Benefits with QuikCAST and ProCAST Software

- Quality improvement

- Optimization and saving in the design

- Improvement of production

- Enhanced precision

- Flexibility of use

- Reduction of calculation times

- Reduction of production rejects

- Saves money

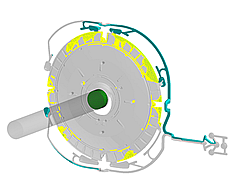

Centrifugal Casting: What it is

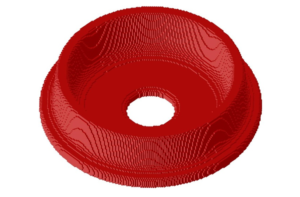

Centrifugal casting is a melting process of metals in which liquid metal, cast into a metal or refractory form spinning around, binds to the walls of the form itself thanks to the centrifugal force developed and is cooled at high speed until it quickly solidifies.

This type of process produces hollow castings, typically axisymmetric, without the use of cores: appropriately dispensing the molten metal achieves the effect that the produced piece remains hollow along the rotation axis of the shell/form. The centrifugal casting process is used to produce pipes, medical components or jewellery.

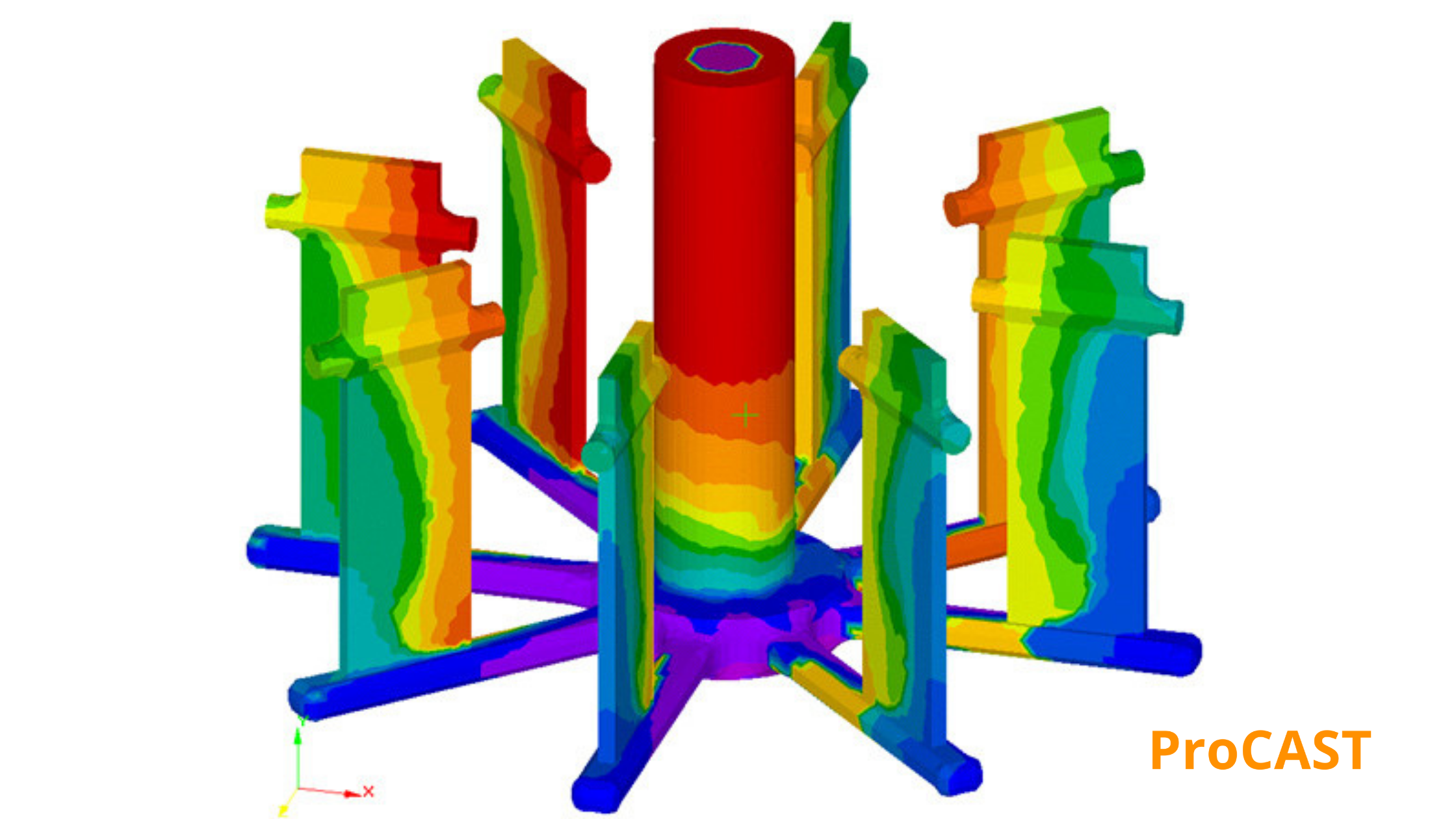

Centrifugal Casting Simulation: How it works

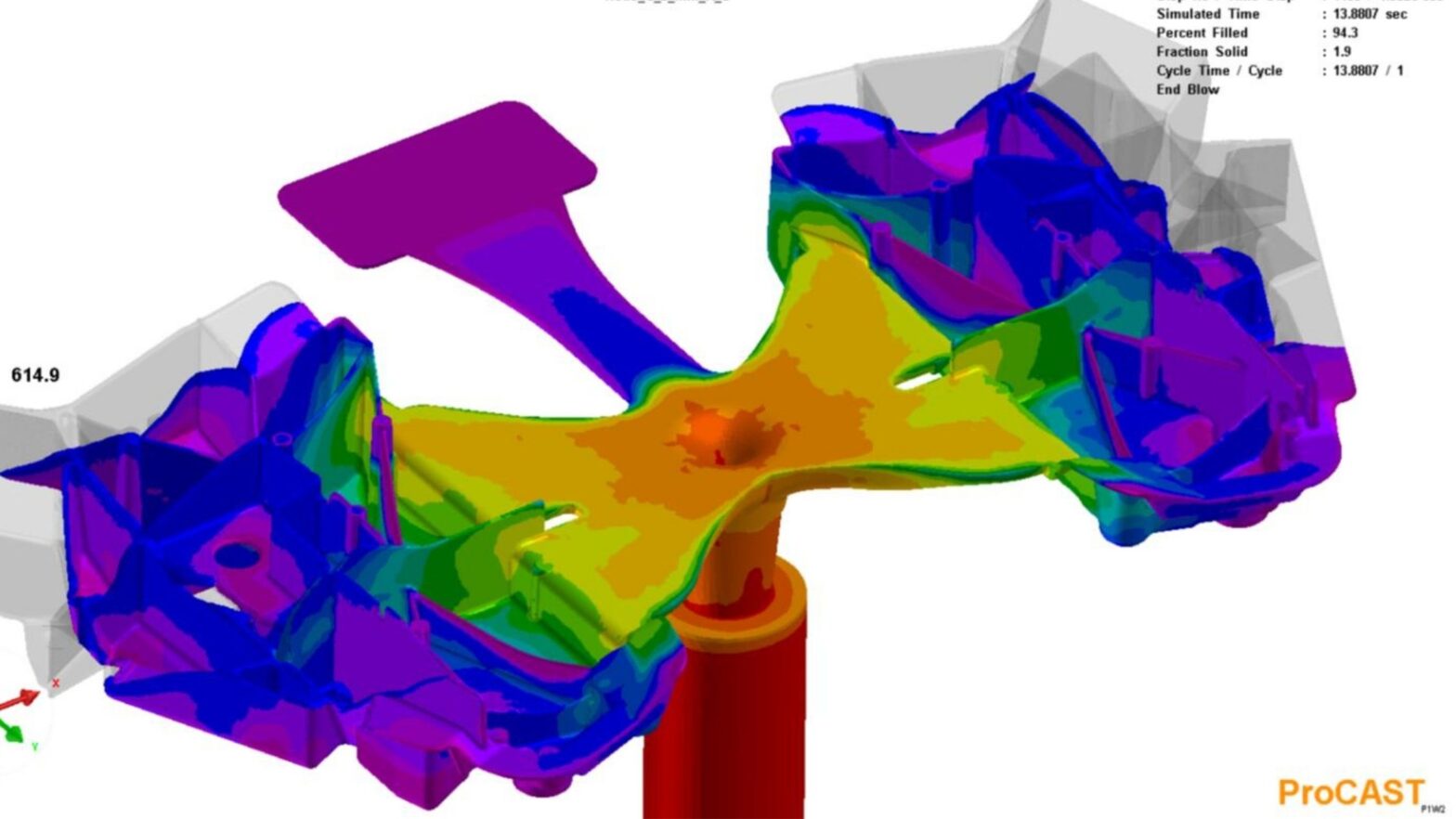

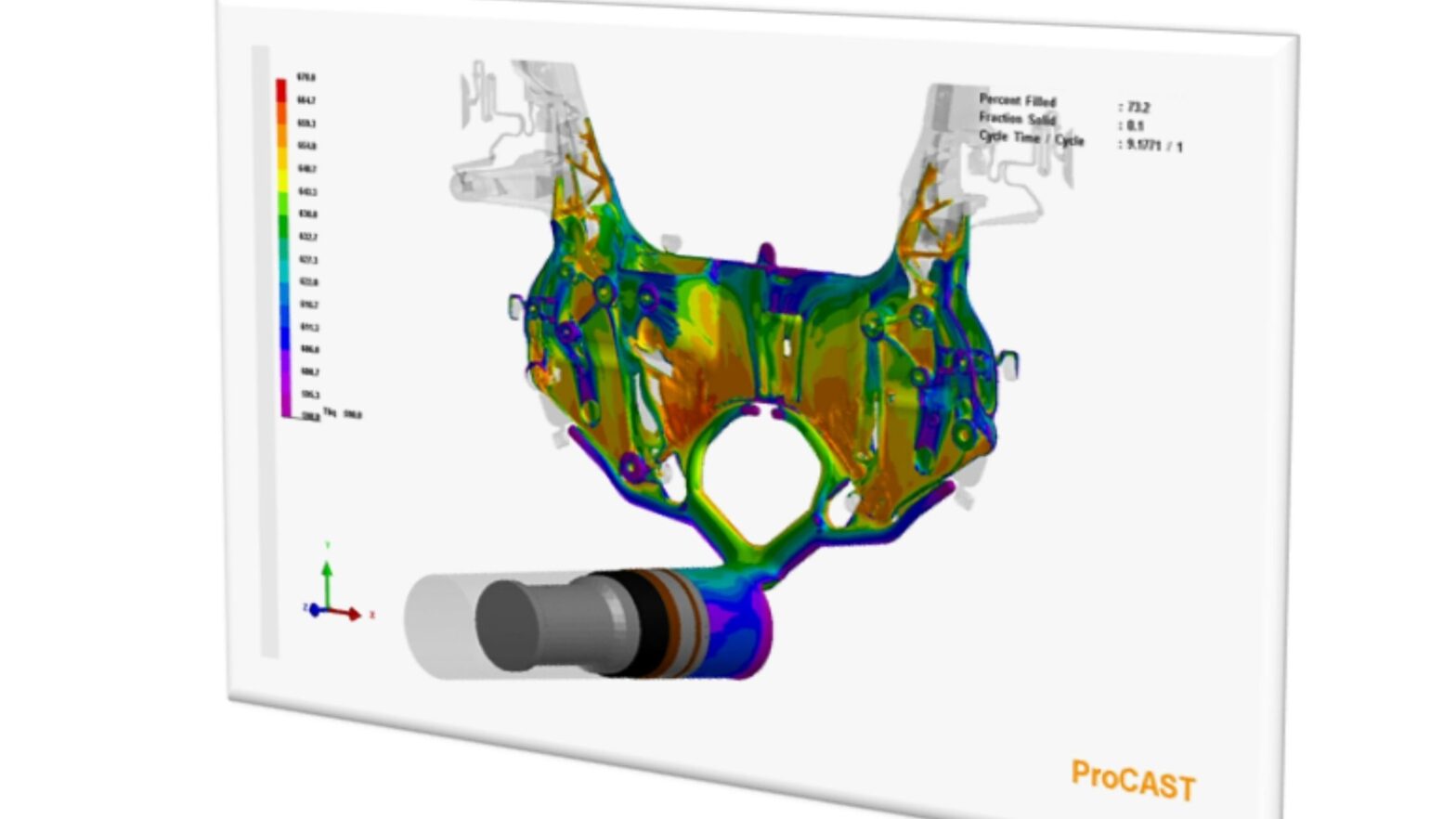

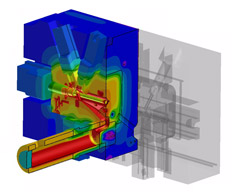

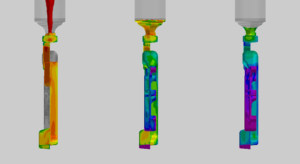

The ProCAST simulation software allows the centrifugal forces and Coriolis to be taken into consideration to model vertical and horizontal centrifugal castings, including the effect of these forces on the expected porosity. During the simulation process, a modelled mould spins at high speed around its vertical or horizontal axis, while the metal is being poured. The fluid dynamic equations are resolved in a reference system at relative speed (rotating).

ProCAST is the most advanced centrifugal casting simulation software. It offers a complete suite of modules and foundry tools to meet all of today’s industrial requirements. Based on the powerful finite element technology (FEM), ProCAST allows performing predictive evaluations of the entire process of the casting, including filling and solidification defects, mechanical properties and the complex distortion of the part. It allows you to quickly view the effects of design modifications and provides a basis for a correct decision-making process, from the initial production stages. ProCAST can model all casting processes of all pourable alloys, and also addresses other important production processes of the foundry.

QuikCAST is a quick and efficient solution to assess the complete process. QuikCAST has been designed to help the user cut costs and reduce time to market. It can be used in an initial stage to develop the mould and the process and to assess the quality of the molten piece.

For the purchase, hire or a DEMO of the software or if you want to take advantage of a simulation service specially-made by our technical department, write or call us at +39 030 3365383

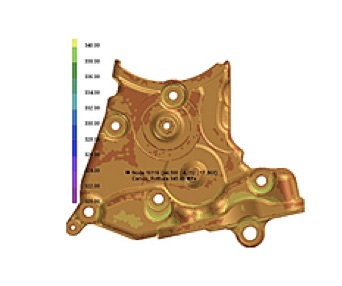

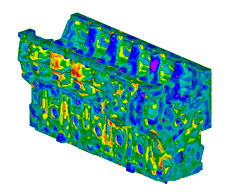

ELONGATION

The software can provide the elongation % map

ULTIMATE TENSILE STRENGTH

The simulator provides the map of the Ultimate Tensile Strength of the Component “As Cast” and after Heat Treatment

YIELD STRESS

The simulator provides the map of the Yield Stress of the Unfinished Component and after Heat Treatment

HARDNESS

The simulation can indicate the Hardness that can be obtained and its profile through its thickness

SDAS

The casting simulator shows the map of the SDAS (Secondary Dendrite Arm Spacing), a useful indicator of component performance

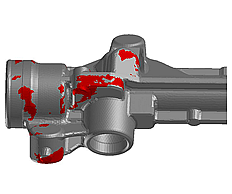

GAS POROSITY

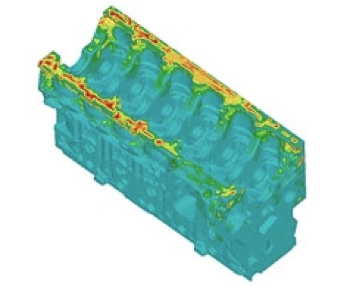

Map of Porosity from Gas encapsulated during filling. Reduction of mechanical and bonding performance of the component

OXIDES

The alloy oxidizes during filling and the simulation points out where the oxides hide and where they move during filling

DELAMINATIONS

The simulator shows the delaminations, related to imperfect bonding of the alloy during filling

INCOMPLETENESS

Incomplete pieces or with joinings and retrieved lines

Undersized gating system or incorrect gas exhaust

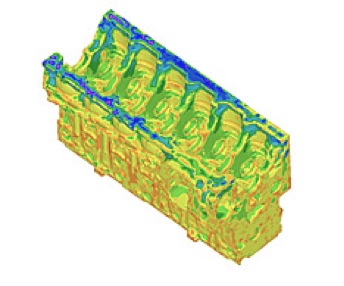

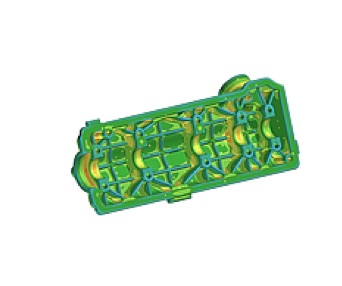

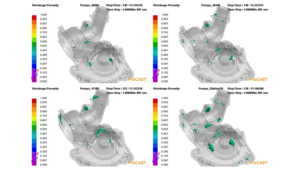

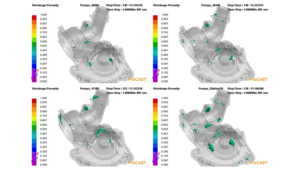

SHRINKAGE POROSITY

Map of Shrinkage Porosity.

Geography and Dimension of defect in mm3.

CRACKS

Map of hot and cold cracks on casting

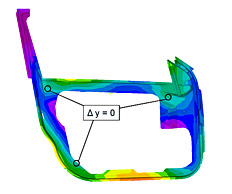

DIMENSIONAL

Dimensions and deformations of piece during solidification, extraction, cooling, blanking and any heat treatment

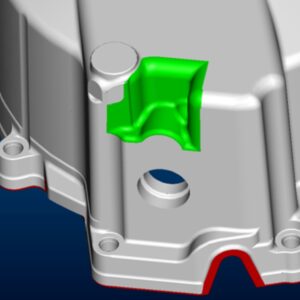

CO-DESIGN

Eliminate defects by acting on the causes and not on the effects

ALLOYS

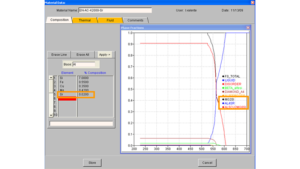

Impact of the alloy on the mechanical features and on the defects

CHEMICAL ANALYSIS

QuikCAST Light, QuikCAST and ProCAST characterise the alloy initiating from the chemical analysis. Assessment, for example, of the consequences of the addition of 200 ppm of Strontium

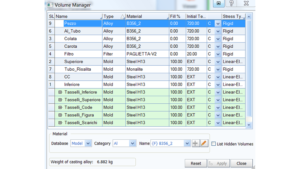

DATABASE

Complete archive of mould steels, sands, cores, insulation and exothermic sleeves, chillers, shells

DESCRIPTION

The simulation allows you to set a preview of the ideal process parameters for production of the component. This way the actual sampling underwent a positive result by eliminating fine tunings for the correct set of process parameters. Furthermore, the Optimizer Module of the software automatically defines the minimum and maximum ranges of the parameters guaranteeing the consistency and stability of the process.

DIE

The casting simulation shows the thermal die cycling simulation, the conditioning or thermal circuits, lubrication, deformation and die duration

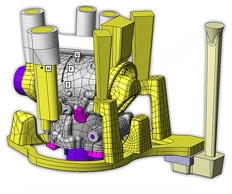

PLATE

Optimization of the plate, positioning of the chillers, sleeves, filters and die assembly of the cores. Maximum yield.

CASTING MACHINE

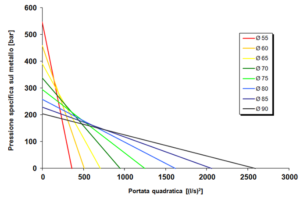

The casting simulation allows you to know the required casting machine and therefore the tonnes necessary

SYSTEM

Simulation of the entire injection cycle, complete with container, riser tube, tipping, automatic, manual system

FINITE VOLUMES

The finite volumes or Finite Differences Technology is the introductory technology to casting simulation.

QuikCAST and QuikCAST Light

FINITE ELEMENTS

The Finite Elements Technology is the top technology that provides the maximum performance of the casting simulator.

ProCAST