DEFORM Benefits

- cost reduction

- reject reduction

- production and delivery time reduction

- component design improvement

- component efficiency improvement

- improved die duration

Coining: What it is

Coining is a modelling operation by compression of the metal that generates different thicknesses and shapes on the processed object. A punch, housed inside a mould driven by a press, generates pressure on the material and moulds it, modifying its shape.

The coining of coins is the transfer process of a drawing from a die to a metal round bar, by using two metal punches (cones) which impress the negative of the chosen images to mark the coins.

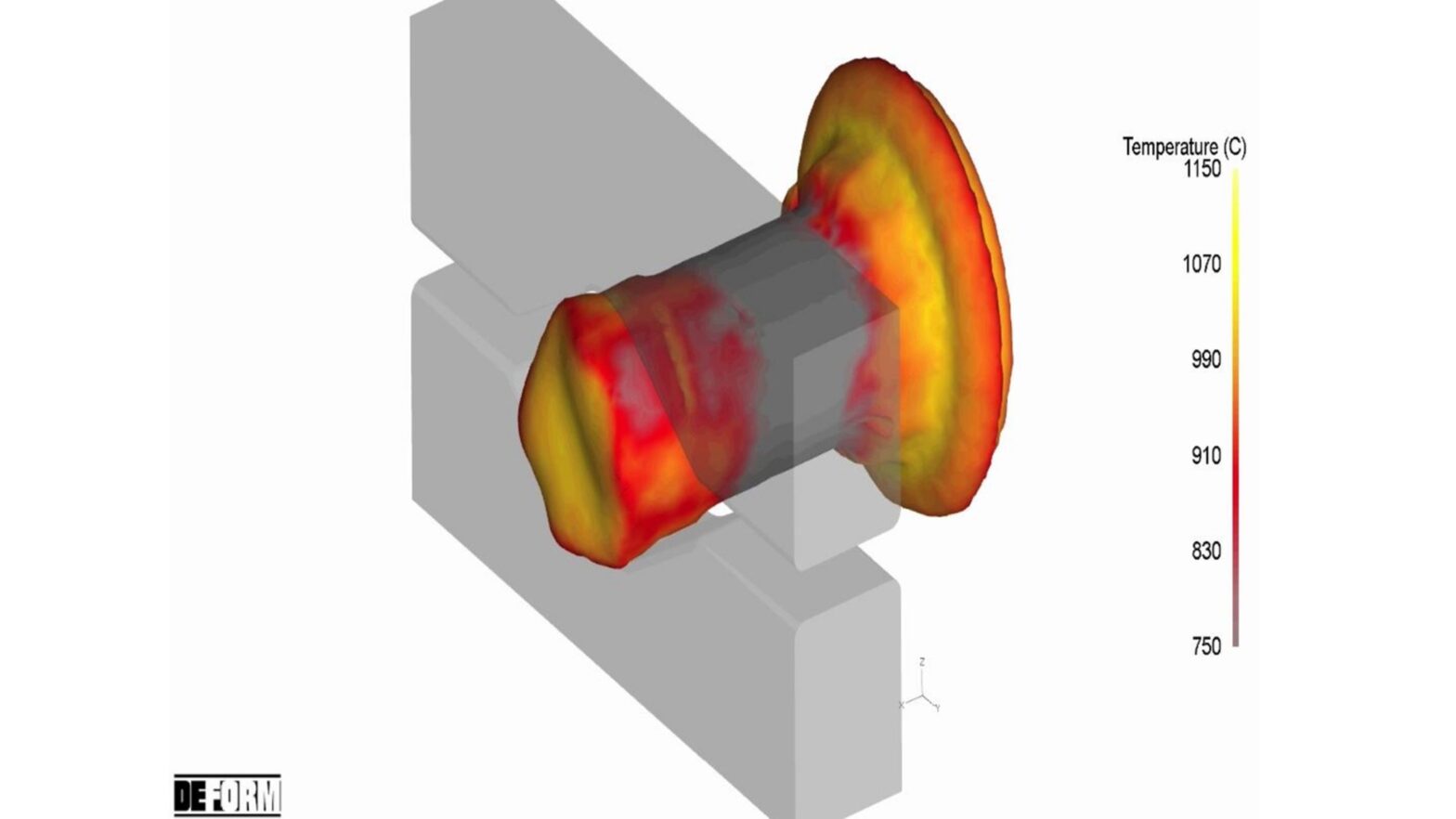

Coining Simulation of a bi-metallic coin

Coining Simulation: How it works

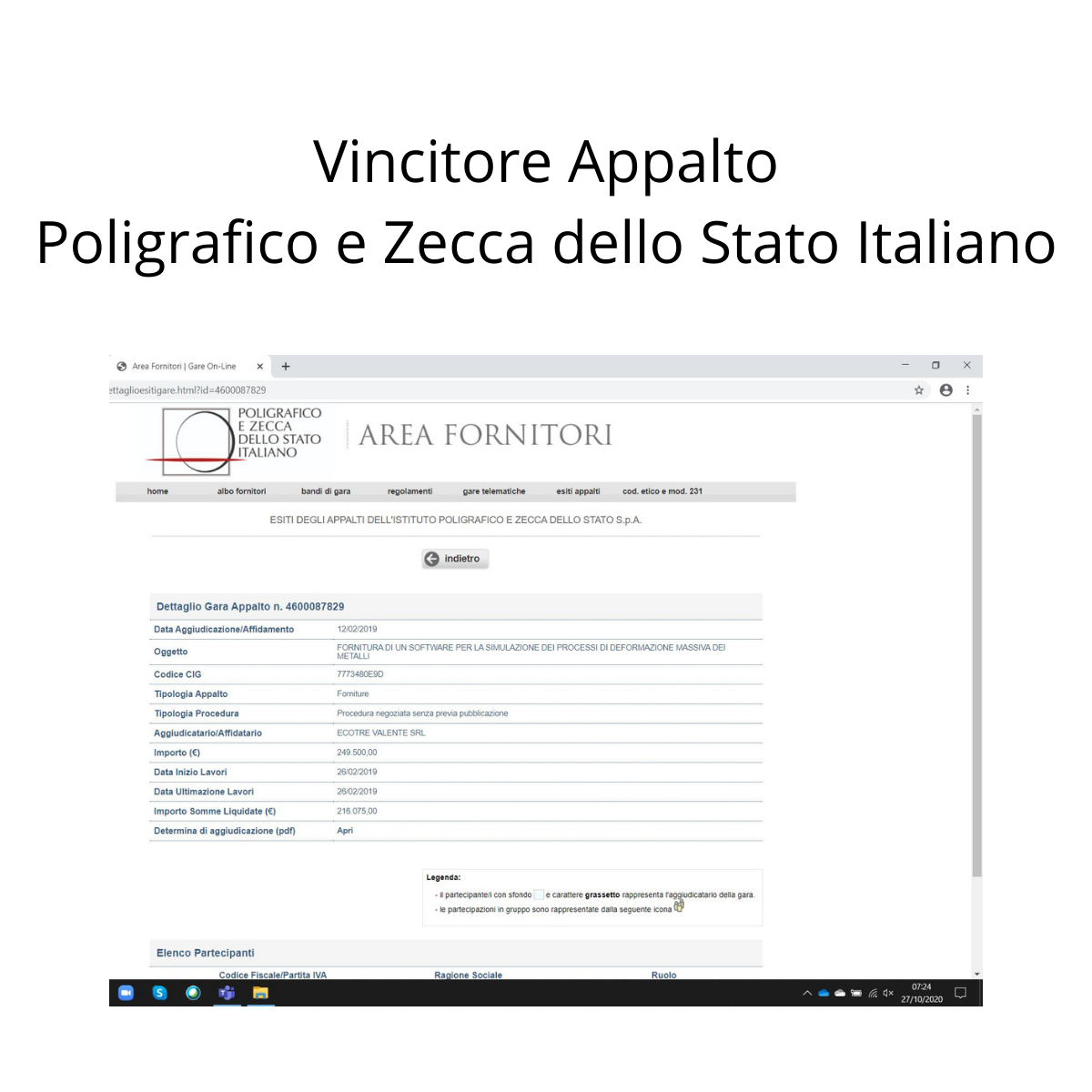

DEFORM simulation software is the only one of its kind capable of replicating coining, without wasting material and with real results.

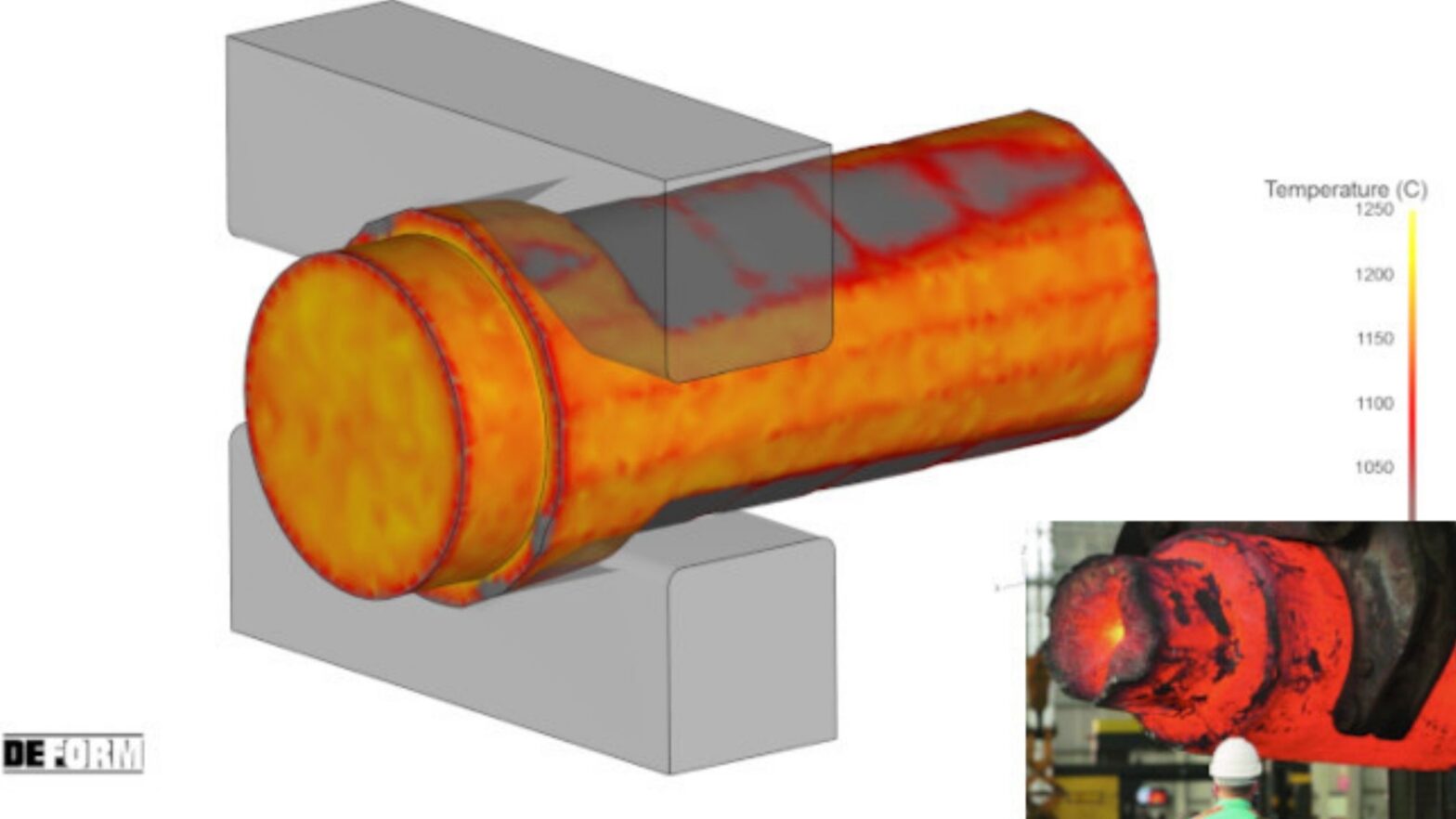

For example, for a bi-metallic coin with a stainless steel core and a copper edge mechanically joined during final forming, the result of the simulation shows the formed coin, with 1.3 million elements in the core and 1 million elements in the edge. The die used in this coining process engraved the text and all the other details. A considerable amount of elements is required to analyse stresses: approximately 2 million mesh elements. An analysis was also carried out uncoupled from mould stress.

DEFORM is capable of magnifying details of the simulated coin with an unprecedented resolution.

What customers say about DEFORM:

DEFORM coining simulation software is American and has been optimised to be reliable, quick and easy.

- EXCELLENT AGREEMENT OF “SOFTWARE RESULTS” WITH “REALITY” DEFORM is the most widely used cold forming simulation software in the world

- SAMPLING IMMEDIATELY POSITIVEThe simulation makes it possible to identify defects obtained during forming, to understand their causes and therefore to undertake the right corrective actions

- STARTING TIMES REDUCED TO A MINIMUM The press setting was already tested in simulation. The real sampling will dispose of the machine setup card already defined.

- REQUIRED PRESS DEFINITION DEFORM indicates the required tonnage for each workstation and therefore indicates which machine is necessary for the process. Planning of samplings and production

- LONGER MOULD DURATION Tool wear known and reduced thanks to modified mould mechanics. Mould damage phenomena eliminated because expected and therefore taken care of in simulation

For the purchase, hire or a DEMO of the software or if you want to take advantage of a simulation service specially-made by our technical department, write or call us at +39 030 3365383