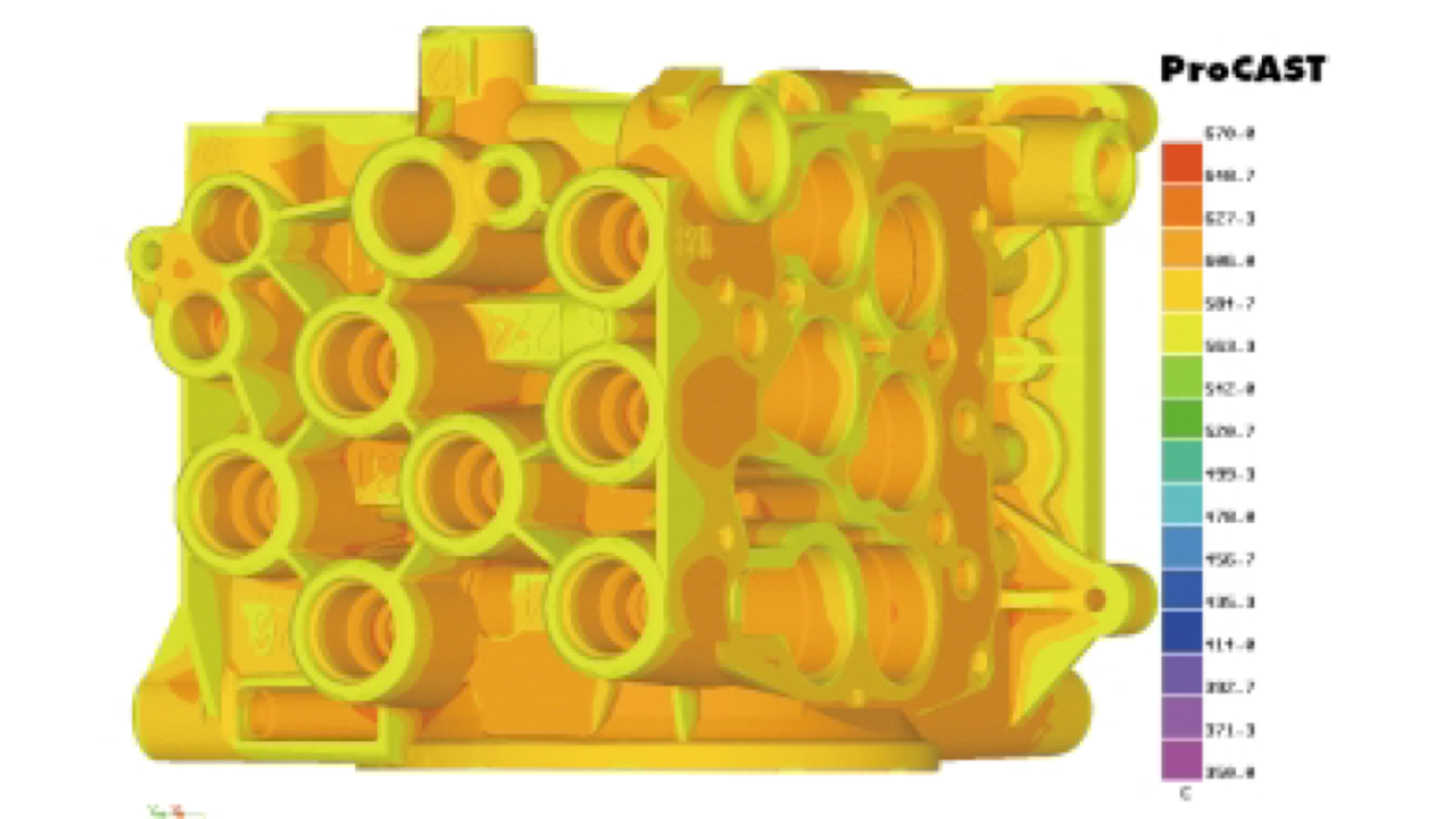

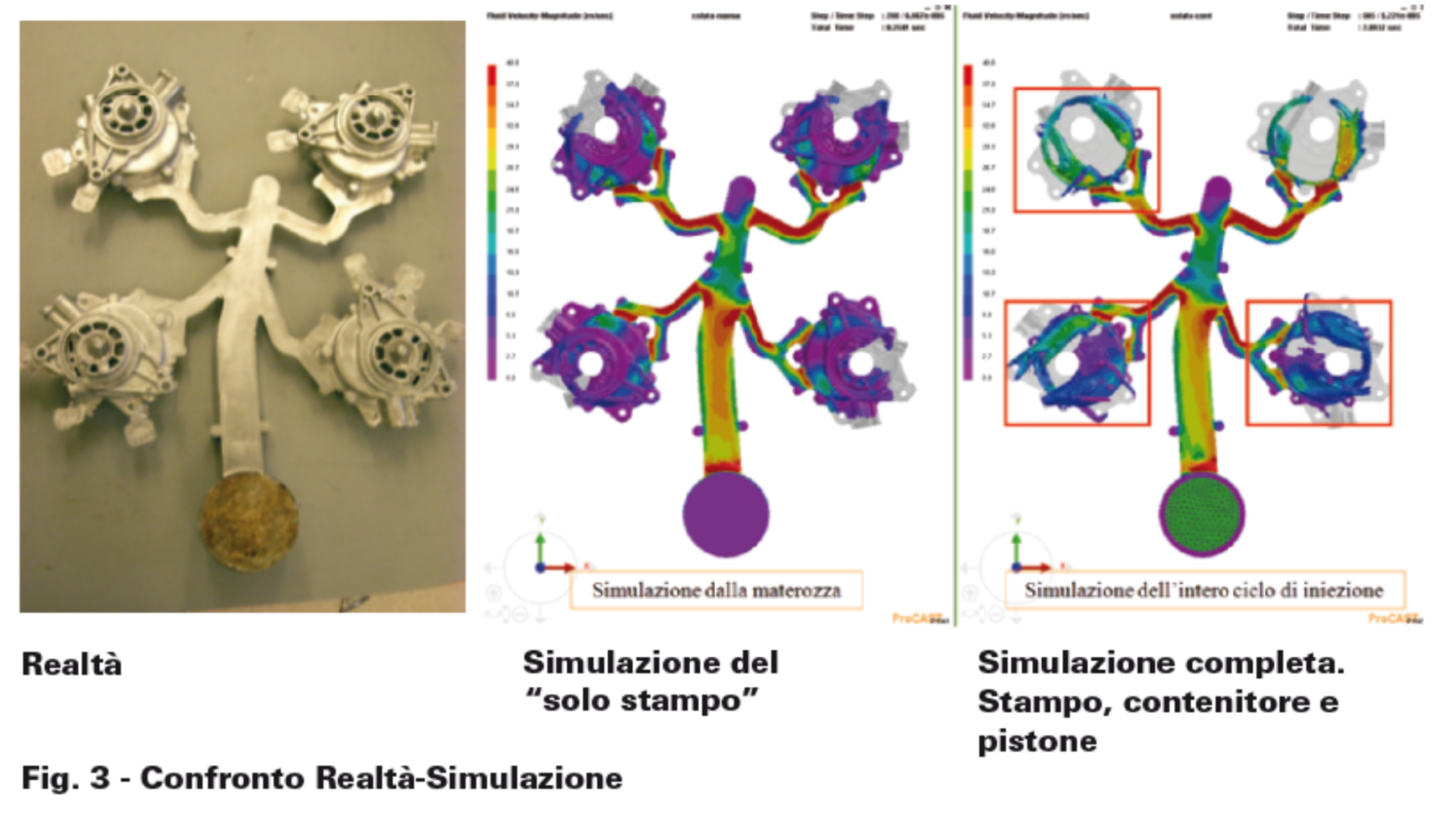

Alupress spa, based Bressanone (BZ), diecasting foundry since the beginning ready to invest in innovative technologies, bought the license of ProCAST, casting simulation software, after proving it for one year thanks to the flexible lease form.

In fact, this user-friendly software, its calculation quickness and the correspondence between simulation and foundry, confirmed the validity of ProCAST.

It is interesting to highlight the particular technical solution chosen by Alupress for its own organising structure: floating license of ProCAST.

Thanks to this license it was possible to install the simulator on any company PC, so that each person could access to the simulation.

From the analysis of more than 900 cases of diecasting simulations over a three-year period focusing attention on the filling phase, it emerged that the complete simulation of die, container and pouring should be considered to correspond to reality. Article in Italian

Read More

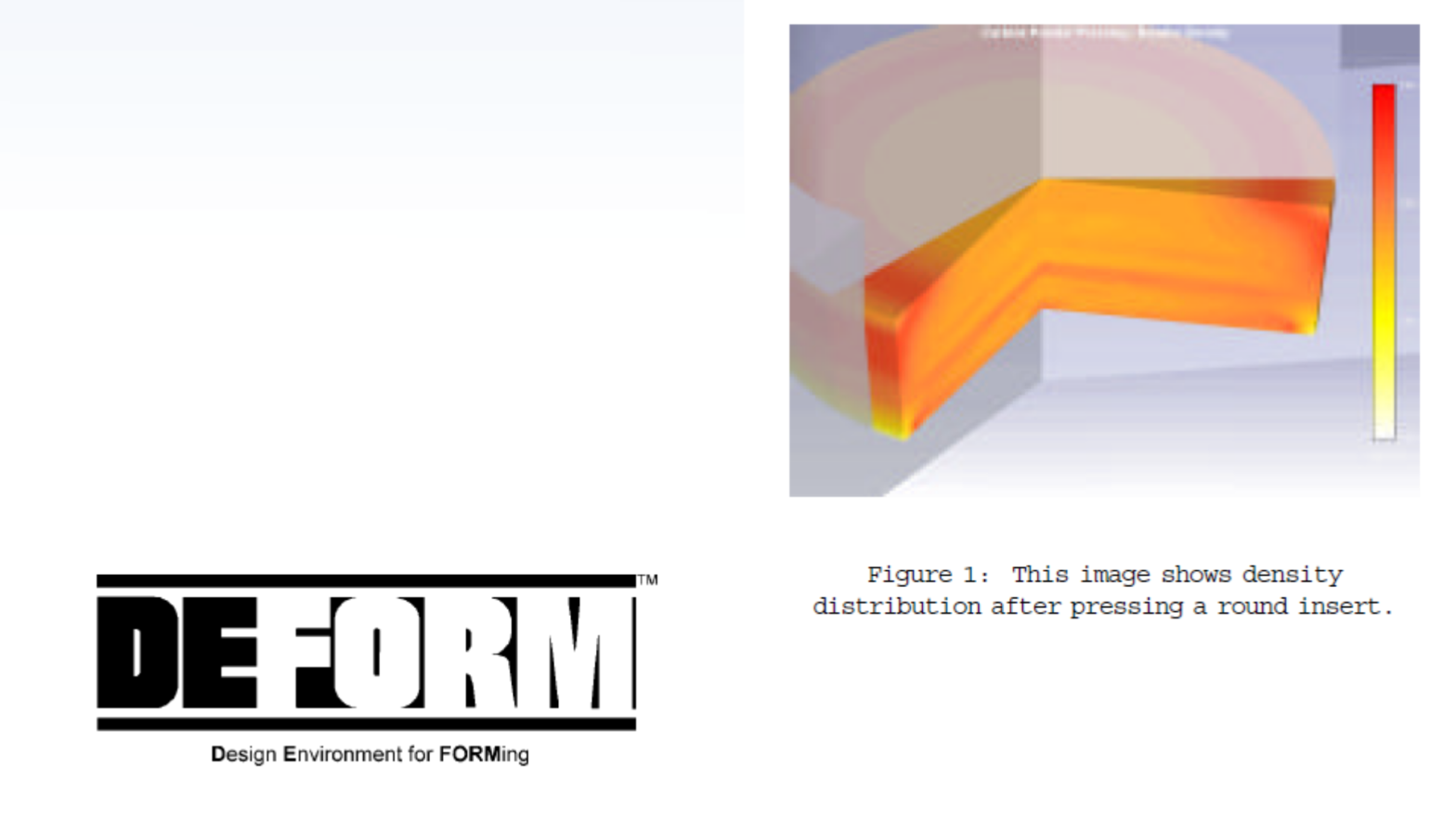

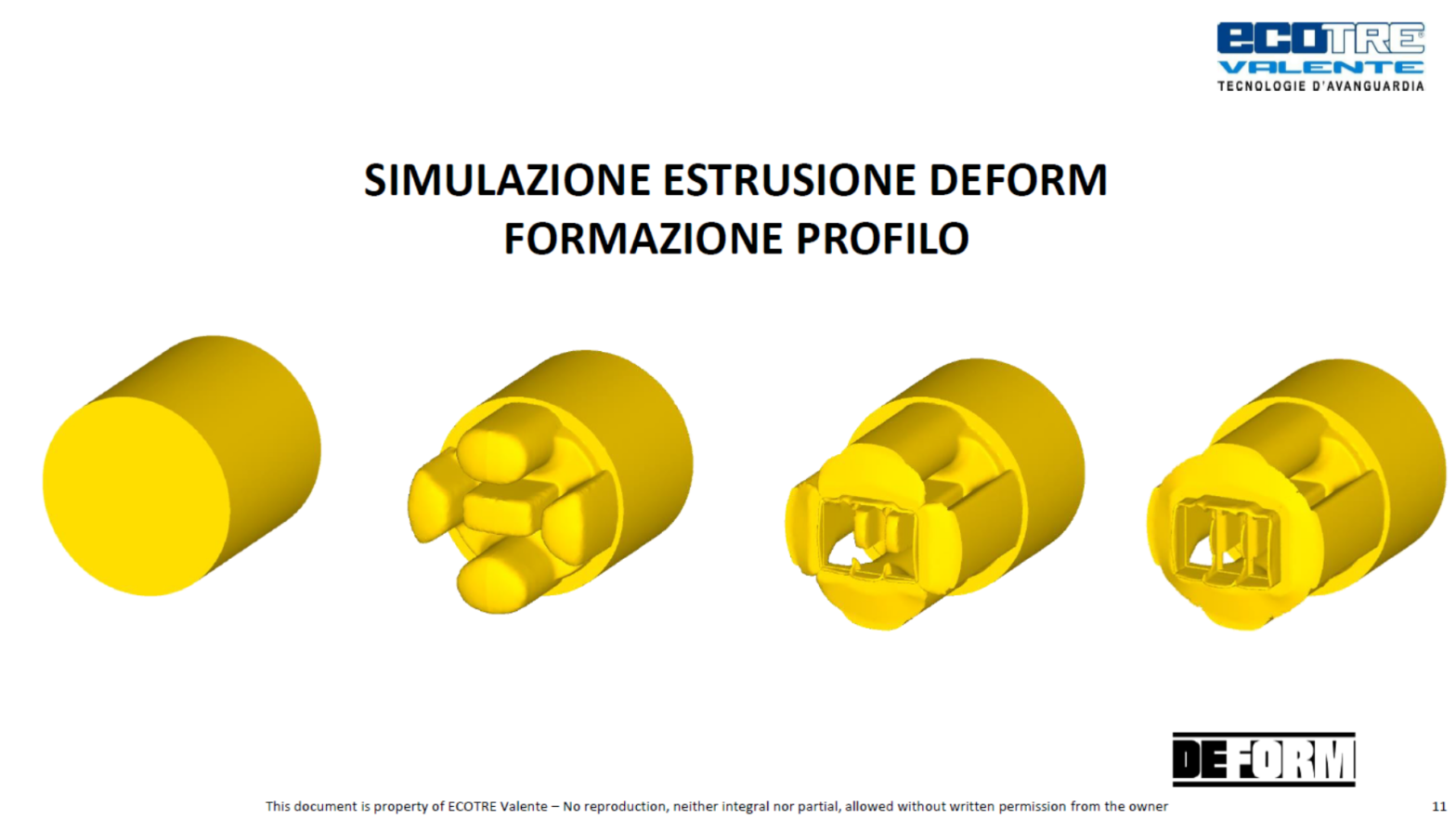

Since 2000 DEFORM has been simulating sintering processes. DEFORM allows using a tool owned by ECOTRE to create a counter deformation to correct the deformations obtained during sintering. Article in Italian

Read More

Computer simulation of the pressing and sintering process for tungsten carbide metal cutting inserts has been demonstrated. Modeling pressing and sintering using DEFORM™ can provide an opportunity for cost savings by improving the performance and reliability of the process.

Read More

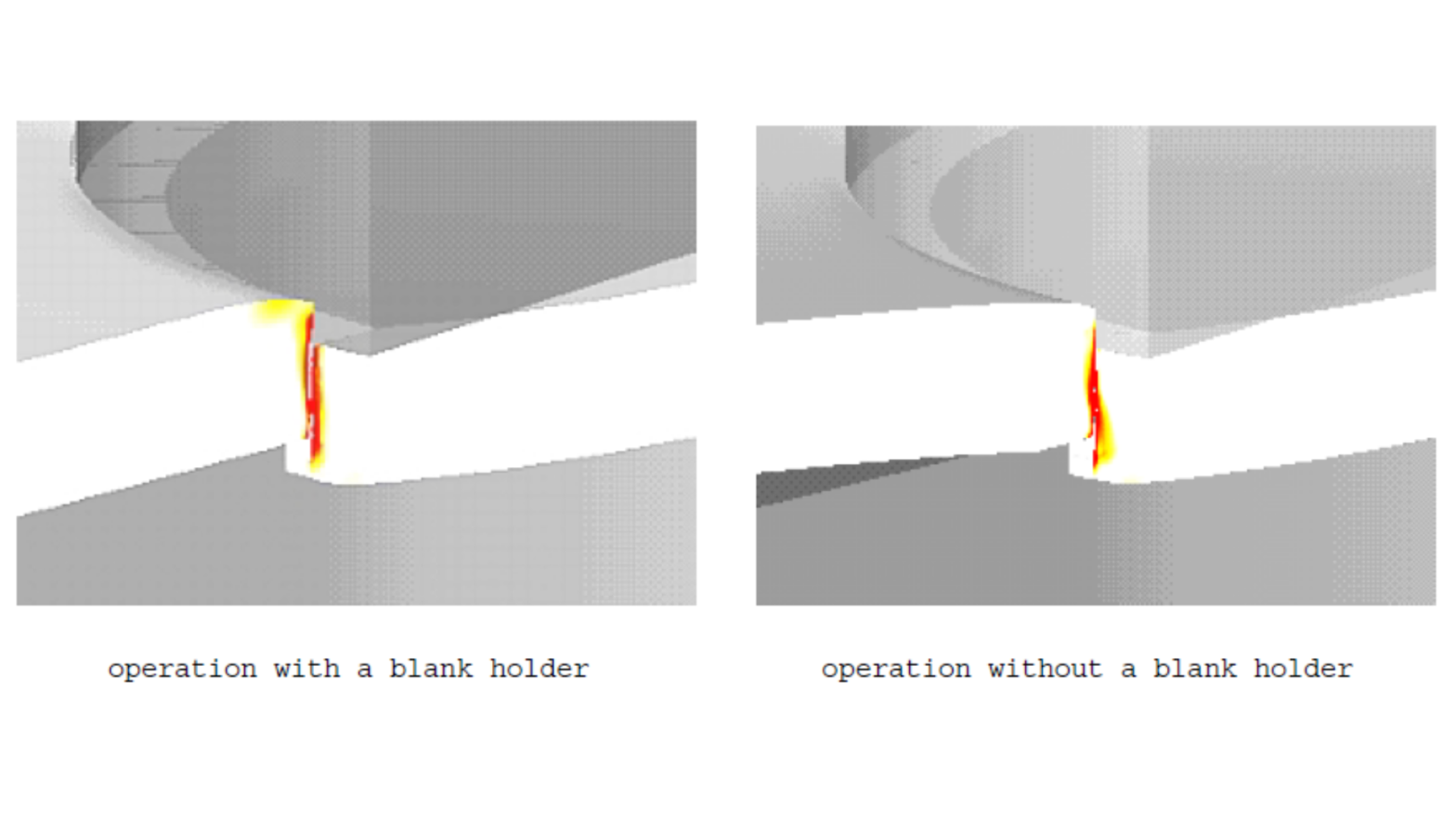

The DEFORM™ System is capable of simulating blanking and piercing processes. The capabilities are included in the system, with no additional programming required. It is possible to develop different damage models and implement them via user subroutines for research applications.

While the determination of a material’s CDV is becoming more commonplace, it still requires a good understanding of the process. On the other hand, the methods used are fairly simple and straightforward.

Working on simulation systems to measure (and modify) production processes

The more the hi-tech universe gets pushed, the more the way of thinking about it must keep up. Indeed, he must do at least two forward, overcoming it.

Article in Italian

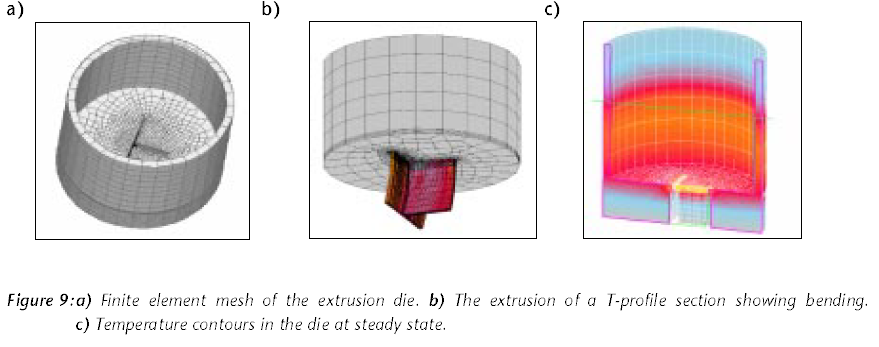

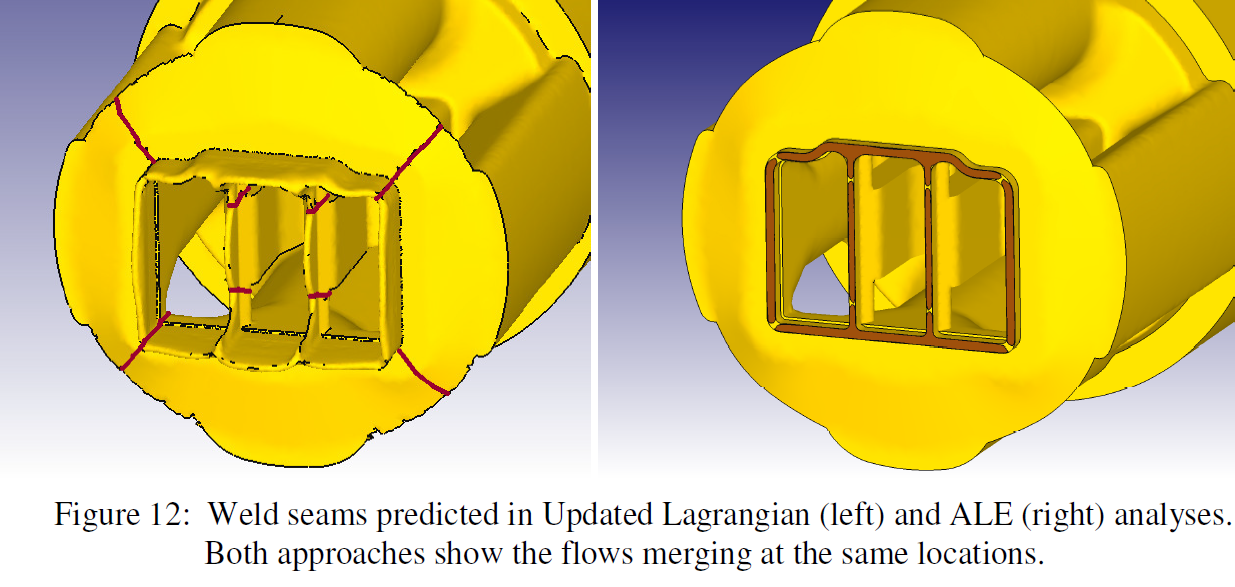

In this paper the problems of the extrusion process are discussed, the capabilities of DEFORM and the process developments are shown through several direct industrial cases of extrusion simulations.

Read More

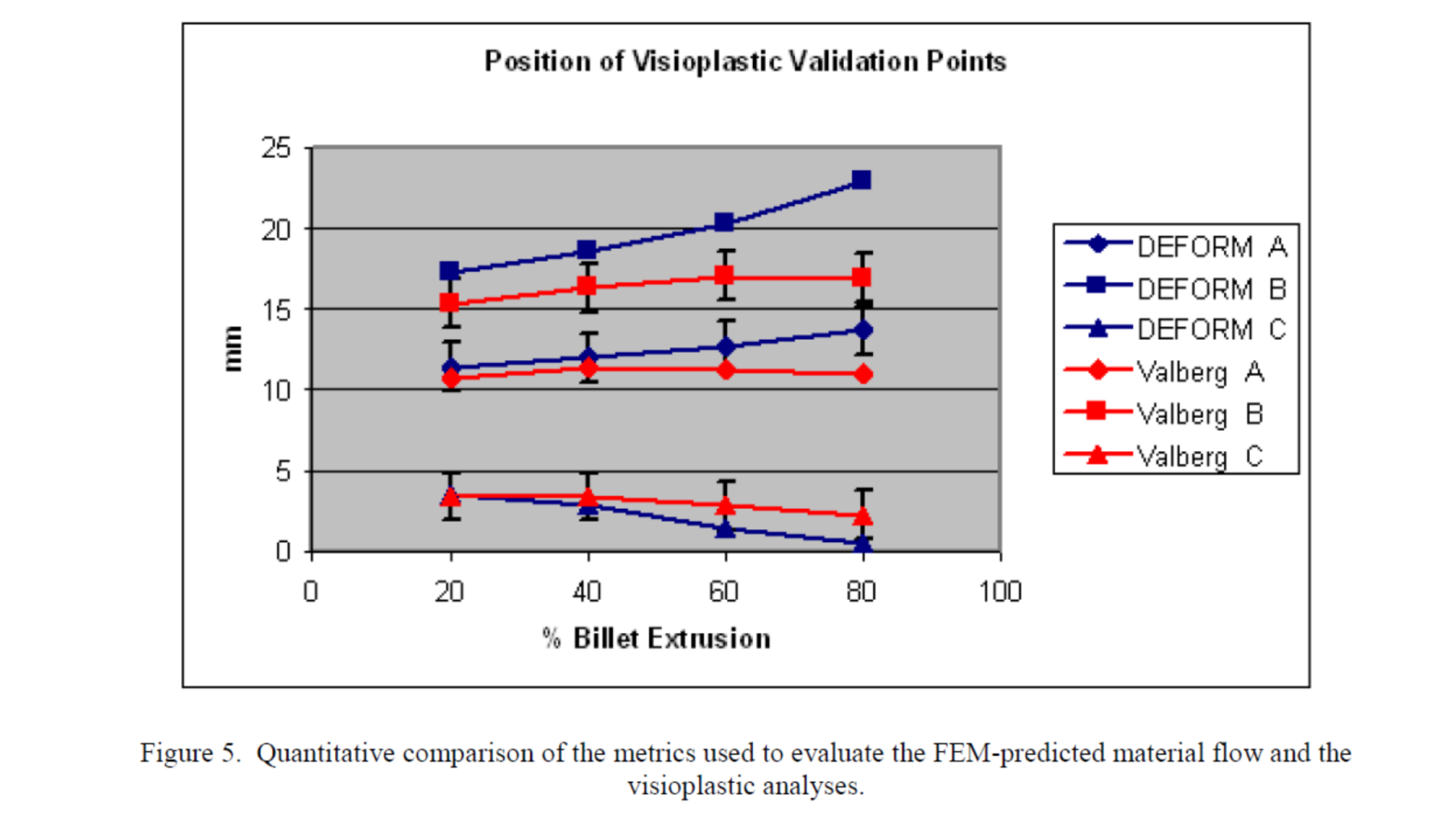

Process modeling software based on the finite element method (FEM) is a valuable tool in analyzing metal forming processes [1,2]. Extrusion is one such process where important information can be gained by using simulation [3,4]. The material flow during extrusion can be analyzed, giving insight into the initial transient behavior in the die, weld seam formation, etc. Stresses in the die components can also be obtained using simulation, allowing die modifications to be analyzed to see if they would improve the stress state and make die cracking less likely.

Read More

Finite element modeling of indirect extrusion Multiple extrusion simulations were performed, using the DEFORM FEM code. The alloy studied was aluminum 6061, for which there are data on the thermomechanical material in DEFORM (flow stress, thermal conductivity, etc.).

Read More

The DEFORM extrusion simulation software shows profile and equipment problems Excellent alignment of “Simulation Software Results” with “Reality” The simulation allows you to identify the defects obtained during extrusion, understand their causes and then take the right corrective actions Positive sampling at the first shot, if simulated Certain raw material supply Start-up times reduced to a minimum because already computer tested Press selection: sampling and production planning Increased die life thanks to positive samples that do not require subsequent modifications and repairs, even with possible welding Verification of Estimate Reliability Greater productivity

Read More

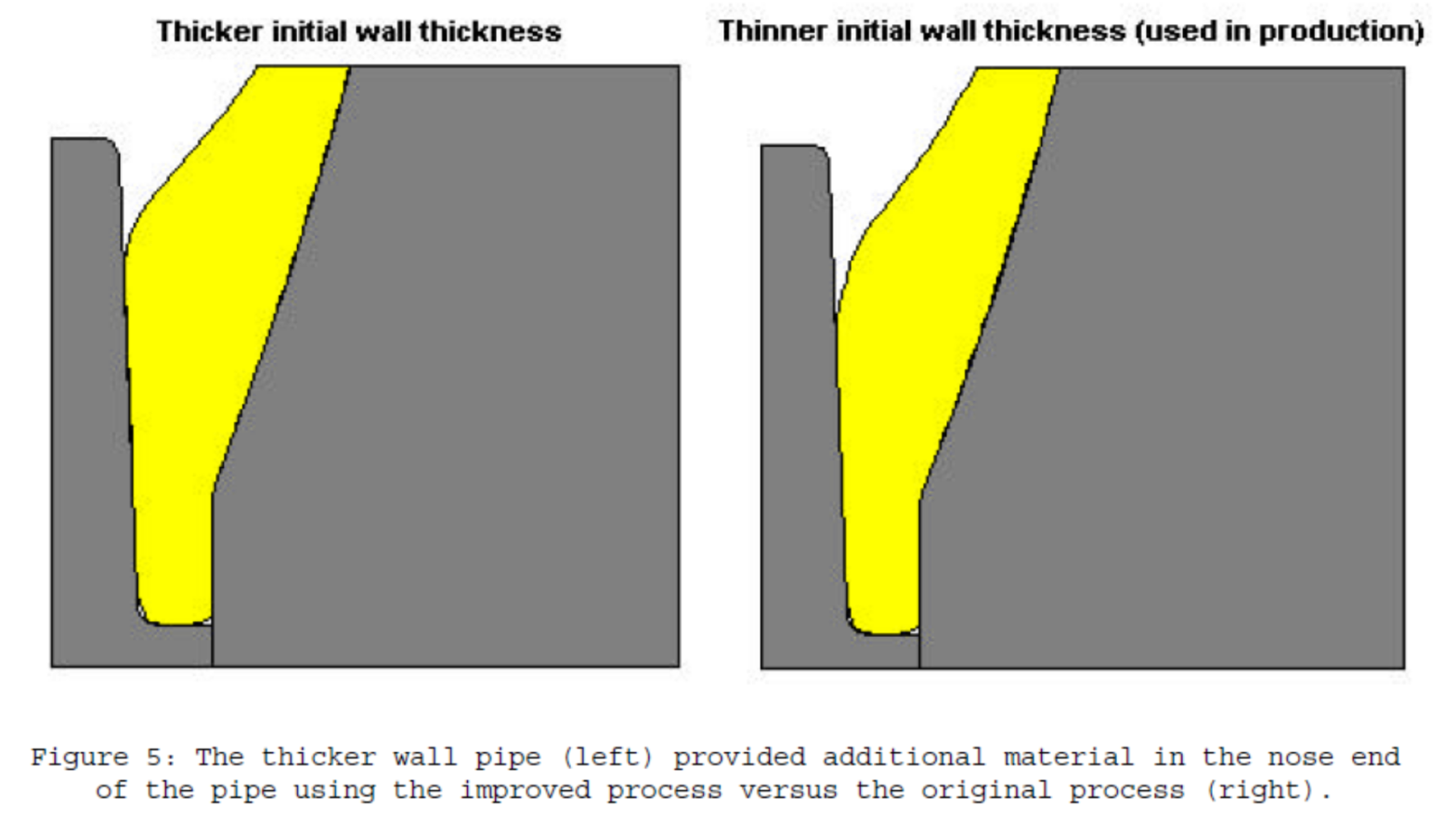

DEFORM™-3D was used in these process simulations to analyze and understand the process. The results correlated well with actual production experience.

Process simulation can be used to understand the influence of preform, plunger displacement and pressure profile on the finished product.

Since this study was performed, thousands of bomb cases have been produced using the thick walled pipe.

General Dynamics has reported that the defect rate due to insufficient nose material decreased by over 20%.

Problems related to under-gauge material in the nose region and pipe bulging have been essentially eliminated.