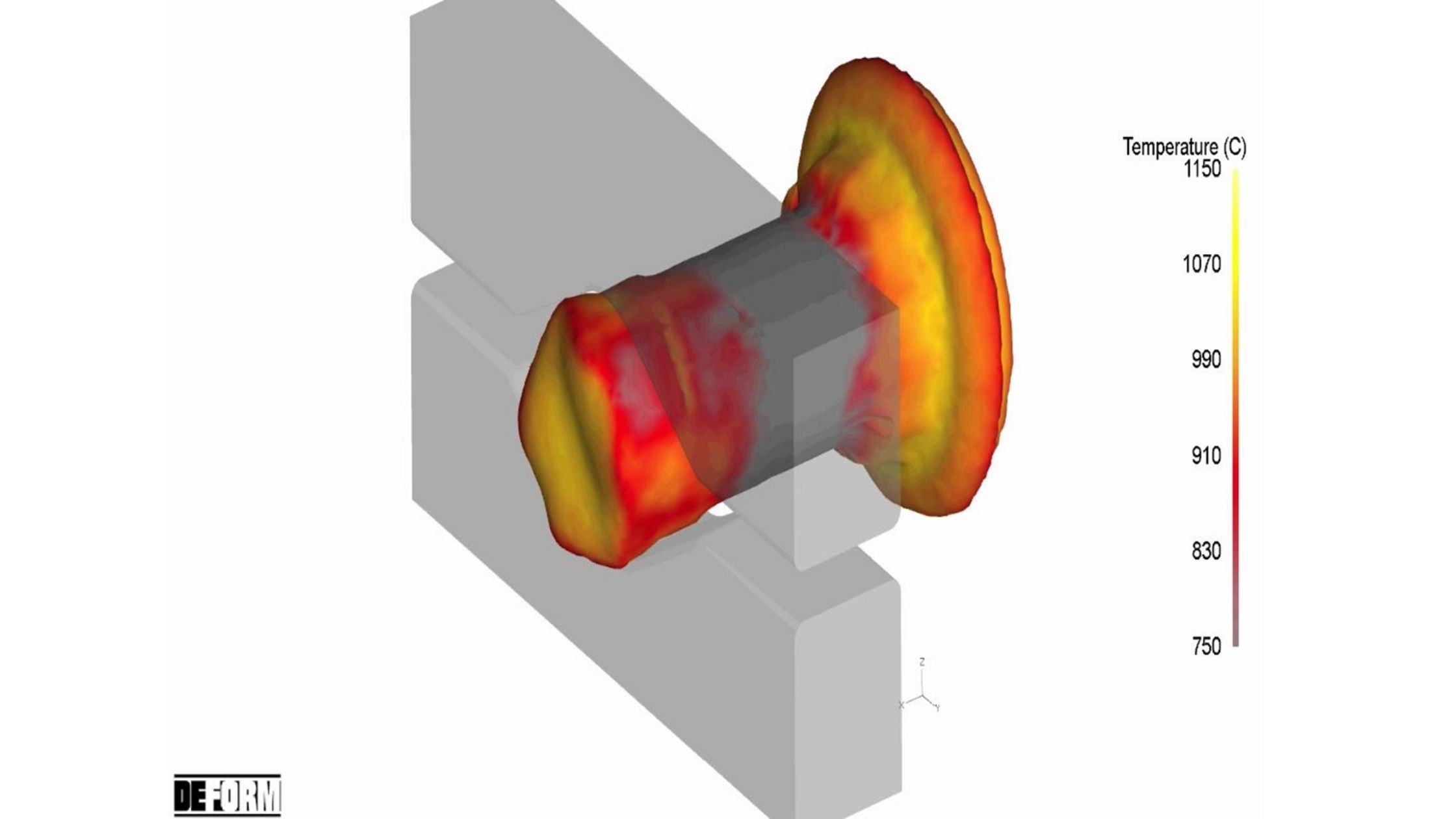

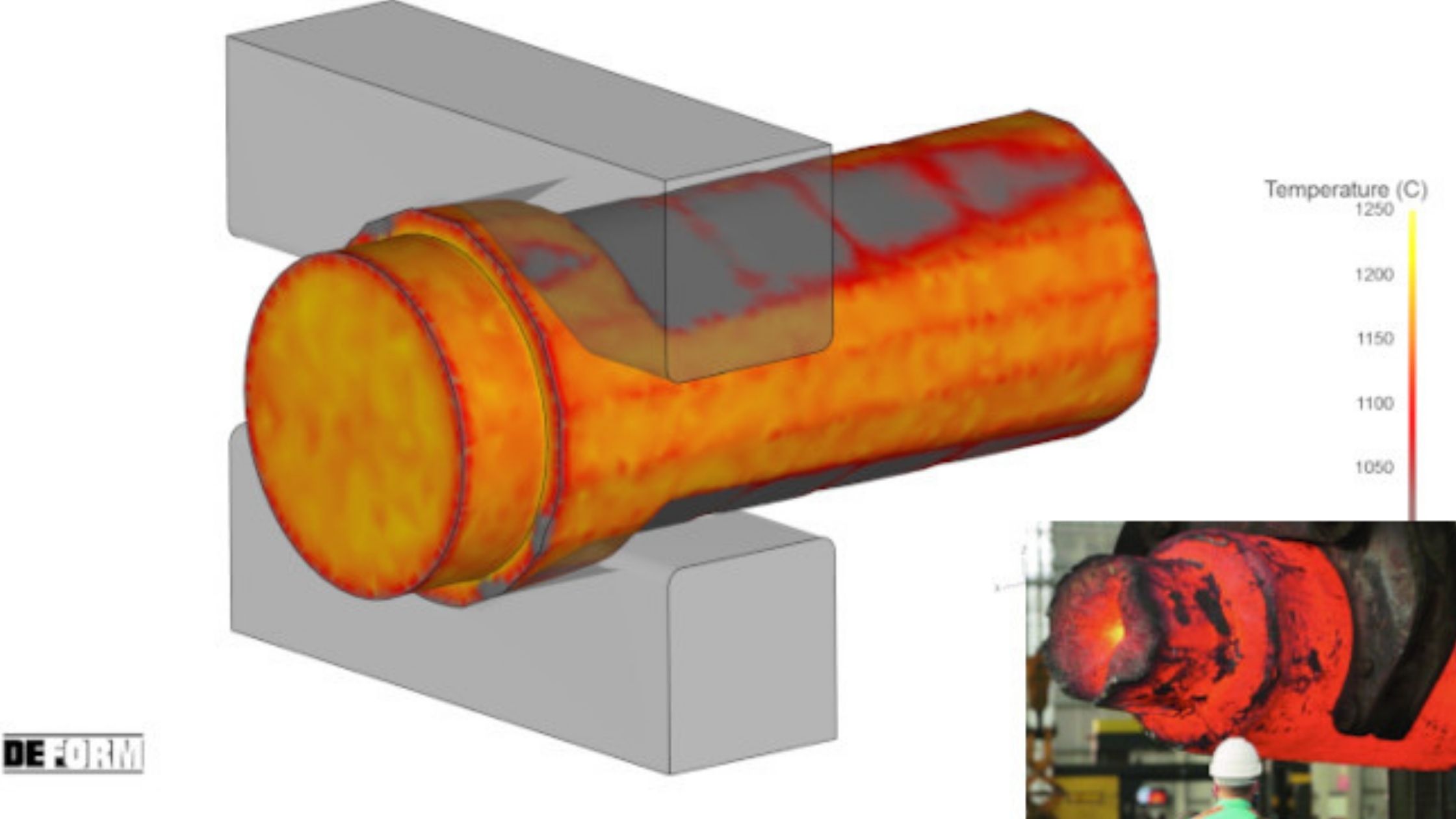

At Stand 31, Ecotre will demonstrate a selection of critical steelmaking and metalworking processes that can be modelled using ProCAST and DEFORM software. Emphasis will be placed on predictive design, defect mitigation and thermo‑mechanical optimisation.

Simulation will be applied to:

- Continuous casting

- Profile and tube rolling

- Ingot casting

- Forging

- Heat treatment

Attendees will be able to observe 3D simulation case studies based on real industrial scenarios, engage in discussions of process parameters, and evaluate the tangible benefits of predictive modelling for improving repeatability and sustainability in operations.

Key metallurgical concerns addressed include segregation, residual stresses, porosity, deformation and metallurgical defects. The simulations will offer practical strategies for enhancing process control and reliability.

Ecotre’s technical presentation at ESTAD 2025: predictive simulation for Duferco Group

During the event, Cristian Viscardi, Technical Director at Ecotre, will deliver the presentation: “Digital Manufacturing for the Development of a Novel Beam Rolling Mill”.

He will demonstrate how the integrated use of FEM‑based simulation across continuous casting, reheating and rolling phases — utilising ProCAST and DEFORM — enabled the design and development of Duferco Group’s new Smart Beam Manufacturing line.

By fully digitalising each stage from casting to rolling, it was possible to optimise process parameters, reduce energy consumption, prevent defects, and implement predictive maintenance strategies.

Enabling the twin transition via digital metallurgy

In alignment with the thematic focus of ESTAD 2025, Ecotre’s contribution will illustrate how metallurgical simulation facilitates the twin transition, by enabling the integration of predictive models into well‑established production workflows.

This represents a tangible opportunity for professionals in the steel sector to minimise physical testing, cut down on production errors and reduce rework costs.

We’ll see you on 6 / 7 / 8 / 9 October 2025 at Stand 31, Veronafiere.

Benefits

- Integrated Design and Optimization

- Enables better design choices

- Improved part moulding

- Fewer defects and better cost control