DEFORM Benefits

- Quality improvement

- Optimization and saving in the design

- Improvement of production

- Enhanced precision

- Flexibility of use

- Reduction of calculation times

- Reduction of production rejects

- Saves money

Thermochemical Treatments of Carburization: What it is

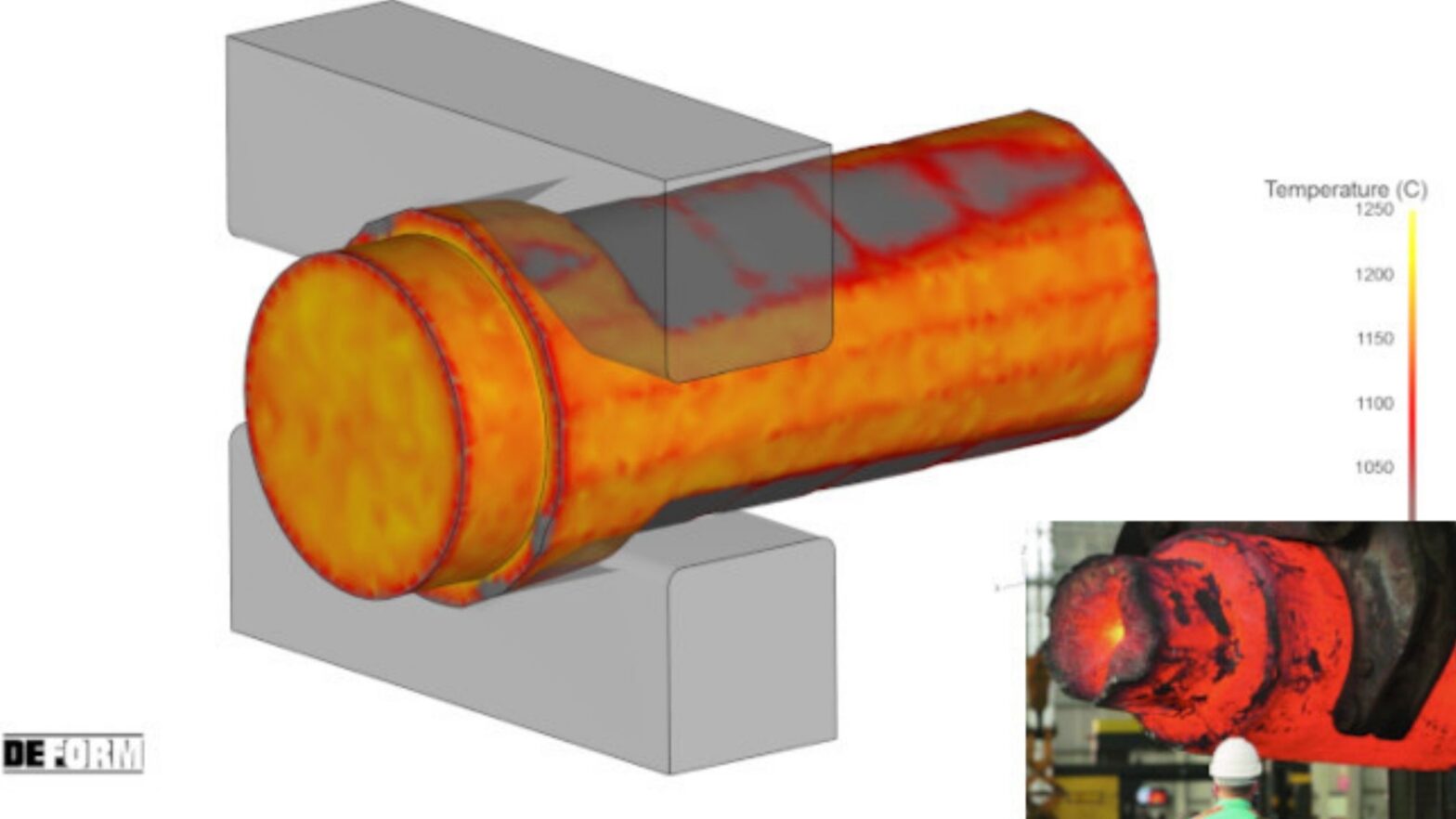

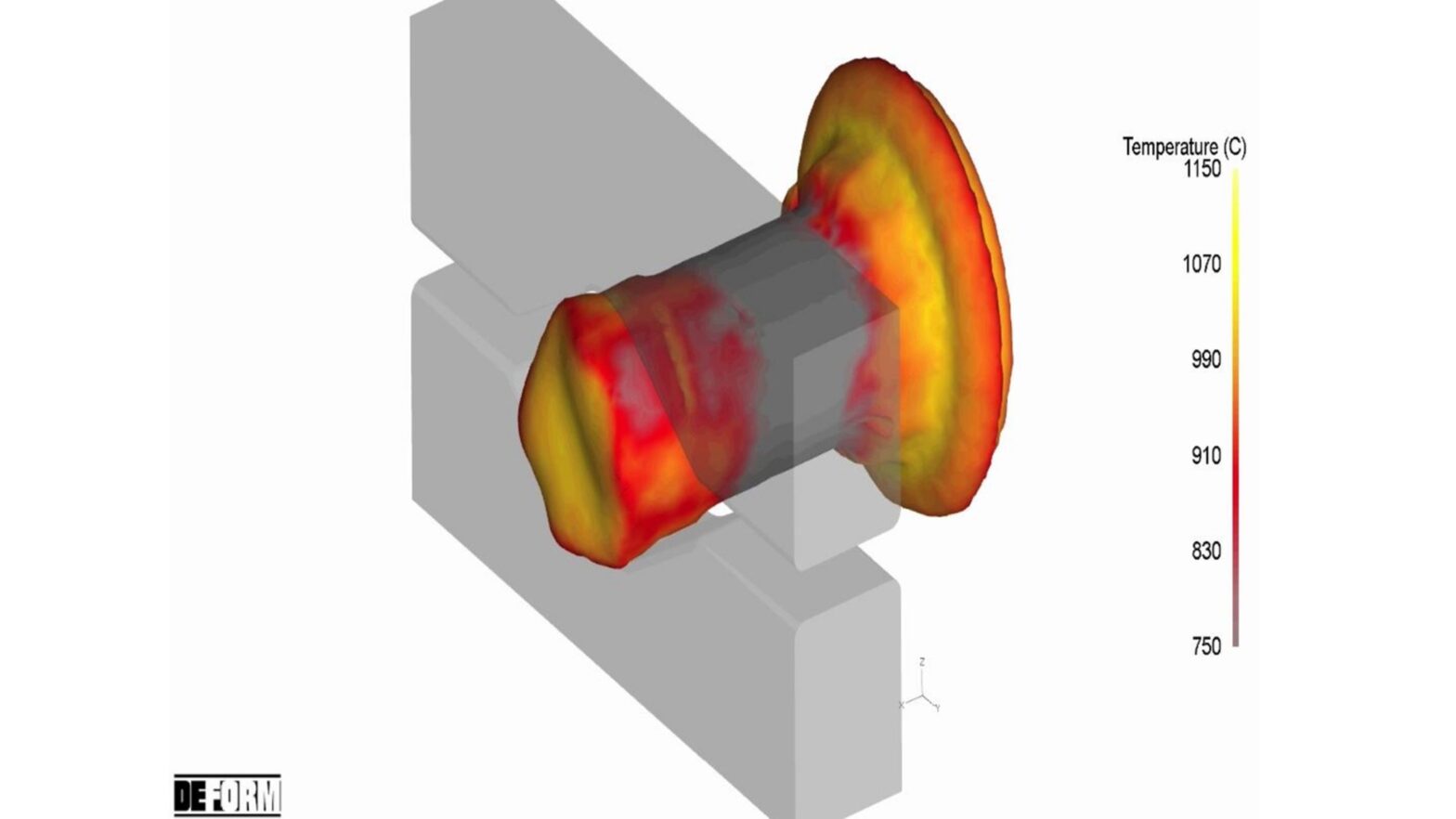

Simulation of carburization and therefore diffusion of carbon in the metal matrix.

Thermal chemical treatments, such as carburization, carbonitriding, gas nitriding, etc. are specific treatments that make use of the diffusion of solute atoms in solid phase in the metal matrix of the base metal. This is done so as to modify the chemical composition of the superficial layer of the alloys and to give them certain properties, such as hardness, wear resistance, resistance to oxidation and fatigue resistance. This type of treatment is used to absorb an extraneous chemical element, which gives the surface itself high hardness or other properties.

Thermochemical Treatments Simulation: Carburization.

Case study: Albero ingranaggio – Centro Tecnologico Arti e Mestieri

Carburization simulation: How it works

DEFORM simulation software makes it possible to develop models that can be used to determine the most effective heat treatment parameters for a particular application, thus restricting sampling and trials to resolve any problems that could arise during the entire thermal process and thereby avoiding wasting money and time.

For example, regarding the carburization process, which is currently the most widely used diffusion process on an industrial scale, thermochemical treatment simulation includes and models the effects of the process parameters on the depth of the carburized layer, carbon concentration, microstructure, residual stress, distortion and deformation. The software predicts, before going on to sampling, the profile and depth of the carbon enriched layer in case-hardened steels modelling the absorption and diffusion of carbon during the entire thermochemical process.

DEFORM works both on PC and on standard 6, 8 and 12 core workstations, automatically showing defects and problems of the entire process on its whole.

What customers say about DEFORM:

- EXCELLENT AGREEMENT OF “SOFTWARE RESULTS” WITH “REALITY” DEFORM is the most widely used cold forming simulation software in the world

- SAMPLING IMMEDIATELY POSITIVEThe simulation makes it possible to identify defects obtained during forming, to understand their causes and therefore to undertake the right corrective actions

For the purchase, hire or a DEMO of the software or if you want to take advantage of a simulation service specially-made by our technical department, write or call us at +39 030 3365383