DEFORM Benefits

- Quality improvement

- Optimization and saving in the design

- Improvement of production

- Enhanced precision

- Flexibility of use

- Reduction of calculation times

- Reduction of production rejects

- Saves money

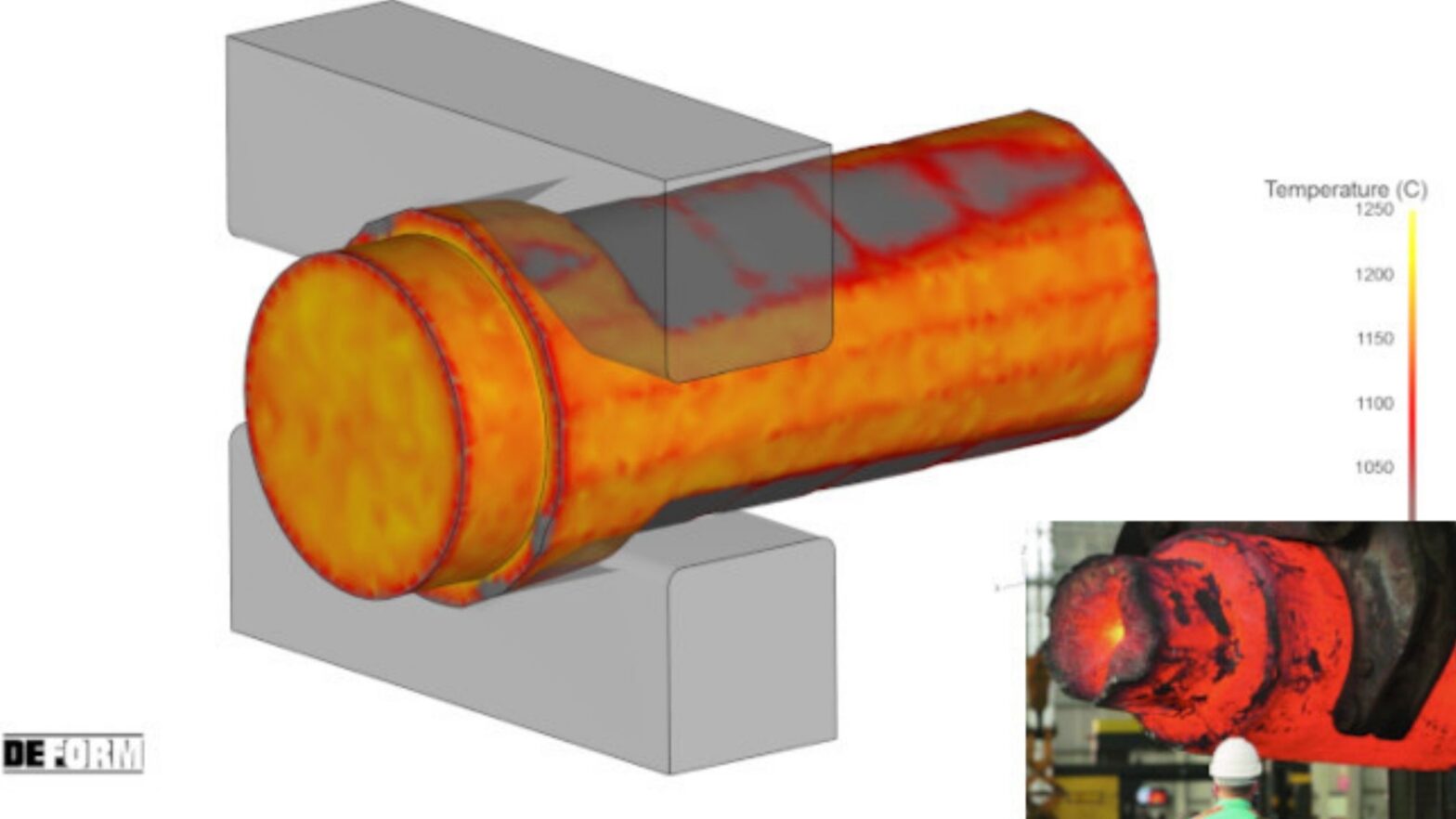

Metal Hot Forming: What it is

Hot forming is a deformation process in which, starting from preheating, the metal is pressed bringing it to the desired shape with the aid of a mold that has the negative shape of the piece. Subsequently we intervene with machining and additional finishes. It is used for small and medium sized components and medium and large production batches.

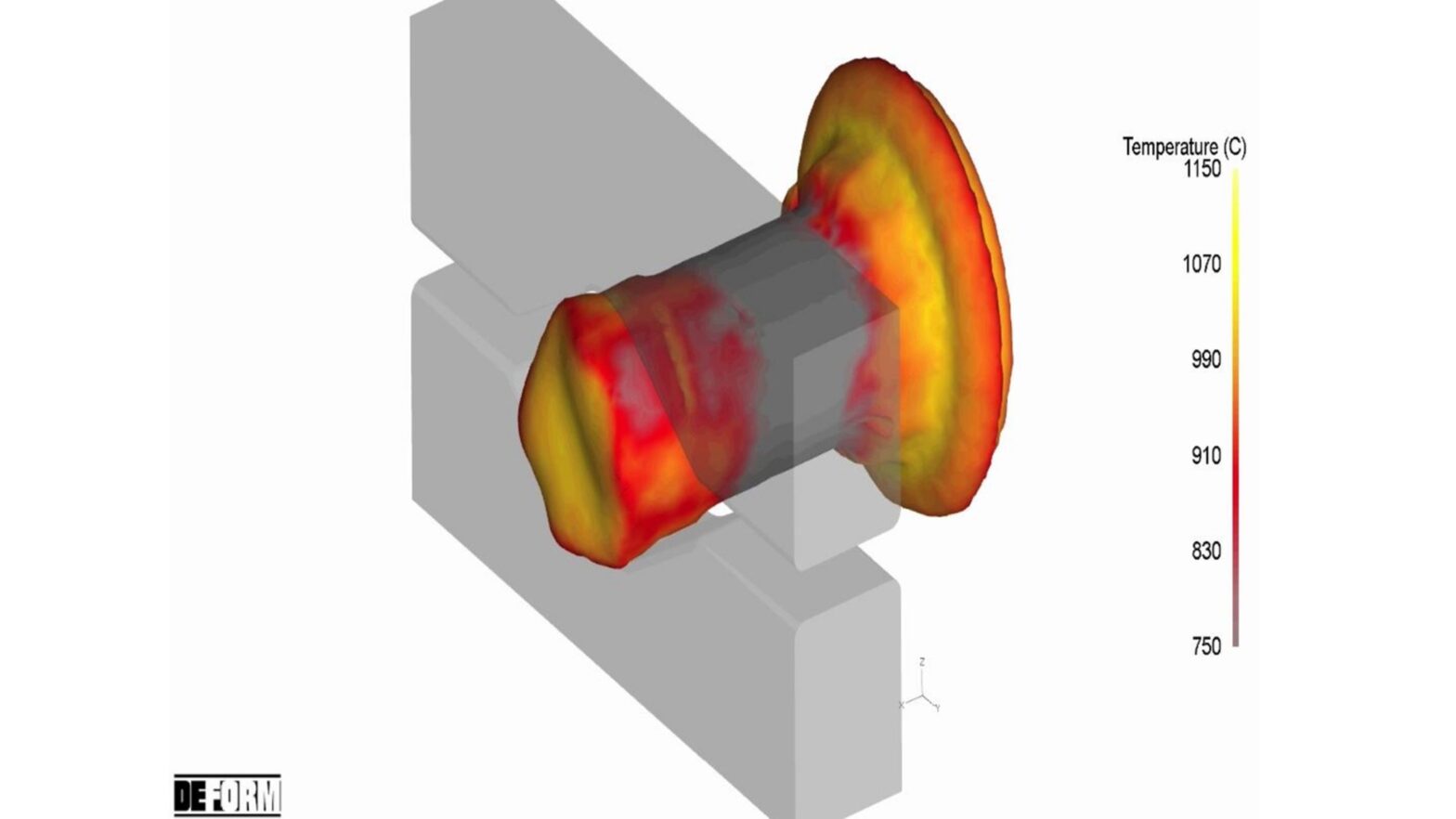

Hot forming simulation: Part forming. Material flows into the mold.

Hot Forming Simulation: How it works

Hot forming simulation of brass, aluminum, steel, titanium and all alloys. DEFORM shows incompleteness, folds, strips, sink marks, cracks, machine loads, wear and mould damage.

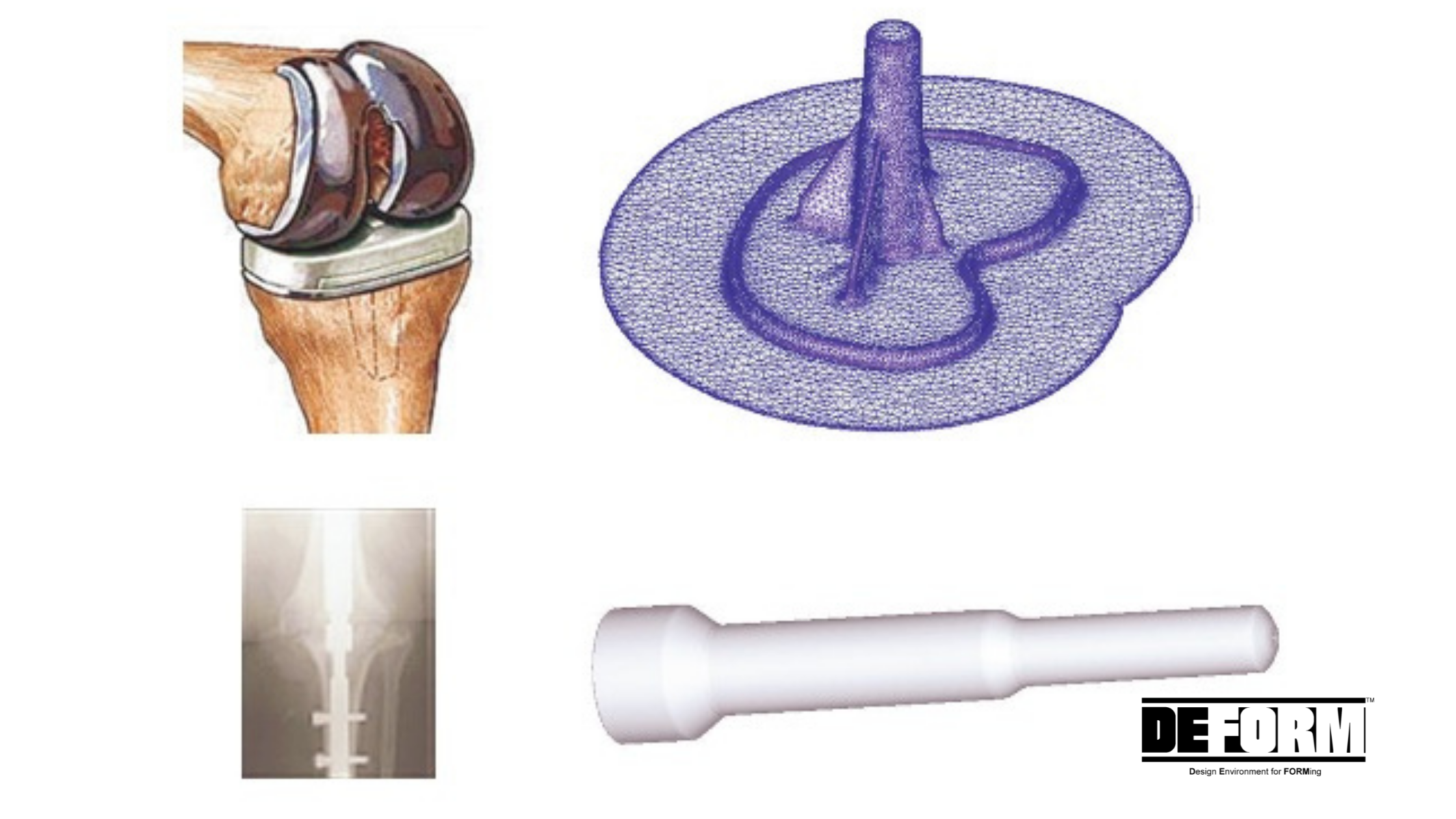

Special "Medical Applications"

DEFORM software is the tool of reference in the medical sector for forming titanium components.

Forges for the hip joint, femoral stems, tibial joints require top performance, guaranteed as expected. DEFORM software allows you to forge them directly at the computer so as to asses production defects and performance in preview. DEFORM is by all means a virtual press allowing you to test, trial and modify the mould and process parameters to achieve a defect-free forge with the required performance.

1) anatomy of the hip joint and position of the prosthetic devices when the hip is not healthy (affected by dysplasia, arthrosis, arthritis or fractured) 2) femoral stem implant (the part of the prothesis that goes into the thighbone) 3) securely fastened 4) tibial joint of the knee (in this case it is a tibial plateau, one of the three components of the knee prothesis) 5) transverse locking screws that fix the revision prosthesis to the bone (that they block the prosthesis to the bone would be more correct, as a matter of fact the figure shows an arthrodesis nail used to block the knee joint).

What customers say about DEFORM:

- EXCELLENT AGREEMENT OF “SOFTWARE RESULTS” WITH “REALITY” DEFORM is the most widely used cold forming simulation software in the world

- SAMPLING IMMEDIATELY POSITIVE The simulation makes it possible to identify defects obtained during forming, to understand their causes and therefore to undertake the right corrective actions

- STARTING TIMES REDUCED TO A MINIMUM The press setting was already tested in simulation. The real sampling will dispose of the machine setup card already defined.

- CERTAIN RAW MATERIAL PROCUREMENT The DEFORM deforming simulation makes it possible to assess different extruded item diameters and therefore to immediately identify the diameter for each code

- REQUIRED PRESS DEFINITION DEFORM indicates the required tonnage for each workstation and therefore indicates which machine is necessary for the process. Planning of samplings and production

- LONGER MOULD DURATION Tool wear known and reduced thanks to modified mould mechanics. Mould damage phenomena eliminated because expected and therefore taken care of in simulation

For the purchase, hire or a DEMO of the software or if you want to take advantage of a simulation service specially-made by our technical department, write or call us at +39 030 3365383