DEFORM Benefits

- Quality improvement

- Optimization and saving in the design

- Improvement of production

- Enhanced precision

- Flexibility of use

- Reduction of calculation times

- Reduction of production rejects

- Saves money

Machining of Milling: What it is

Milling is a mechanical swarf removal process allowing to obtain a wide range of surfaces, cuts, incisions, cavities, shapes and holes on the workpiece. The process is carried out by a tool called a milling machine, with a rotary motion around its axis and a forward motion.

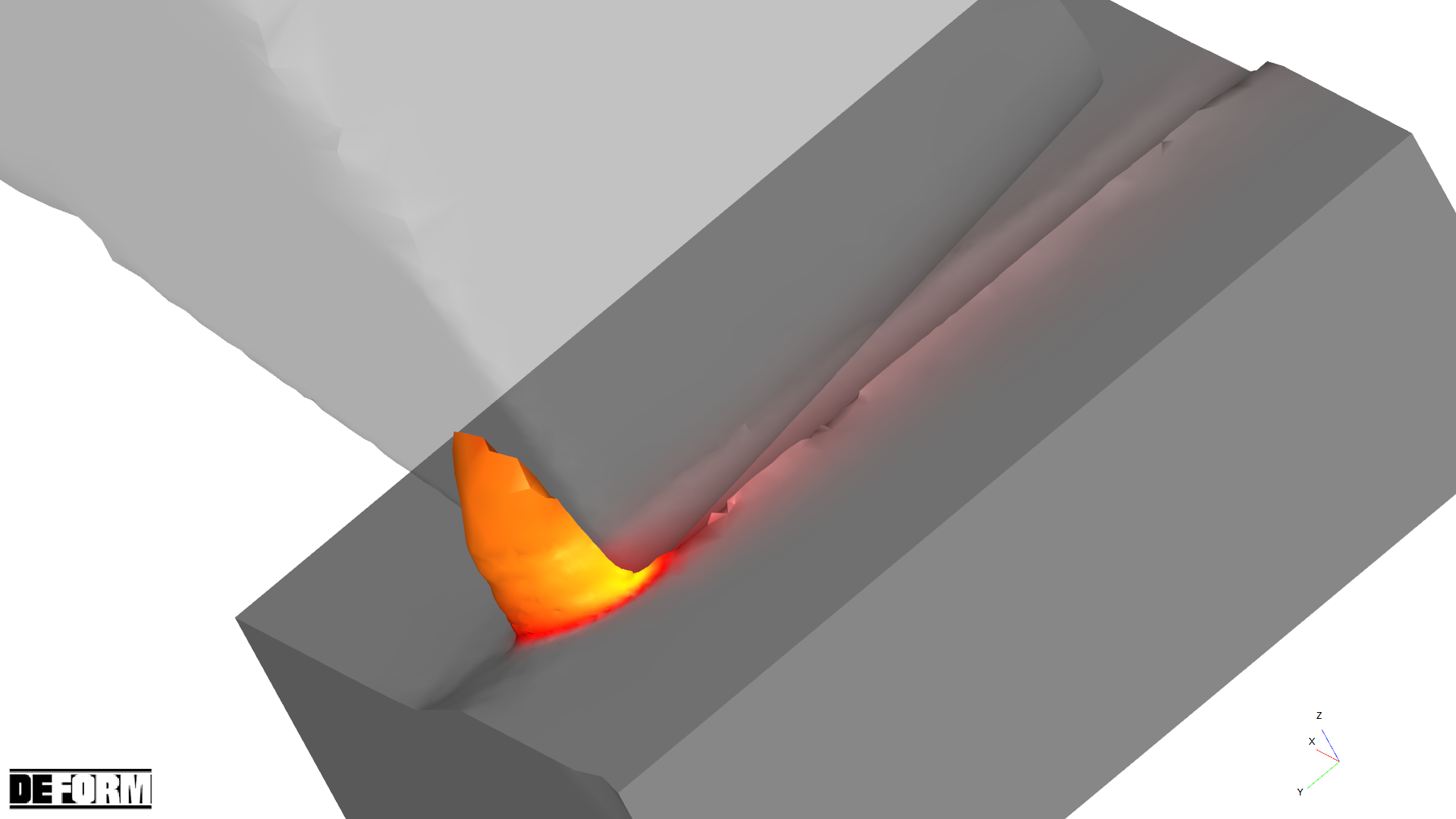

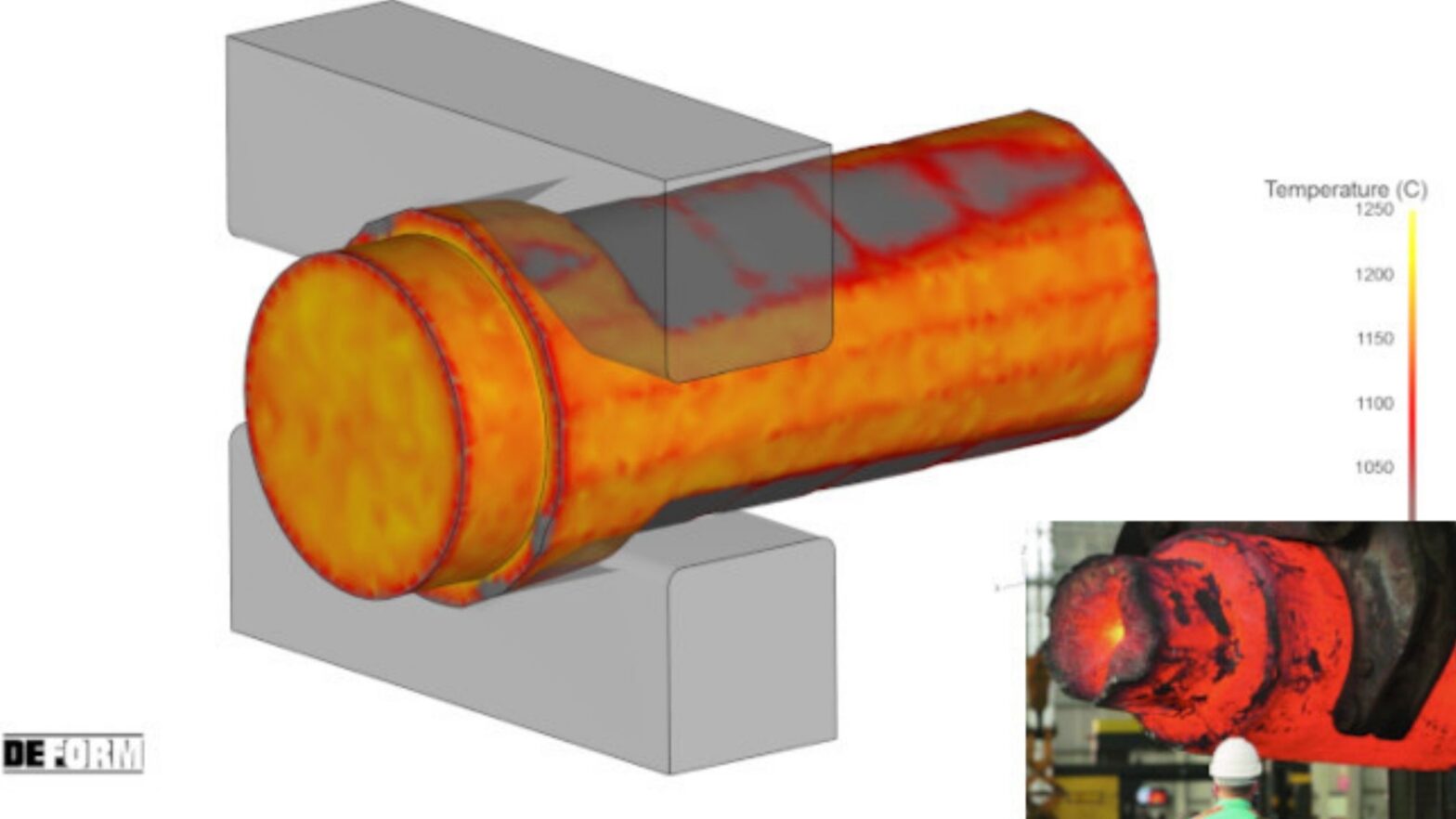

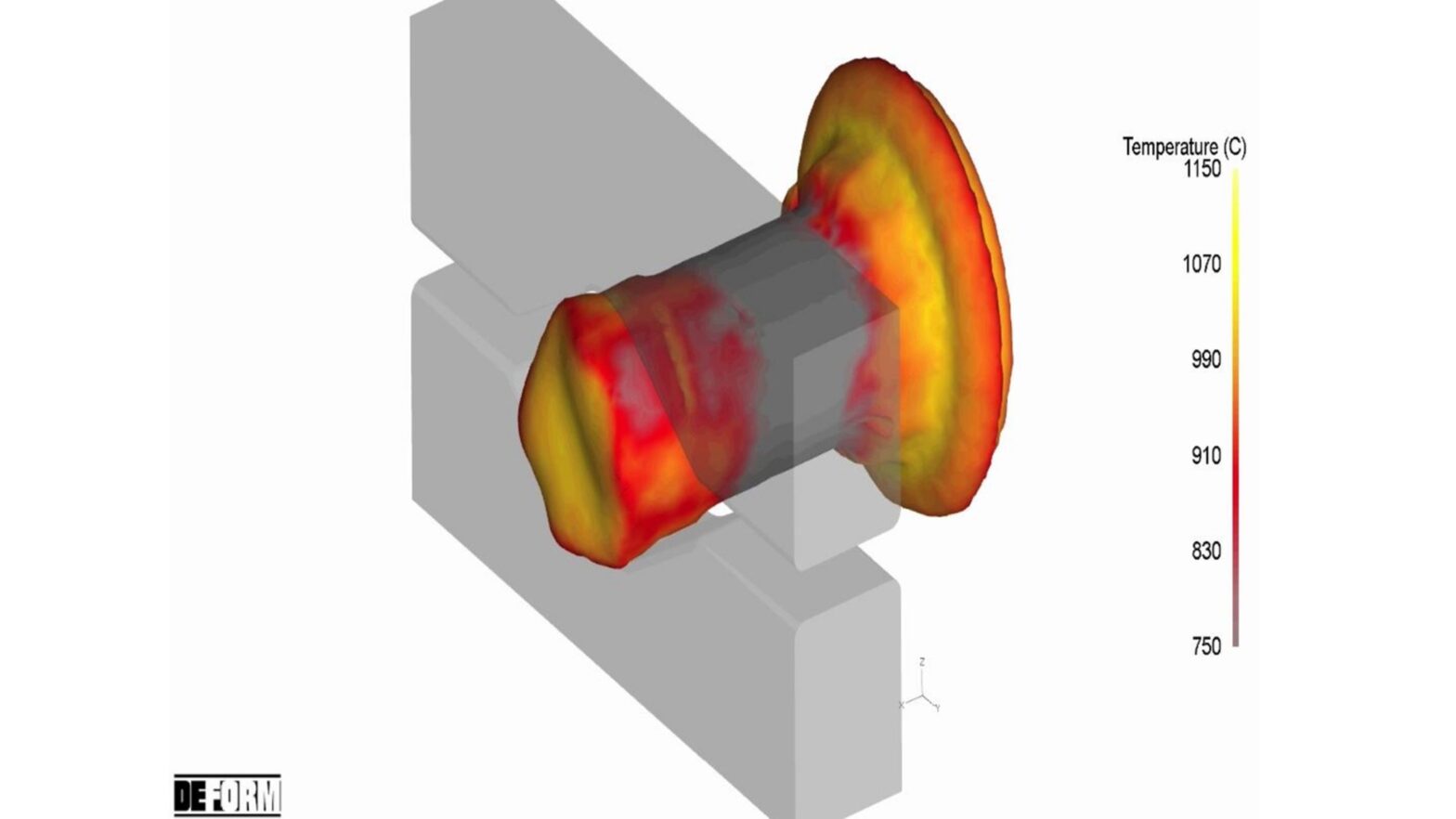

Milling simulation for the calculation of tool wear.

Milling Simulation: How it works

The DEFORM milling simulation software is a practical and effective tool for designers and engineers that can predict the flow of material in milling operations, realistically showing movement of all the axes, both rotary and linear, and eliminating any critical condition.

Based on the finished components, the software has proved to be precise and resistant in industrial applications for over two decades. The simulation engine is capable of predicting with surprising precision a great flow of material deformation and thermal behaviour. DEFORM is the most innovative and used milling simulation program in the world by major research institutes and manufacturers.

It is a tool dedicated to production and therefore simple and intuitive to use, which can be understood not only by operators with great experience in the field. The technical operator, the quality department and the technical department will use milling simulation daily to address problems with the process.

DEFORM can also be used in parallel by the Research & Development department for new products. The Americans, manufacturers of DEFORM, came up with a complete, simple and fast software.

What customers say about DEFORM:

- EXCELLENT AGREEMENT OF “SOFTWARE RESULTS” WITH “REALITY” DEFORM is the most widely used cold forming simulation software in the world

- SAMPLING IMMEDIATELY POSITIVEThe simulation makes it possible to identify defects obtained during forming, to understand their causes and therefore to undertake the right corrective actions

- STARTING TIMES REDUCED TO A MINIMUM The press setting was already tested in simulation. The real sampling will dispose of the machine setup card already defined.

For the purchase, hire or a DEMO of the software or if you want to take advantage of a simulation service specially-made by our technical department, write or call us at +39 030 3365383