Increasing durability and productivity with thermal management of the mould – 9th edition

Increasing durability and productivity with thermal management of the mould – 9th edition

Via Industriale, 106, Lumezzane (BS)

ECOTRE VALENTE, in partnership with Quaker Houghton, Bonomi Acciai and FB TECNO organises a meeting at the BAccademy in Via Industriale, 106, Lumezzane (BS) dedicated to thermal management of the mould to increase durability and productivity.

Now in its 9th edition, the seminar will take place from 9:30 a.m. to 12:30 p.m.

The target audience?

The appointment is aimed at technicians from companies that use the light alloy die-casting process. Professionals from the companies organising the event, who work in the industry and are familiar with the production process, will be speaking at the meeting.

We also invite business owners, finance managers and directors to discuss the impact that this innovation can have on increasing company margins by reducing costs.

The four partners combine their expertise to improve the various aspects of die-casting by acting on the thermal management of the mould. This is a delicate step within the manufacturing process and one that requires special care, especially considering that sub-optimal mould temperature is one of the main causes of flaws in die-casting.

In actual fact, the actions taken at this stage of processing affect:

- The duration of the “life” of the mould;

- The cycle time;

- The final quality of the component.

- Target audience: Moulders, Die-makers and Designers

- Speakers: Ecotre Technical Department

- Duration: Starts Wednesday 20 September 2023 – Ends Thursday 16 November 2023

20-21 September: joint course

28 September, 5-12-19-26 October and 7-9-16 November: individual meeting slots lasting one hour - Time: From 8 a.m. to 12 noon and from 1 p.m. to 4 p.m.

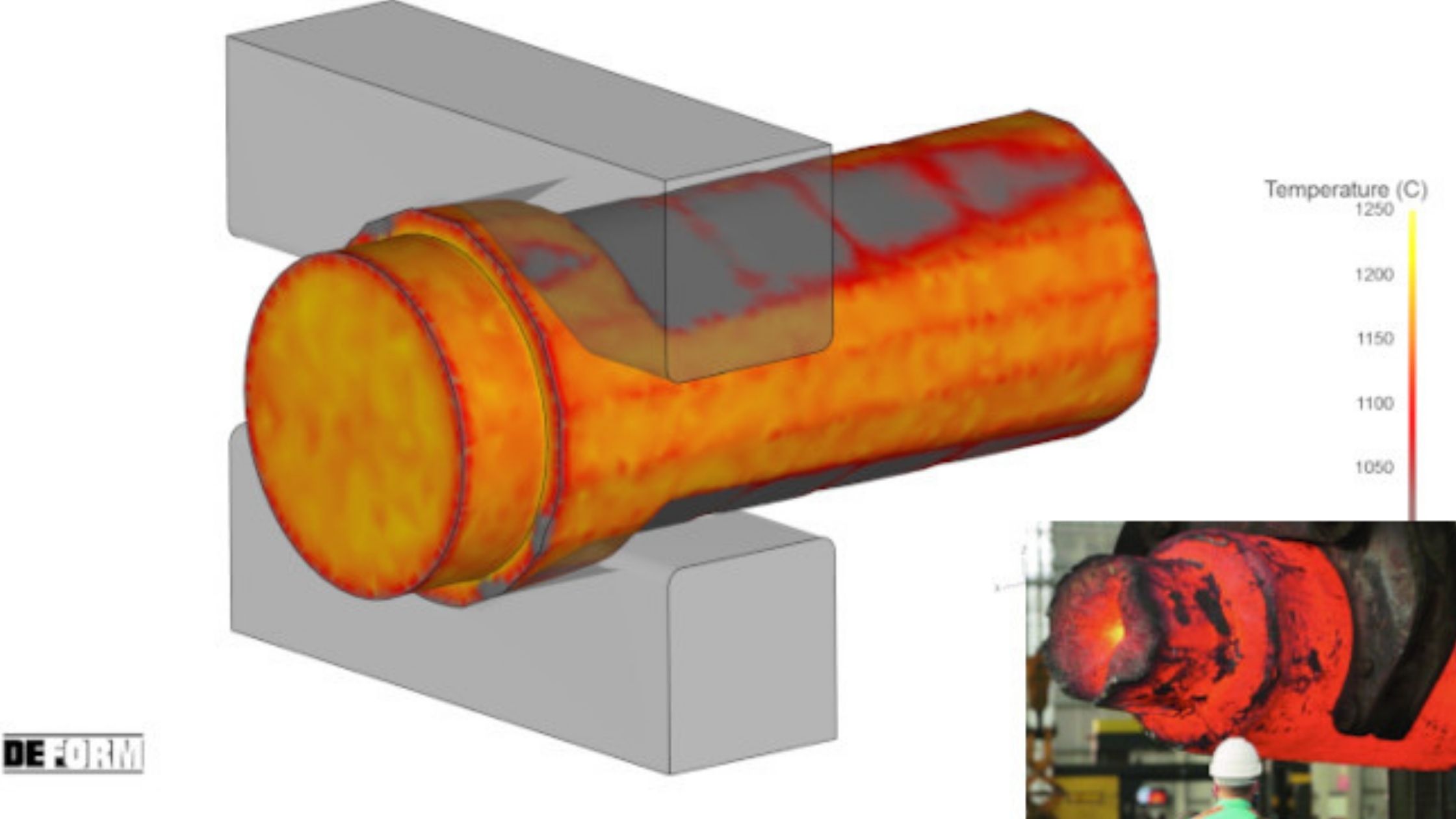

- Material: DEFORM software for the duration of two months, Course notes in pdf format and Attendance Certificate

- Venue: BACCADEMY Srl – Via Industriale, 106 – 25065 Lumezzane (BS)

FILL IN THE FORM FOR FURTHER INFORMATION

In the case of excessively high temperatures, there is a risk of an extended die-casting cycle time, resulting in reduced productivity. If, on the other hand, temperatures are too low or the cooling process is “wrong”, this will result in imperfections in the finished component as well as stress within the mould itself.

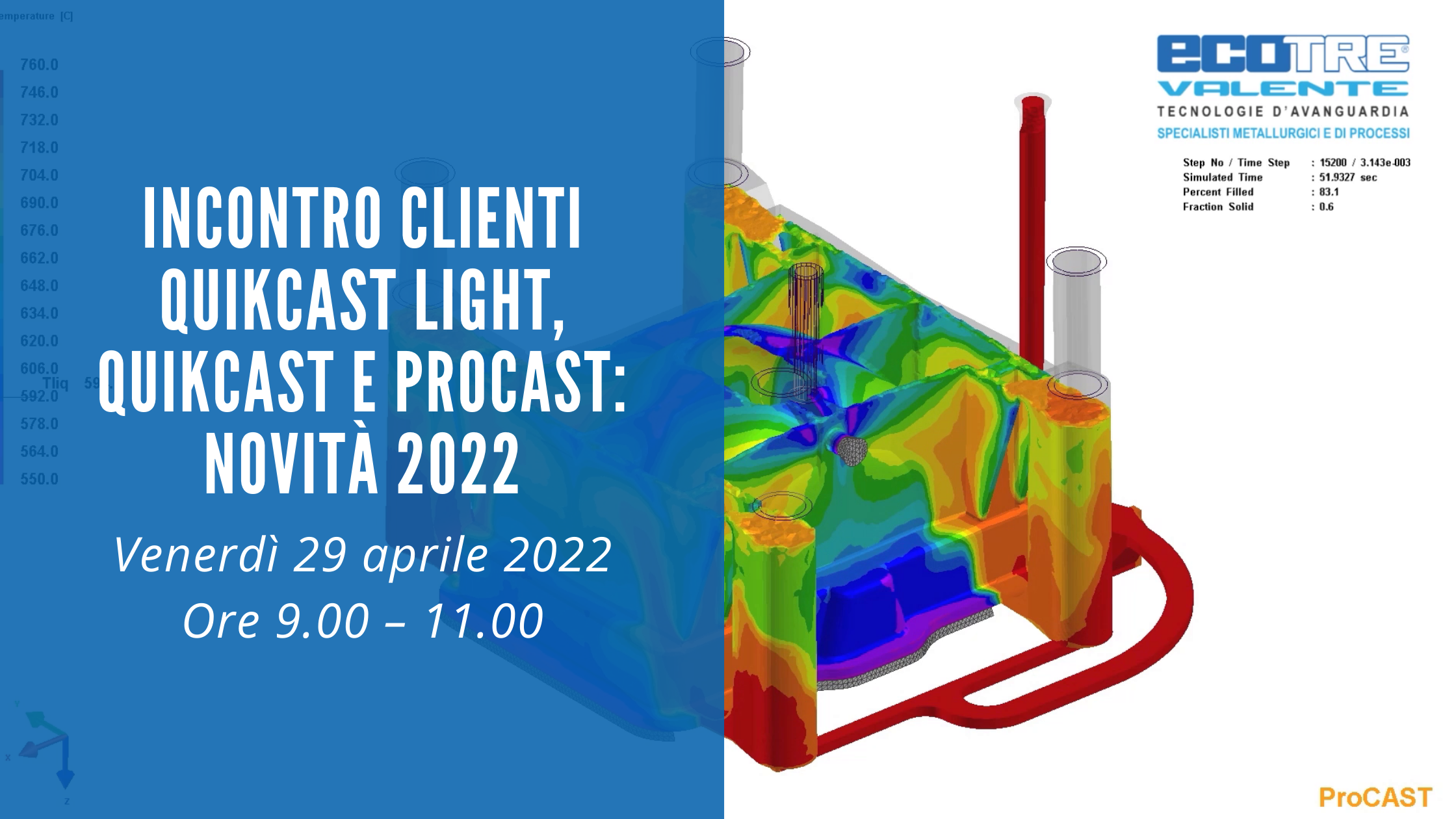

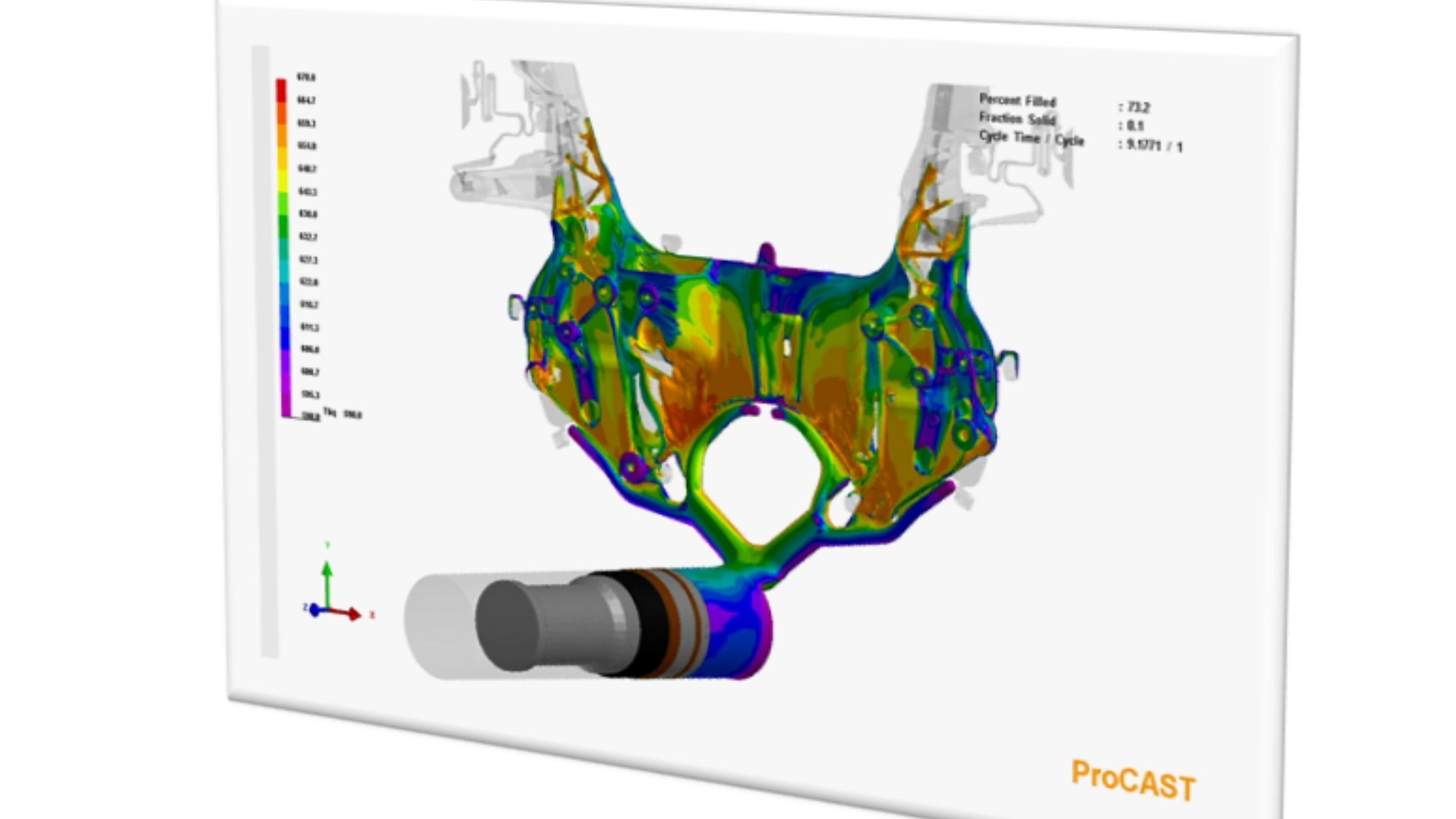

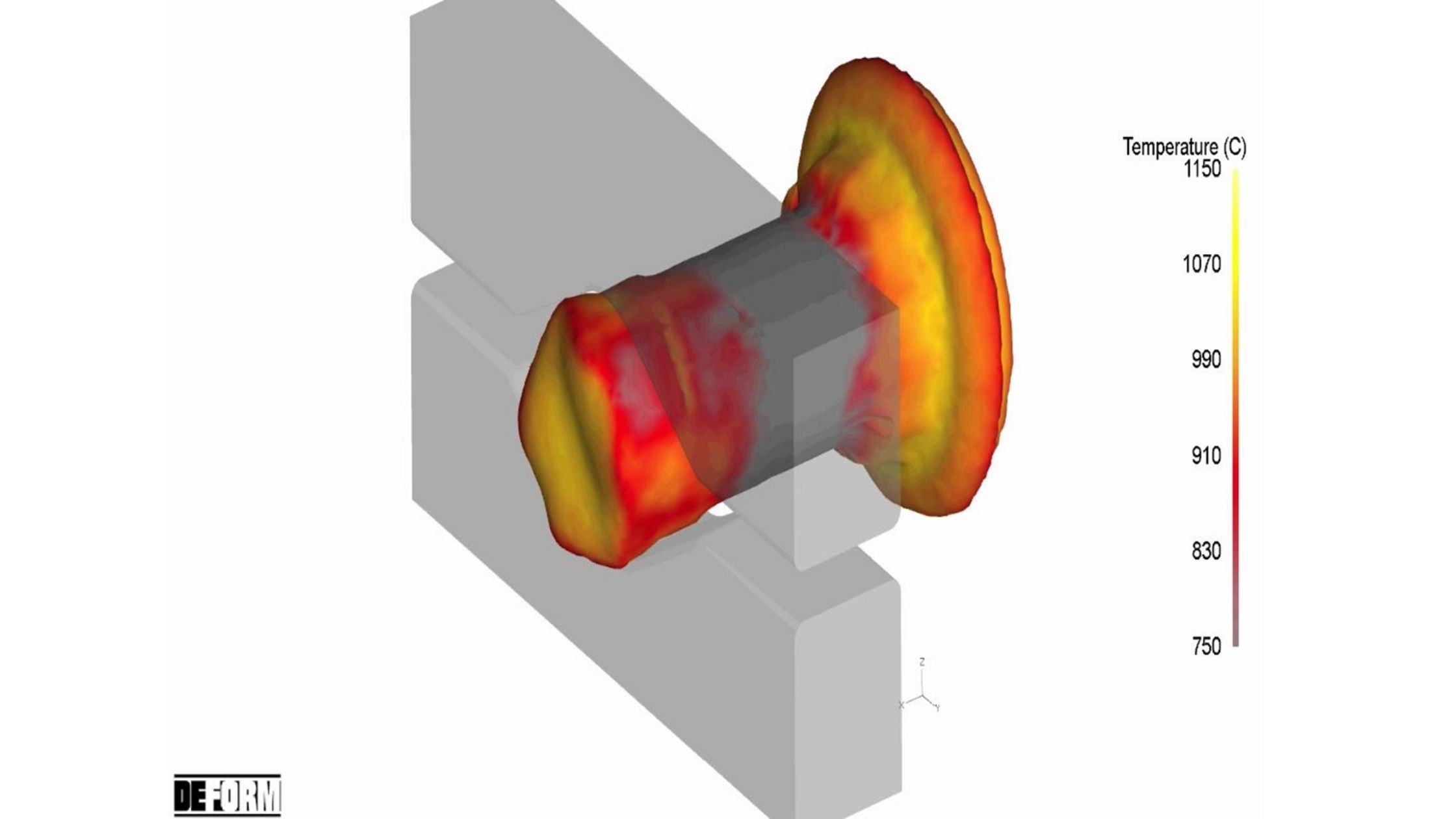

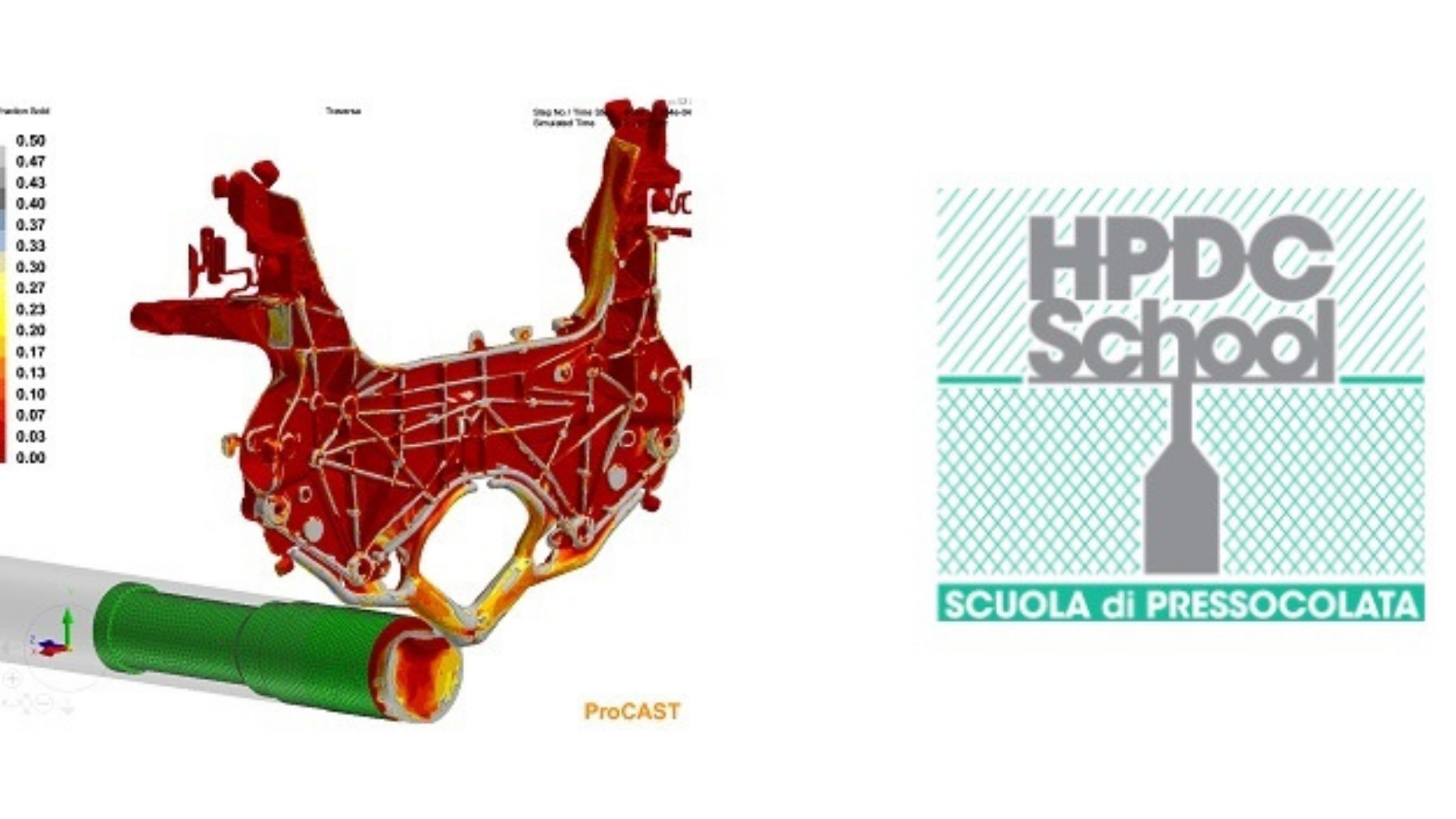

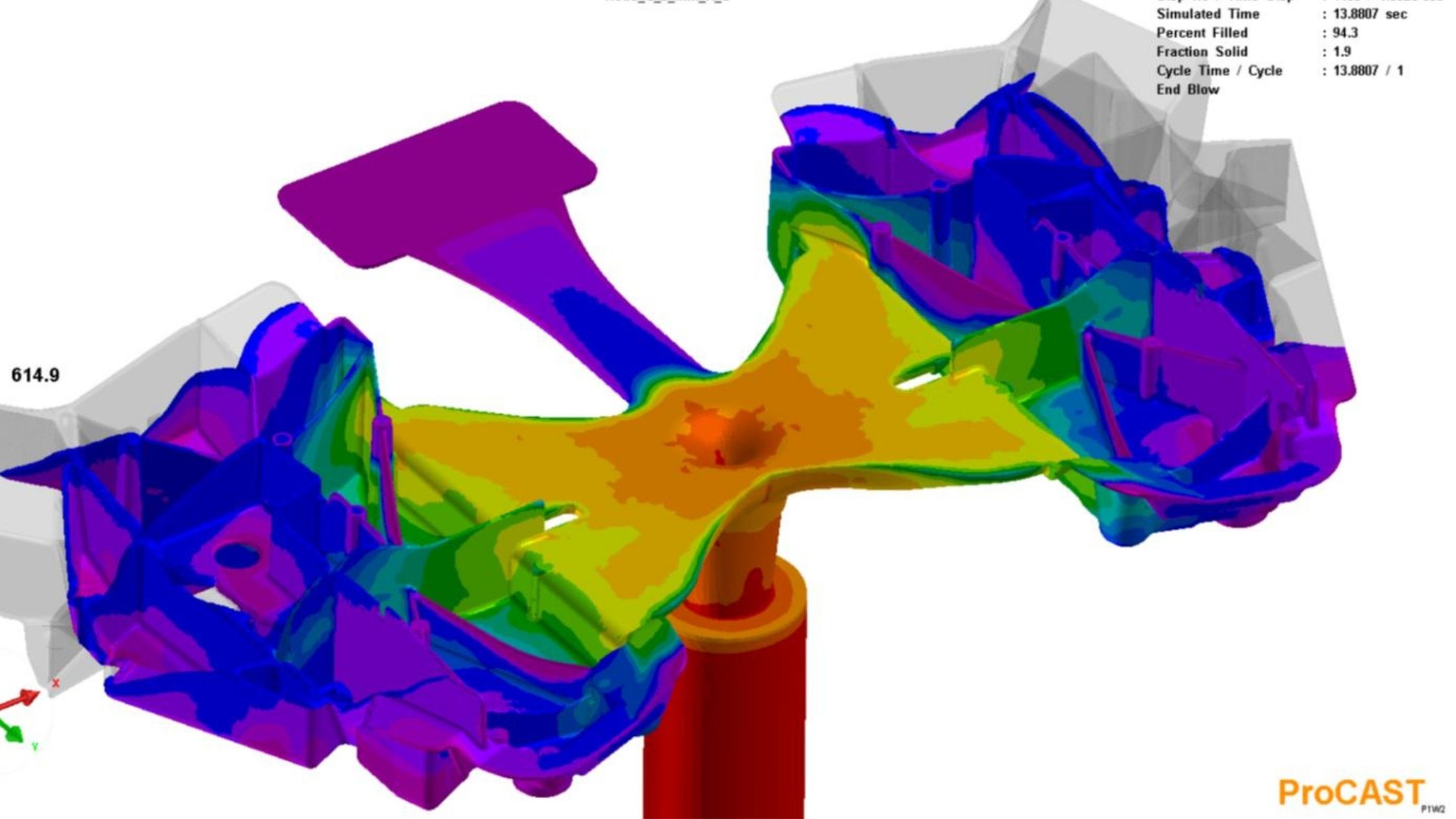

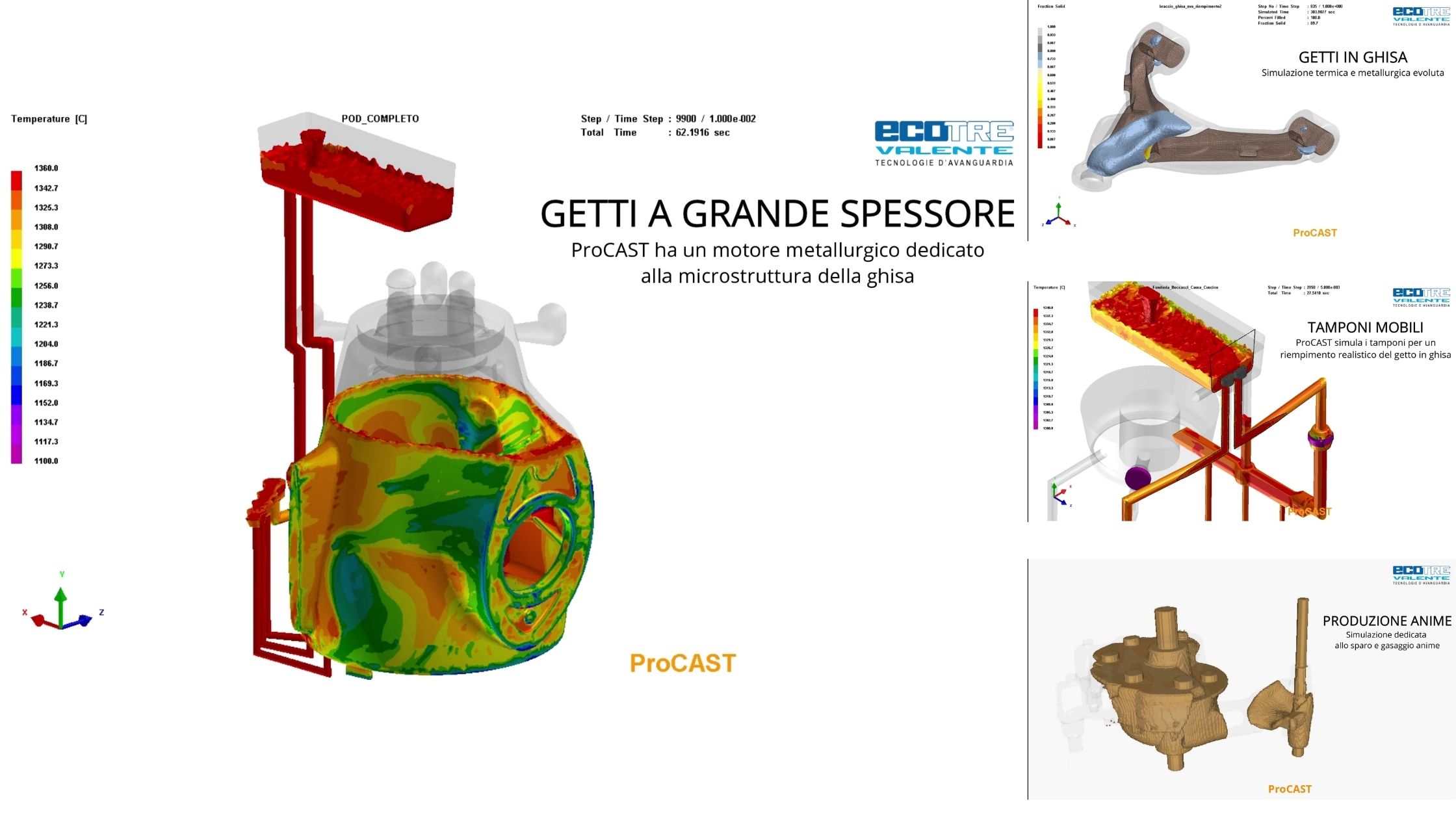

Ecotre Valente’s technical team uses ProCAST digital simulation software to predict and identify these situations.

Simulation makes it possible to intervene and perform the necessary preventive corrections, leading to cycle optimisation, longer mould life and high-quality, uniform die-cast components.

At the end of the meeting, all participants can request an one-to-one meeting with Ecotre Valente engineers, specialists in process and product optimisation, to discuss the specific needs of their company and the solutions that the ProCAST predictive programme can offer.

SIGN UP FOR THE SEMINAR TO FIND OUT HOW TO IMPROVE PRODUCTION IN YOUR METALLURGY COMPANY!

Benefits

- Integrated Design and Optimization

- Enables better design choices

- Improved part moulding

- Fewer defects and better cost control