DEFORM Benefits

- Quality improvement

- Optimization and saving in the design

- Improvement of production

- Enhanced precision

- Flexibility of use

- Reduction of calculation times

- Reduction of production rejects

- Saves money

Drawing of metals: What it is

Drawing is a cold plastic deformation process, in which the workpiece is forced by means of a tensile force to pass through a tool called die, whose diameter decreases bit by bit until reaching the desired diameter; this results in a product with a reduced section, elongated and extremely hardened. The specific feature of the drawing process is that of guaranteeing high dimensional precision, ideal superficial finish and to provide high mechanical characteristics downstream of the process. Products often undergo heat treatments after drawing to facilitate the subsequent deformation processes.

This process is widely used to produce pipes, bars and wires.

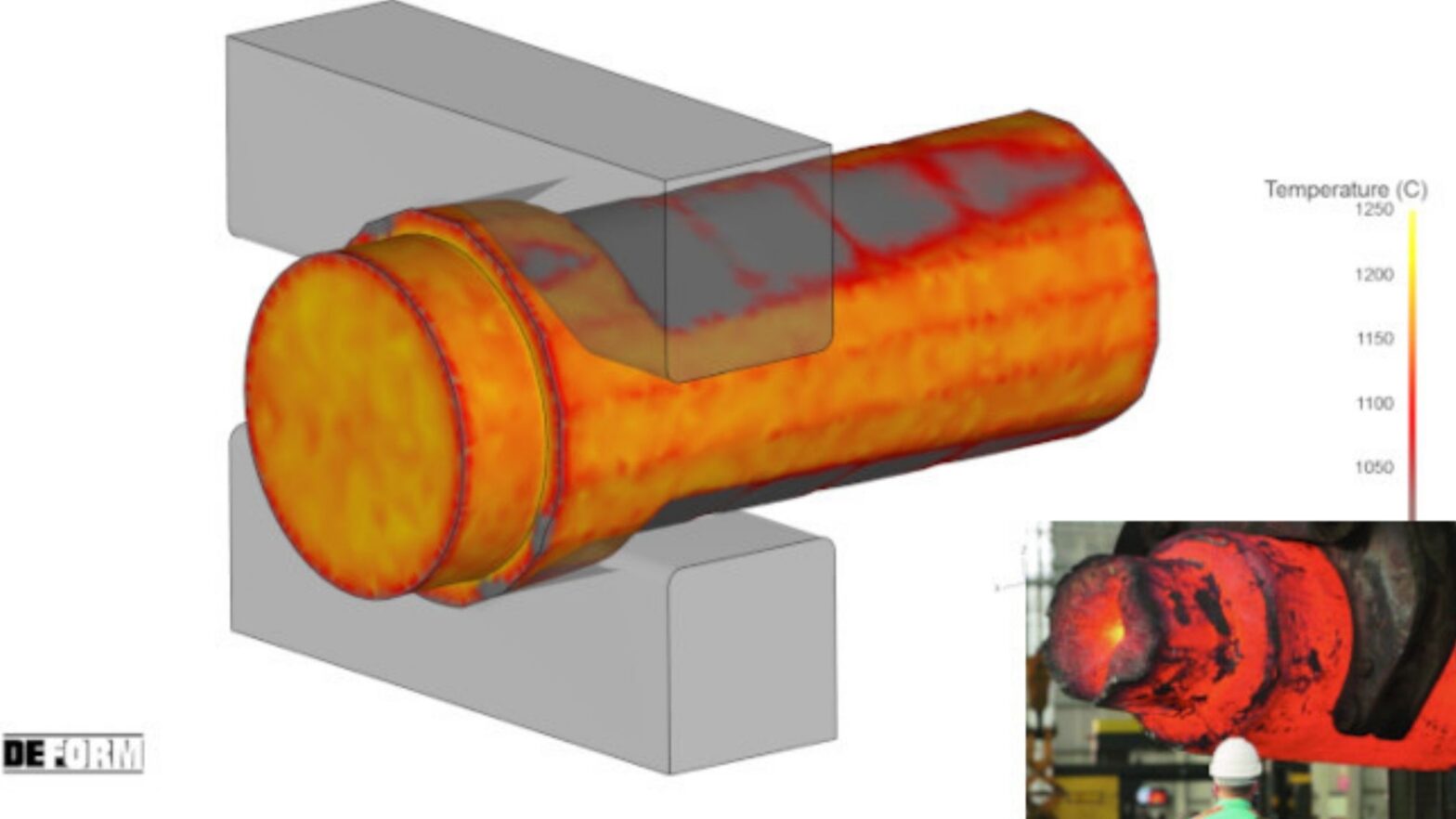

Drawing Simulation: How it works

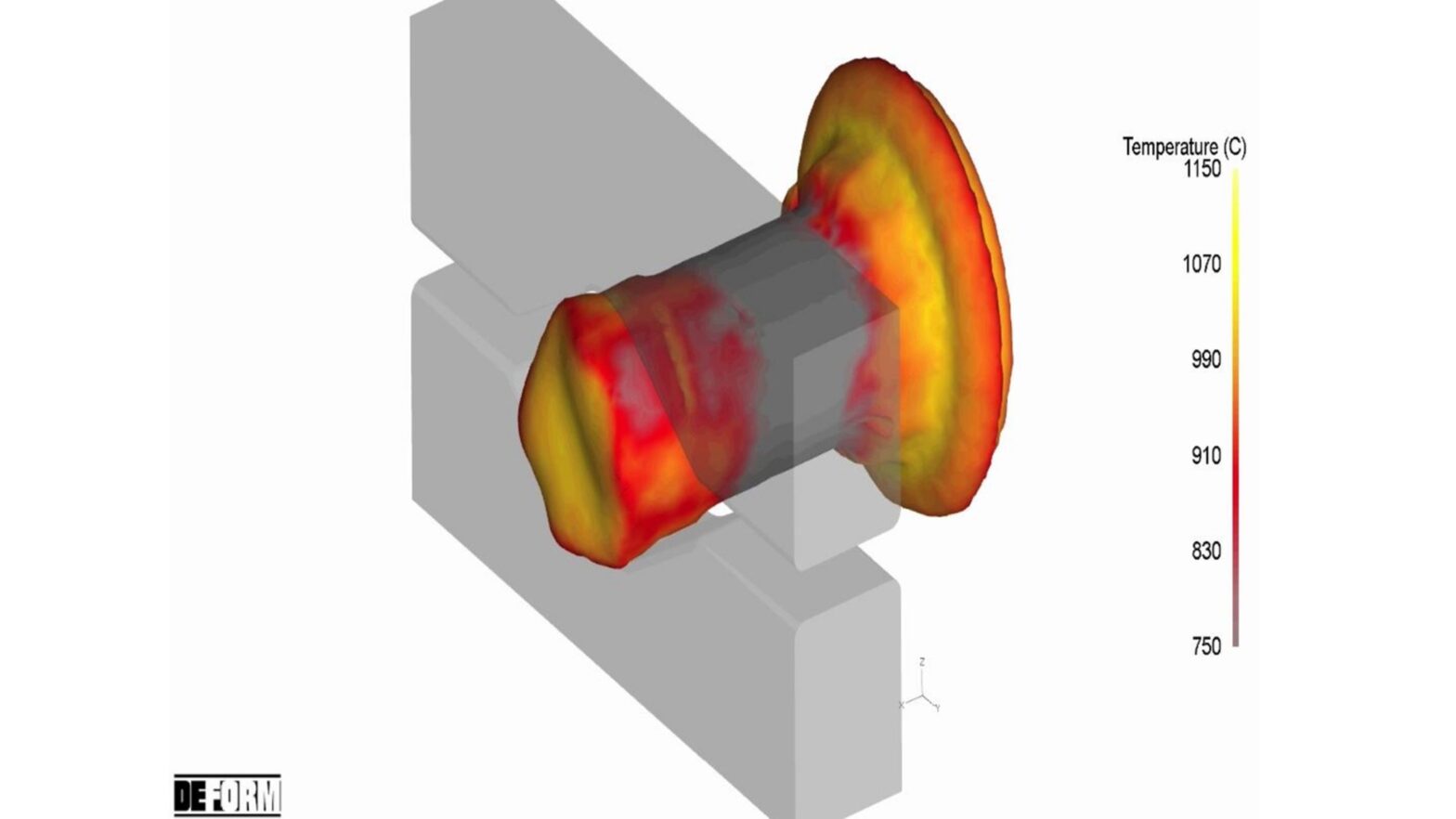

Drawing simulation makes it possible to avoid cracks and internal lacerations, resolving fatigue life problems of the equipment.

DEFORM drawing simulation software, designed to work on desktop PC or standard 6, 8 and 12 core workstations, allows you to verify the entire upstream process, in particular analysing and evaluating the heat treatment that the machine and wire will undergo, so as to control dynamics involving outfeed of the workpiece.

DEFORM is a tool dedicated to production and is therefore simple to use. The Americans, manufacturers of DEFORM, came up with a complete, simple and fast software.

What customers say about DEFORM:

- EXCELLENT AGREEMENT OF “SOFTWARE RESULTS” WITH “REALITY” DEFORM is the most widely used cold forming simulation software in the world

- SAMPLING IMMEDIATELY POSITIVEThe simulation makes it possible to identify defects obtained during forming, to understand their causes and therefore to undertake the right corrective actions

- STARTING TIMES REDUCED TO A MINIMUM The press setting was already tested in simulation. The real sampling will dispose of the machine setup card already defined.

- CERTAIN RAW MATERIAL PROCUREMENTThe DEFORM deforming simulation makes it possible to assess different extruded item diameters and therefore to immediately identify the diameter for each code

- REQUIRED PRESS DEFINITION DEFORM indicates the required tonnage for each workstation and therefore indicates which machine is necessary for the process. Planning of samplings and production

- LONGER MOULD DURATION Tool wear known and reduced thanks to modified mould mechanics. Mould damage phenomena eliminated because expected and therefore taken care of in simulation

For the purchase, hire or a DEMO of the software or if you want to take advantage of a simulation service specially-made by our technical department, write or call us at +39 030 3365383