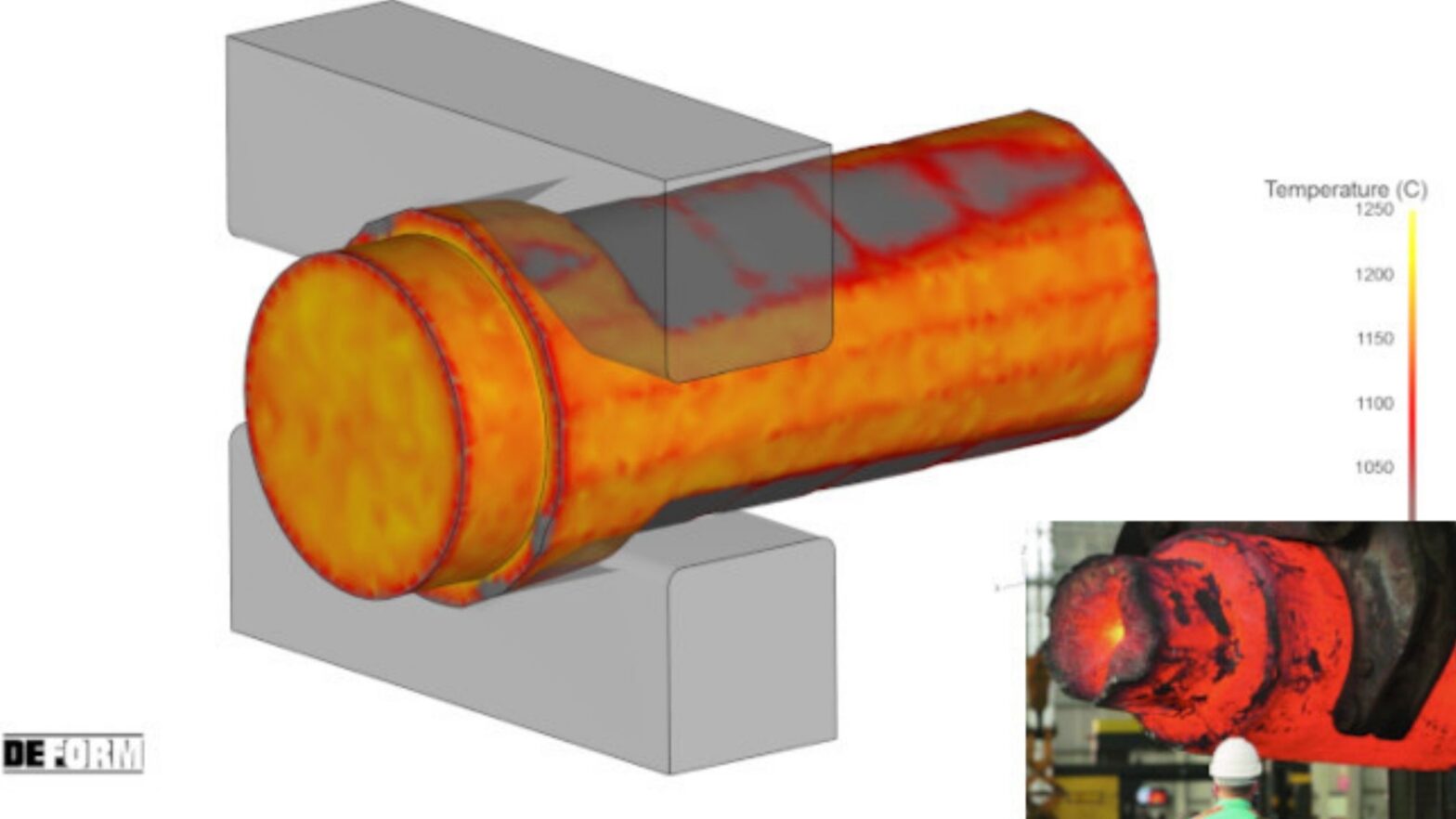

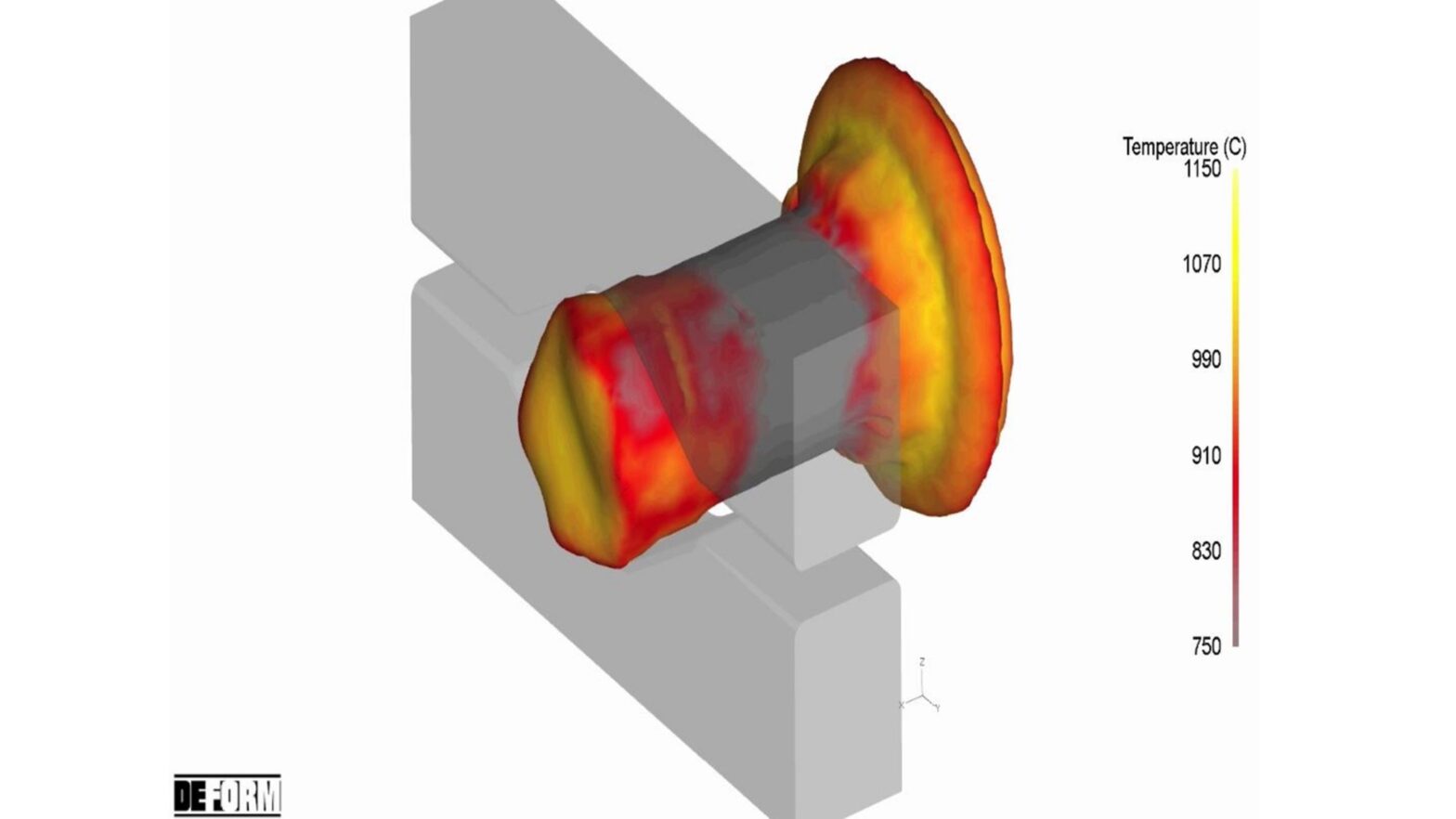

DEFORM Benefits:

- Quality improvement

- Optimization and saving in the design

- Improvement of production

- Enhanced precision

- Flexibility of use

- Reduction of calculation times

- Reduction of production rejects

- Saves money

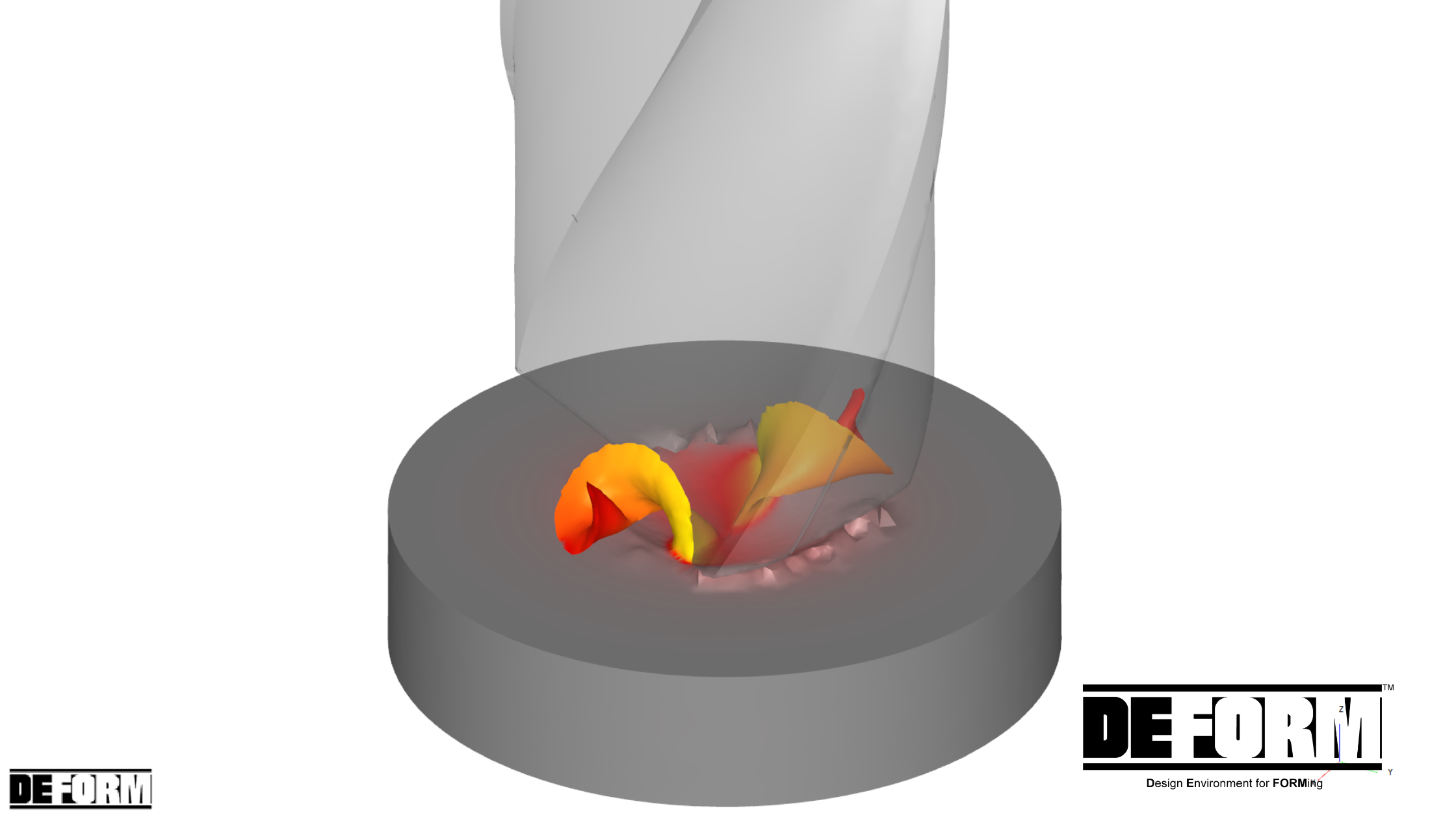

Machining of Drilling: What it is

Drilling is a process for the removal of swarf to make holes by using a rotary and translating tool in an axial direction. The quality of the holes made is subject to a variety of variables, such as advancement speed, material and depth of the hole; due to difficulties in obtaining surfaces with a high finish level under certain conditions, a subsequent boring process is required to reach the required tolerances.

Drilling Simulation: How it works

Drilling simulation to determine the shape of the swarf, torque and tool loads.

The drilling operation can include the following operational phases:

– Centring (identification of the hole axis)

– Drilling (making the hole)

– Widening (increasing the hole diameter)

– Boring (hole finishing operation)

Fundamental aspects to take into consideration for an efficient work process are cutting strength and power, drilling times, tools and material.

DEFORM software allows you to view and simulate drilling and fixing operations carried out by the drilling machine. This allows you to correctly position the hole or fixing element, not to get the size of the hole wrong and not to perform it in the assembly phase, to be able to insert the correct fixing element for the type of material used, to avoid collisions with the structure or fixing element, to be able to perform double drilling and filling.

The drilling simulation software allows you to view the workpiece, the tool, the spindle, the equipment and the finished piece, providing a graphical view of the work movements. It makes it possible to check for collisions of all parts for total safety of the process. It is also possible to quickly simulate the areas of the concerned part and to view interferences and remaining material, also allowing to compare the finished piece with the processed piece to determine any residual material or probable removal of material of the finished piece.

DEFORM software is designed to work on desktop PC or workstation. The Americans, manufacturers of DEFORM, came up with a complete, simple and fast software.

What customers say about DEFORM:

DEFORM drilling simulation software is American and has been optimised to be reliable, quick and easy.

- EXCELLENT AGREEMENT OF “SOFTWARE RESULTS” WITH “REALITY” DEFORM is the most widely used deforming simulation software in the world

- SAMPLING IMMEDIATELY POSITIVEThe simulation makes it possible to identify defects obtained during forming, to understand their causes and therefore to undertake the right corrective actions

- STARTING TIMES REDUCED TO A MINIMUM The machine setting was already tested in simulation. The real sampling will dispose of the machine setup card already defined.

For the purchase, hire or a DEMO of the software or if you want to take advantage of a simulation service specially-made by our technical department, write or call us at +39 030 3365383