LOW PRESSURE AND GRAVITY DIE CASTING COURSE

LOW PRESSURE AND GRAVITY DIE CASTING COURSE

AQM Srl Via Edison , 18 - Provaglio d'Iseo (BS)

Description:

The members of Ecotre Valente’s technical team will be lecturing at the specialised Low Pressure and Gravity Die Casting course, a training course intended for foundries or companies that process, transform or use low pressure castings or castings created with other technologies. The course will be held at the premises of AQM S.r.l. in Provaglio d’Iseo (BS), starting on 21 October.

The in-depth theoretical and practical study of this technique is particularly useful not only for those working in the automotive sector, traditionally linked to the use of the low pressure die casting technique, but also for those working in totally different sectors such as the building industry and tap fittings.

The aim is to offer participants high-level, certified technical training designed to meet new market challenges.

In order to develop the production of foundries using the low pressure casting system and make them competitive, it is necessary to have technicians in the company who have an in-depth knowledge of the casting process, alloys, the low pressure die casting process, heat treatments, surface finishes and machining, moulds, quality and safety.

After completing the LPDC Technologist course, certified participants will possess the metallurgical knowledge and practical skills to manage the machining cycles related to the low pressure die casting process for making products that meet the required productivity and specifications.

During the course, the Ecotre Valente technical team will teach participants how to increase the efficiency of production and product processes related to low pressure and gravity die casting with the help of QuikCAST and ProCAST software.

NEW FOR 2023: Starting this year, Lorenzo Valente, CEO of Ecotre Valente has been appointed to the technical-scientific committee of the Low Pressure School.

Ecotre Valente’s technical team is the best resource available not only for teaching but also for offering targeted advice to companies operating in the foundry sector that need to optimise and improve their products and production processes.

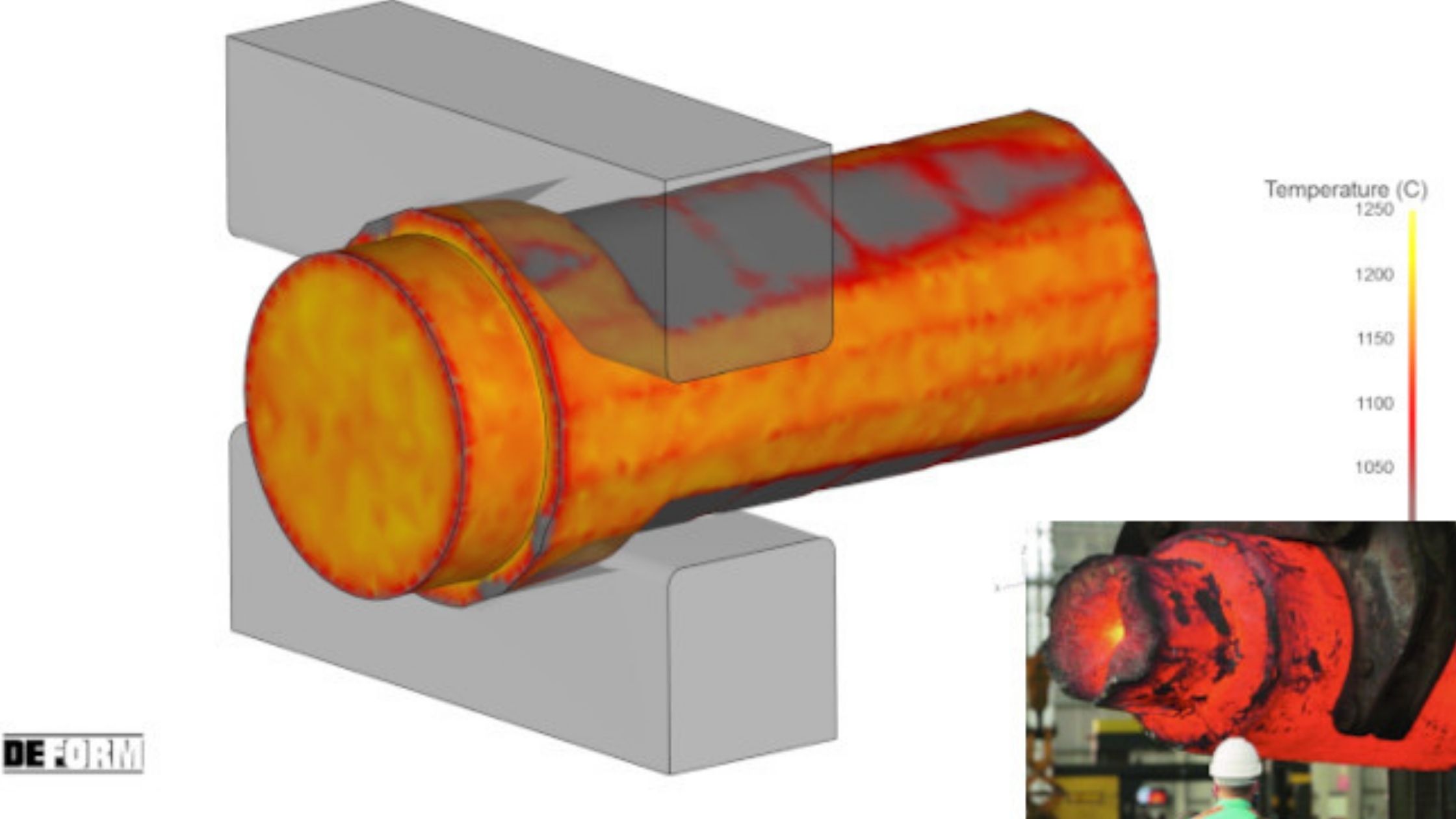

Our specialists will accompany you in the implementation of an advanced manufacturing process digitisation method that allows you to predict, analyse and quantify casting defects and design flaws in advance, reducing wasted time and resources for reworking parts.

- Target audience: Moulders, Die-makers and Designers

- Speakers: Ecotre Technical Department

- Duration: Starts Wednesday 20 September 2023 – Ends Thursday 16 November 2023

20-21 September: joint course

28 September, 5-12-19-26 October and 7-9-16 November: individual meeting slots lasting one hour - Time: From 8 a.m. to 12 noon and from 1 p.m. to 4 p.m.

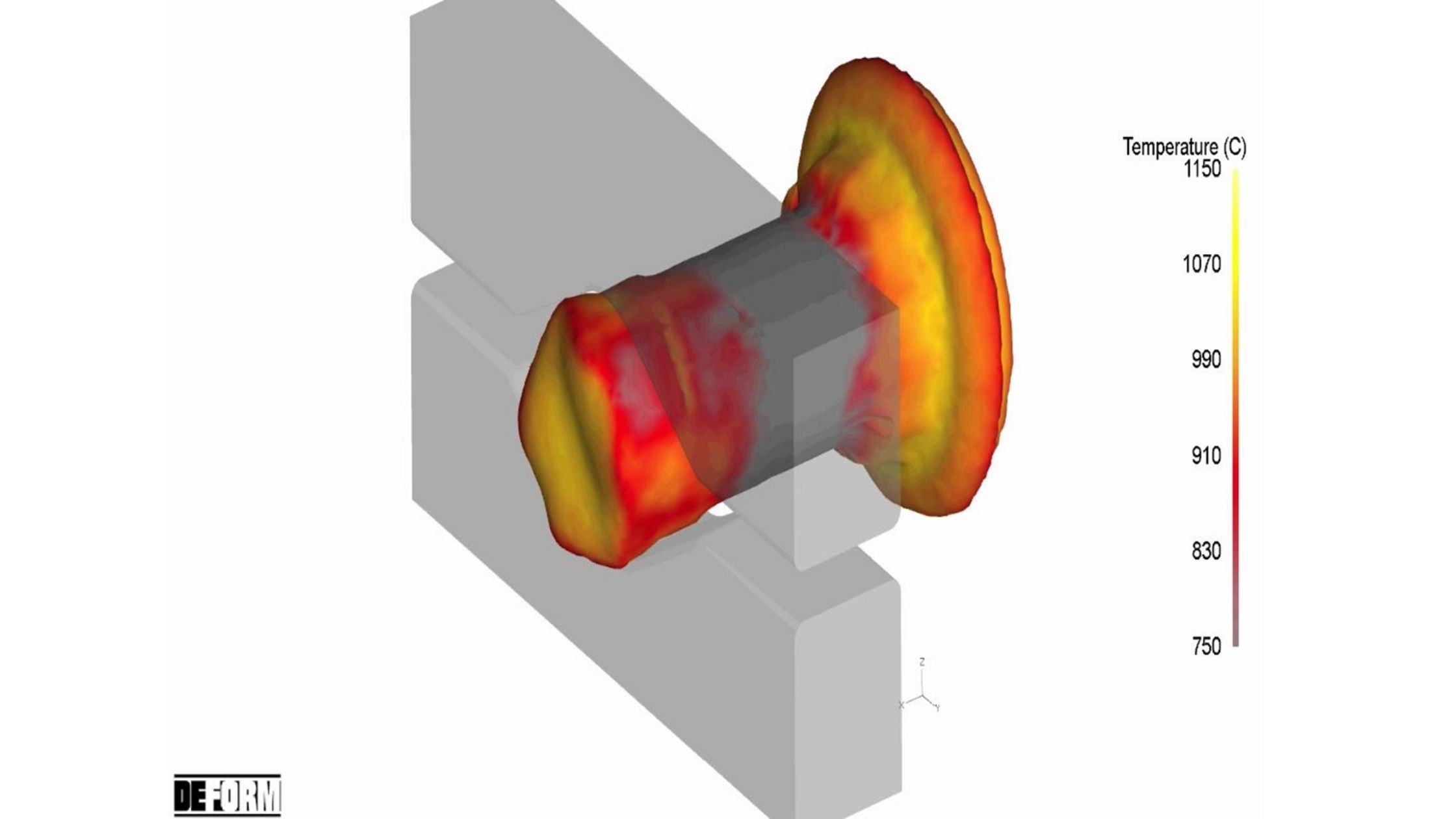

- Material: DEFORM software for the duration of two months, Course notes in pdf format and Attendance Certificate

- Venue: BACCADEMY Srl – Via Industriale, 106 – 25065 Lumezzane (BS)

FILL IN THE FORM FOR FURTHER INFORMATION

Benefits

- Integrated Design and Optimization

- Enables better design choices

- Improved part moulding

- Fewer defects and better cost control