Lost-wax casting is a technique that dates back to ancient times. Among the best-preserved examples from antiquity are the Bronzes of Riace.

The lost-wax casting method is used in the fashion and jewellery industry: a reproduction of the piece is created in wax or using 3D printing. Additional pieces, casting channels and uprights are then added, creating the tree, also made of wax. The shaft, also known as the “cluster”’, is placed in a cylinder that is filled with refractory material. The cylinder undergoes two heating cycles, the first to remove the wax from the cavity, the second to pre-heat the plaster so that the liquid metal can be poured into the cylinder avoiding gaps and cold joints.

After the metal poured inside the cylinder has solidified, the plaster is broken away and the various pieces are separated from the column. The item is finished off with post-casting surface operations. The quality control department then inspects the item and certifies its conformity.

ProCAST software is dedicated to the fashion and jewellery industry. ProCAST digitises the injection of wax into the rubber mould and focuses on digitising casting and solidification.

The aim is to eliminate casting tests, which are carried out on the computer with ProCAST

ELONGATION

The software can provide the elongation % map

ULTIMATE TENSILE STRENGTH

The simulator provides the map of the Ultimate Tensile Strength of the Component “As Cast” and after Heat Treatment

YIELD STRESS

The simulator provides the map of the Yield Stress of the Unfinished Component and after Heat Treatment

HARDNESS

The simulation can indicate the Hardness that can be obtained and its profile through its thickness

SDAS

The casting simulator shows the map of the SDAS (Secondary Dendrite Arm Spacing), a useful indicator of component performance

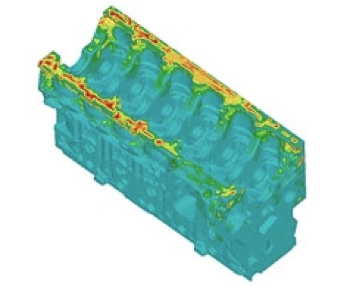

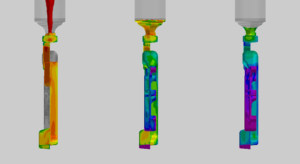

GAS POROSITY

Map of Porosity from Gas encapsulated during filling. Reduction of mechanical and bonding performance of the component

OXIDES

The alloy oxidizes during filling and the simulation points out where the oxides hide and where they move during filling

DELAMINATIONS

The simulator shows the delaminations, related to imperfect bonding of the alloy during filling

INCOMPLETENESS

Incomplete pieces or with joinings and retrieved lines

Undersized gating system or incorrect gas exhaust

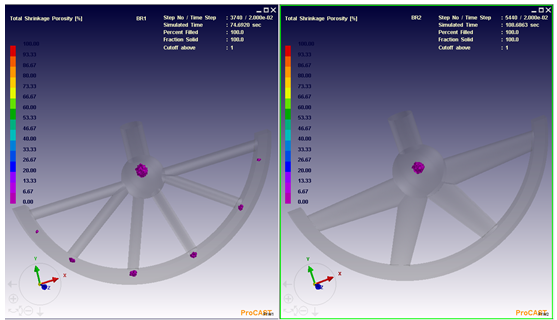

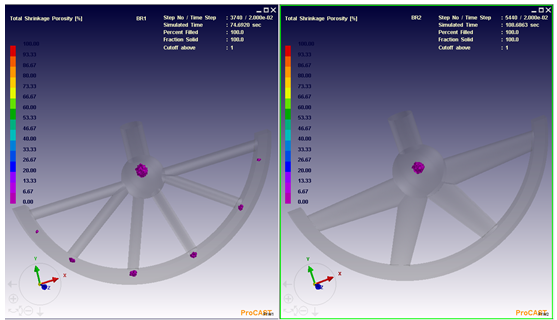

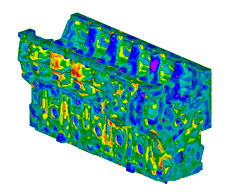

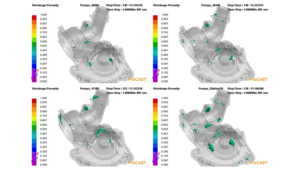

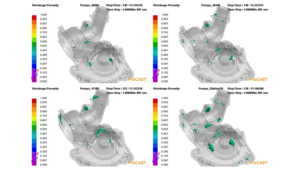

SHRINKAGE POROSITY

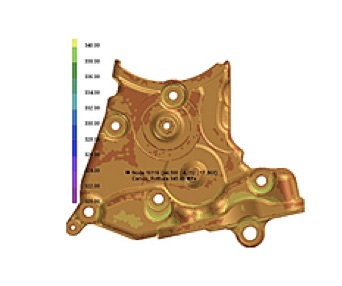

Map of Shrinkage Porosity.

Geography and Dimension of defect in mm3.

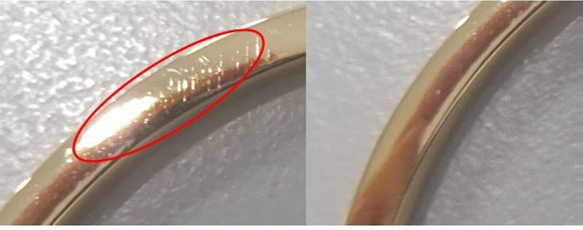

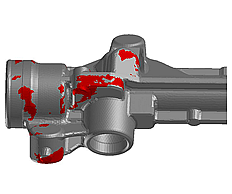

CRACKS

Map of hot and cold cracks on casting

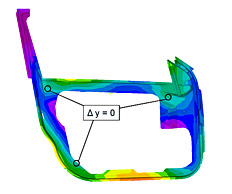

DIMENSIONAL

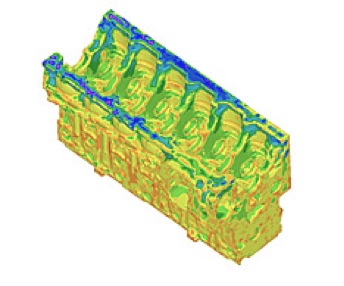

Dimensions and deformations of piece during solidification, extraction, cooling, blanking and any heat treatment

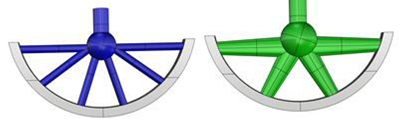

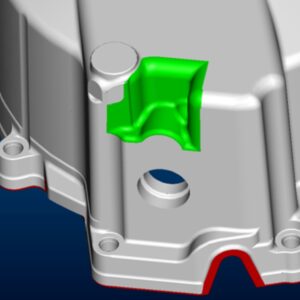

CO-DESIGN

Eliminate defects by acting on the causes and not on the effects

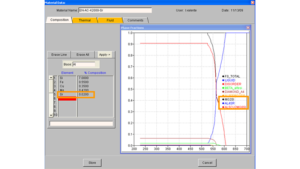

ALLOYS

Impact of the alloy on the mechanical features and on the defects

CHEMICAL ANALYSIS

QuikCAST Light, QuikCAST and ProCAST characterise the alloy initiating from the chemical analysis. Assessment, for example, of the consequences of the addition of 200 ppm of Strontium

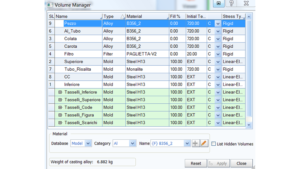

DATABASE

Complete archive of mould steels, sands, cores, insulation and exothermic sleeves, chillers, shells

DESCRIPTION

The simulation allows you to set a preview of the ideal process parameters for production of the component. This way the actual sampling underwent a positive result by eliminating fine tunings for the correct set of process parameters. Furthermore, the Optimizer Module of the software automatically defines the minimum and maximum ranges of the parameters guaranteeing the consistency and stability of the process.

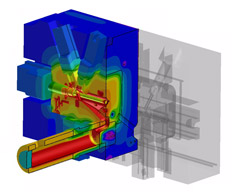

DIE

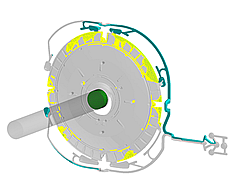

The casting simulation shows the thermal die cycling simulation, the conditioning or thermal circuits, lubrication, deformation and die duration

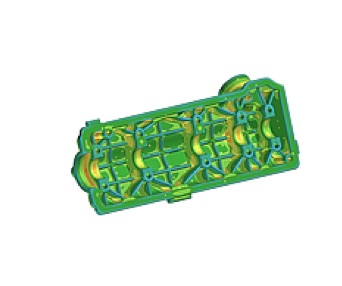

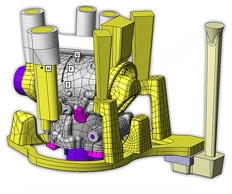

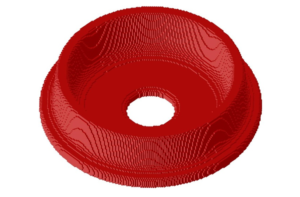

PLATE

Optimization of the plate, positioning of the chillers, sleeves, filters and die assembly of the cores. Maximum yield.

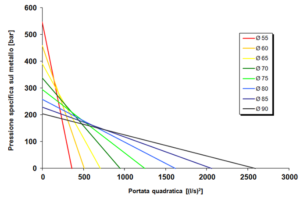

CASTING MACHINE

The casting simulation allows you to know the required casting machine and therefore the tonnes necessary

SYSTEM

Simulation of the entire injection cycle, complete with container, riser tube, tipping, automatic, manual system

FINITE VOLUMES

The finite volumes or Finite Differences Technology is the introductory technology to casting simulation.

QuikCAST

FINITE ELEMENTS

The Finite Elements Technology is the top technology that provides the maximum performance of the casting simulator.

ProCAST