DEFORM Benefits:

- High quality welded products

- Elimination of rejects and reduction of defects

- Elimination of samplings

- Improved mechanical features of the workpiece

- Greater strength of the workpiece

- Reduced welding times

- Reduced welding costs

Arc Welding: What it is

Arc welding is called this way due to the electric arc generated between the electrode and the metal to be welded.

It can permanently join two metal pieces using electrodes which act as filler material. Thanks to the very high temperatures reached by way of the electric arc developed between the electrode and basic metal, the two materials can merge together creating the welded joint element.

In this welding, the melting bath must be protected against oxygen in the air. Different systems have been studied for this purpose to isolate the melted zone from contact with air ranging from use of electrode coatings to the use of specific inert gases.

The main types of electric arc welding are:

• manual metal arc welding (MMA)

• submerged arc welding (SAW)

• continuous wire under gaseous protection (MIG/MAG)

• under gaseous protection and with infusible electrode (TIG)

Arc Welding Simulation: How it works

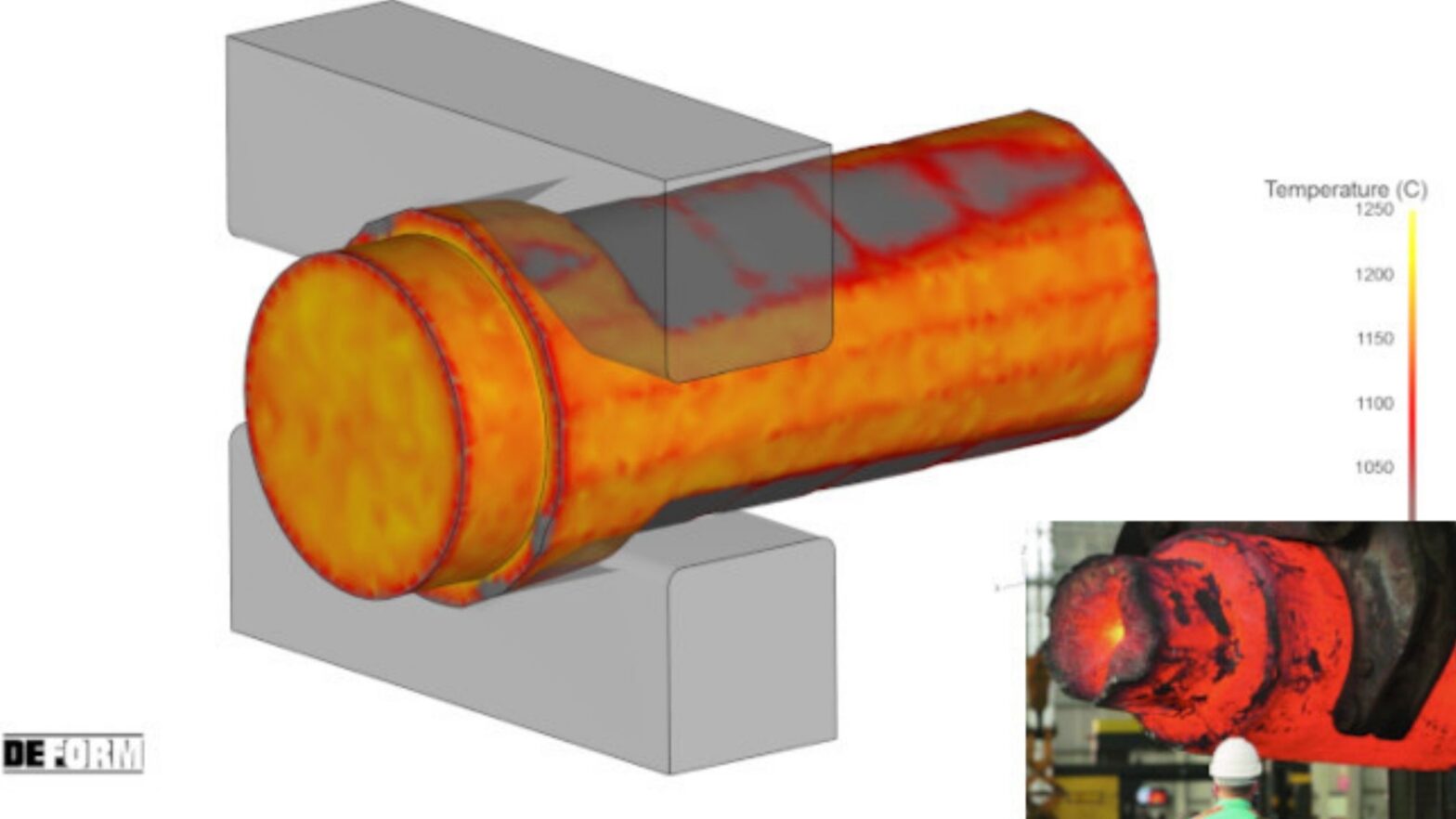

DEFORM, simulation software manufactured by the American SFTC – Scientific Forming Technologies Corporation, is capable of predictably simulating on computer the entire arc welding process in its different types.

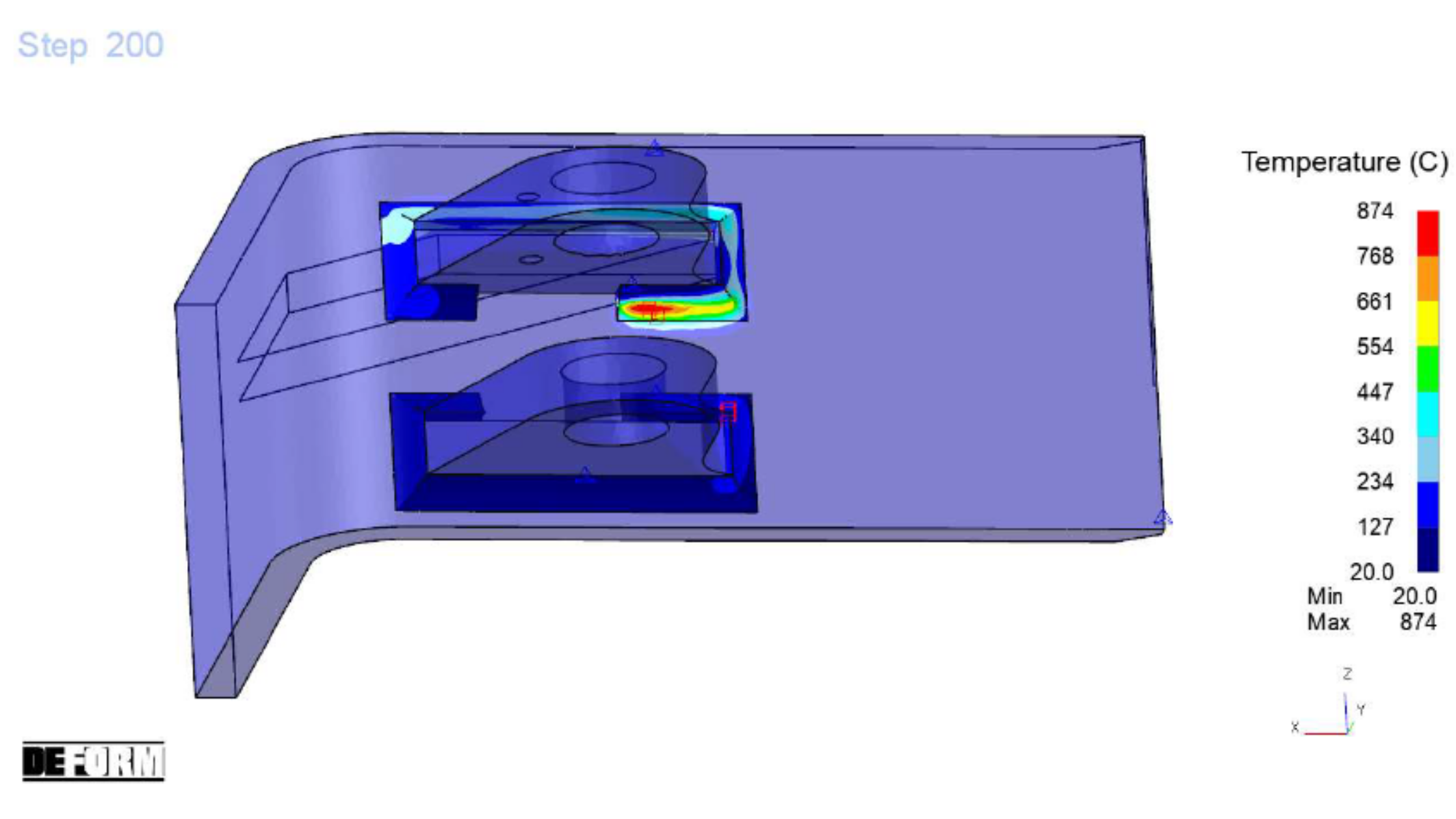

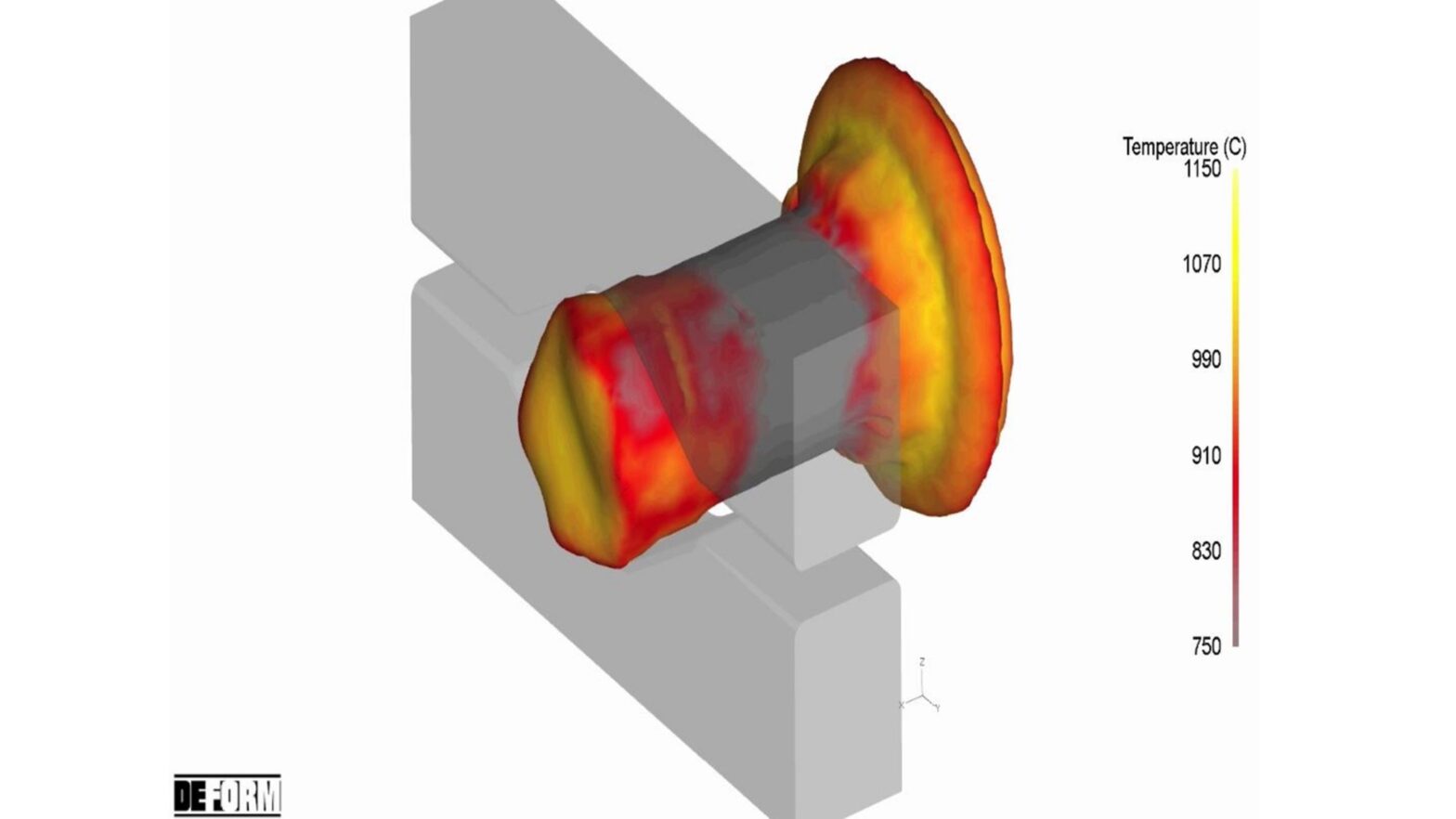

The arc welding simulation setting starts by defining the process parameters. Each thermal area affected is represented by a customisable, localised and mobile heat source model. CAD geometries are coupled to the automatic generation of the welding route to easily define the welding bead. The welding bead is dynamically “deposited” during the process by using an innovative element generation technology. The welding beads can entail a single pass or several composition passes (element layers).

The thermomechanical calculation of the welded joint performed by the software allows the end users to get critical information on the thermal response and on the resulting distortion in an arc welding process.

The arc welding simulation provided by DEFORM software gives the welded parts of the component the best mechanical strength.

What customers say about DEFORM:

- EXCELLENT AGREEMENT OF “SOFTWARE RESULTS” WITH “REALITY” DEFORM is the most widely used cold forming simulation software in the world

- SAMPLING IMMEDIATELY POSITIVE The simulation makes it possible to identify defects obtained during forming, to understand their causes and therefore to undertake the right corrective actions

For the purchase, hire or a DEMO of the software or if you want to take advantage of a simulation service specially-made by our technical department, write or call us at +39 030 3365383