registration closed Friday 24 June 2022 – Idra, Travagliato (BS)Wednesday 29 June 2022 – Mille Miglia Museum (BS) Organizers:Prof. Annalisa Pola – University of BresciaIng. Lorenzo Valente – Ecotre Valente, Brescia Ask for a meeting with one of our experts When we talk about structural diecastings we typically mean chassis parts for motor vehicles, but… Continue reading AIM Study Day: structural castings 2022

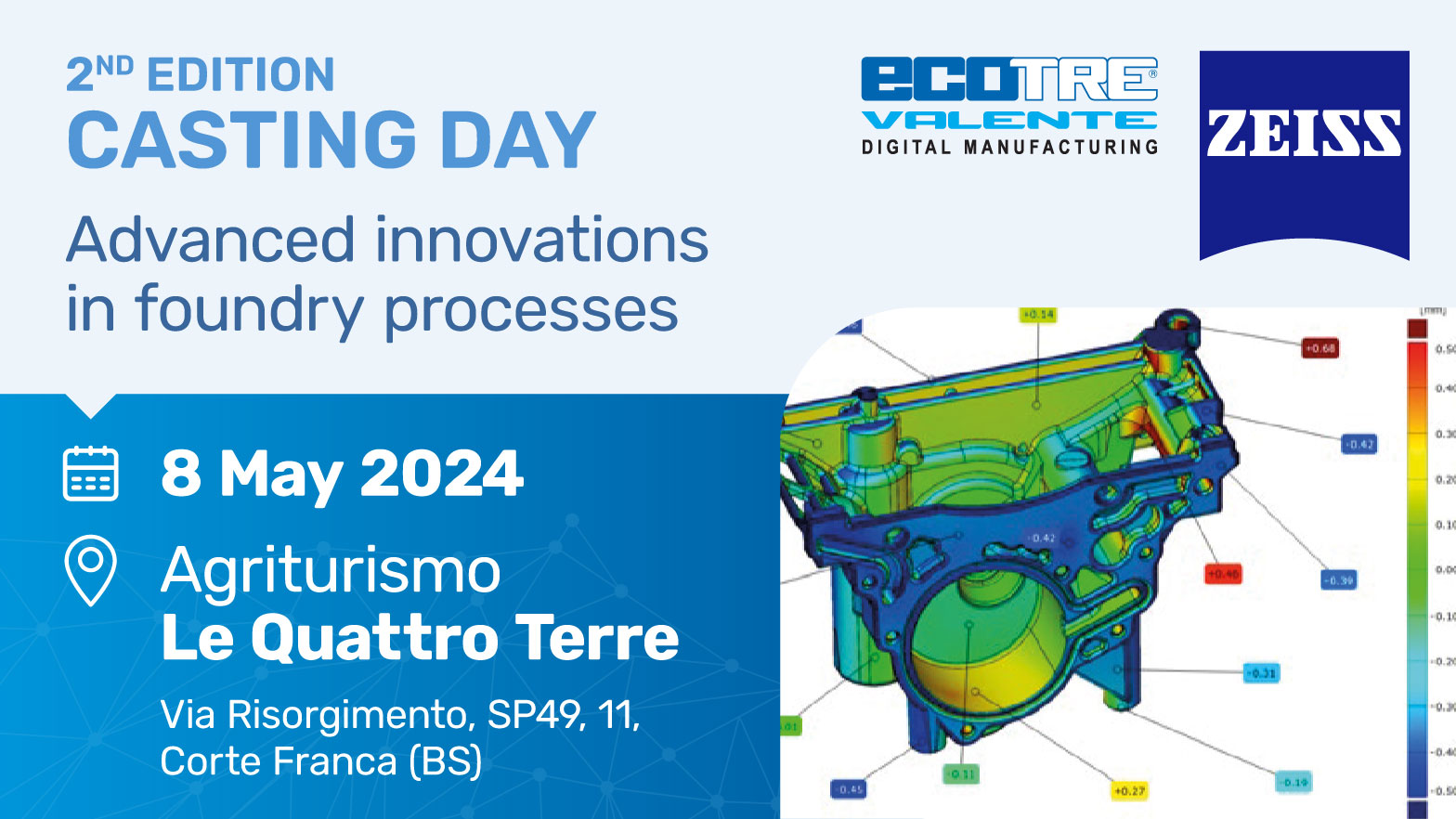

DOWNLOAD THE COMPLETE EVENT PROGRAMME ZEISS organised the first Italian event dedicated to our foundry world in 2024. ZEISS has selected three partners renowned for their know-how and technology; Ecotre is the partner of choice for the digitisation of the foundry process. At 11 a.m., our Lorenzo Valente will be delivering an exclusive Italian presentation… Continue reading CASTING DAY

Advanced innovations in foundry processes

SEE THE COMPLETE EVENT PROGRAMME ZEISS organised the first Italian event dedicated to our foundry world in 2024. ZEISS has selected three partners renowned for their know-how and technology; Ecotre is the partner of choice for the digitisation of the foundry process. After the great success of the first edition held on the 4th of… Continue reading CASTING DAY

Advanced innovations in foundry processes – Second edition

registrations closed To give continuity to its initiatives, the AIM Diecasting Technical Committee proposes a series of webinar presentations on defects in diecastings.The first was dedicated to shrinkage porosity and saw the organization and the report of our CEO, Eng. Ing. Lorenzo Valente.WHO IS IT FOR?Foundries, mold makers and designers.METHOD OF USEWEBINAR: The support platform… Continue reading Defects in diecastings. The shrinkage porosity

registrations closed Coordinators Prof. Pola Annalisa, professor at the University of BresciaIng. Valente Lorenzo, CEO of Ecotre Valente srl The diecasting of zinc alloys is one of the most convenient production processes for functional and design products both for large series and, often, for small production volumes. The high fluidity of these alloys favors the… Continue reading Die casting of zinc alloys

registrations closed Description: Ecotre Valente, metallurgical and process specialists and exclusive distributor for Italy of the DEFORM Simulation Software, organizes, in collaboration with BACCADEMY, a course for solving metallurgical problems with the DEFORM software for simulation of hot and cold forming. The course includes 2 initial days dedicated to the use of the DEFORM software… Continue reading ECOTRE & BACCADEMY: DEFORM for the simulation of cold and hot forming of brass, aluminum and steel

registrations closed Description: Ecotre Valente, metallurgical and process specialists and exclusive distributor for Italy of the DEFORM Simulation Software, organizes, in collaboration with BACCADEMY, a course for solving metallurgical problems with the DEFORM software for simulation of hot and cold forming. The course includes 2 initial days dedicated to the use of the DEFORM software… Continue reading ECOTRE & BACCADEMY: DEFORM for the simulation of cold and hot forming of brass, aluminum and steel – 2nd edition

fill in the form below Description: Ecotre Valente, metallurgical and process specialists and exclusive distributor for Italy of the DEFORM Simulation Software, organizes, in collaboration with BACCADEMY, a course for solving metallurgical problems with the DEFORM software for simulation of hot and cold forming. The course includes 2 initial days dedicated to the use of… Continue reading ECOTRE & BACCADEMY: DEFORM for the simulation of cold forming of brass, aluminum and steel – 3rd edition

Description: Ecotre Valente, metallurgical and process specialists and exclusive distributor for Italy of the DEFORM Simulation Software, organizes, in collaboration with BACCADEMY, a course for solving metallurgical problems with the DEFORM software for simulation of hot forming. The course includes 2 initial days dedicated to the use of the DEFORM software shared between companies, followed… Continue reading ECOTRE & BACCADEMY: DEFORM for the simulation of hot forming and blanking of brass, aluminum and steel

Ecotre Valente’s technical team trains students from Professional and Technical Schools and Technical Colleges in digital manufacturing with ProCAST and DEFORM process simulation software Request information to have a trained student at your company THE PARTNERSHIP On 26 January, Lorenzo Viscardi, Technical Manager of Ecotre Valente, had the honour of presenting the new protocols of… Continue reading Ecotre & Technical and Professional Schools

A strategic alliance for companies in the metallurgical sector

fill in the form below Description: The course organised in collaboration between Ecotre Valente and BAccademy on the digitisation of production processes with DEFORM software for the hot moulding of brass, aluminium and steel is now in its fourth edition. The course will start on Wednesday 20 September 2023 at the premises of BACCADEMY Srl… Continue reading ECOTRE and BACCADEMY: DEFORM for the hot moulding of brass, aluminium and steel – 4th edition

registrations closed The AIM Thermal Treatment and Metallography Study Center proposed this Study Day with the aim of providing the most up-to-date knowledge for the design, construction and use of molds. Among the speakers, our technical department manager, Eng. Cristian Viscardi.The aspects related to the performance of the die and of the respective components have… Continue reading Forming: properties of steel, heat treatment, damage mechanisms

registrations closed 11:00 hrsThe casting simulation to predict and solve the defectSpeaker: Ing. Cristian Viscardi, Technical manager of Ecotre Valente Srl This Study Day, organized by the Diecasting Study Center, is part of a cycle of days that aim to analyze the various defects that can occur in diecastings, thus offering ideas for optimizing the… Continue reading GdS AIM: Defects of diecasting components: Metallization

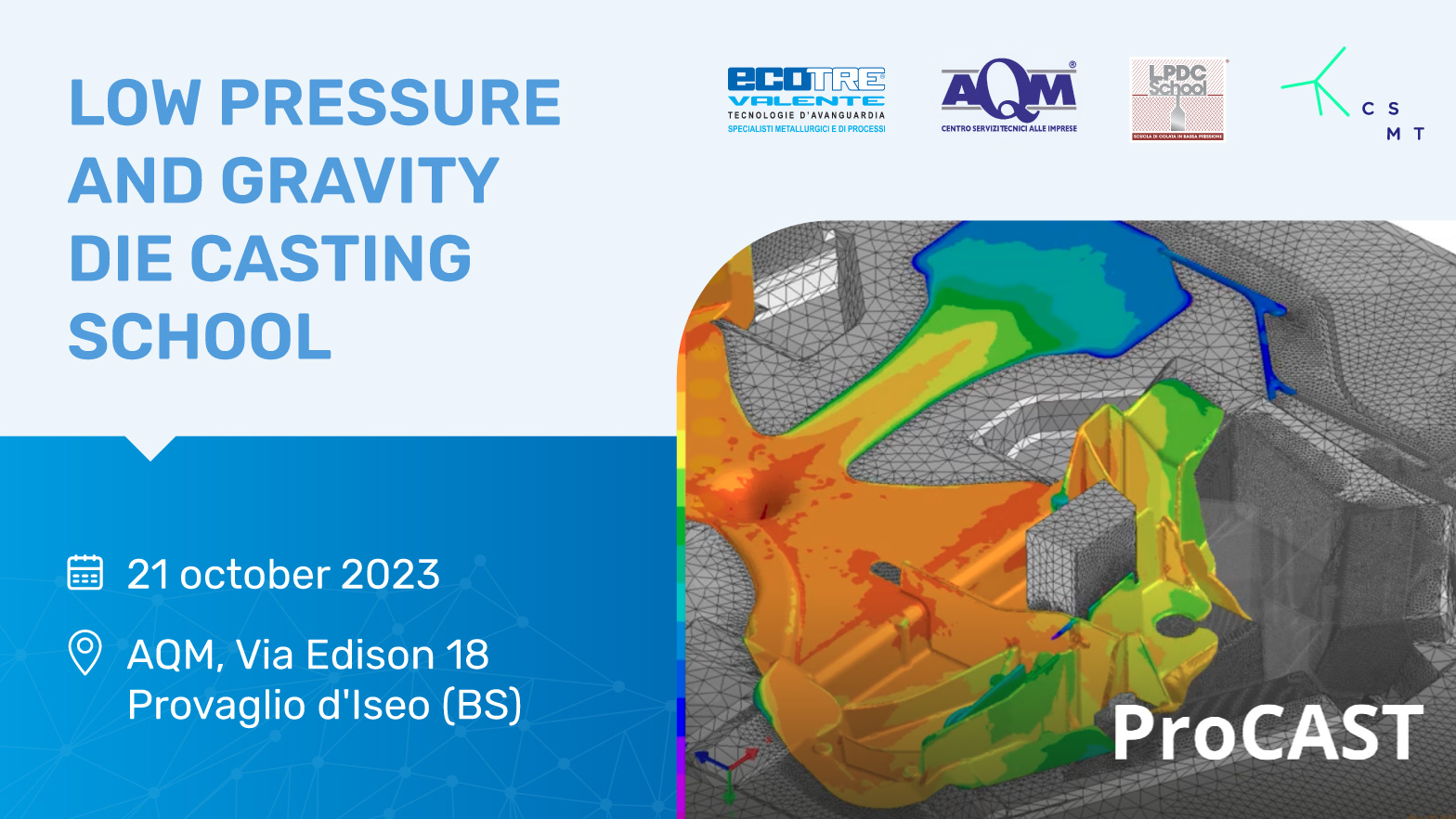

fill in the form below Description: The members of Ecotre Valente’s technical team will be lecturing at the specialised Low Pressure and Gravity Die Casting course, a training course intended for foundries or companies that process, transform or use low pressure castings or castings created with other technologies. The course will be held at the… Continue reading LOW PRESSURE AND GRAVITY DIE CASTING COURSE

fill in the form below Description: Learn more about the potential of modern LPDC (Low Pressure Die Casting) and its applications for the production of structural castings with complex and lightened shapes with a parallel increase in resistance. The results are increasingly high-performance and sustainable foundry products for the automotive and other industries, such as… Continue reading NEW LPDC INDUSTRY Integration of design and process metallurgy for innovative, complex and sustainable structural castings

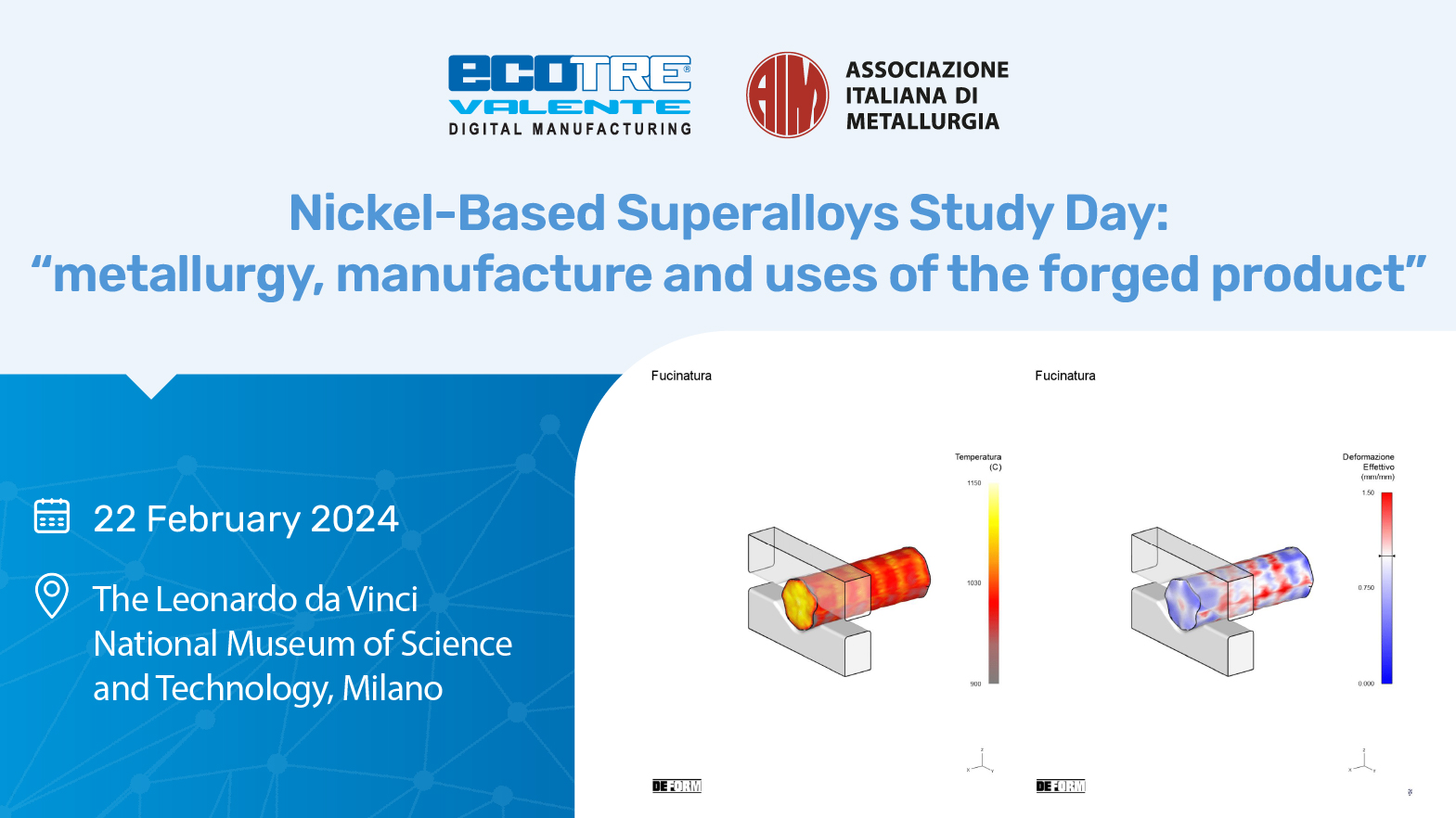

fill in the form below Ecotre Valente, together with Vecchiato Officine Meccaniche s.r.l., sponsors the Study Day organised by the AIM (Italian Association of Metallurgy) Forging Study Centre dedicated to Nickel-based Superalloys. The event is scheduled to take place in Milan, on 22 February 2024, at the Leonardo da Vinci National Museum of Science and… Continue reading Nickel-Based Superalloys Study Day: metallurgy, manufacture and uses of the forged product

registrations closed Modern modeling tools allow you to perform extremely reliable heat treatment simulations, capable of predicting the microstructure and stress state of industrial components with excellent accuracy.Several companies have developed algorithms and databases for metal systems which have been implemented in powerful software tools.For its part, the continuous evolution of hardware has significantly reduced… Continue reading The potential of numerical simulation for heat treatments

registrations closed Coordinator: Lorenzo Valente, Ecotre Valente CEO The Die Casting Technical Committee invites foundries and mold makers to participate in the second edition of the Course “Thermal fatigue. Increase the die life “. In the first edition of 2018, the 14 speakers shared their knowledge and experience with the participants, from the University, to… Continue reading Thermal Fatigue: Increase die life