DEFORM benefits

- Cost reduction

- Reject reduction

- Production and delivery time reduction

- Component design improvement

- Component efficiency improvement

- Production of defect-free objects with reduced residual stresses

Additive Manufacturing: What it is

Additive Manufacturing consists of a set of processes for the creation of components, starting from their 3D CAD models, through the binding of material through layer overlapping, then proceeding on the contrary to traditional subtractive processes to remove swarf.

Additive manufacturing allows you to build the workpiece through the application of thin metal powder layers melted or sintered by a laser until the complete formation of the workpiece. This technology is used to make shapes, even very complex, designed to achieve greater lightness, while keeping strength intact and guaranteeing the required properties.

Additive Manufacturing simulation: How it works

SFTC, the US company that produces DEFORM software, has developed a new simulation module dedicated to selective laser sintering processes and fused deposition modelling.

DEFORM allows you to design components in 3D printing that meet dimensional and structural requirements, taking account of the specificity of the selected printing technology.

Tools which integrate the structural analysis and material design are required by the aerospace and automotive industry to speed up the introduction of additive manufacturing, to allow for innovative designs so as to achieve the goal of weight reduction, which is essential nowadays. DEFORM allows you to make virtual samplings to verify, on the computer, that the component made by additive manufacturing is compliant.

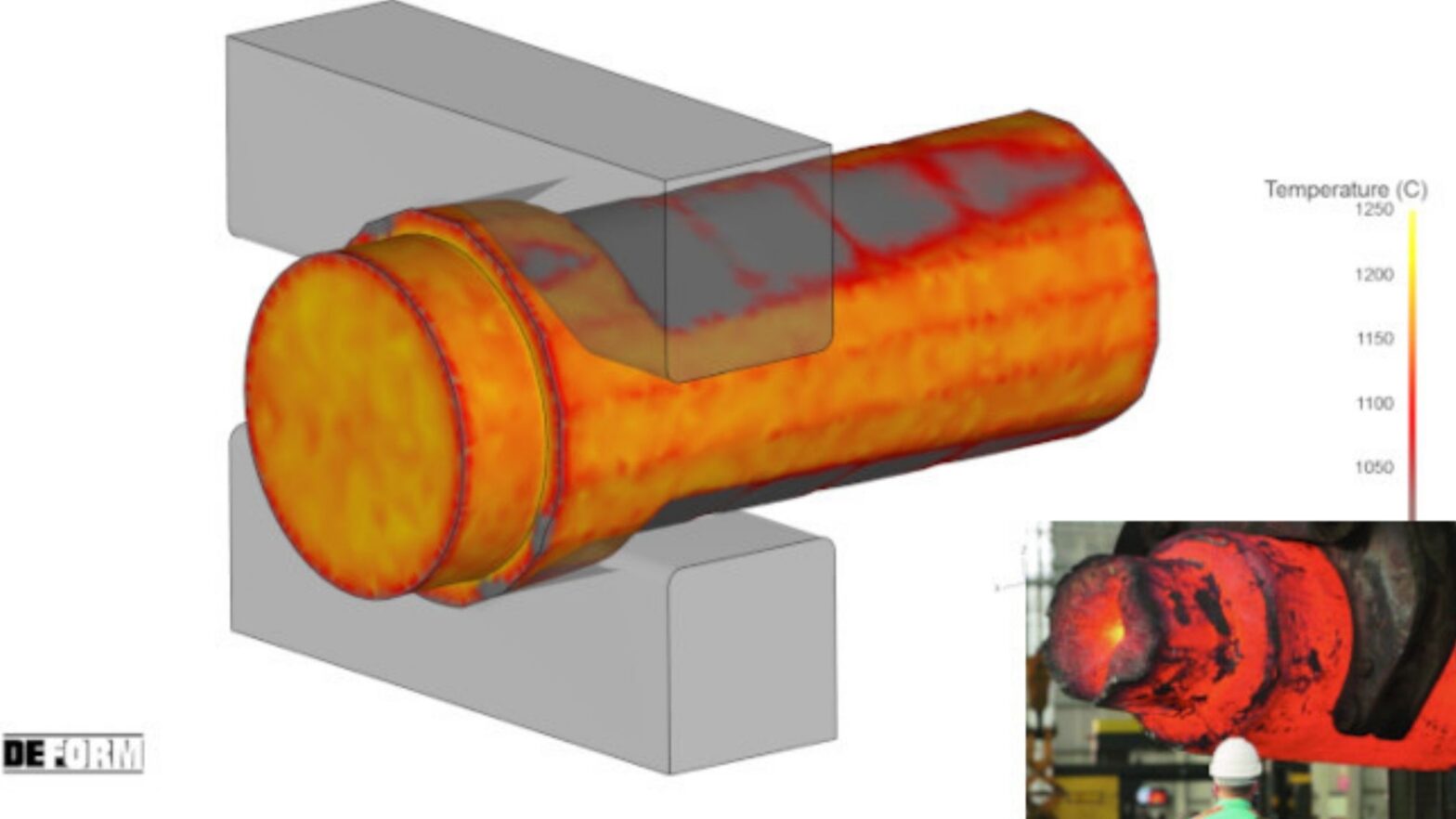

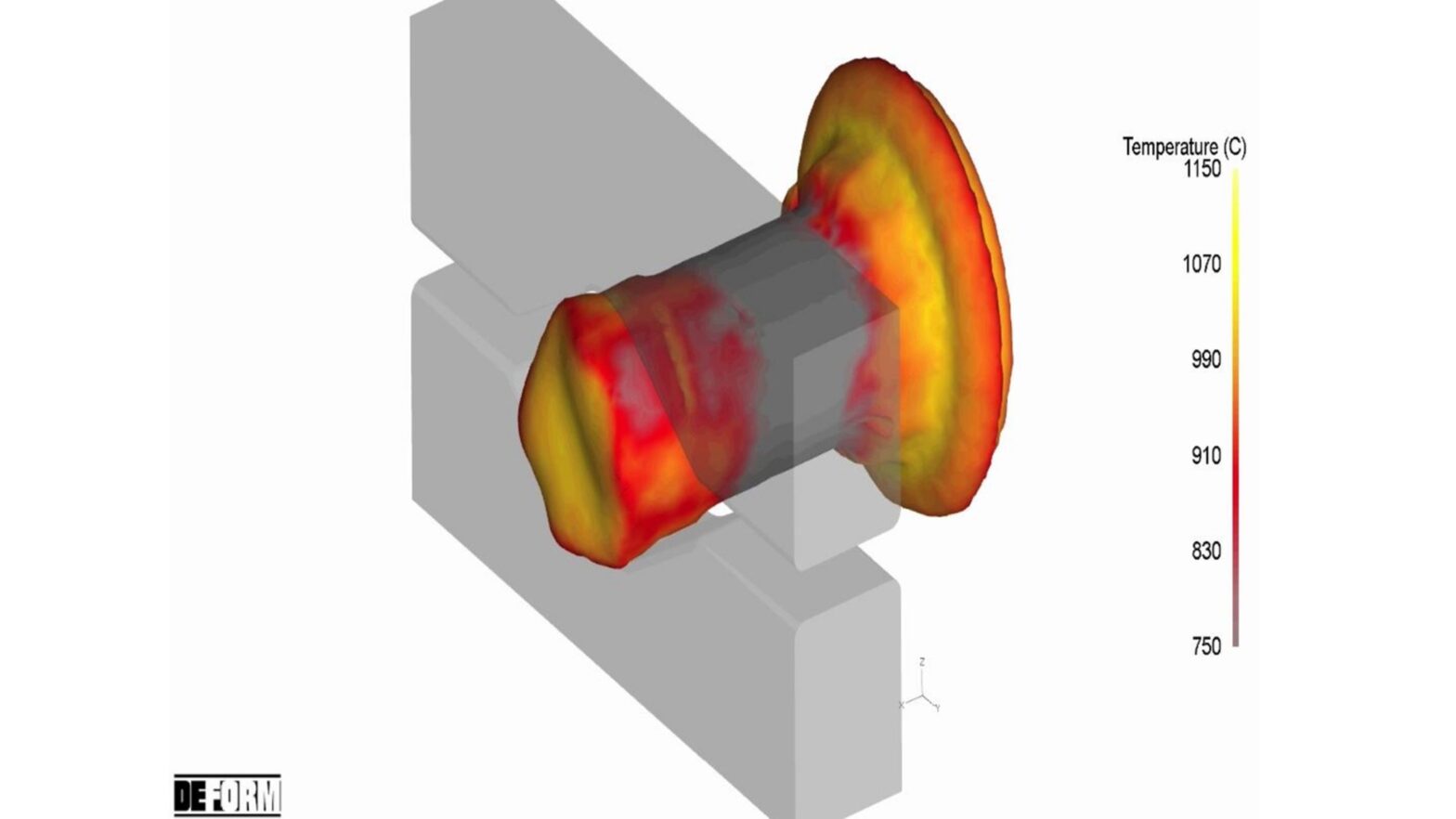

DEFORM simulates the effects of thermal energy, showing the thermal map of the component. These data allow to determine both the deformation and influence of the base plate.

For the purchase, hire or a DEMO of the software or if you want to take advantage of a simulation service specially-made by our technical department, write or call us at +39 030 3365383