5th International conference on thermal process modelling and simulation (TPMS-5)

5th International conference on thermal process modelling and simulation (TPMS-5)

Lecce, Università del Salento, Dip. Ingegneria, Edificio "Angelo Rizzo", Corpo Y

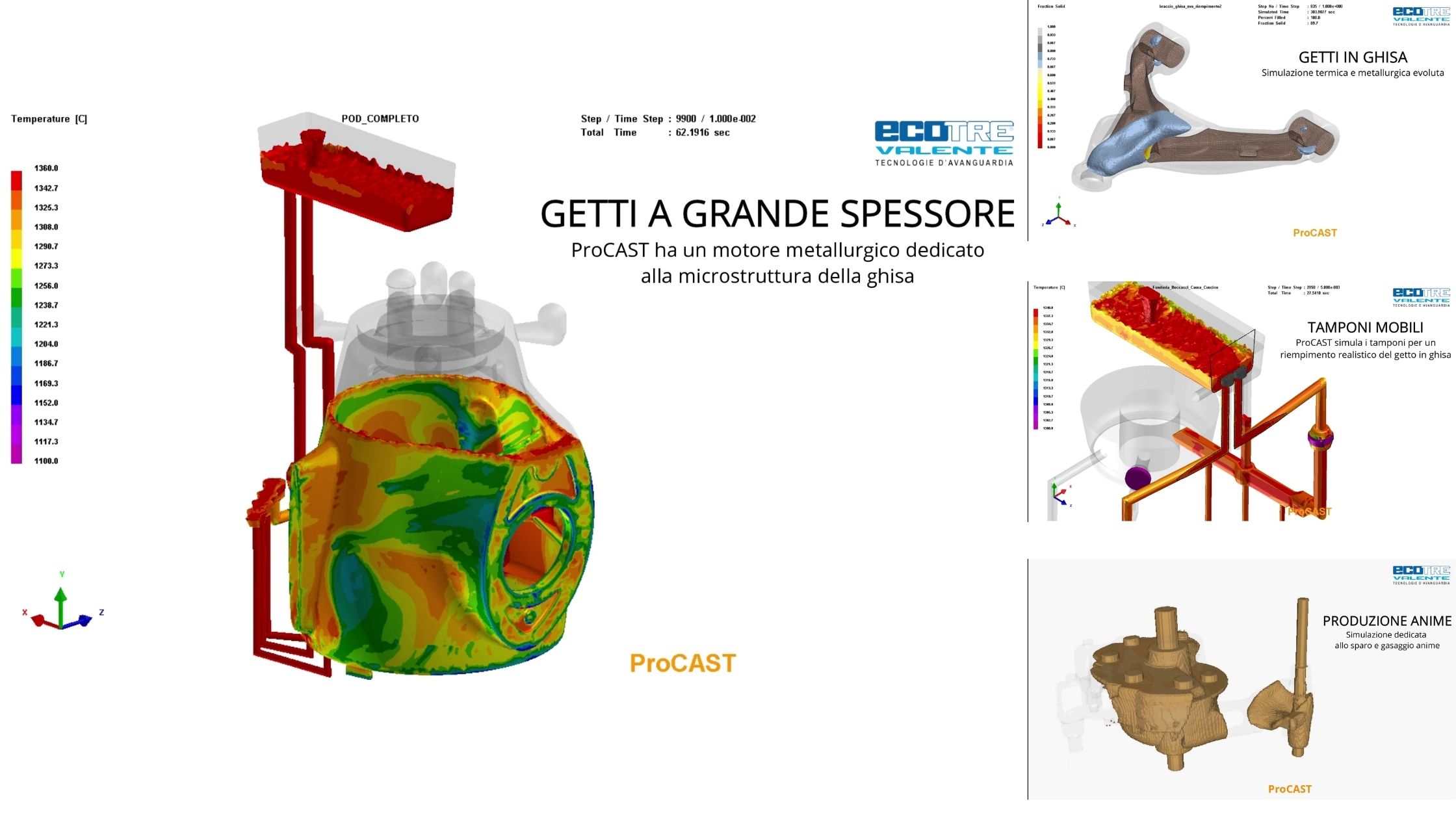

Ecotre Valente is proud to be part of the scientific committee of the 5th International conference on thermal process modelling and simulation (TPMS-5) to be held at the Università del Salento (Lecce) from the 17th to the 19th of April 2024.

The conference organised by AIM (Associazione Italiana di Metallurgia), IFHTSE (International Federation for Heat Treatment) and Università del Salento aims to be an opportunity for engineers, scientists, researchers and production managers to examine and discuss the basics, new challenges, recent progress and emerging topics in the fields of advanced heat treatment and surface engineering technology.

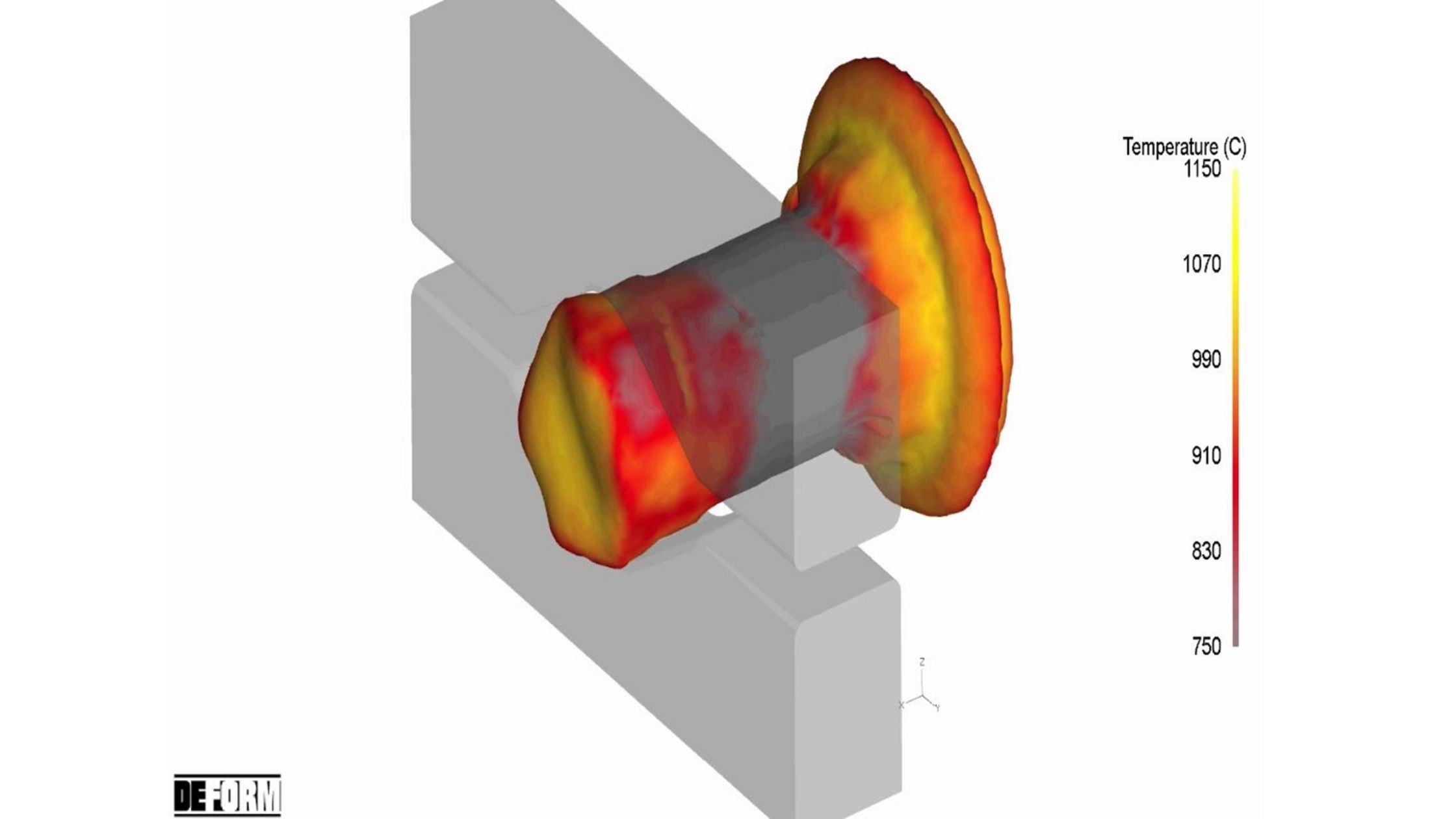

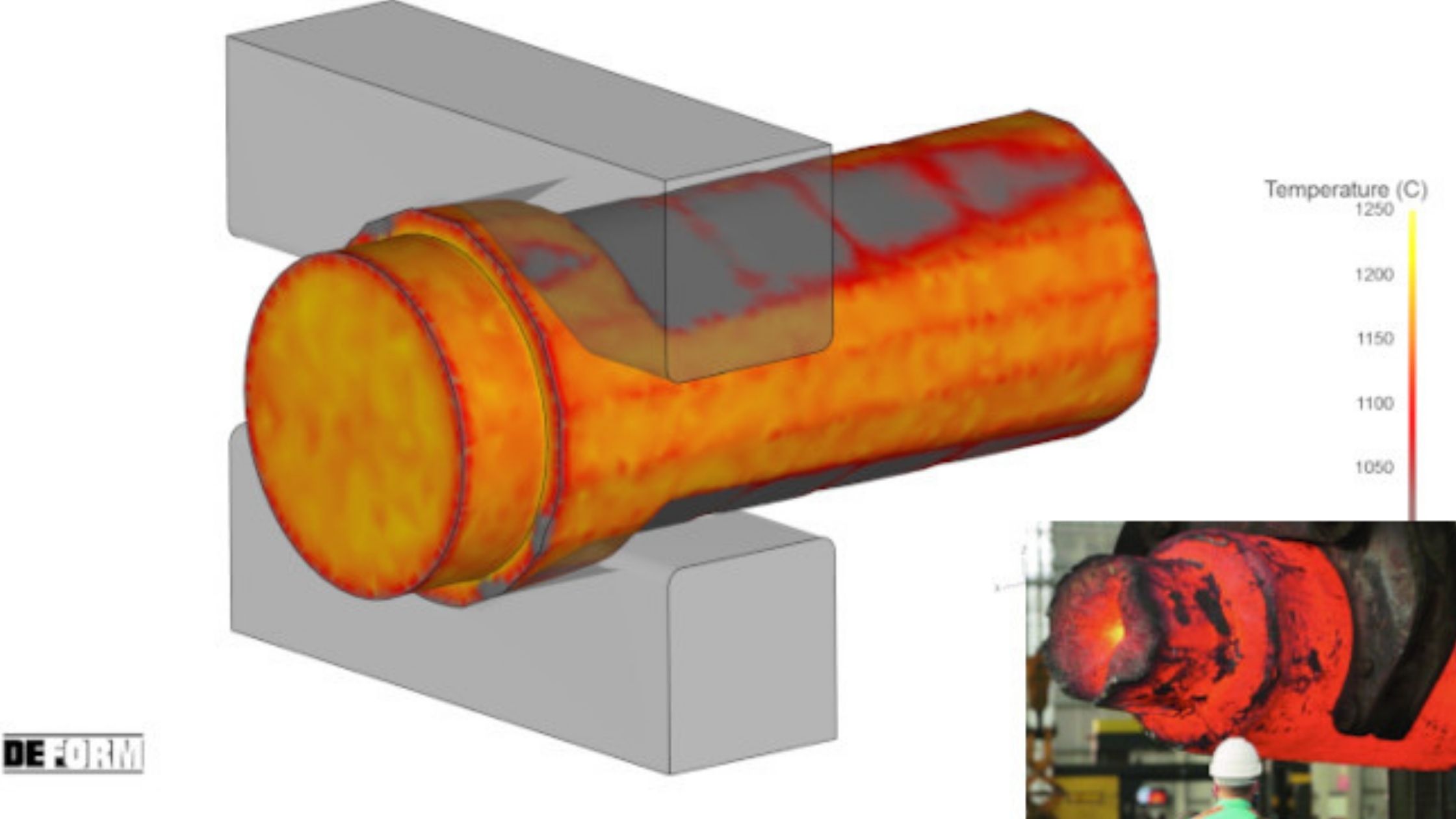

On the 18th of April, Mr Cristian Viscardi, Technical Manager of Ecotre Valente, will be holding two talks in the “Deformation & Recrystallization” section, dedicated to the “Digitisation of heat treatment with DEFORM software” and “Preliminary investigation of a 36-tonne steel ingot: defect assessment and analysis using numerical simulation”.

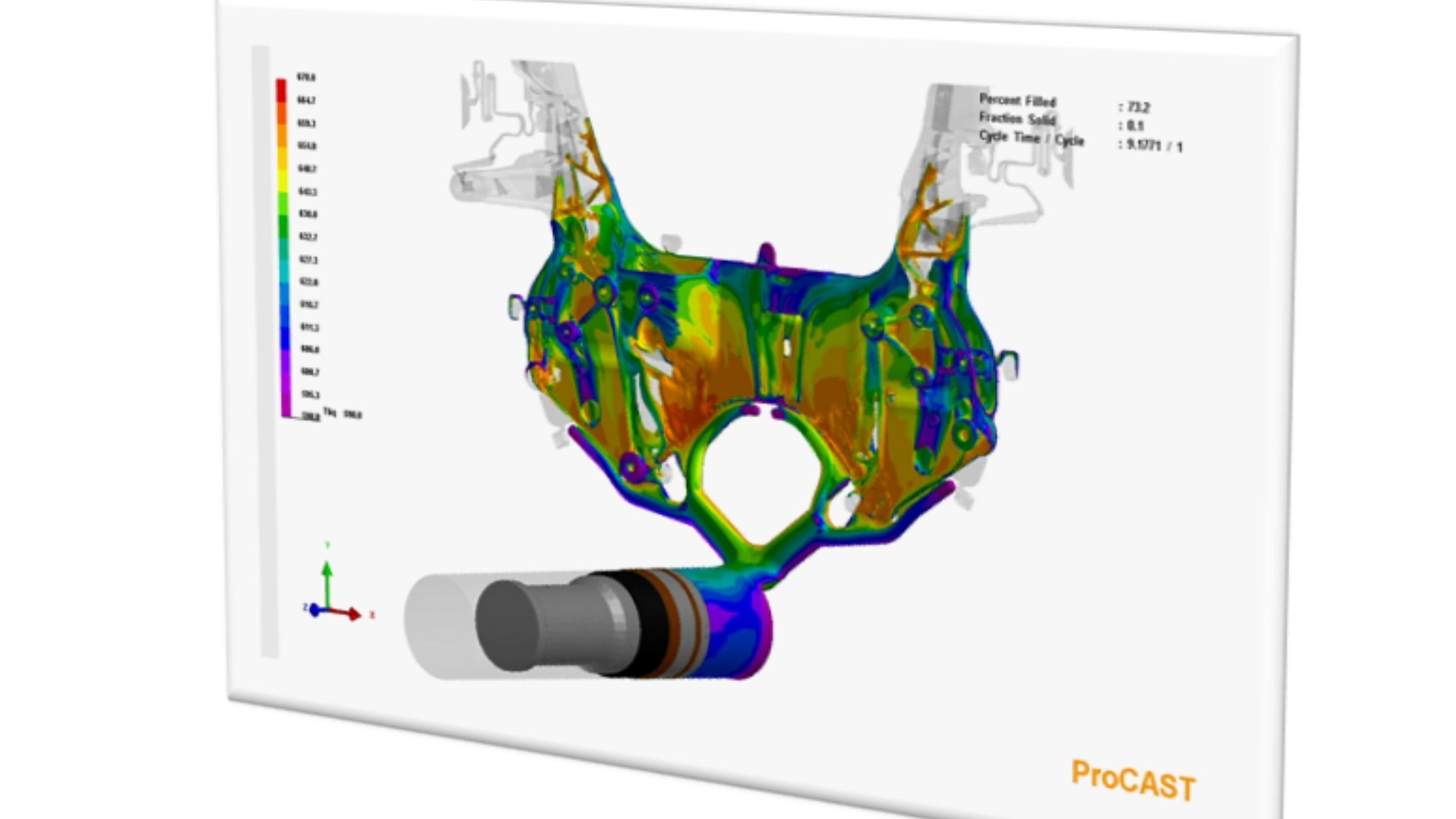

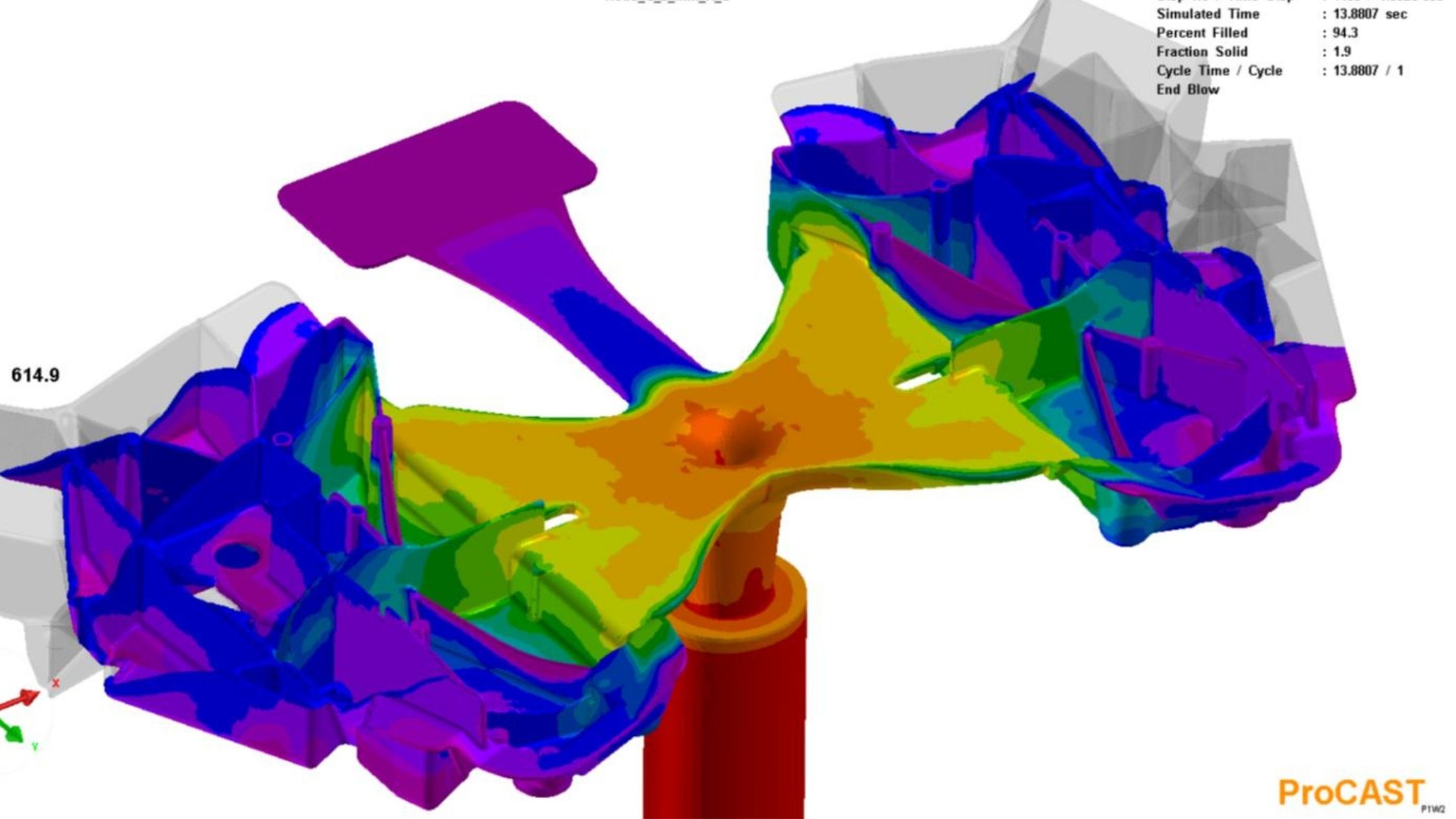

DEFORM software is a widely used tool in the materials engineering and manufacturing sector to simulate and optimise machining processes, including heat treatment. The digitisation of heat treatment with DEFORM involves the use of advanced computational models to simulate the thermal, mechanical and metallurgical process involved in the transformation of materials.

Here are some key points regarding the digitisation of heat treatment with DEFORM software:

- Process simulation: DEFORM allows detailed simulation of the heat treatment process, taking into account various parameters such as temperature, time, part geometry and material properties.

- Process optimisation: Using DEFORM, heat treatment parameters can be optimised to improve material performance, reduce production time and minimise costs.

- Prediction of material properties: DEFORM allows you to predict material properties after heat treatment, such as microstructure, hardness, strength and toughness. This information is crucial for designing components with optimal performance.

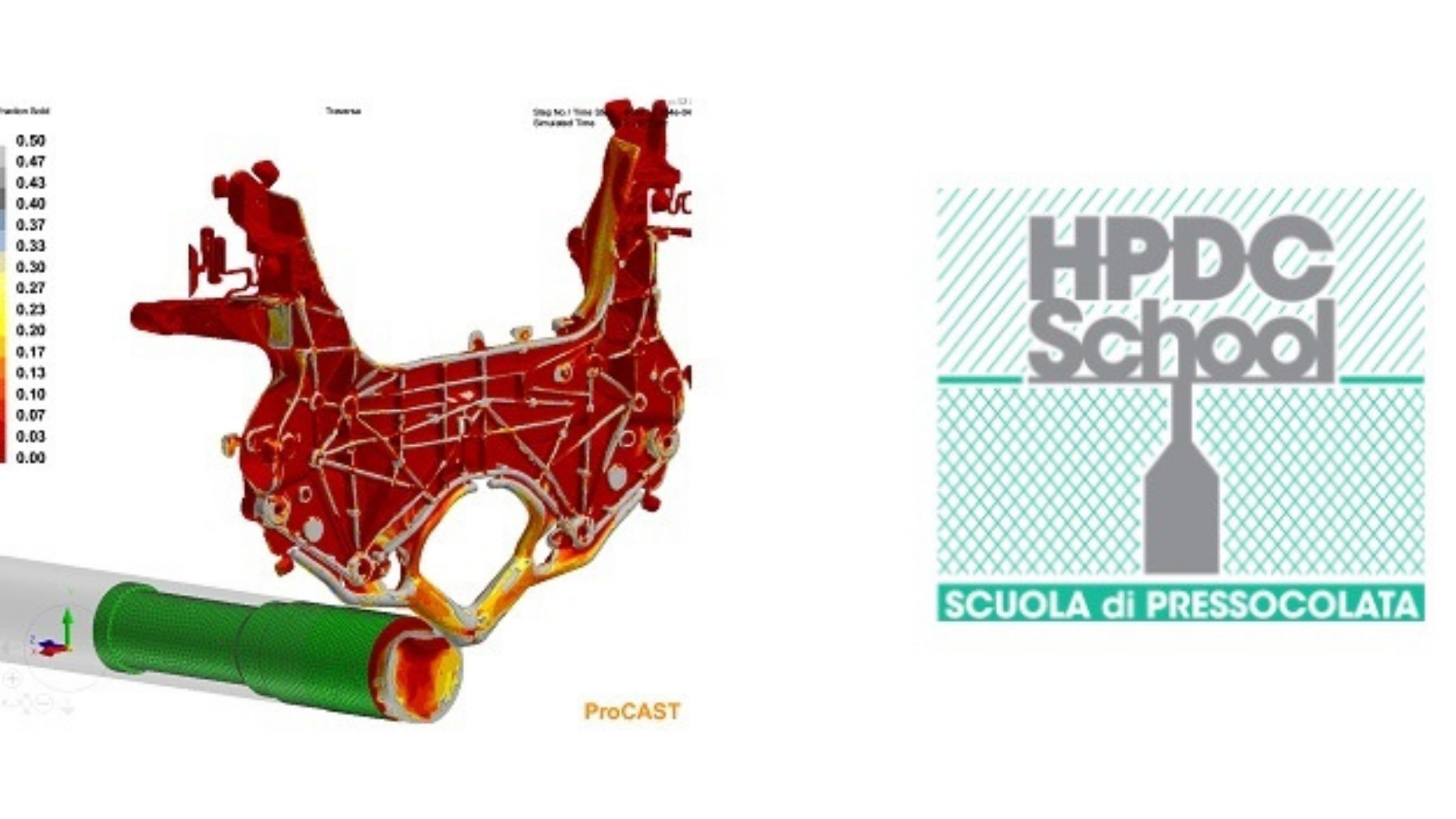

- Defect analysis: The software also makes it possible to identify potential defects or problems in the heat treatment process, allowing engineers to make preventive corrections before going into production.

- Integration with other software and tools: DEFORM can be integrated with other design and simulation software for a more comprehensive analysis of the production process and to support decision-making.

In short, the digitisation of heat treatment with DEFORM software offers numerous benefits, including more efficient design, optimised production and a greater understanding of material transformation processes.

- Target audience: Moulders, Die-makers and Designers

- Speakers: Ecotre Technical Department

- Duration: Starts Wednesday 20 September 2023 – Ends Thursday 16 November 2023

20-21 September: joint course

28 September, 5-12-19-26 October and 7-9-16 November: individual meeting slots lasting one hour - Time: From 8 a.m. to 12 noon and from 1 p.m. to 4 p.m.

- Material: DEFORM software for the duration of two months, Course notes in pdf format and Attendance Certificate

- Venue: BACCADEMY Srl – Via Industriale, 106 – 25065 Lumezzane (BS)

FILL IN THE FORM FOR FURTHER INFORMATION

Benefits

- Integrated Design and Optimization

- Enables better design choices

- Improved part moulding

- Fewer defects and better cost control