NEW LPDC INDUSTRY Integration of design and process metallurgy for innovative, complex and sustainable structural castings

NEW LPDC INDUSTRY Integration of design and process metallurgy for innovative, complex and sustainable structural castings

AQM Srl Via Edison , 18 - Provaglio d'Iseo BS

Description:

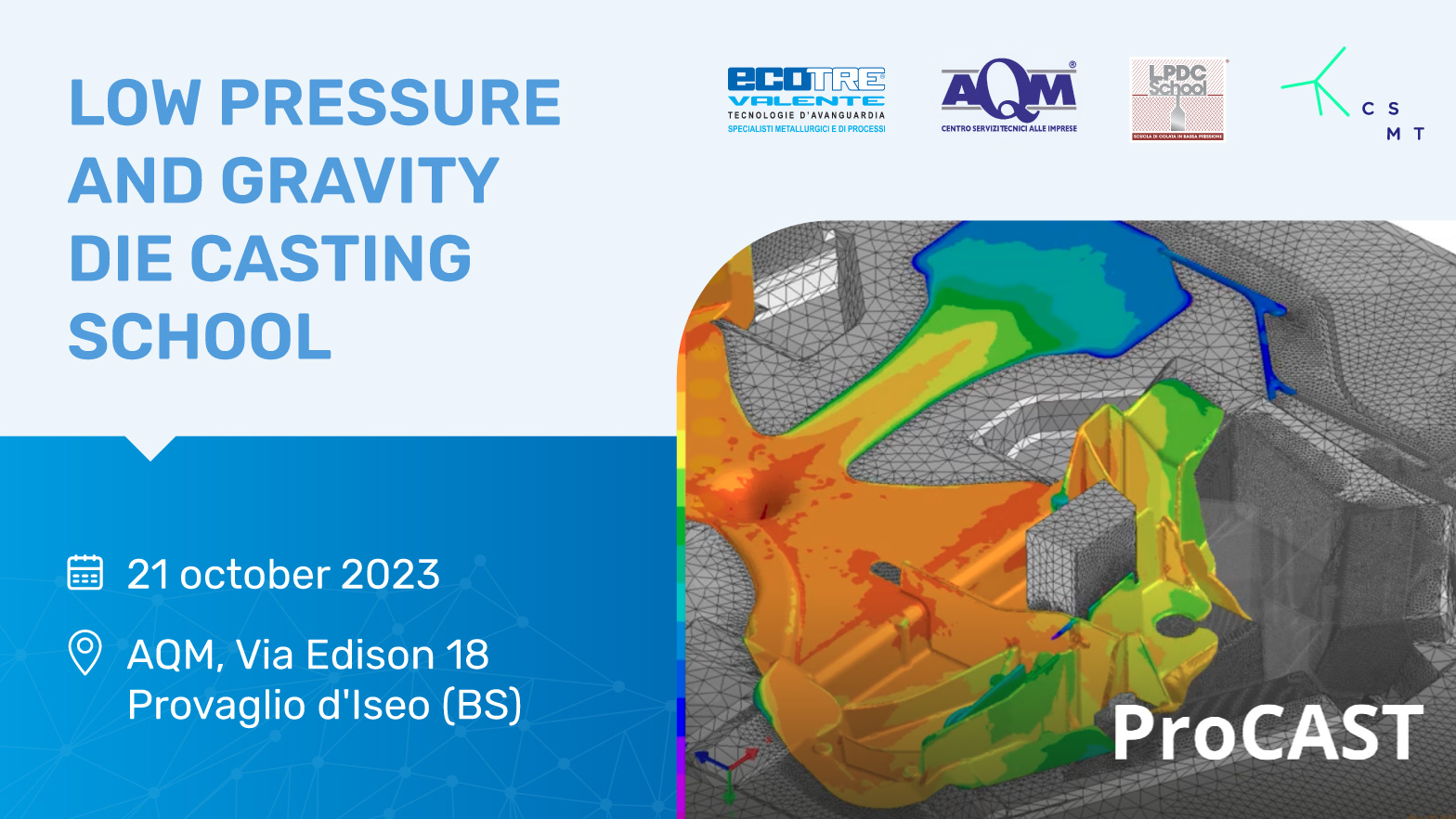

Learn more about the potential of modern LPDC (Low Pressure Die Casting) and its applications for the production of structural castings with complex and lightened shapes with a parallel increase in resistance. The results are increasingly high-performance and sustainable foundry products for the automotive and other industries, such as the construction industry and tap fittings.

During the LPDC course Lorenzo Valente, CEO of Ecotre Valente, will talk about “Evolved simulation of low pressure with digital concatenation between part design and foundry” to bring designers of structural elements closer to metallurgical paradigms, with a view to innovation and sustainability. A real practical demonstration by a casting specialist using technologies that are useful right from the design of the desired part.

The metallurgical and mechanical properties obtained from low-pressure die-casting (LPDC) are of the highest quality, and the excellent surface finish obtained makes it possible to produce components in which aesthetics play a leading role. This is why it is essential to have an in-house figure trained and experienced in this specific type of processing.

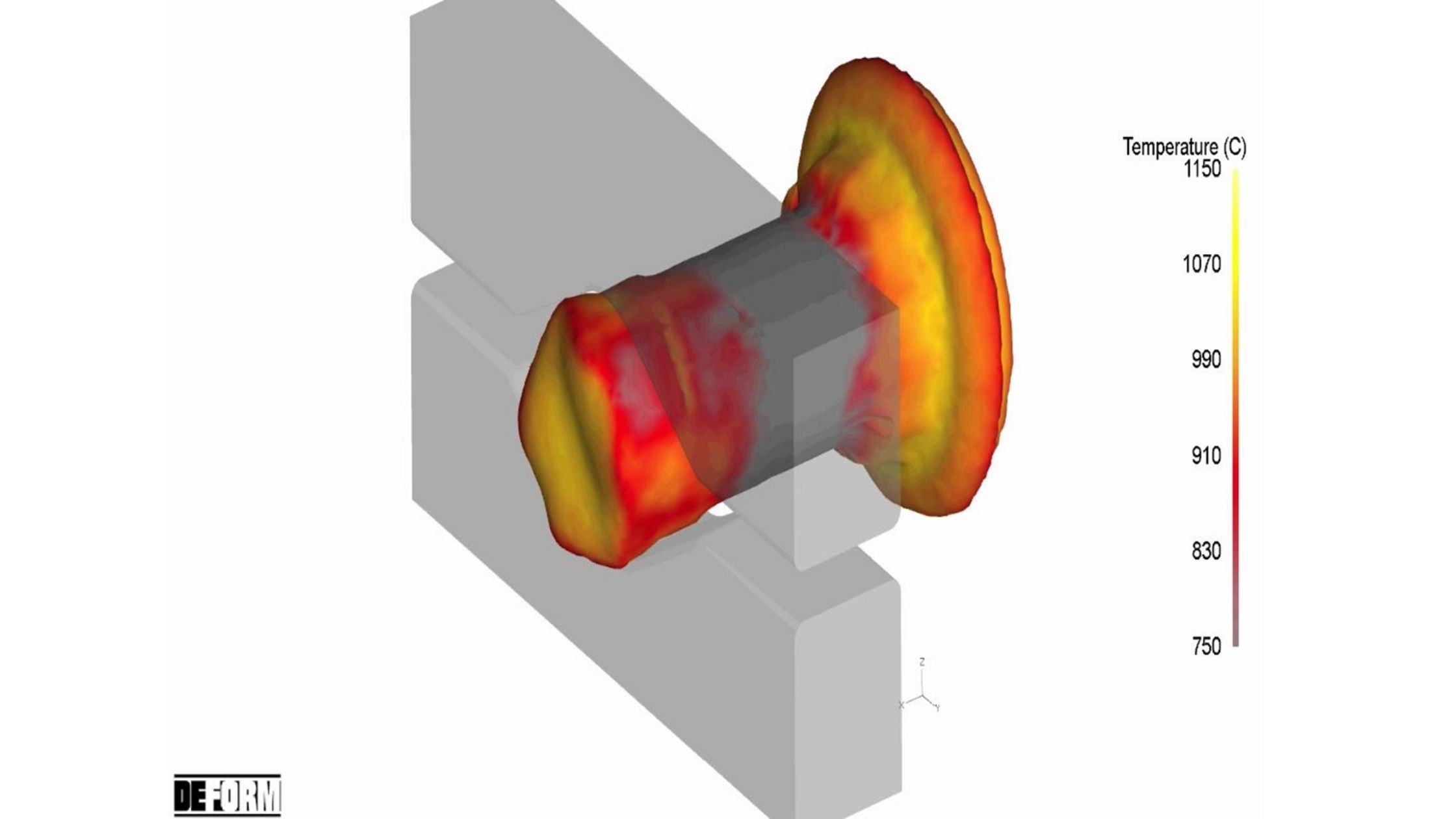

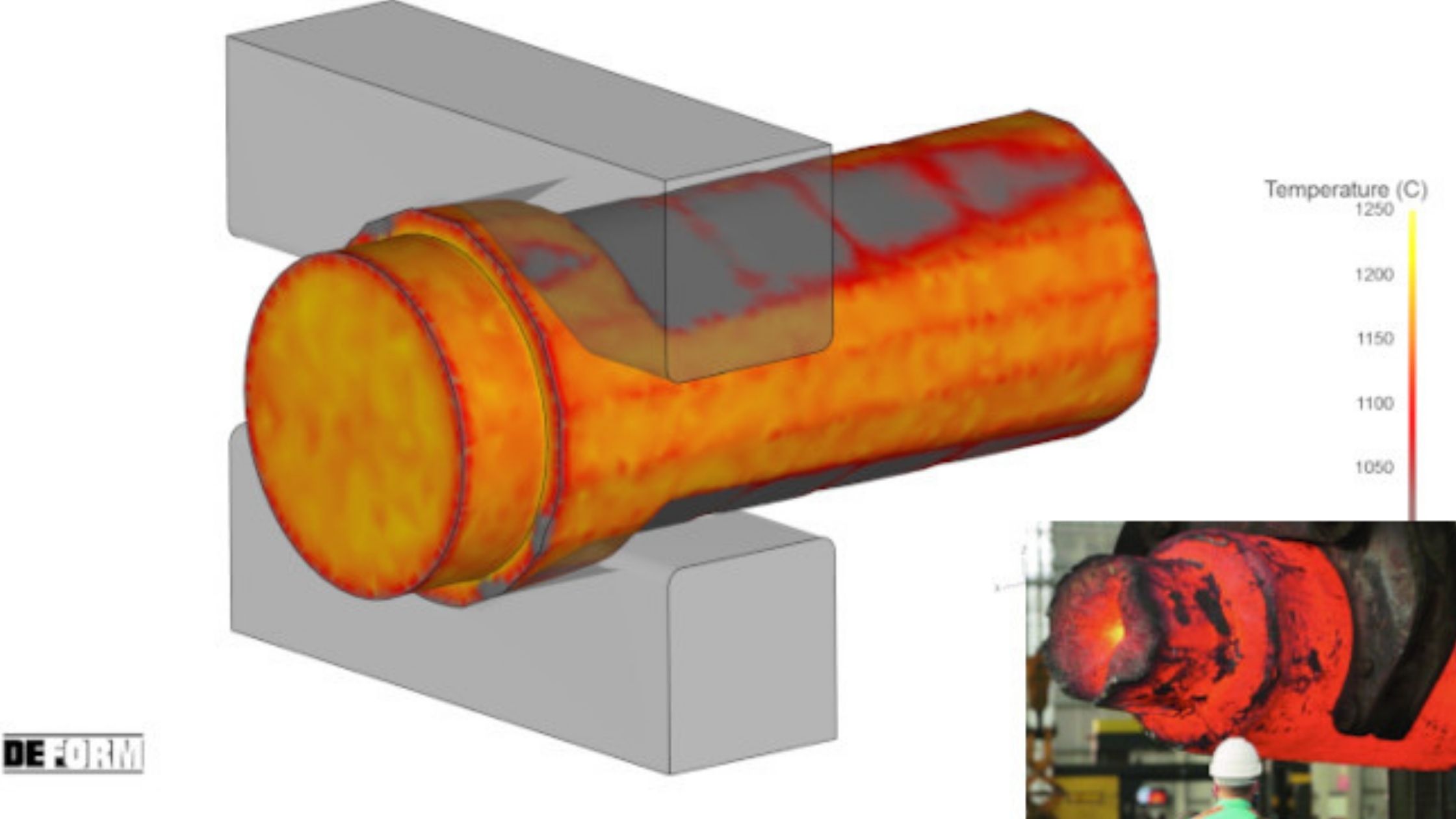

The process includes filling, solidification and stress assessment with simulation of tensions and deformations. The distribution of defects in the cast is assessed by means of simulation and the initial model is adjusted to minimise them.

These tools make it possible to predict, analyse and quantify the most common casting defects in advance and adjust the design process to minimise rejects and costly repetition work, while meeting the delivery times and quality standards demanded by the customer.

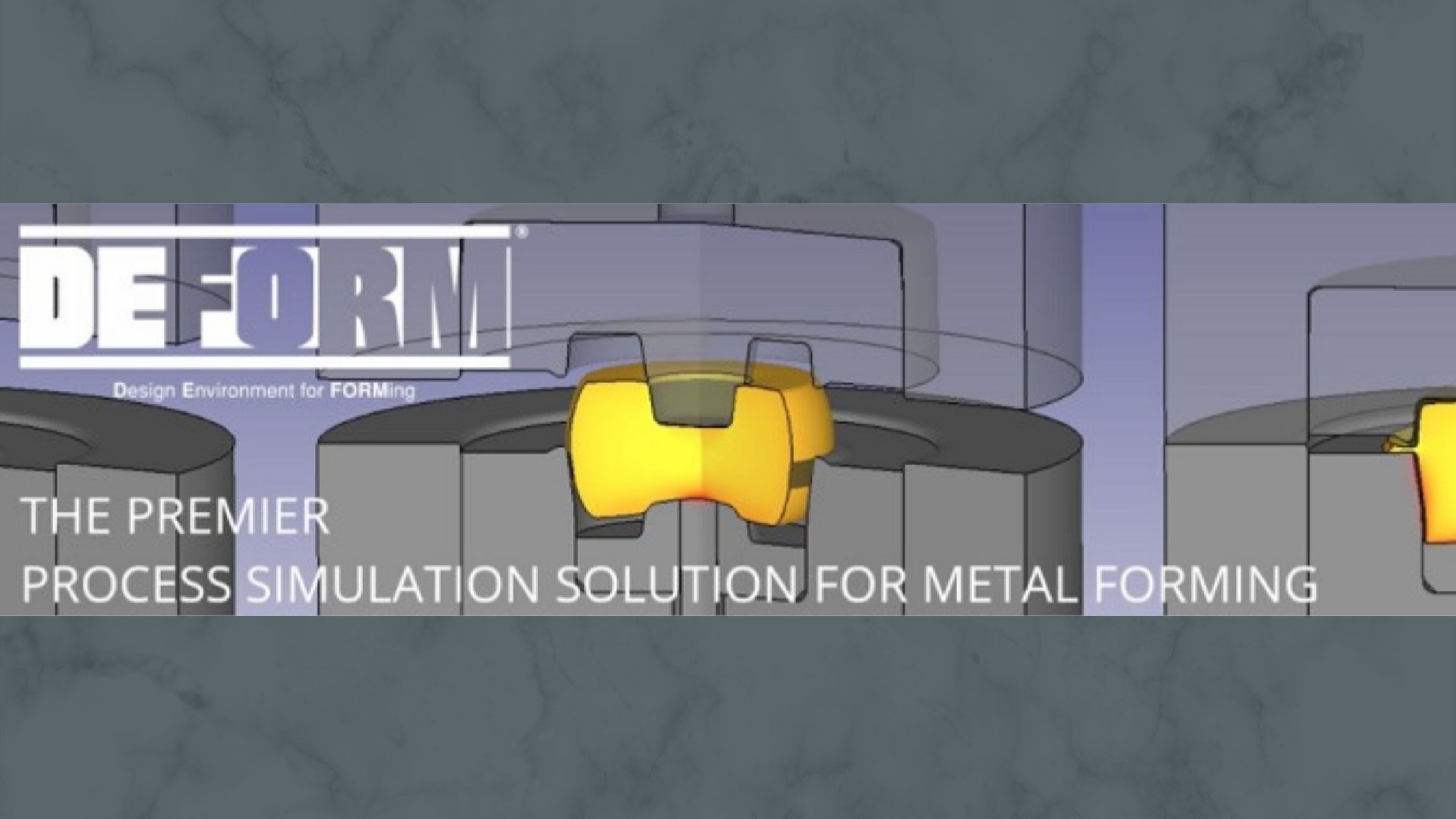

All this is made possible by QuickCAST Light, QuikCAST and ProCAST simulation software, the best on the market, equipped with a complete set of tools to create models of the low-pressure casting process as well as die-casting, shell gravity and sand gravity.

Ecotre Valente’s technical team is the best resource available not only for teaching but also for offering targeted advice to companies operating in the foundry sector that need to optimise and improve their products and production processes.

- Target audience: Moulders, Die-makers and Designers

- Speakers: Ecotre Technical Department

- Duration: Starts Wednesday 20 September 2023 – Ends Thursday 16 November 2023

20-21 September: joint course

28 September, 5-12-19-26 October and 7-9-16 November: individual meeting slots lasting one hour - Time: From 8 a.m. to 12 noon and from 1 p.m. to 4 p.m.

- Material: DEFORM software for the duration of two months, Course notes in pdf format and Attendance Certificate

- Venue: BACCADEMY Srl – Via Industriale, 106 – 25065 Lumezzane (BS)

FILL IN THE FORM BELOW TO ATTEND

Benefits

- Integrated Design and Optimization

- Enables better design choices

- Improved part moulding

- Fewer defects and better cost control