Nickel-Based Superalloys Study Day: metallurgy, manufacture and uses of the forged product

Nickel-Based Superalloys Study Day: metallurgy, manufacture and uses of the forged product

National Museum of Science and Technology Leonardo da Vinci, Via San Vittore 21 - Milan

Ecotre Valente, together with Vecchiato Officine Meccaniche s.r.l., sponsors the Study Day organised by the AIM (Italian Association of Metallurgy) Forging Study Centre dedicated to Nickel-based Superalloys.

The event is scheduled to take place in Milan, on 22 February 2024, at the Leonardo da Vinci National Museum of Science and Technology, in Via San Vittore 21.

The study day is dedicated to forged and rolled products made of Nickel-based Superalloys, and offers participants an interesting itinerary that embraces both the theoretical and fundamental aspects of physical metallurgy and plastic deformation, as well as the practical aspects related to production processes.

The significant training proposal is enriched by practical process experiences, witnessed by experienced professionals in the field who have directed the design of the cycles, faced the related challenges, performed in the field with appropriate analytical insights and obtained tangible end results.

The programme covers topics closely related to the production process, such as recasting, forging, rolling and heat treatment technologies. Participants will have the opportunity to share their experiences and gain knowledge both at theoretical level and related to the implementation of the process.

Ecotre Valente, together with Vecchiato Officine Meccaniche s.r.l., sponsors the Study Day organised by the AIM (Italian Association of Metallurgy) Forging Study Centre dedicated to Nickel-based Superalloys.

The event is scheduled to take place in Milan, on 22 February 2024, at the Leonardo da Vinci National Museum of Science and Technology, in Via San Vittore 21.

The study day is dedicated to forged and rolled products made of Nickel-based Superalloys, and offers participants an interesting itinerary that embraces both the theoretical and fundamental aspects of physical metallurgy and plastic deformation, as well as the practical aspects related to production processes.

The significant training proposal is enriched by practical process experiences, witnessed by experienced professionals in the field who have directed the design of the cycles, faced the related challenges, performed in the field with appropriate analytical insights and obtained tangible end results.

The programme covers topics closely related to the production process, such as recasting, forging, rolling and heat treatment technologies. Participants will have the opportunity to share their experiences and gain knowledge both at theoretical level and related to the implementation of the process.

- Target audience: Moulders, Die-makers and Designers

- Speakers: Ecotre Technical Department

- Duration: Starts Wednesday 20 September 2023 – Ends Thursday 16 November 2023

20-21 September: joint course

28 September, 5-12-19-26 October and 7-9-16 November: individual meeting slots lasting one hour - Time: From 8 a.m. to 12 noon and from 1 p.m. to 4 p.m.

- Material: DEFORM software for the duration of two months, Course notes in pdf format and Attendance Certificate

- Venue: BACCADEMY Srl – Via Industriale, 106 – 25065 Lumezzane (BS)

LESSONS AND CONSULTING SERVICES

ECOTRE WITH CRISTIAN VISCARDI

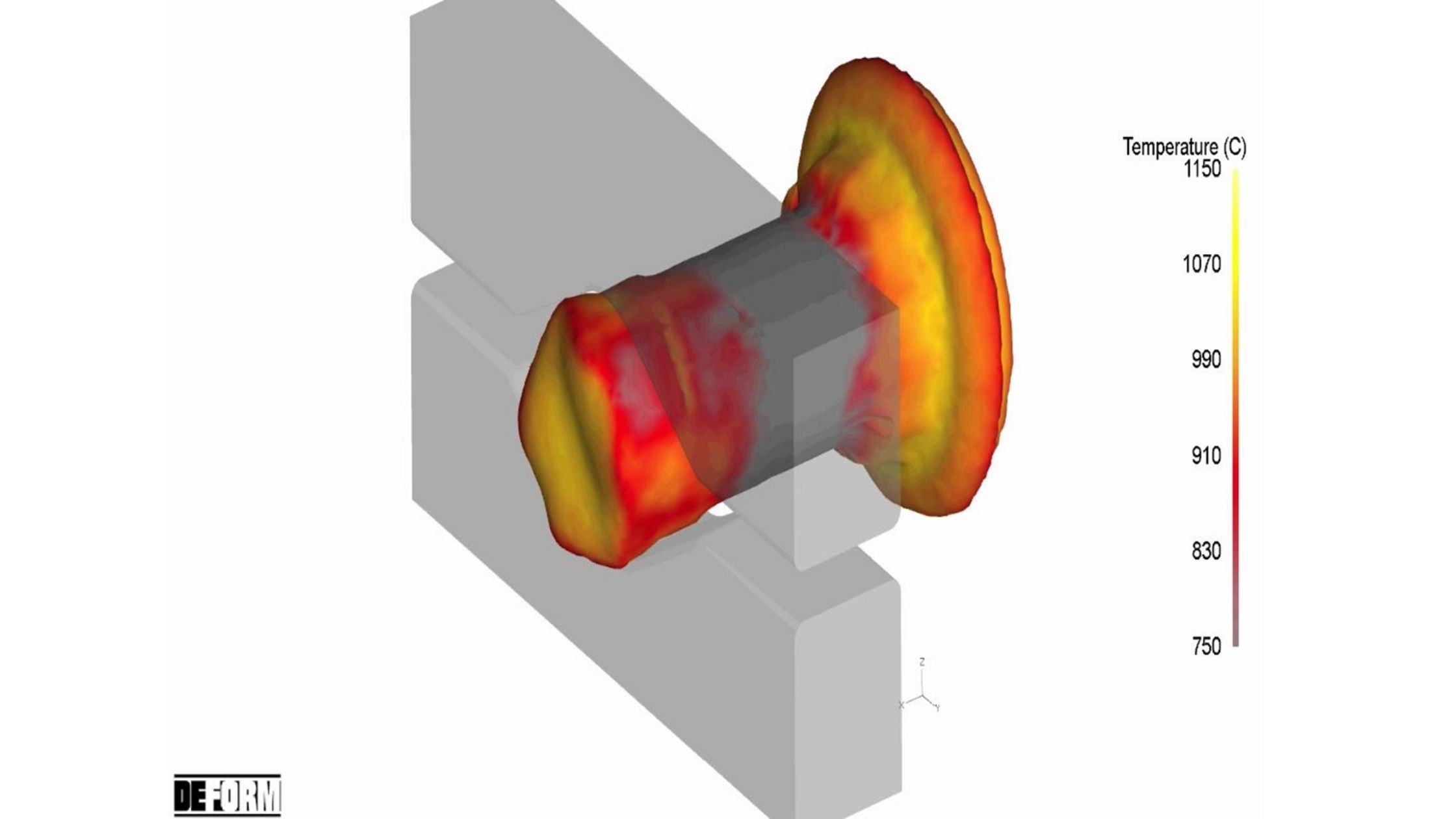

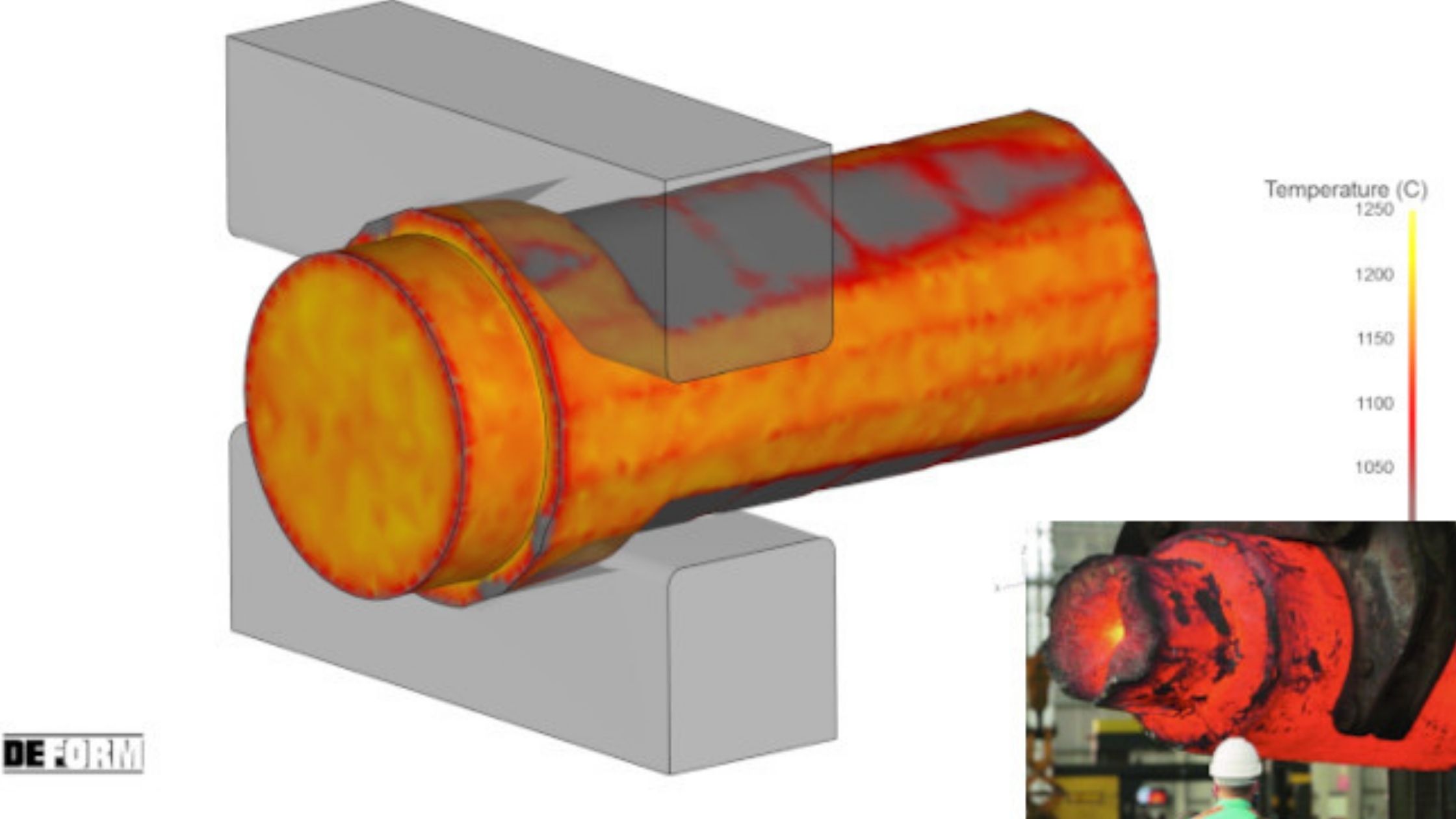

Cristian Viscardi, Technical Manager of Ecotre Valente, will be delivering a talk on Digital Manufacturing in the field of super alloys. In particular, he will be looking at the casting of this type of alloy, the forging and heat treatment of these high value-added materials.

Digital Manufacturing enables the pursuit of digital forging, digital heat treatment and digital casting.

NOT JUST LESSONS BUT CONSULTING SERVICES TOO

An Ecotre Valente information point will be open throughout the event, offering participants a place to meet the Ecotre technical team to discuss a metallurgical production problem they might have.

FILL IN THE FORM FOR FURTHER INFORMATION

Benefits

- Integrated Design and Optimization

- Enables better design choices

- Improved part moulding

- Fewer defects and better cost control