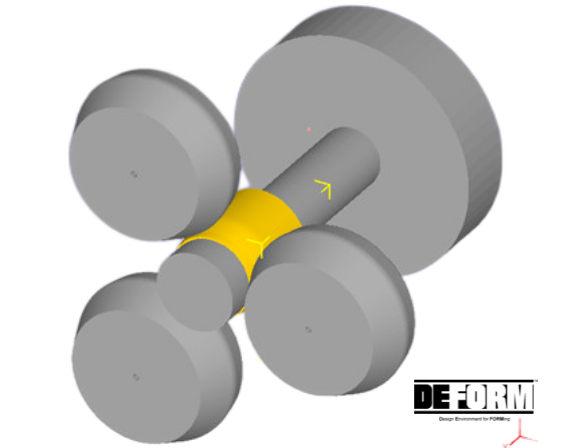

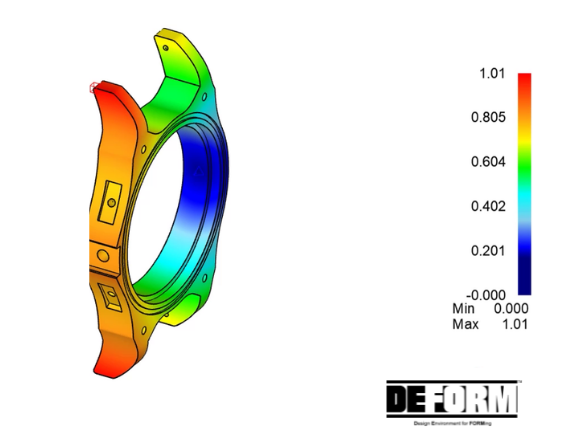

DEFORM Benefits Quality improvement Optimization and saving in the design Improvement of production Enhanced precision Flexibility of use Reduction of calculation times Reduction of production rejects Saves money Flow Forming of metals: What it is The flow forming process can be carried out both hot and cold. It is achieved by applying a uniform pressure… Continue reading Flow Forming

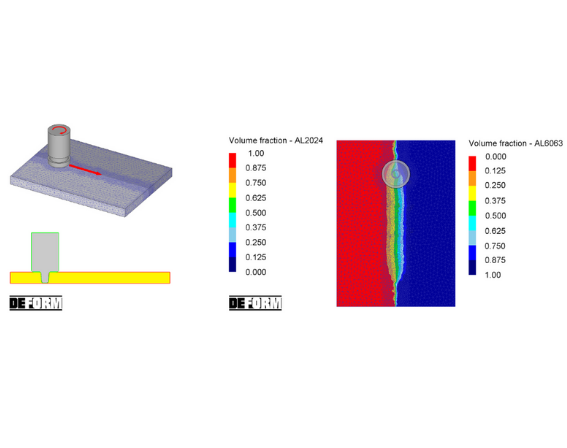

DEFORM Benefits High quality welded products Elimination of rejects and reduction of defects Elimination of samplings Improved mechanical features of the workpiece Greater strength of the finished piece Reduced welding times Reduced welding costs More energy-saving Friction Stir Welding: What it is Friction Stir Welding (FSW) is a type of friction welding at the solid-state… Continue reading Friction Stir Welding

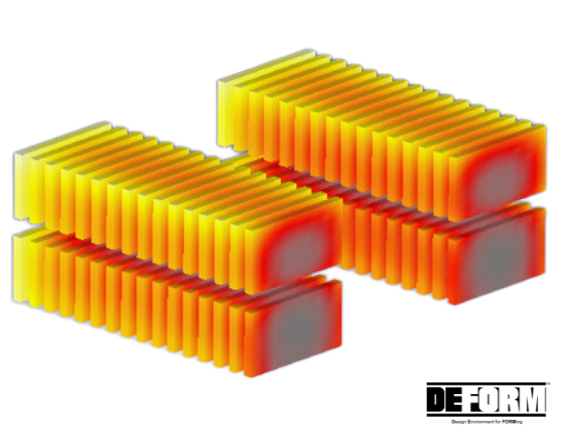

DEFORM Benefits: Quality improvement Optimization and saving in the design Improvement of production Enhanced precision Flexibility of use Reduction of calculation times Reduction of production rejects Saves money Furnaces Simulation: What and how it works A heating furnace must therefore guarantee, in addition to excellent production, ideal heating quality and ever less energy consumption and… Continue reading Furnaces

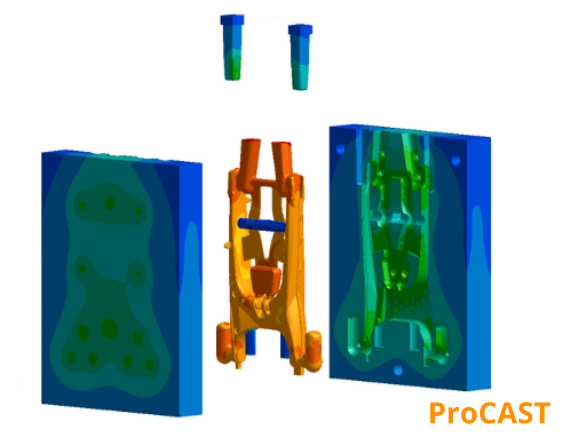

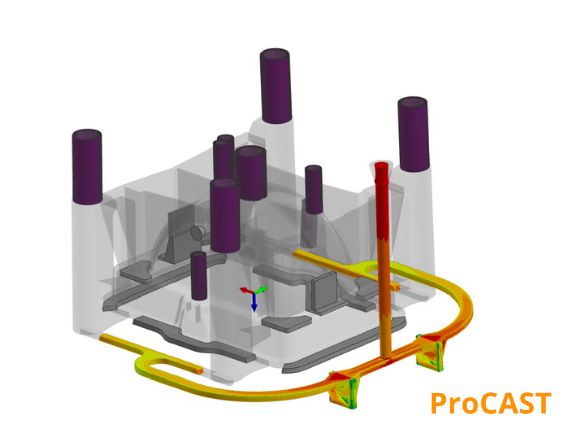

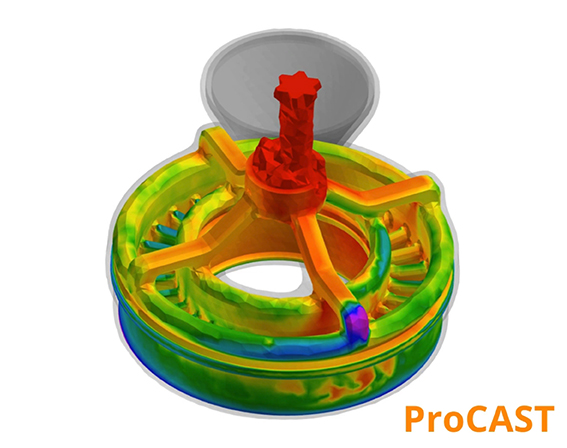

QuikCAST and ProCAST Software Benefits Saves sampling time and costs Extends mould life Improves the superficial finish of the castings and their mechanical properties Eliminates porosity Streamlines the process Process optimization Gravity Die Casting: What it is Gravity die casting is a process in which foundries use gravity for pouring, through a filling channel, molten… Continue reading Gravity Die Casting

QuikCAST and ProCAST Software Benefits Quality improvement Optimization and saving in the design Improvement of production Enhanced precision Flexibility of use Reduction of calculation times Reduction of production rejects Saves money Melting in sand gravity, also called in earth, is a process in which the liquid metal is poured into a form made of a… Continue reading Gravity Sand Casting

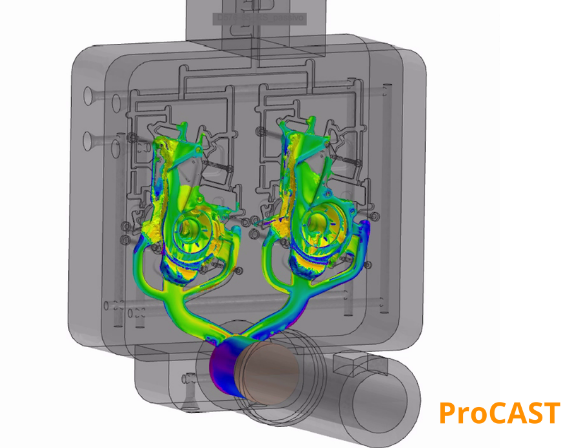

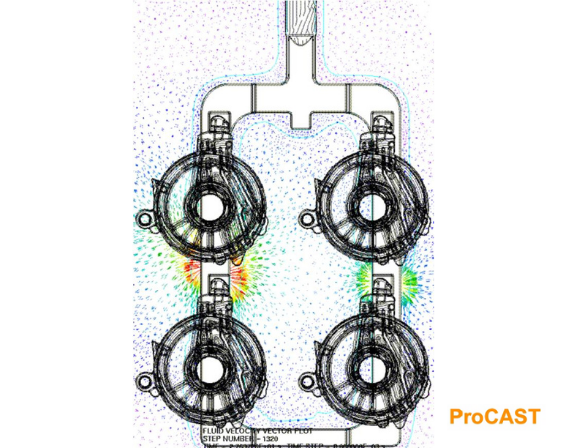

QuikCAST and ProCAST Software Benefits Quality improvement Optimization and saving in the design Improvement of production Enhanced precision Flexibility of use Reduction of calculation times Reduction of production rejects Saves money High Pressure Die Casting: What it is Die casting is a process which entails introducing molten metal, held in a tank, into steel dies… Continue reading High Pressure Die Casting

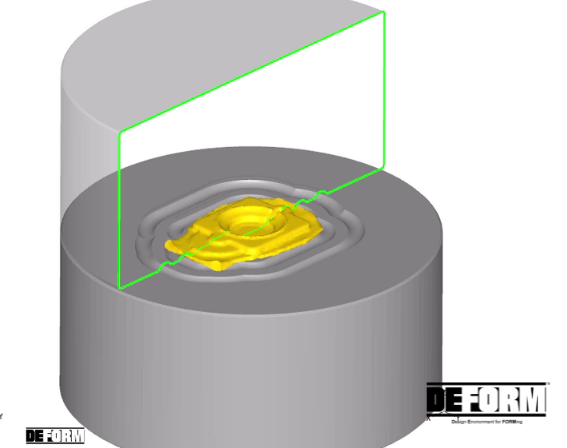

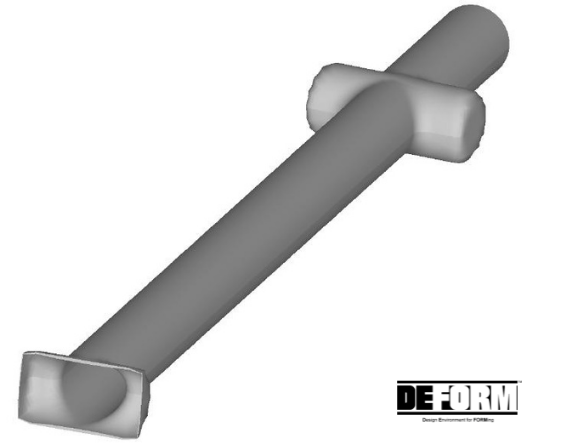

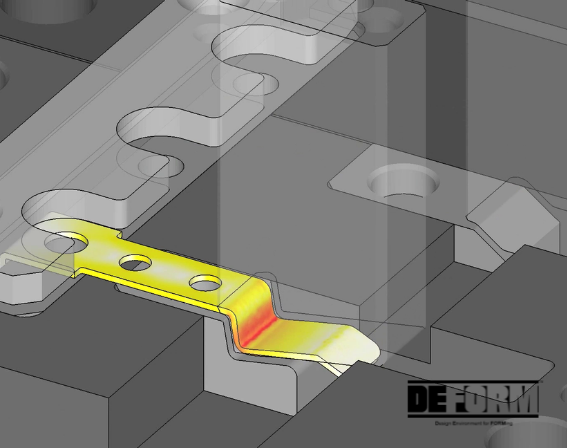

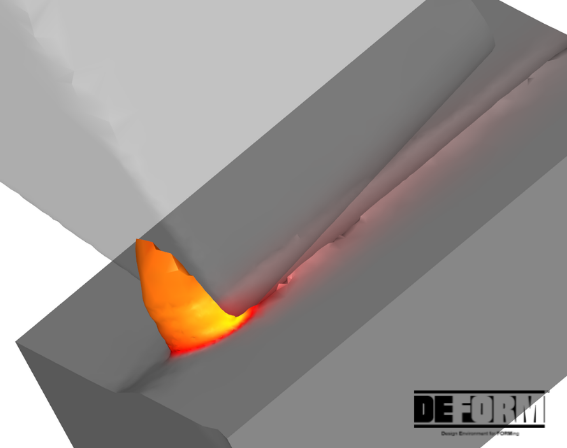

DEFORM Benefits Quality improvement Optimization and saving in the design Improvement of production Enhanced precision Flexibility of use Reduction of calculation times Reduction of production rejects Saves money Metal Hot Forming: What it is Hot forming is a deformation process in which, starting from preheating, the metal is pressed bringing it to the desired shape… Continue reading Hot Forming

DEFORM Benefits Quality improvement Optimization and saving in the design Improvement of production Enhanced precision Flexibility of use Reduction of calculation times Reduction of production rejects Saves money Hydroforming of metals: What it is The hydroforming process consists in forming a component by means of the pressure exerted on it by a hydraulic fluid, such… Continue reading Hydroforming

DEFORM Benefits Quality improvement Optimization and saving in the design Improvement of production Enhanced precision Flexibility of use Reduction of calculation times Reduction of production rejects Saves money Incremental Sheet Metal Forming: What it is Incremental Sheet Metal Forming is a production method that involves different types of machining through a series of workstations. These… Continue reading Incremental Sheet Metal Forming

QuikCAST and ProCAST Software Benefits Quality improvement Optimization and saving in the design Improvement of production Enhanced precision Flexibility of use Reduction of calculation times Reduction of production rejects Ingot Casting Simulation: What and how it works Ingot casting simulation with multi-way and single way plate, complete column and root filling. The ingot casting process… Continue reading Ingot Casting

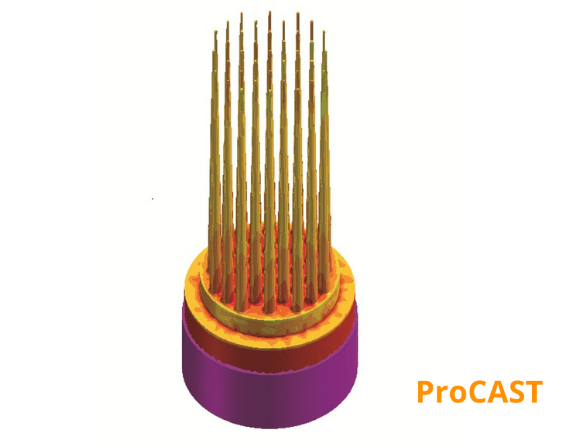

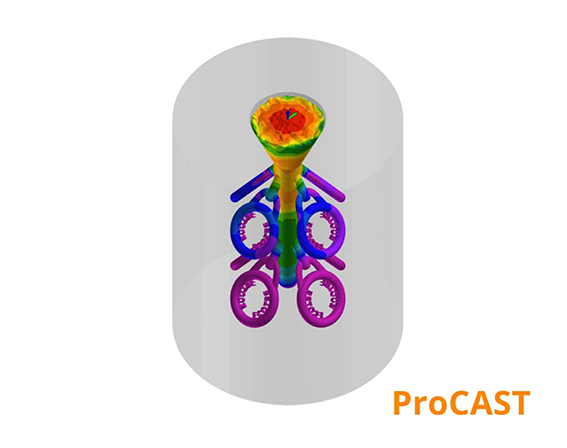

QuikCAST and ProCAST Software Benefits Quality improvement Optimization and saving in the design Improvement of production Enhanced precision Flexibility of use Reduction of calculation times Reduction of production rejects Saves money Investment Casting: What it is The investment casting process, also called lost wax microfusion, begins by building the mould to produce wax models. Afterwards… Continue reading Investment Casting

QuikCAST and ProCAST Software Benefits Quality improvement Optimization and saving in the design Improvement of production Enhanced precision Flexibility of use Reduction of calculation times Reduction of production rejects Saves money Liquid Forging: What it is The liquid forging process is a light alloys melting method that entails application of a very high pressure on… Continue reading Liquid Forging

QuikCAST and ProCAST Software Benefit Quality improvement Optimization and saving in the design Improvement of production Enhanced precision Flexibility of use Reduction of calculation times Reduction of production rejects Saves money Lost Foam : What it is The lost foam process consists in creating a form in expanded polystyrene, placed in a container filled with… Continue reading Lost Foam

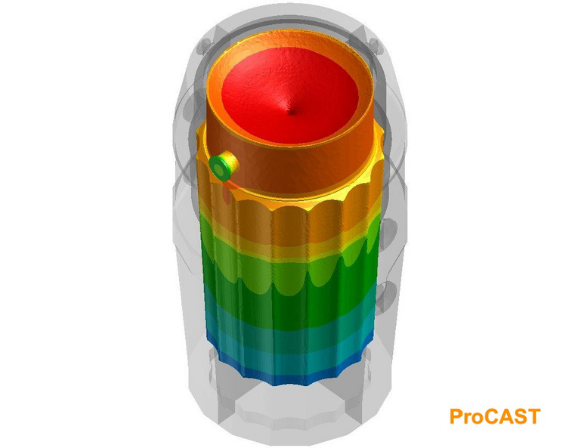

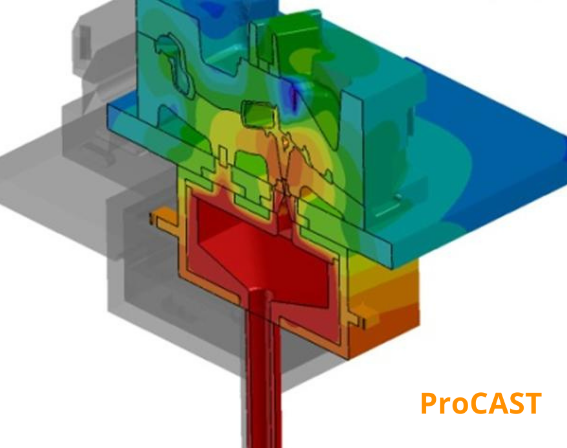

Benefits with QuikCAST and ProCAST Software Quality improvement Optimization and saving in the design Improvement of production Enhanced precision Optimum control of process parameters Flexibility of use Reduction of calculation times Reduction of production rejects Saves money Low Pressure Die Casting: What it is Low pressure die casting (LPDC) is a process in which molten… Continue reading Low Pressure Die Casting

DEFORM Benefits High quality forming products Elimination of rejects and reduction of defects Elimination of samplings Improved mechanical features of the workpiece Greater strength of the workpiece Reduced 3D printing times Reduced 3D printing costs Metal Binder Jetting Simulation: What it is and how it works The Metal Binder Jetting is used for 3D printing… Continue reading Metal Binder Jetting

Benefits with QuikCAST and ProCAST Software Quality improvement Optimization and saving in the design Improvement of production Enhanced precision Flexibility of use Reduction of calculation times Reduction of production rejects Saves money MIM Simulation: What and How it works Metal Injection Molding (MIM) is a metallurgic process for the production of complex shaped materials, starting… Continue reading Metal Injection Molding (MIM)

Lost-wax casting is a technique that dates back to ancient times. Among the best-preserved examples from antiquity are the Bronzes of Riace. The lost-wax casting method is used in the fashion and jewellery industry: a reproduction of the piece is created in wax or using 3D printing. Additional pieces, casting channels and uprights are then… Continue reading Micro casting

DEFORM Benefits Quality improvement Optimization and saving in the design Improvement of production Enhanced precision Flexibility of use Reduction of calculation times Reduction of production rejects Saves money Machining of Milling: What it is Milling is a mechanical swarf removal process allowing to obtain a wide range of surfaces, cuts, incisions, cavities, shapes and holes… Continue reading Milling