Forming: properties of steel, heat treatment, damage mechanisms

Forming: properties of steel, heat treatment, damage mechanisms

Confindustria Canavese, Ivrea - Italy

The AIM Thermal Treatment and Metallography Study Center proposed this Study Day with the aim of providing the most up-to-date knowledge for the design, construction and use of molds. Among the speakers, our technical department manager, Eng. Cristian Viscardi.

The aspects related to the performance of the die and of the respective components have been studied in depth, starting from the properties of the different steels for hot forming, from the selection criteria, to the thermal and thermochemical treatments, to the coating processes which are flanked by modeling and simulation of components.

The reports held by university professors and technicians with proven experience in their fields, provided application details, with references also to the search for anomalies that occur during use, through examples of failure analysis.

The Study Day was aimed at industry experts and operators, design engineers, manufacturers and users of dies and tools.

PROGRAM

8.30 Participants registration

9.00 Welcome and introduction

D. Petta – President of the AIM CdS Heat Treatments and Metallography

STEELS AND PROPERTIES

9.15 Tool steels for machining and hot forging

R. Zanchetta – Uddeholm div. of voestalpine High Performance Metals Italia, Milan

TREATMENT

9.45 Fundamentals of heat treatment of tool steels

D. Magistroni – Böhler div. of voestalpine High Performance Metals Italia, Milan

10.15 Heat treatment of tool steels by cold forming

S. Roggero, D. Franchi – Genta div. Ferioli & Gianotti, Caselette

10.45 Break

11.00 Heat treatment of tool steels for hot working

L. Cislaghi – TTN, Nerviano

11.30 Thermochemical treatments. Hot steel nitriding

M. Pellizzari – University of Trento, Trento

12.00 PVD coatings

M. Ferrando – CRT, Nerviano

12.30 Lunch

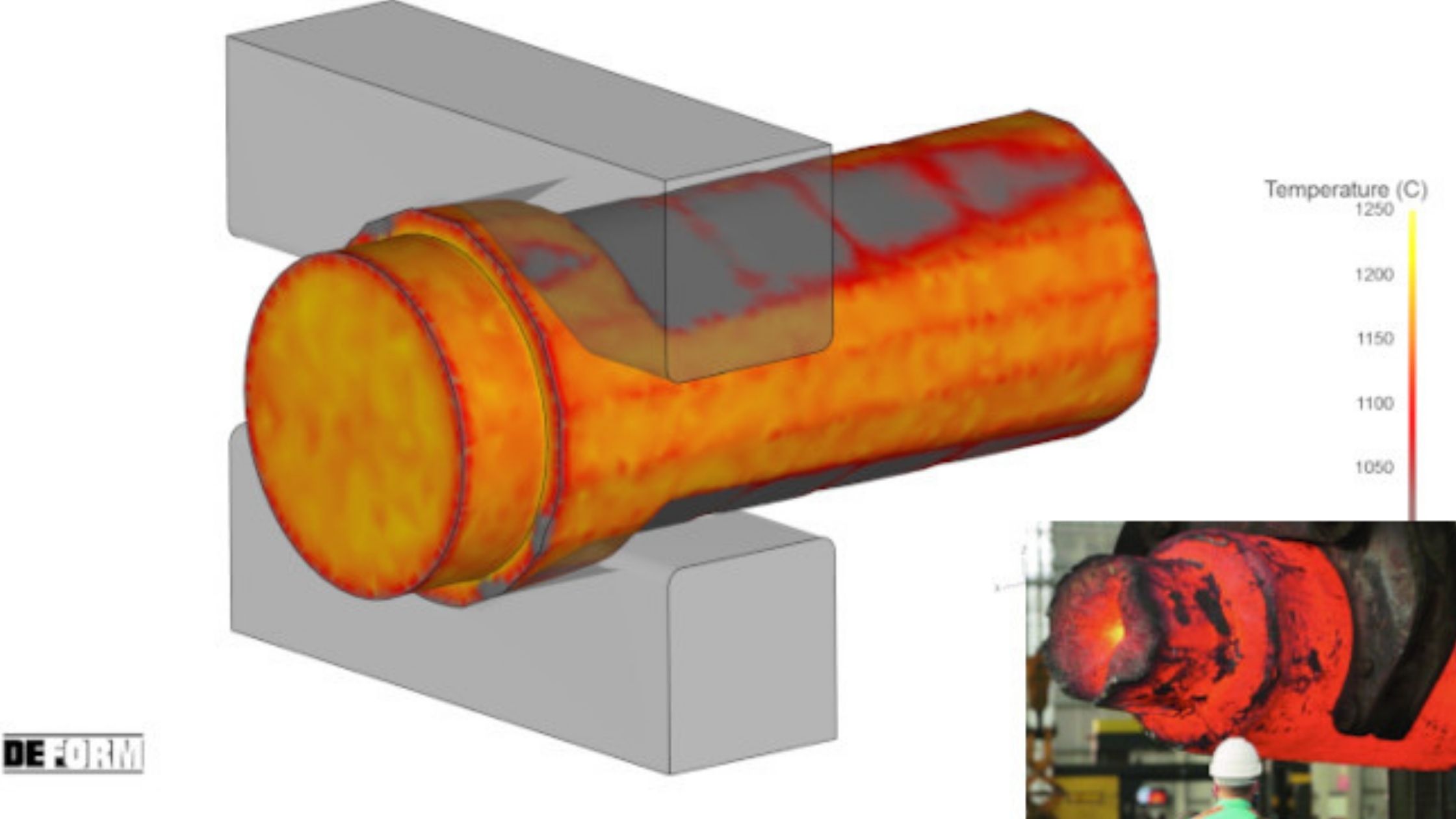

14.00 Hot forging – Closed Die Forging

M. Bortolotti, A. Rivolta – Böhler div. of voestalpine High Performance Metals Italia

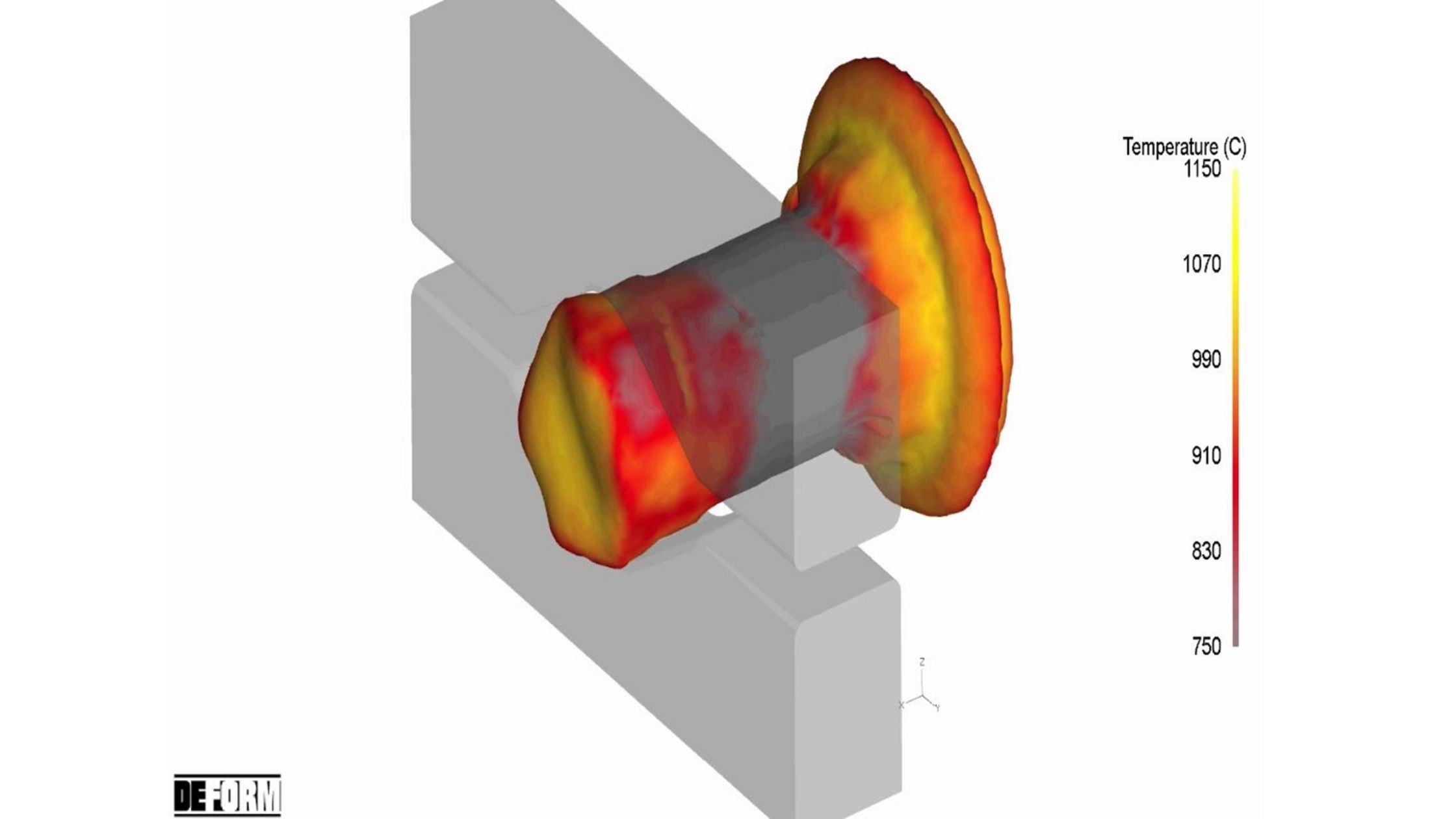

14.30 Simulation – Modeling in Metal Forming

C. Viscardi – Ecotre Valente, Brescia

CASES FAILURE

15.00 Study on the breaking of a mold by hot pressing

of brass

E. Prati – B.A. Bonomi Acciai, Lumezzane

15. 30 Interval

15.45 Cases of failure

M. De Sanctis, D. Magistroni – voestalpine High Performance Metals Italy, Milan

16.30 Failure analysis of large dies

D. Firrao – Polytechnic of Turin

17. 00 In-depth analysis and comparisons

REGISTRATION FEES

Discounted fees (by 1 October 2020)

AIM / Confindustria Canavese / UNISA MEMBERS Euro 190.00 *

NON-MEMBERS Euro 315.00 **

Full rates (after 1 October 2020)

AIM / Confindustria Canavese / UNISA MEMBERS Euro 220.00 *

NON-MEMBERS Euro 355.00 **

* The registration fees reserved for AIM, Confindustria Canavese and

UNISA, are not subject to VAT and include the revenue stamp.

** Registration fees for NON-MEMBERS include 22% VAT