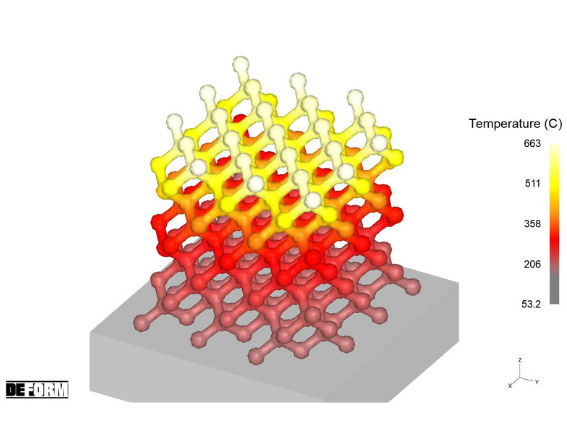

DEFORM benefits Cost reduction Reject reduction Production and delivery time reduction Component design improvement Component efficiency improvement Production of defect-free objects with reduced residual stresses Additive Manufacturing: What it is Additive Manufacturing consists of a set of processes for the creation of components, starting from their 3D CAD models, through the binding of material through… Continue reading Additive Manufacturing

DEFORM Benefits: reduction of residual stresses greater workability enhanced ductility Heat Treatments of Annealing: What it is The annealing heat treatment of a metal alloy is a process consisting of heating a piece at a temperature higher than that of austenitizing, followed by a dwell time sufficient to transform it completely into austenite and a… Continue reading Annealing

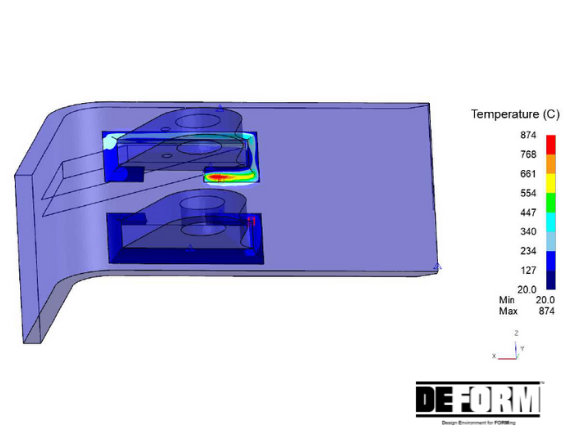

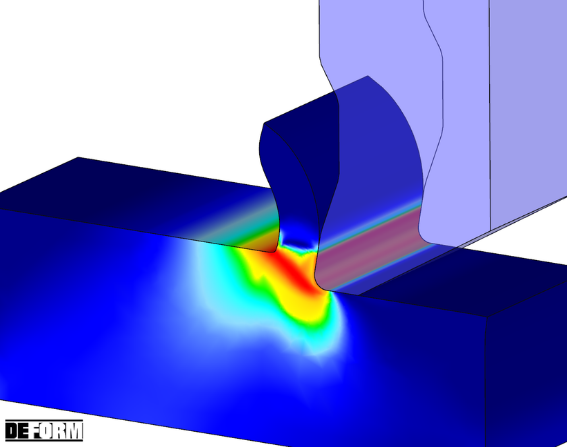

DEFORM Benefits: High quality welded products Elimination of rejects and reduction of defects Elimination of samplings Improved mechanical features of the workpiece Greater strength of the workpiece Reduced welding times Reduced welding costs Arc Welding: What it is Arc welding is called this way due to the electric arc generated between the electrode and the… Continue reading Arc Welding

DEFORM Benefits Quality improvement Optimization and saving in the design Improvement of production Enhanced precision Flexibility of use Reduction of calculation times Reduction of production rejects Saves money Bending of metals: What it is Bending is a mechanical process that entails the permanent deformation of the metal object by applying bending forces. This type of… Continue reading Bending

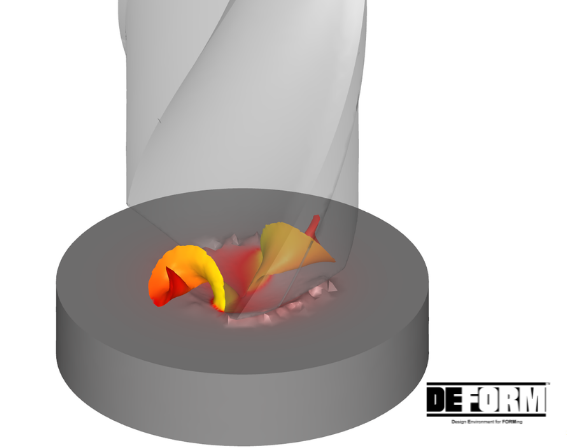

DEFORM Benefits: Quality improvement Optimization and saving in the design Improvement of production Enhanced precision Flexibility of use Reduction of calculation times Reduction of production rejects Saves money Machining of Boring: What it is Boring is a mechanical process for the removal of swarf to obtain high precision holes. It is one of the most… Continue reading Boring

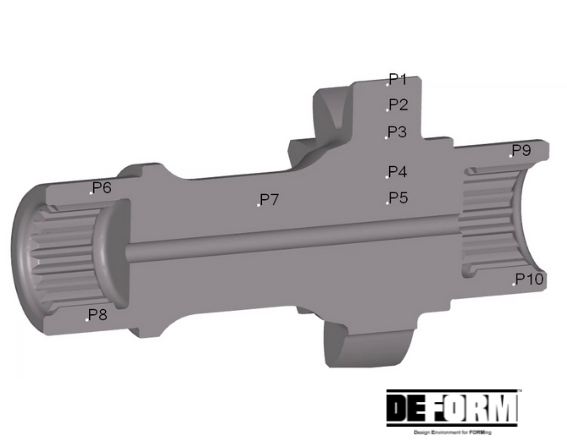

DEFORM Benefits: Optimisation of tolerances required on teeth Elimination of rejects and reduction of defects Elimination of samplings Optimisation of the size of the profile of the teeth Less time in producing new or already existing components Correction of design errors before physical trials Improvement of process quality Improved mechanical features of the workpiece Greater… Continue reading Broaching

DEFORM Benefits Quality improvement Optimization and saving in the design Improvement of production Enhanced precision Flexibility of use Reduction of calculation times Reduction of production rejects Saves money Thermochemical Treatments of Carburization: What it is Simulation of carburization and therefore diffusion of carbon in the metal matrix. Thermal chemical treatments, such as carburization, carbonitriding, gas… Continue reading Carburization

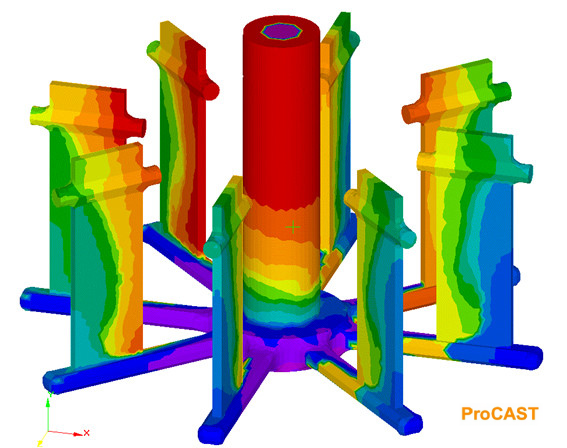

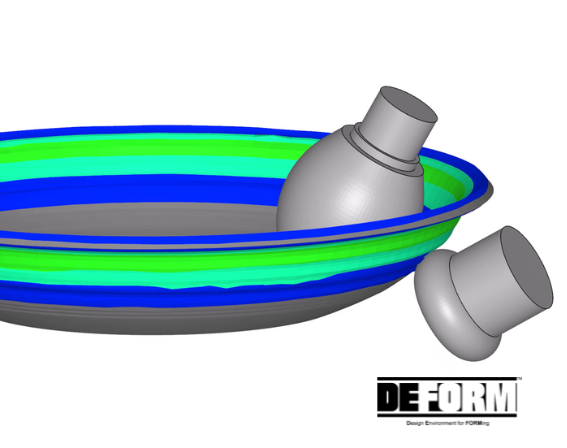

Benefits with QuikCAST and ProCAST Software Quality improvement Optimization and saving in the design Improvement of production Enhanced precision Flexibility of use Reduction of calculation times Reduction of production rejects Saves money Centrifugal Casting: What it is Centrifugal casting is a melting process of metals in which liquid metal, cast into a metal or refractory… Continue reading Centrifugal Casting

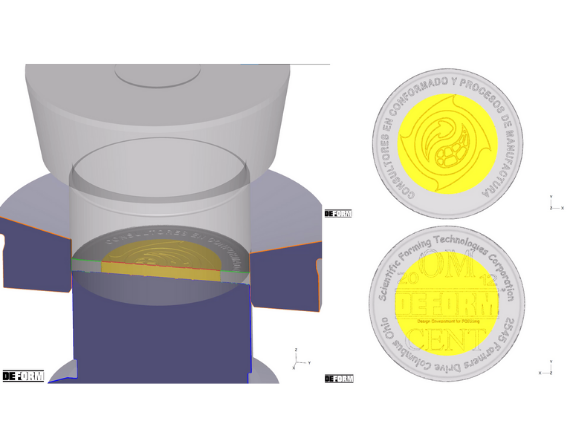

DEFORM Benefits cost reduction reject reduction production and delivery time reduction component design improvement component efficiency improvement improved die duration Coining: What it is Coining is a modelling operation by compression of the metal that generates different thicknesses and shapes on the processed object. A punch, housed inside a mould driven by a press, generates… Continue reading Coining

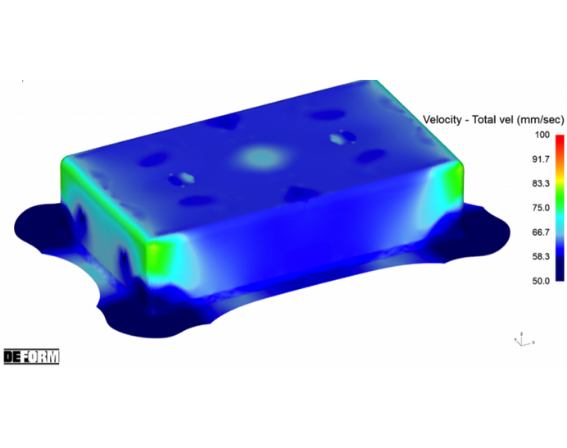

DEFORM Benefits Quality improvement Optimization and saving in the design Improvement of production Enhanced precision Flexibility of use Reduction of calculation times Reduction of production rejects Saves money Metal Cold Forming: What it is Cold forming is a deformation process carried out by presses which compress material, bringing it to the desired shape with the… Continue reading Cold Forming

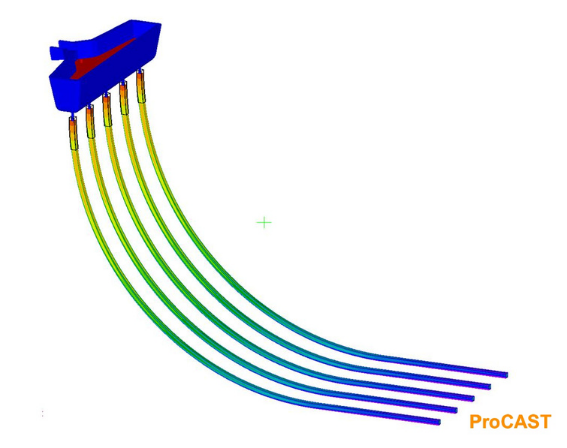

Benefits with QuikCAST and ProCAST Software quality improvement optimization and saving in the design improvement of production enhanced precision flexibility of use reduction of calculation times reduction of production rejects saves money Continuous Casting: What it is Continuous casting is a process during which molten metal is poured into an open and oscillating mould called… Continue reading Continuous Casting

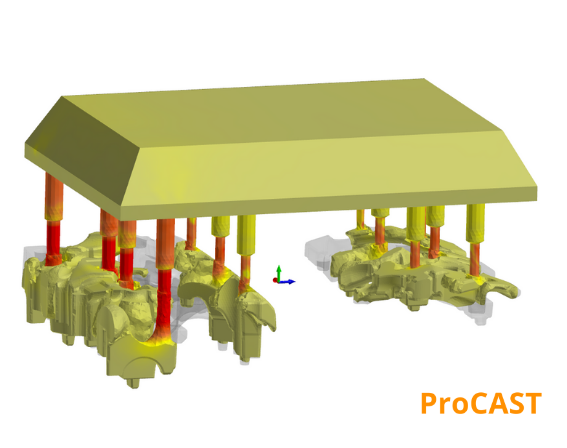

QuikCAST and ProCAST Software Benefits Quality improvement Optimization and saving in the design Improvement of production Enhanced precision Flexibility of use Reduction of calculation times Reduction of production rejects Saves money Core Blowing: What it is The core blowing process is carried out using core blowing machines which, in a few instants, fill and compact… Continue reading Core Blowing

DEFORM Benefits Quality improvement Optimization and saving in the design Improvement of production Enhanced precision Flexibility of use Reduction of calculation times Reduction of production rejects Saves money Deep Drawing: What it is Deep drawing is a metallurgical process through which sheet metal is plastically deformed to take on a cylindrical or cup like box… Continue reading Deep Drawing

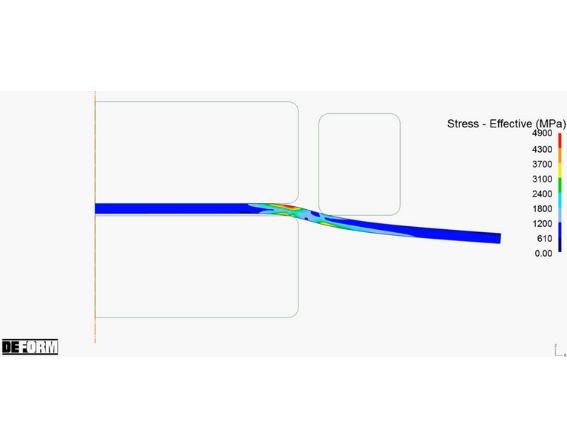

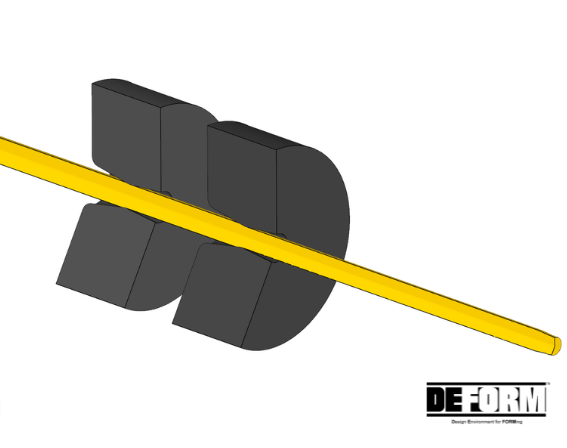

DEFORM Benefits Quality improvement Optimization and saving in the design Improvement of production Enhanced precision Flexibility of use Reduction of calculation times Reduction of production rejects Saves money Drawing of metals: What it is Drawing is a cold plastic deformation process, in which the workpiece is forced by means of a tensile force to pass… Continue reading Drawing

DEFORM Benefits: Quality improvement Optimization and saving in the design Improvement of production Enhanced precision Flexibility of use Reduction of calculation times Reduction of production rejects Saves money Machining of Drilling: What it is Drilling is a process for the removal of swarf to make holes by using a rotary and translating tool in an… Continue reading Drilling

DEFORM Benefits Quality improvement Optimization and saving in the design Improvement of production Enhanced precision Flexibility of use Reduction of calculation times Reduction of production rejects Saves money Edging: What it is Sheet metal edging is a type of sheet metal processing which consists in bending a sheet metal at 180°, creating a real circular… Continue reading Edging

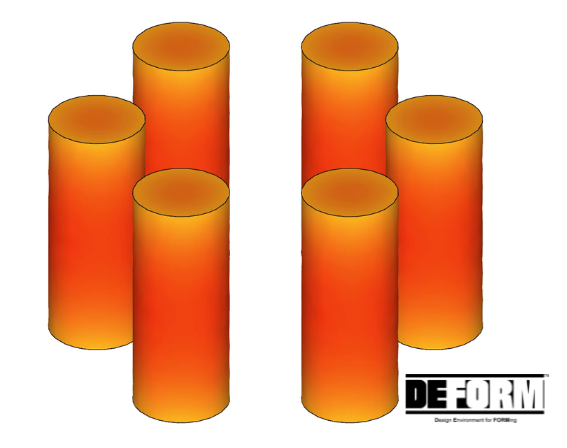

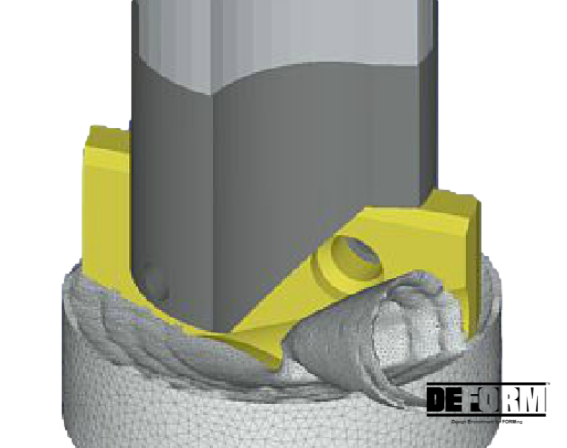

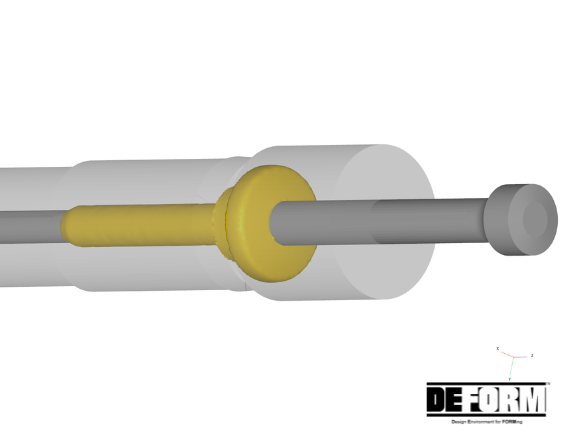

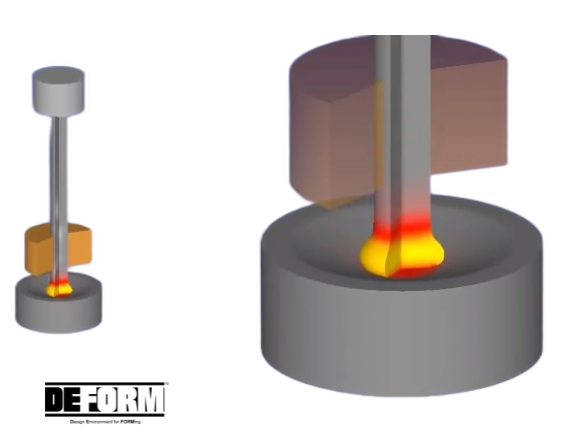

DEFORM Benefits cost reduction reject reduction production and delivery time reduction component design improvement component efficiency improvement improved mould duration Electrical Upsetting: What it is Electrical upsetting is a thermal-mechanical process, representing an evolution in hot forming, in which the metal segment is heated through electrical conduction and at the same time deformed through pressing… Continue reading Electrical Upsetting

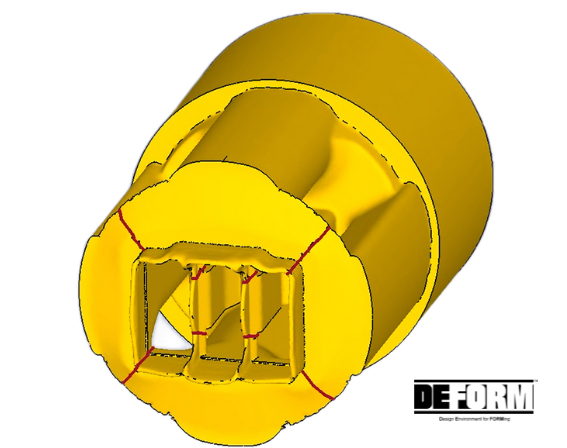

DEFORM Benefits Quality improvement Optimization and saving in the design Improvement of production Enhanced precision Flexibility of use Reduction of calculation times Reduction of production rejects Saves money Extrusion of metals: What it is Extrusion is an industrial plastic deformation production process that allows making pieces with a constant section (for example pipes, bars, profiles,… Continue reading Extrusion