ECOTRE Valente and CORSA 3D at MECSPE 2026: Digitalization of foundry and metallurgical processes for the manufacturing industry

ECOTRE Valente and CORSA 3D at MECSPE 2026: Digitalization of foundry and metallurgical processes for the manufacturing industry

BolognaFiere – Hall 36, Booth D70

From March 4 to 6, 2026, ECOTRE Valente will be exhibiting at MECSPE 2026, Italy’s leading trade fair dedicated to the manufacturing industry and the evolution of production processes.

MECSPE is a key reference event for professionals operating in metallurgy, foundry, and manufacturing, and provides an ideal environment to discuss how to digitalize processes, reduce production criticalities, and support industrial decision-making with reliable technical tools.

Come and visit us at our booth

Digital technologies and industrial applications for foundry and metallurgy

- Target audience: Moulders, Die-makers and Designers

- Speakers: Ecotre Technical Department

- Duration: Starts Wednesday 20 September 2023 – Ends Thursday 16 November 2023

20-21 September: joint course

28 September, 5-12-19-26 October and 7-9-16 November: individual meeting slots lasting one hour - Time: From 8 a.m. to 12 noon and from 1 p.m. to 4 p.m.

- Material: DEFORM software for the duration of two months, Course notes in pdf format and Attendance Certificate

- Venue: BACCADEMY Srl – Via Industriale, 106 – 25065 Lumezzane (BS)

FILL IN THE FORM FOR FURTHER INFORMATION

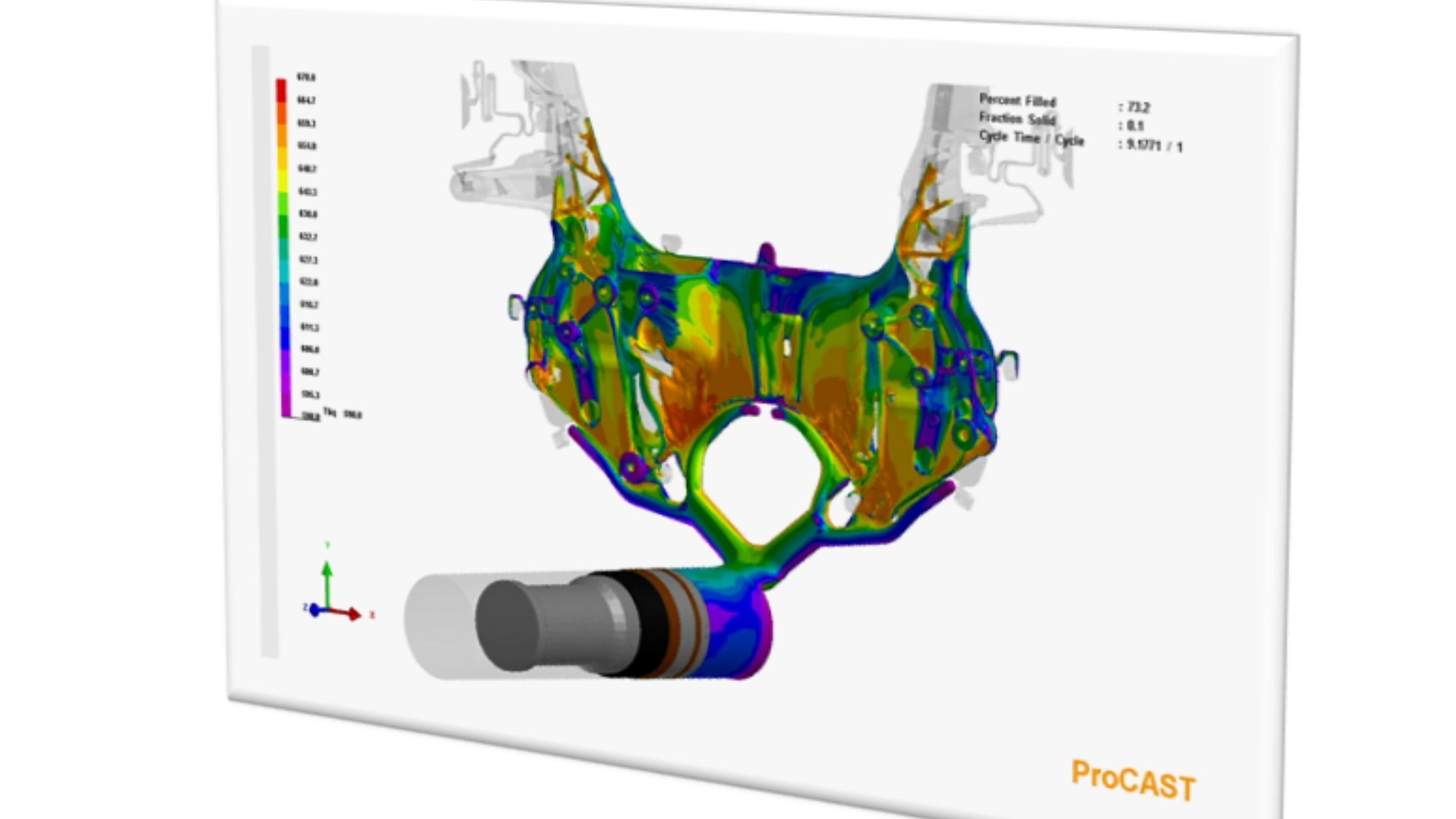

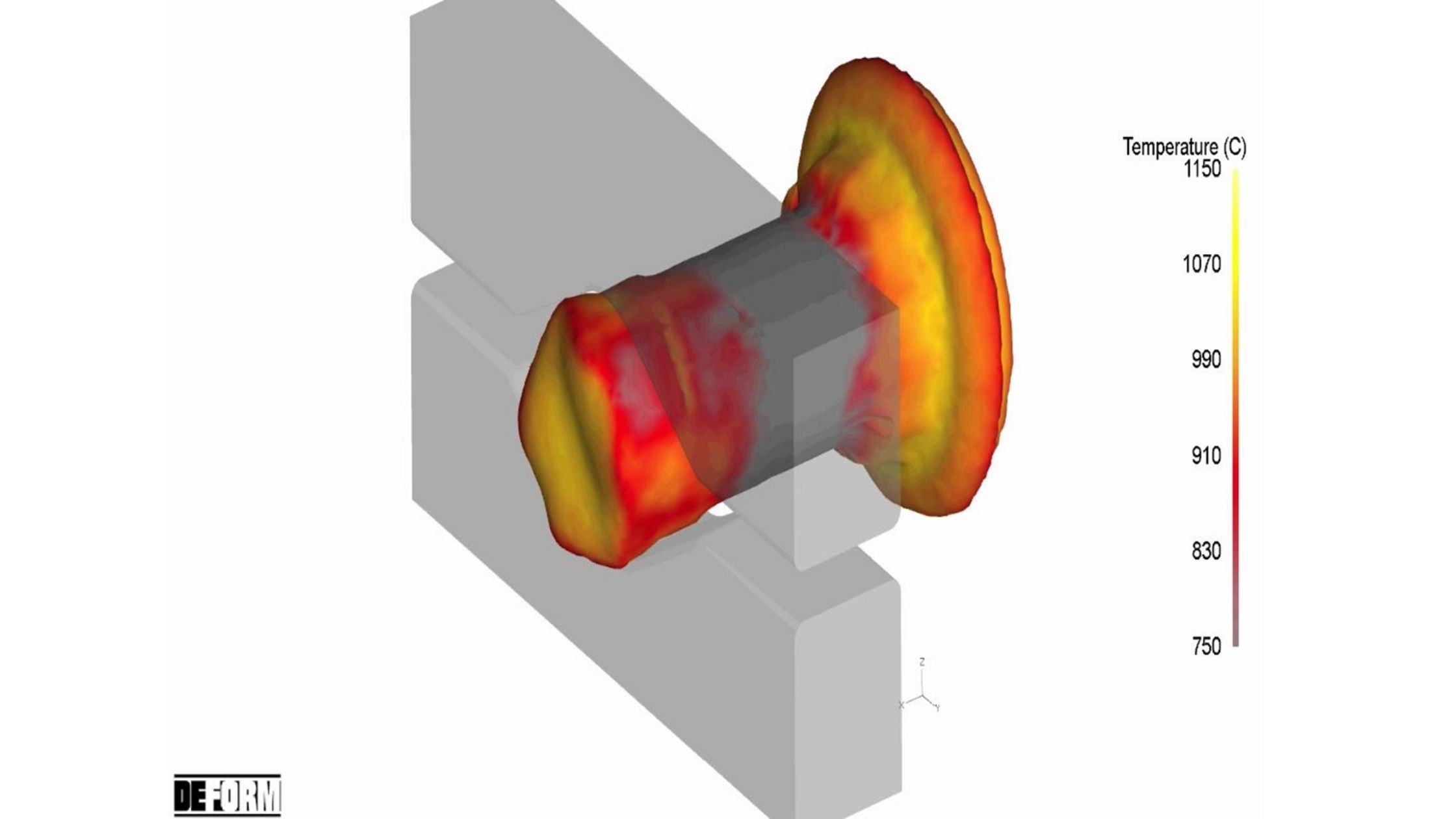

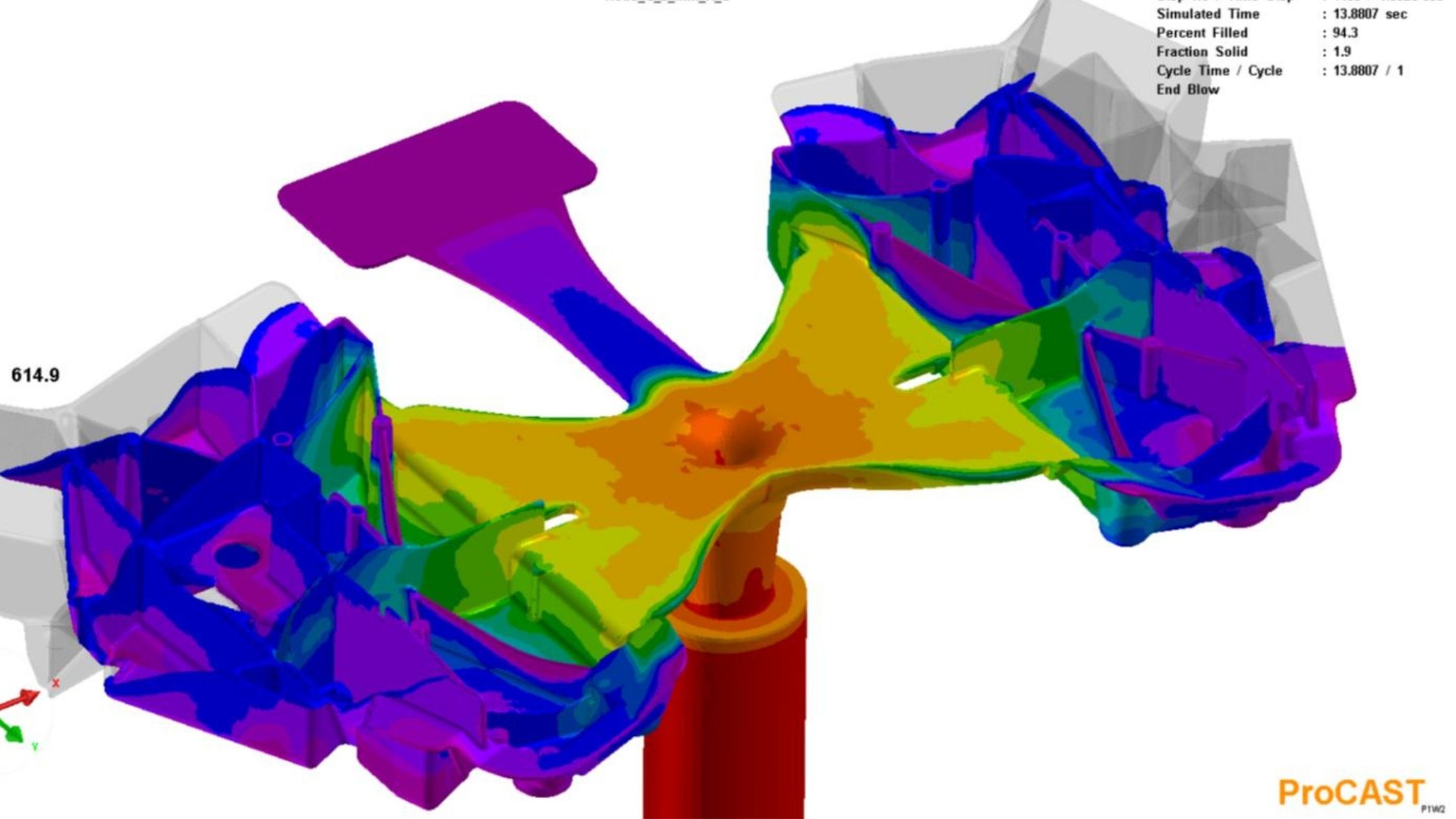

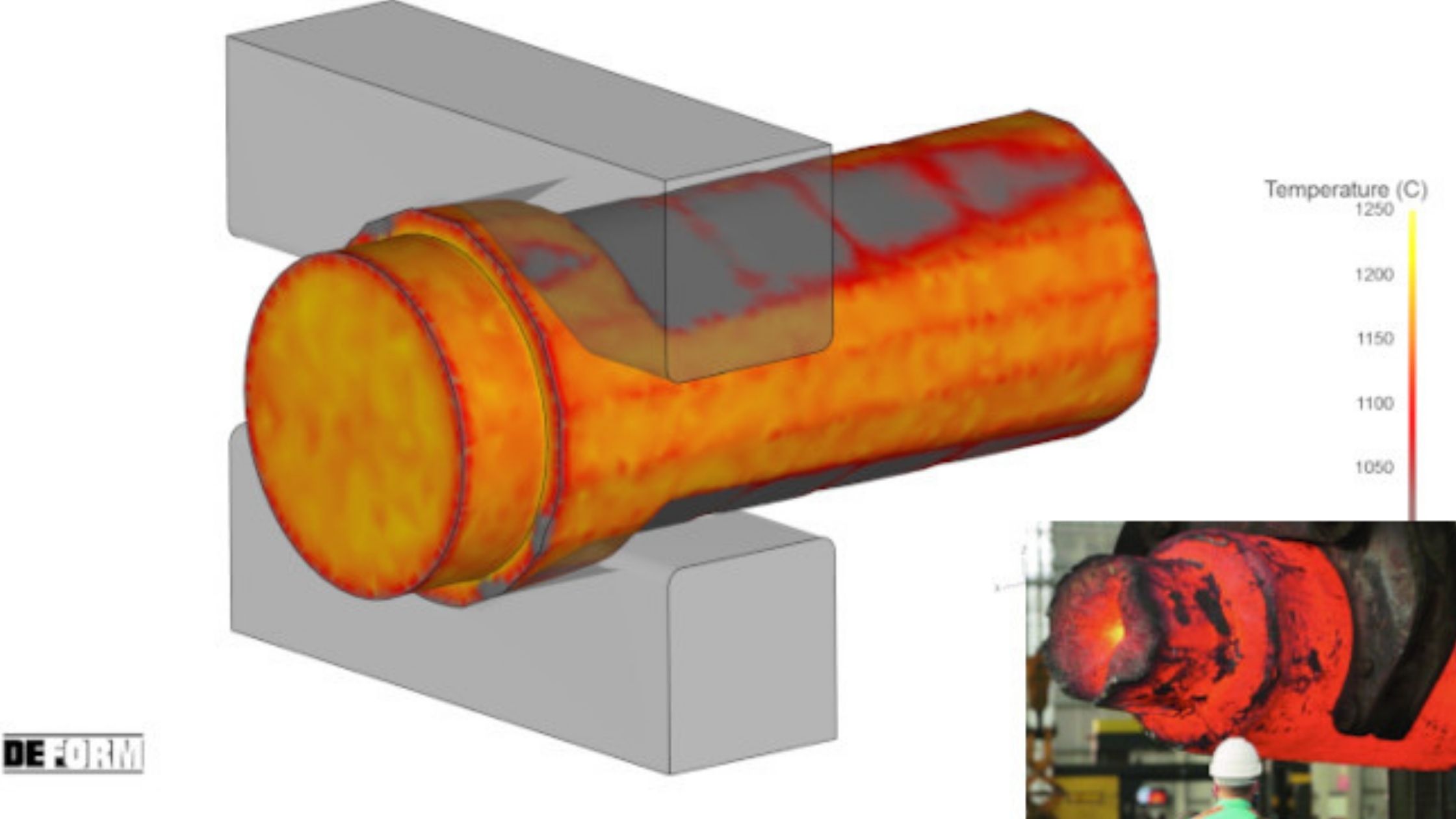

At Booth D70 – Hall 36, ECOTRE Valente will present digital tools and real industrial case studies focused on the analysis and optimization of production processes, with an approach aimed at preventing defects, reducing time and costs, and improving overall plant efficiency.

During the exhibition, visitors will be able to explore real applications used to identify and correct critical issues before physical production, improving process reliability and final product quality.

In particular, the following topics will be presented:

- Additive Manufacturing, in collaboration with Corsa 3D;

- Metal Binder Jetting and Sintering for Metal Injection Molding (MIM), which will be the focus of the fourth edition of the dedicated conference in May;

- Casting and molding processes;

- Focus on welding processes;

- Insights into the Solidification Course, the international solidification training program led by ECOTRE starting from the 2026 edition;

Meet us at our booth

Solidification Course: advanced training on metal solidification

MECSPE 2026 will also be an opportunity to learn more about the Solidification Course, the international training program dedicated to metal solidification, led by ECOTRE Valente starting from the 2026 edition.

The course is developed and delivered by world-renowned professors and industry experts and represents a benchmark for professionals looking to connect scientific fundamentals, process phenomena, and industrial decision-making.

Learn more about the Solidification Course

Digital Green Foundry and industrial partnerships

ECOTRE Valente continues the Digital Green Foundry journey initiated by Corsa 3D—a practical approach to foundry digitalization based on the integration of processes, digital tools, and sustainability.

Within this framework, ECOTRE will be a co-exhibitor with Corsa 3D, technology partner for Additive Manufacturing, with the goal of showing how the integration of digital tools and 3D printing can make processes more efficient, flexible, and controllable.

ExOne technologies will also be showcased as solutions represented by Corsa 3D, completing the digital workflow from design to production.

Why visit the ECOTRE booth at MECSPE 2026

By visiting the ECOTRE booth at MECSPE 2026, you will be able to:

- Discuss real industrial case studies;

- Understand how to reduce defects, development time, and costs;

- Evaluate the integration of digital tools and Additive Manufacturing into your processes;

- Receive targeted technical advice tailored to your company’s needs.

We look forward to seeing you there

Benefits

- Integrated Design and Optimization

- Enables better design choices

- Improved part moulding

- Fewer defects and better cost control