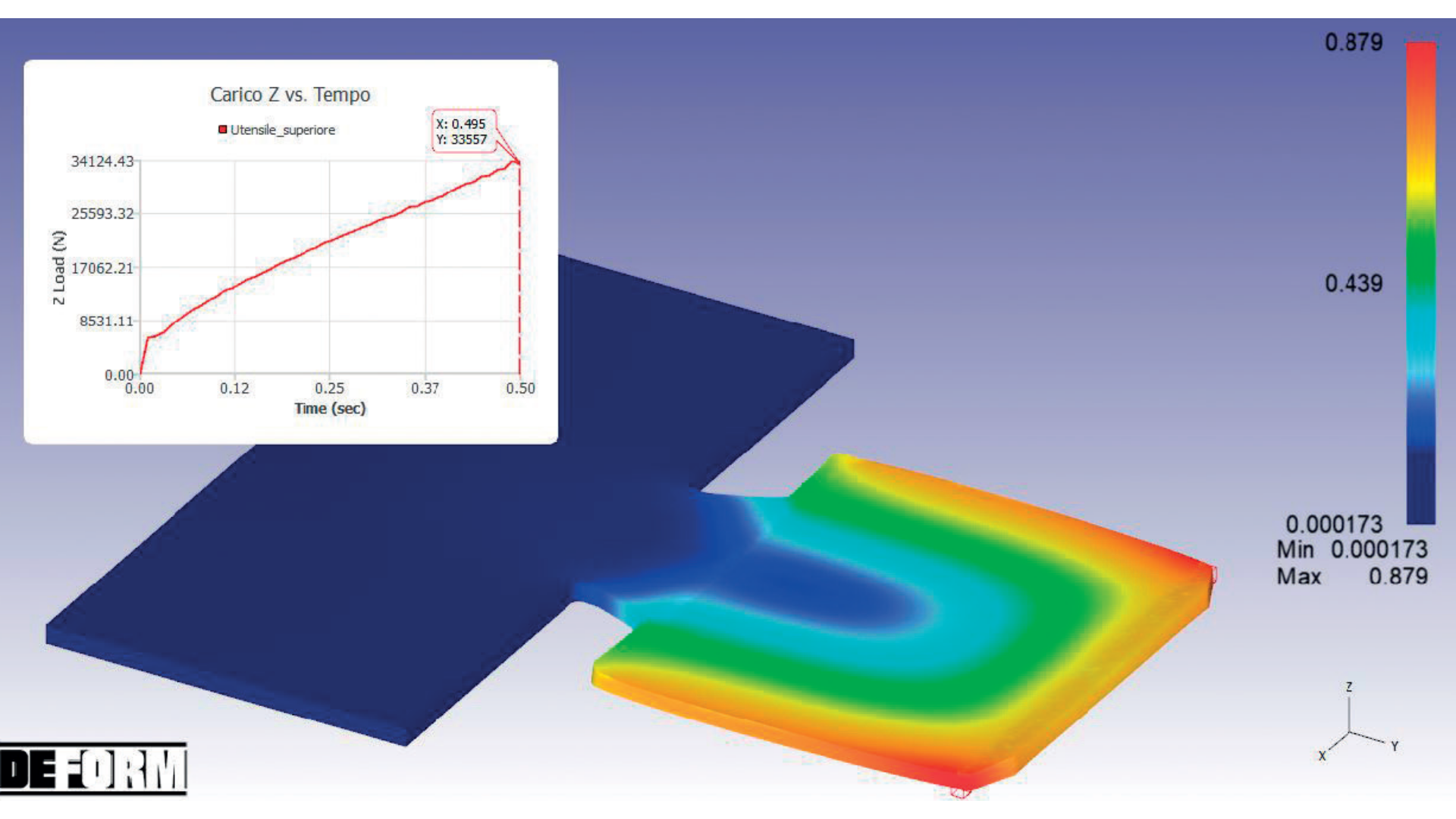

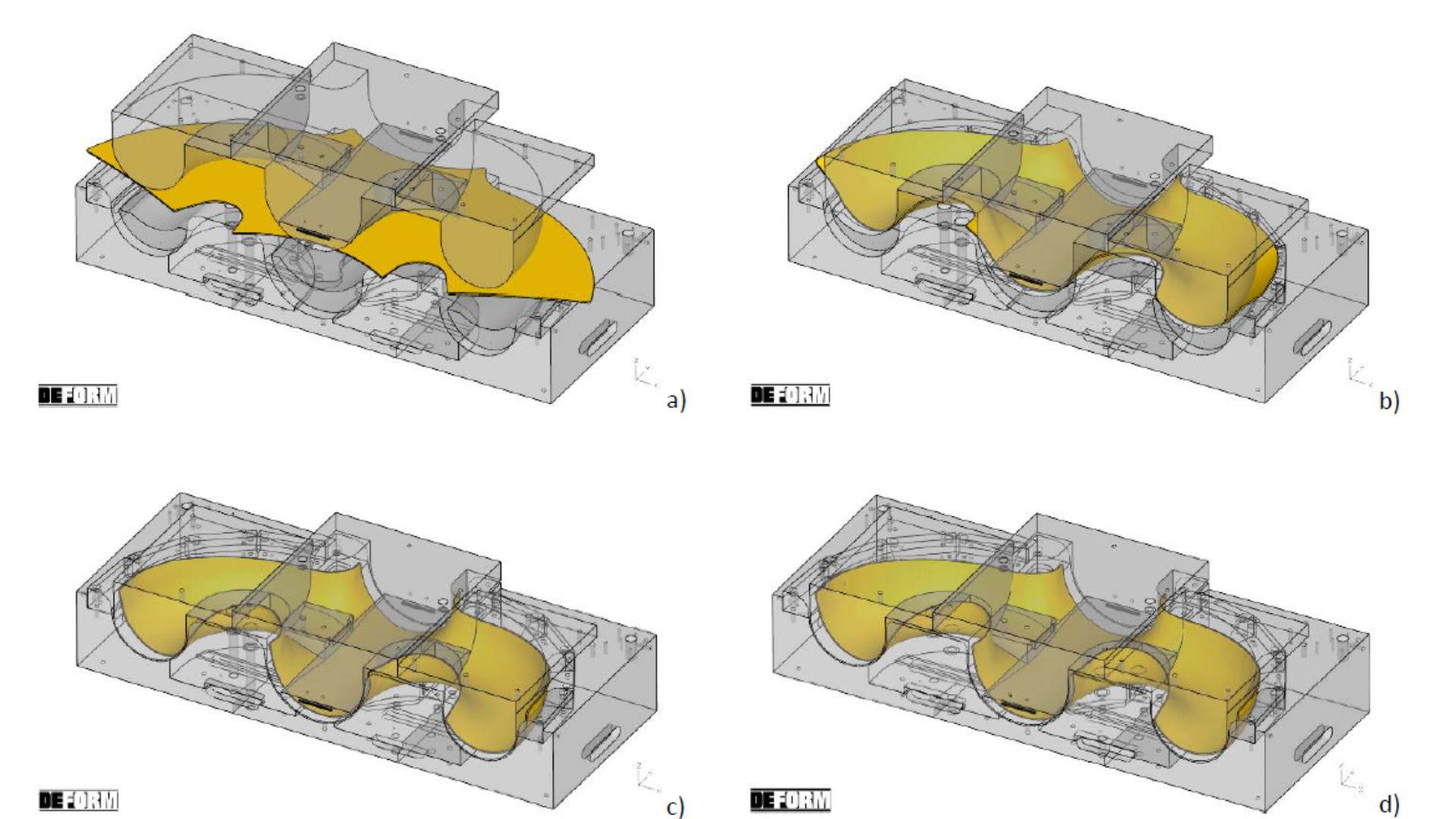

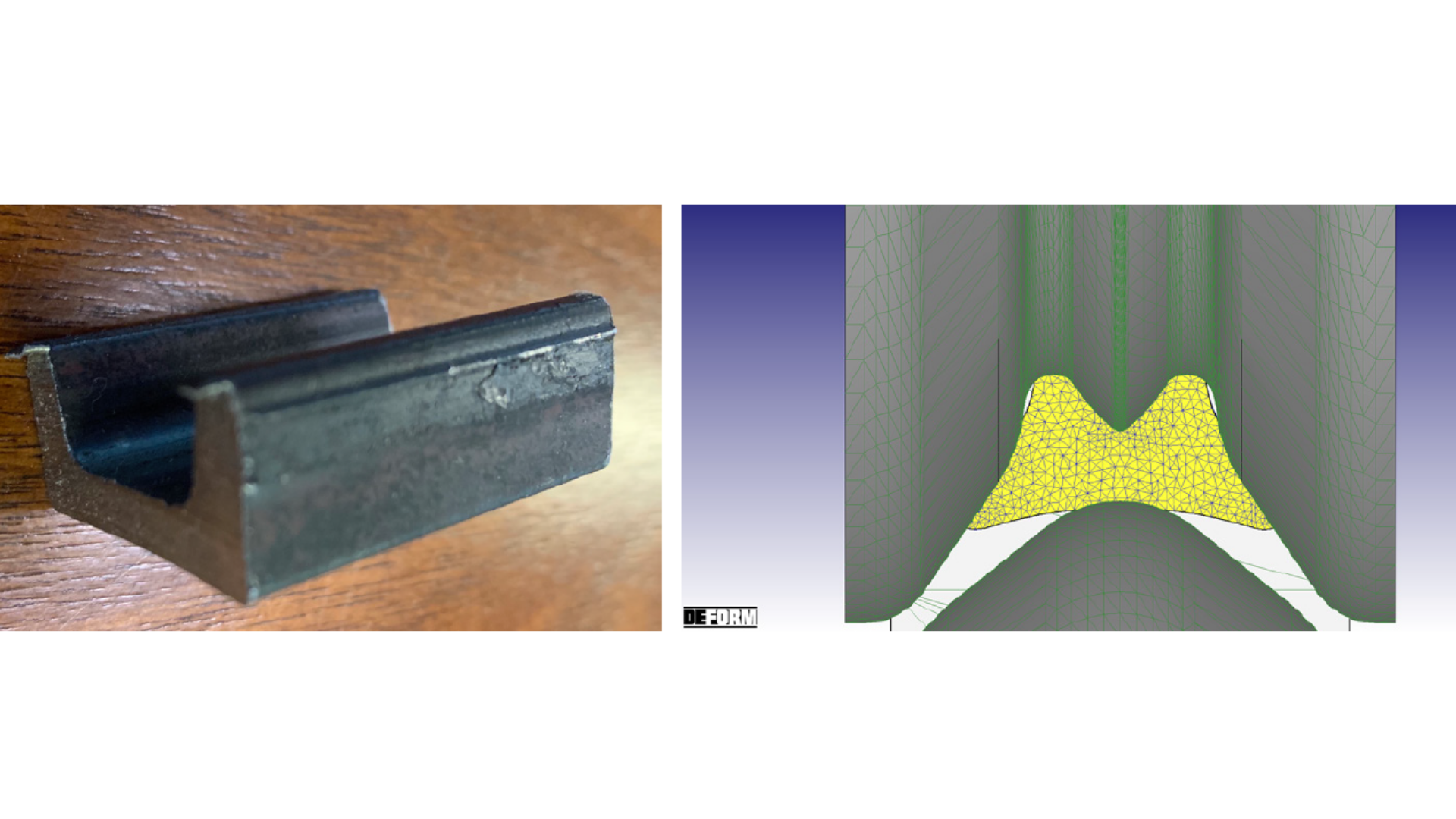

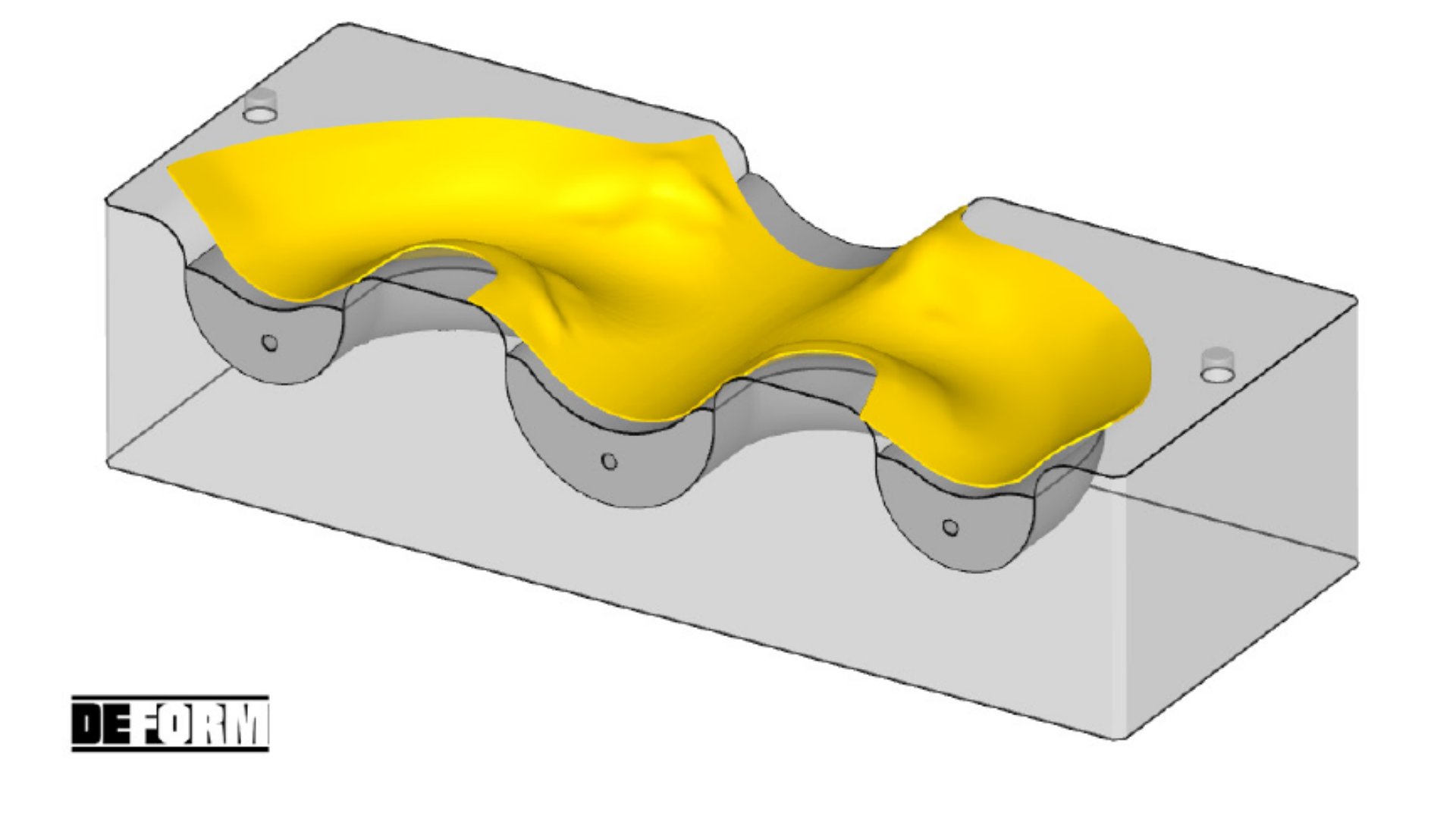

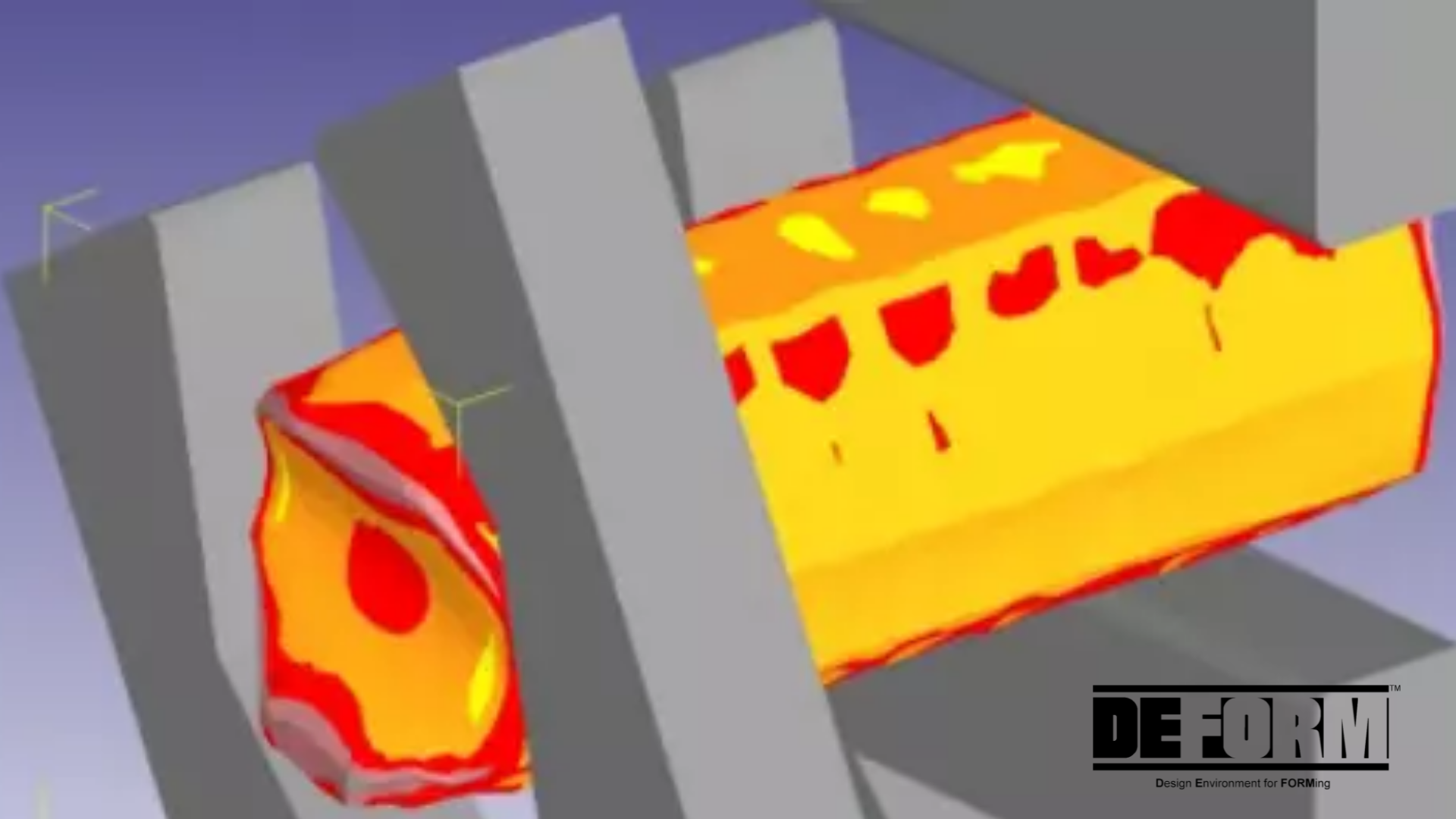

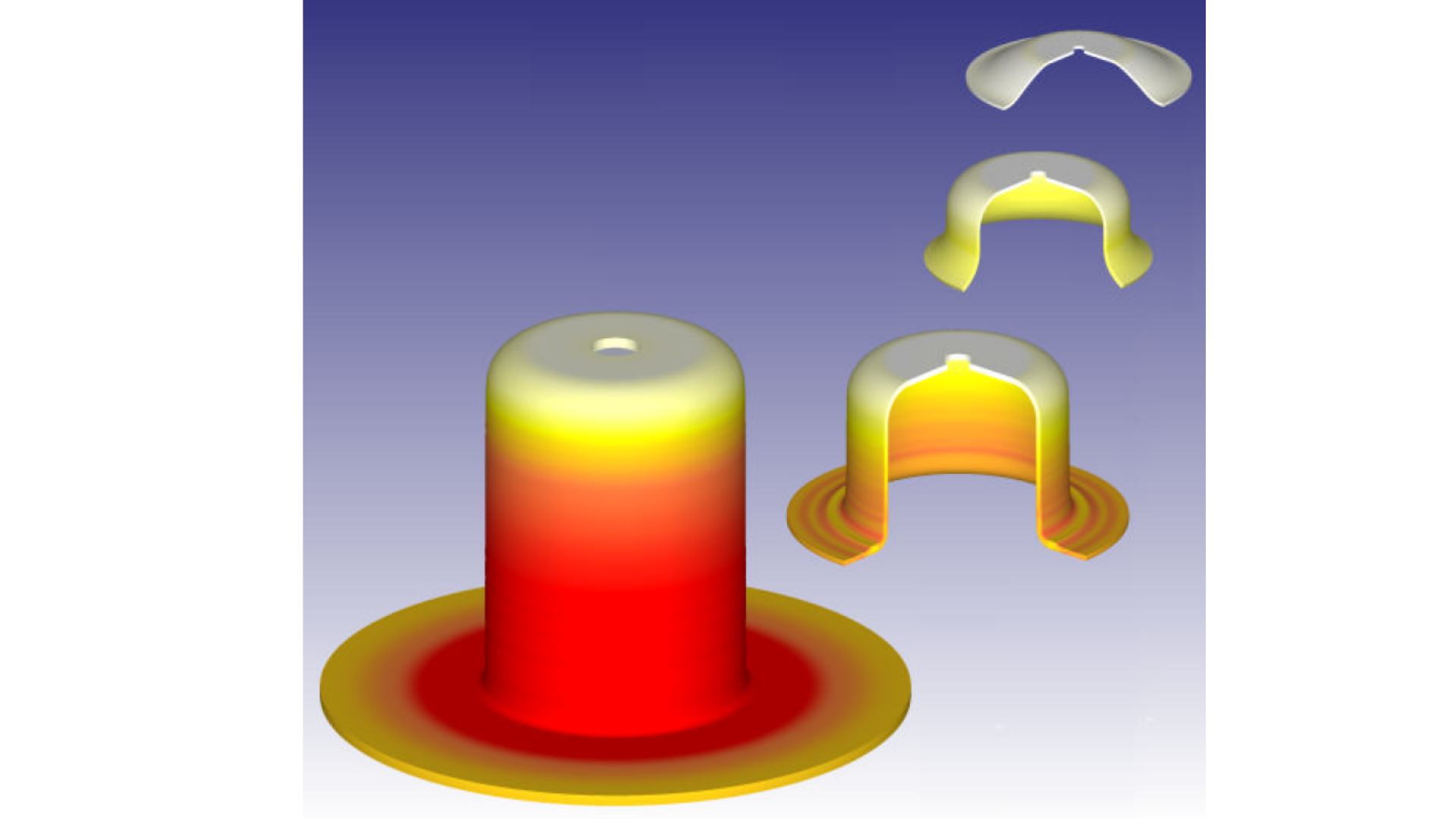

Incremental Sheet Metal Forming simulation – Software DEFORM

Incremental Sheet Metal Forming simulation – Software DEFORM

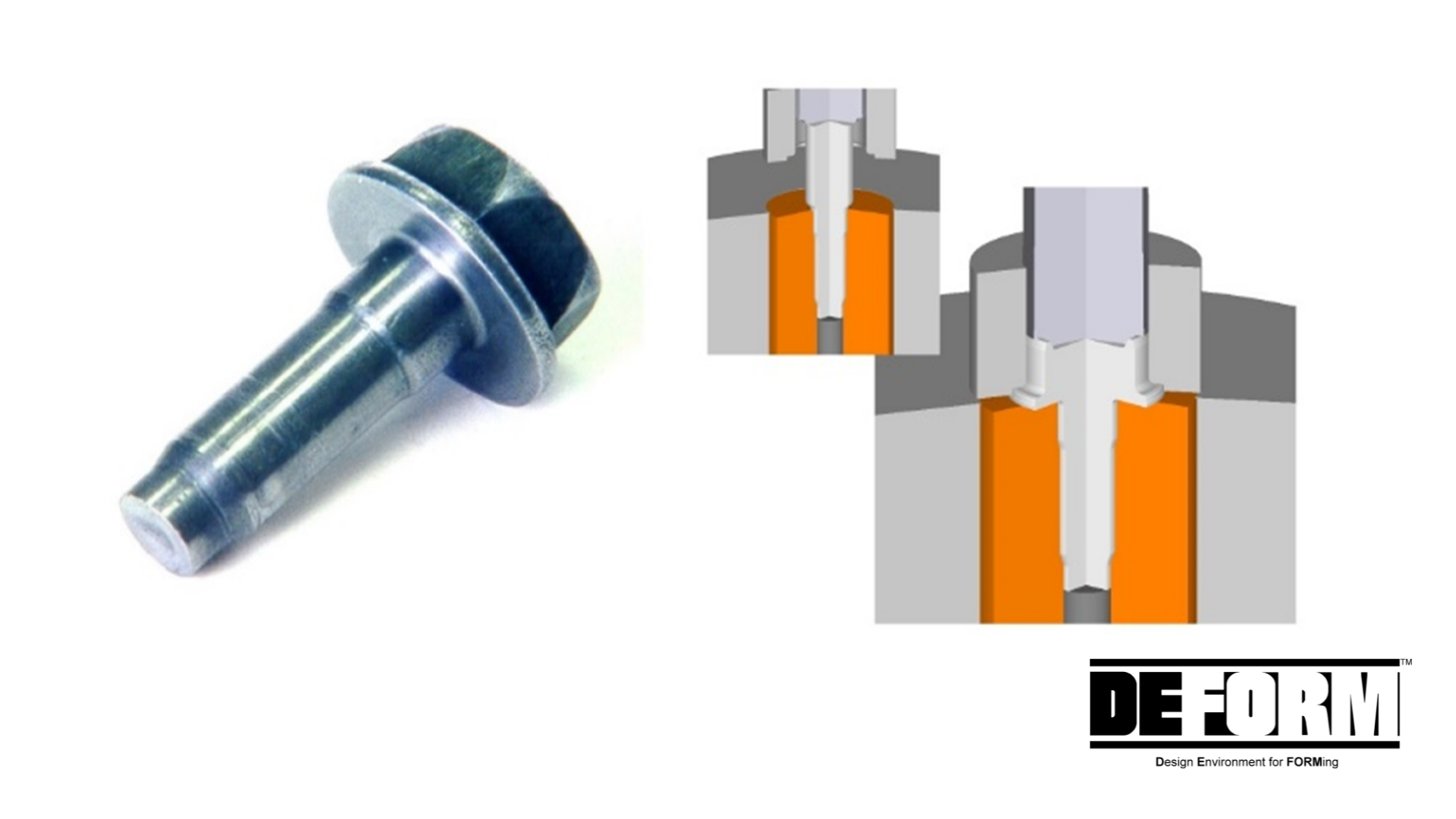

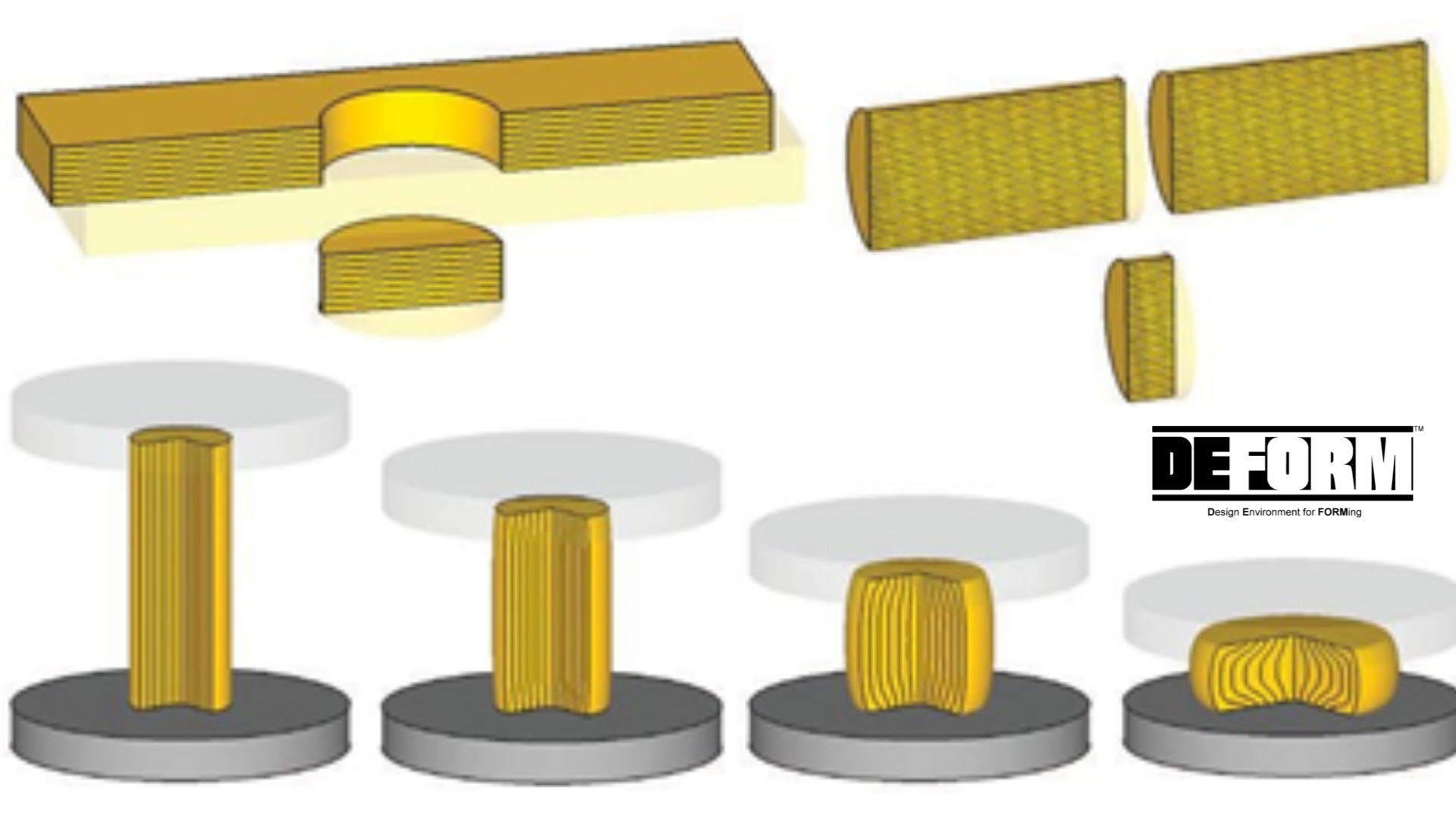

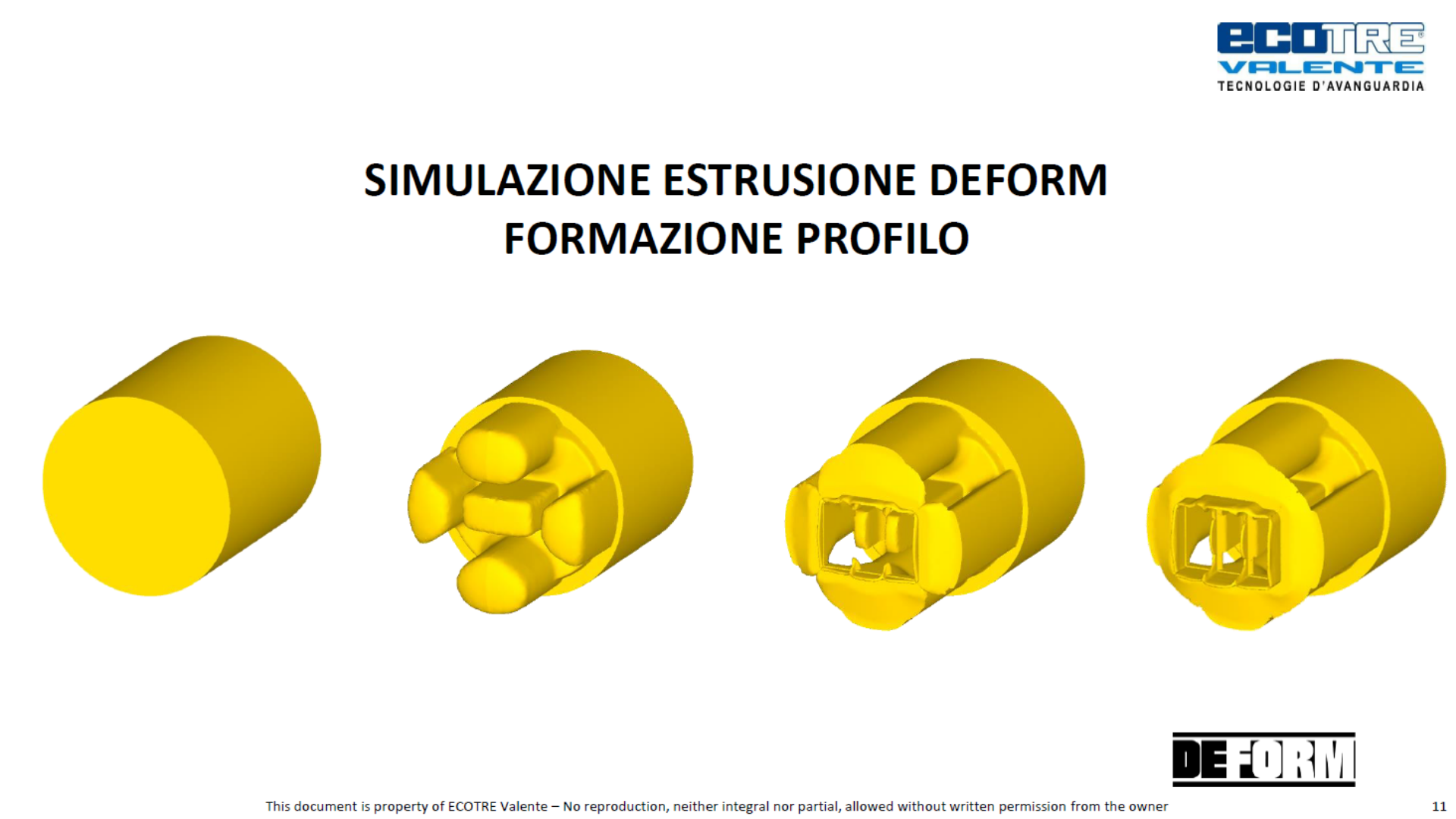

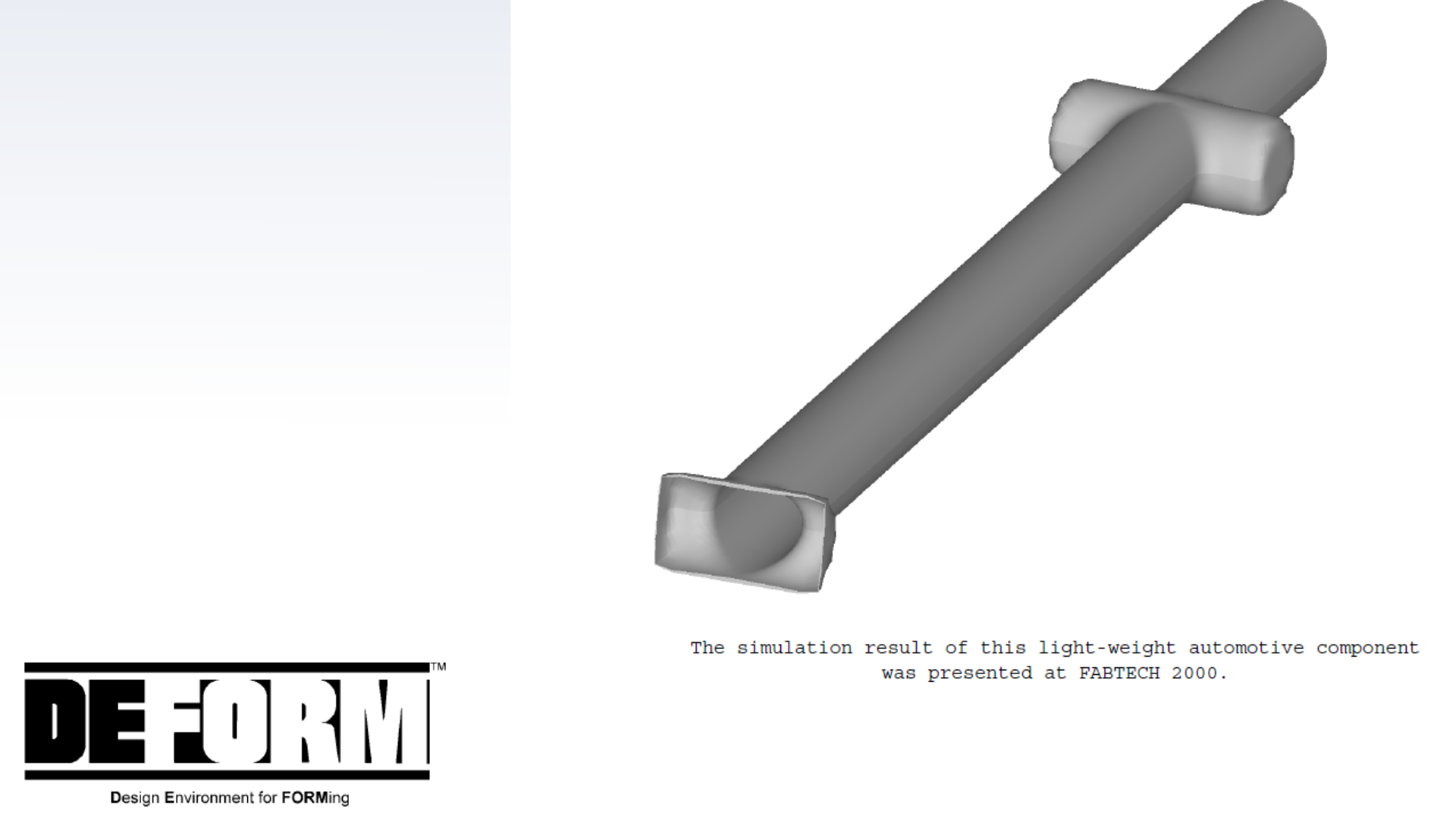

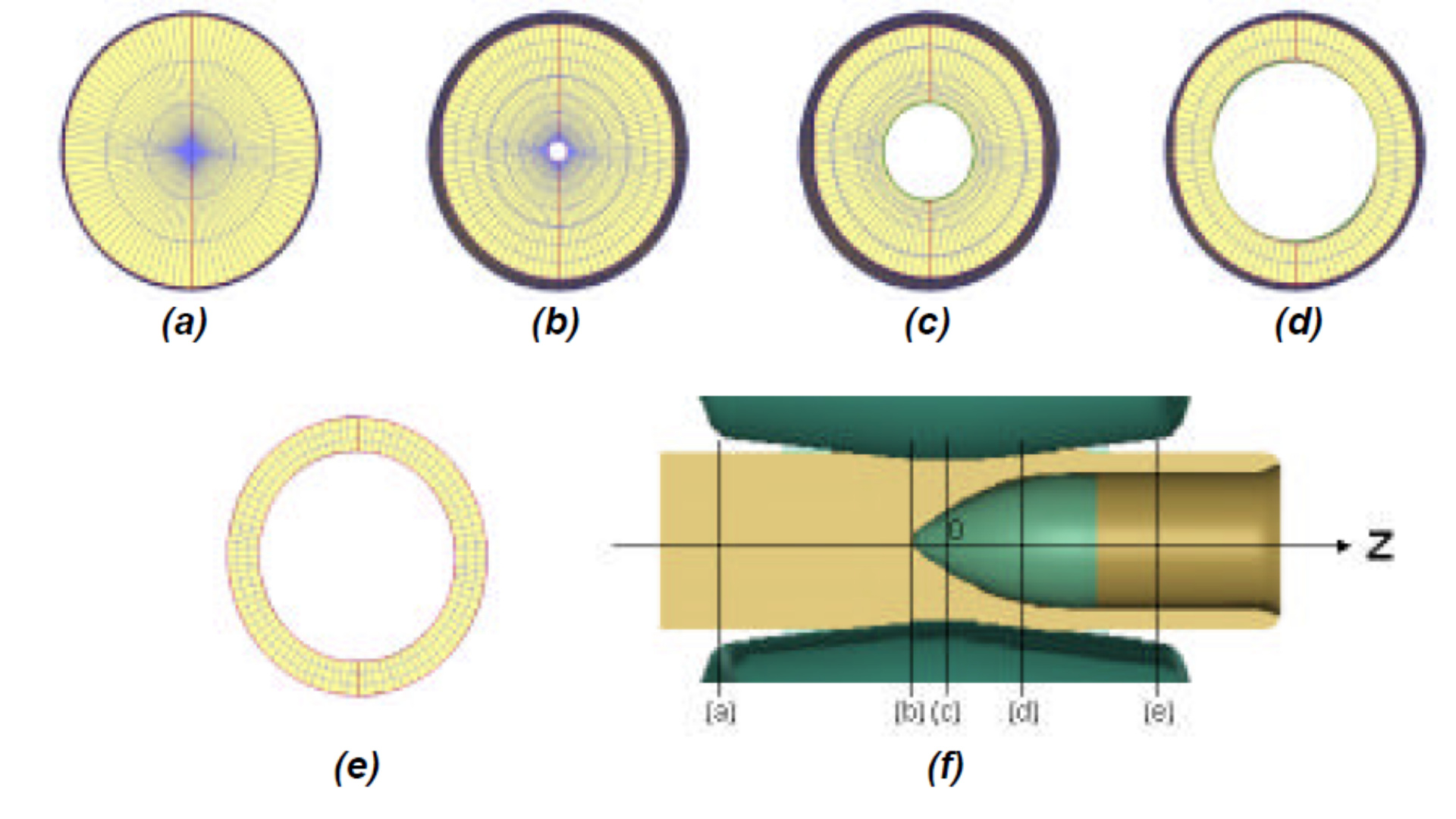

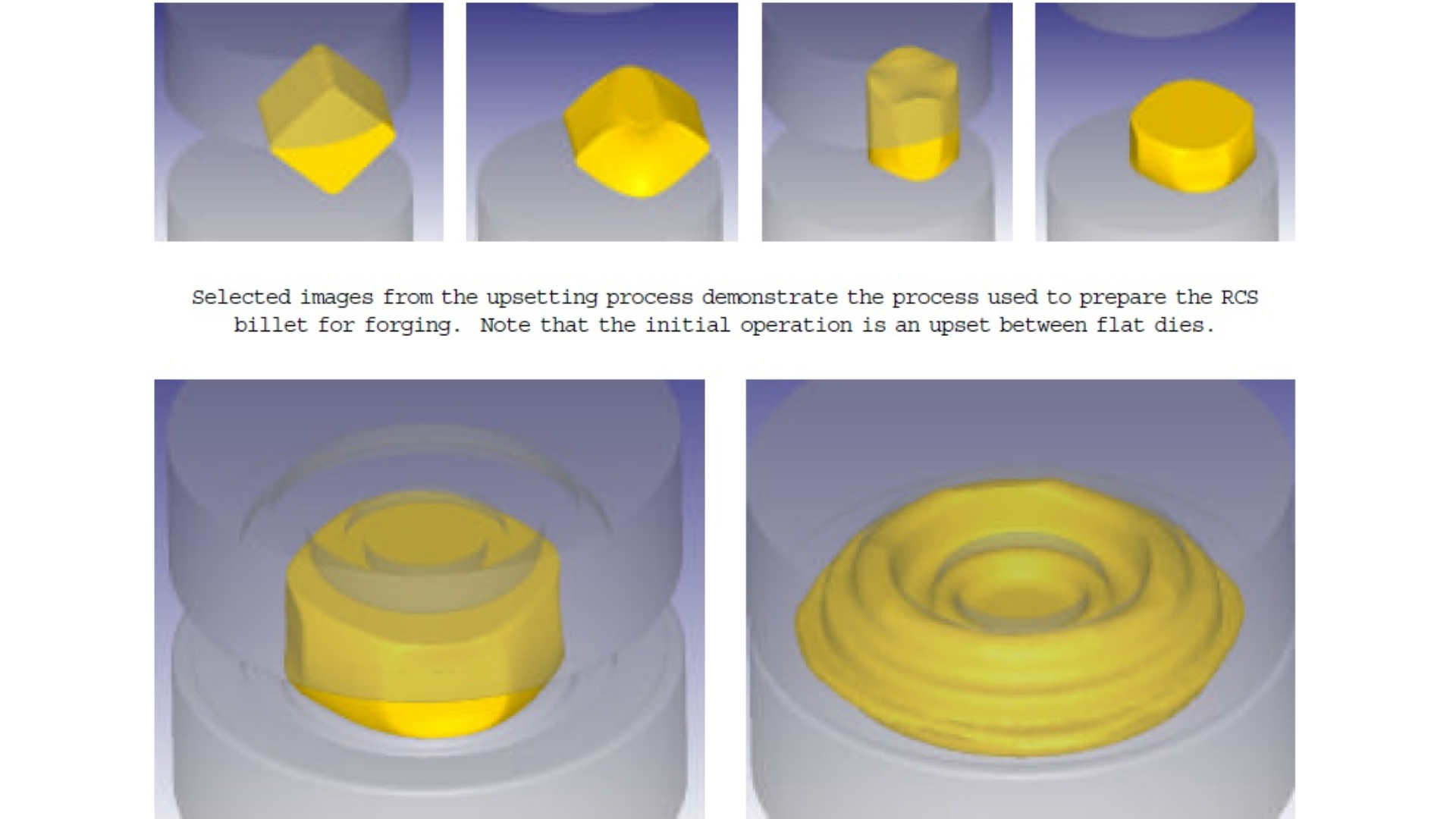

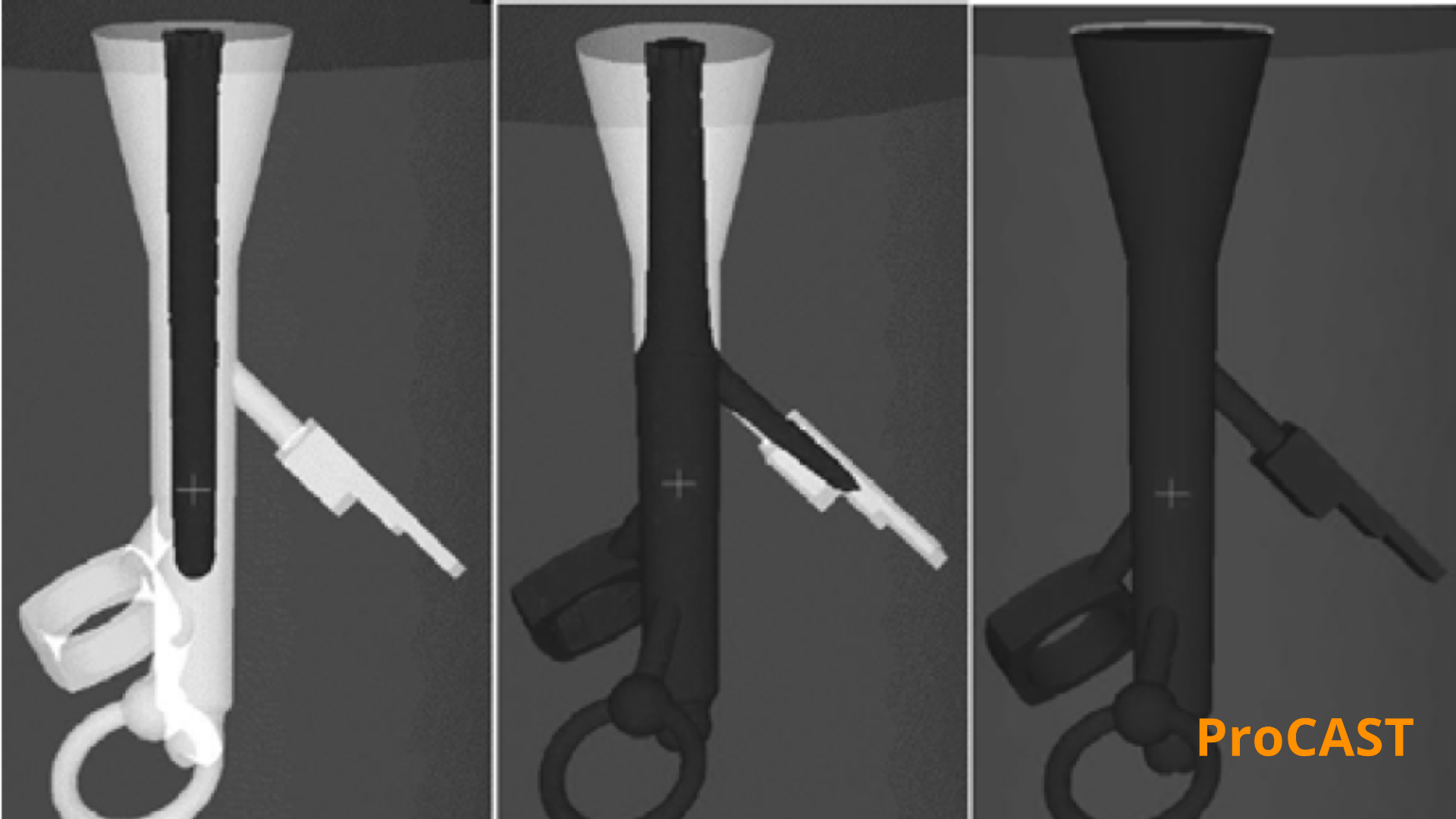

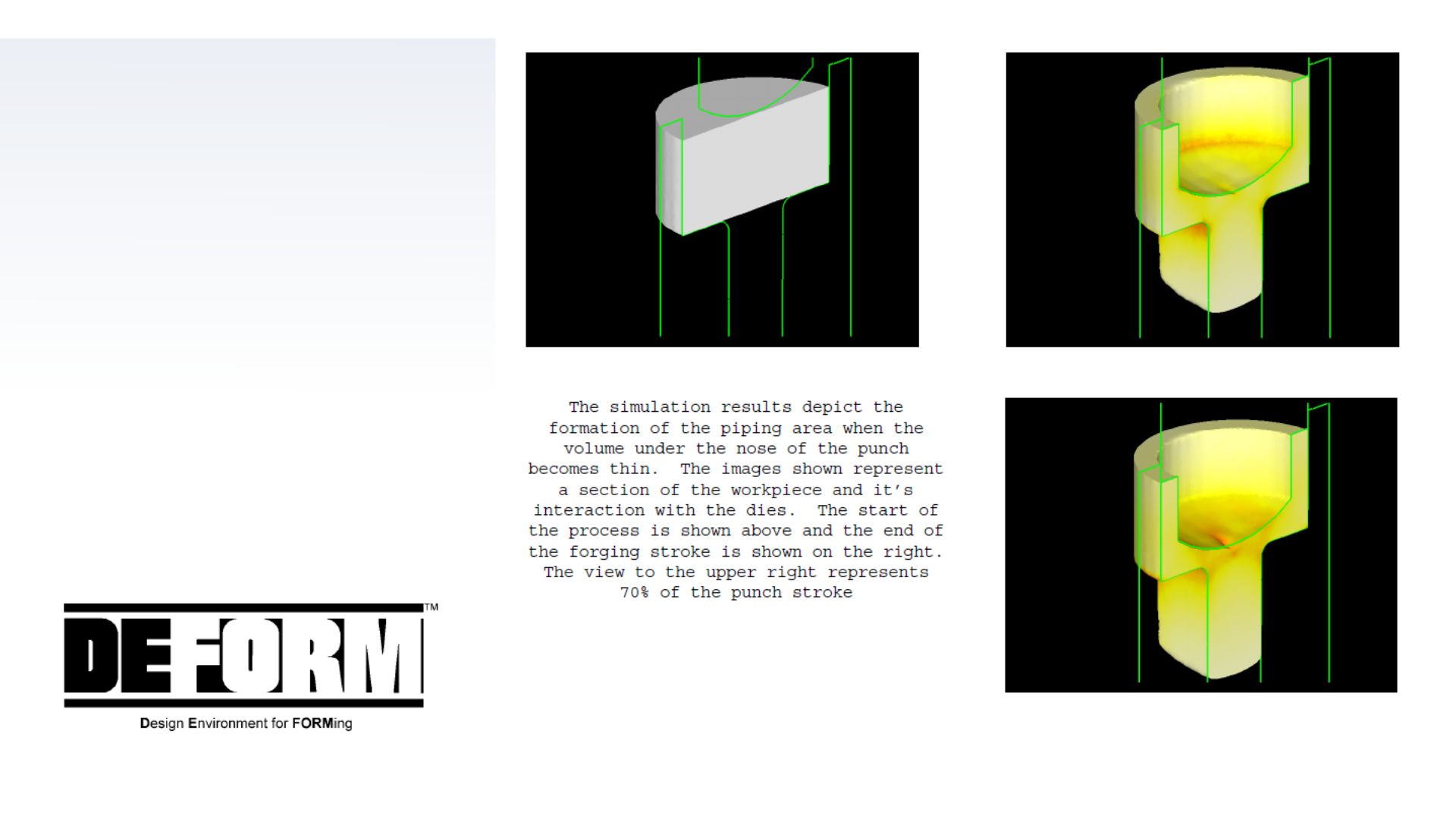

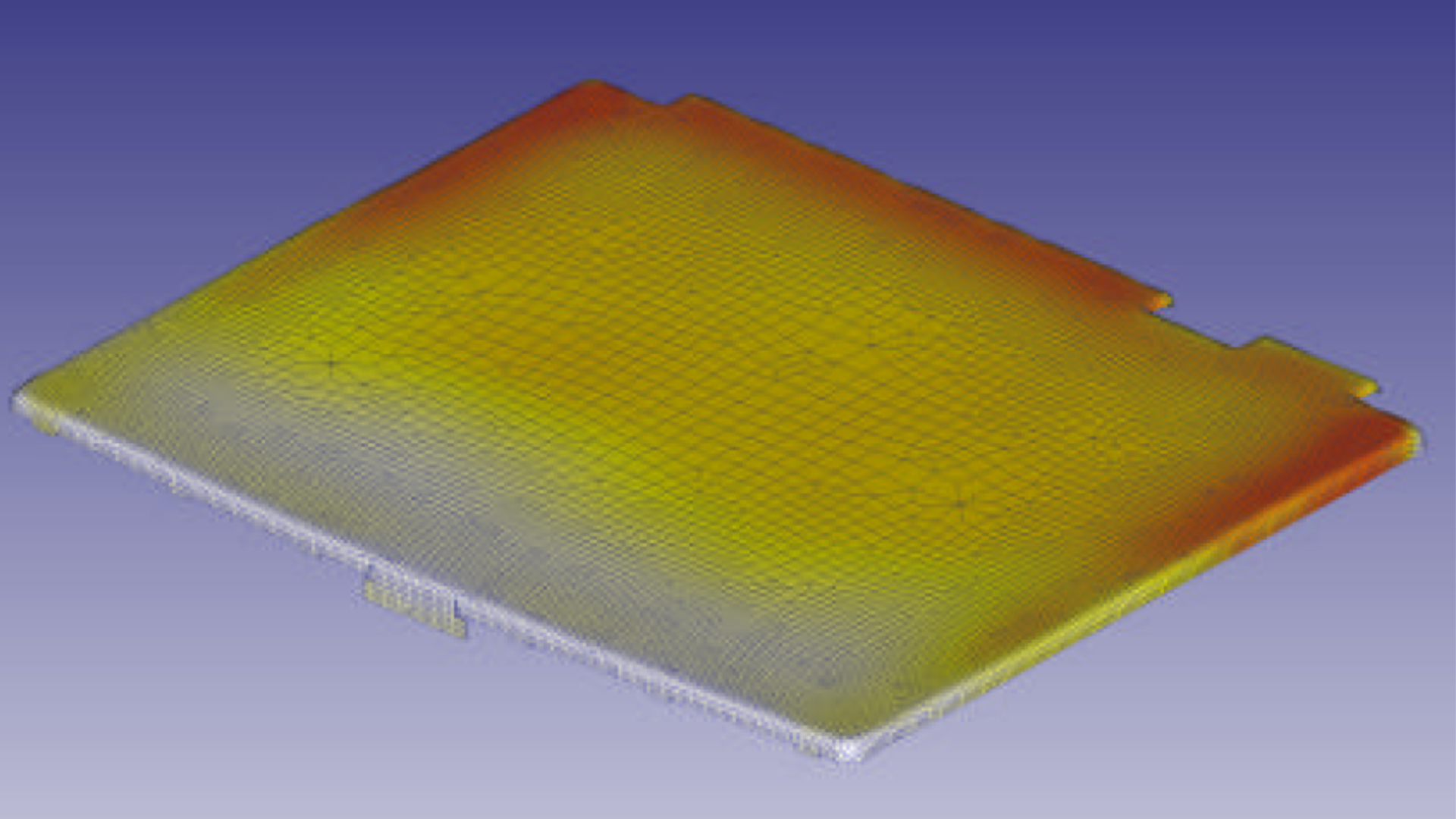

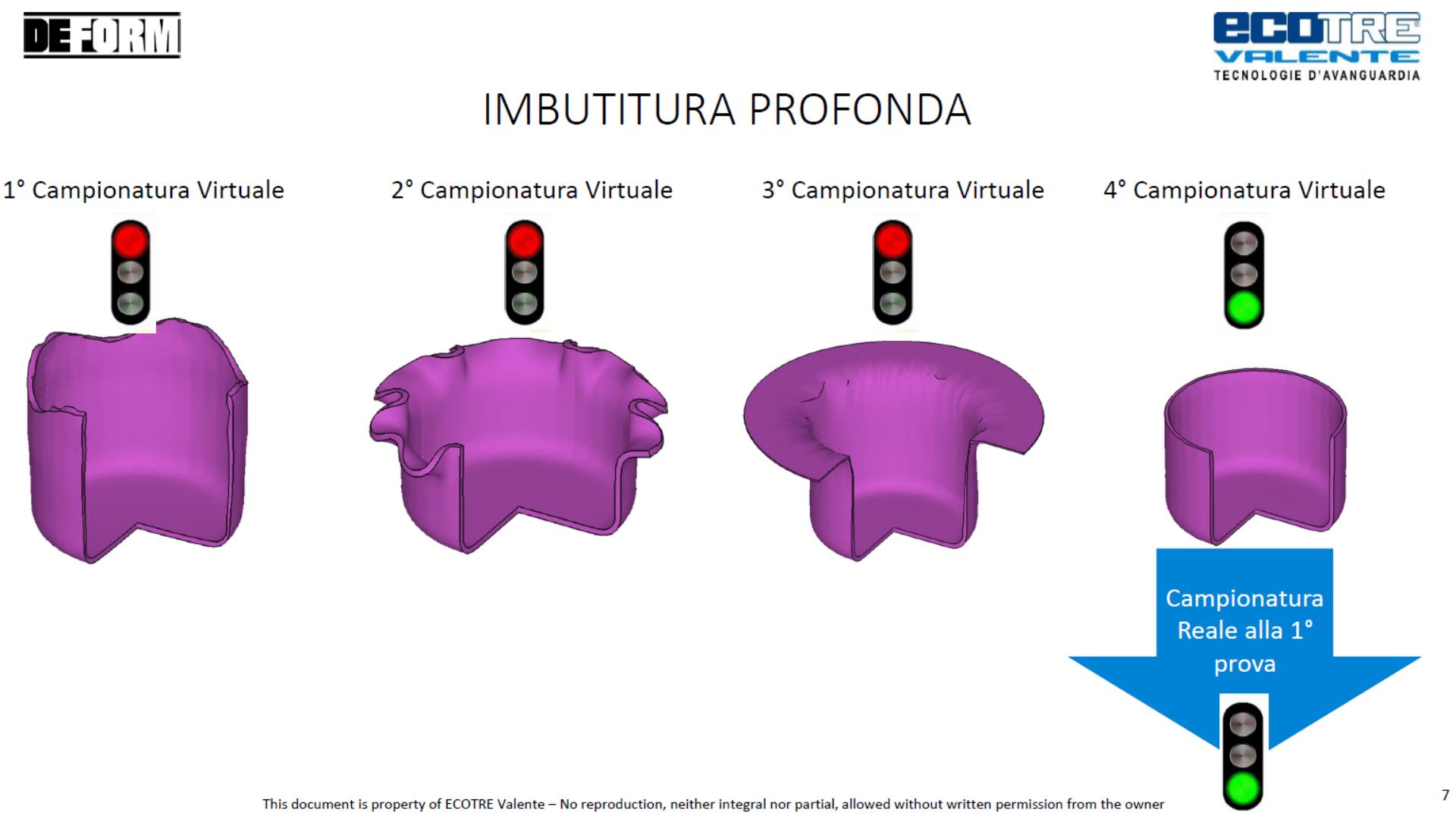

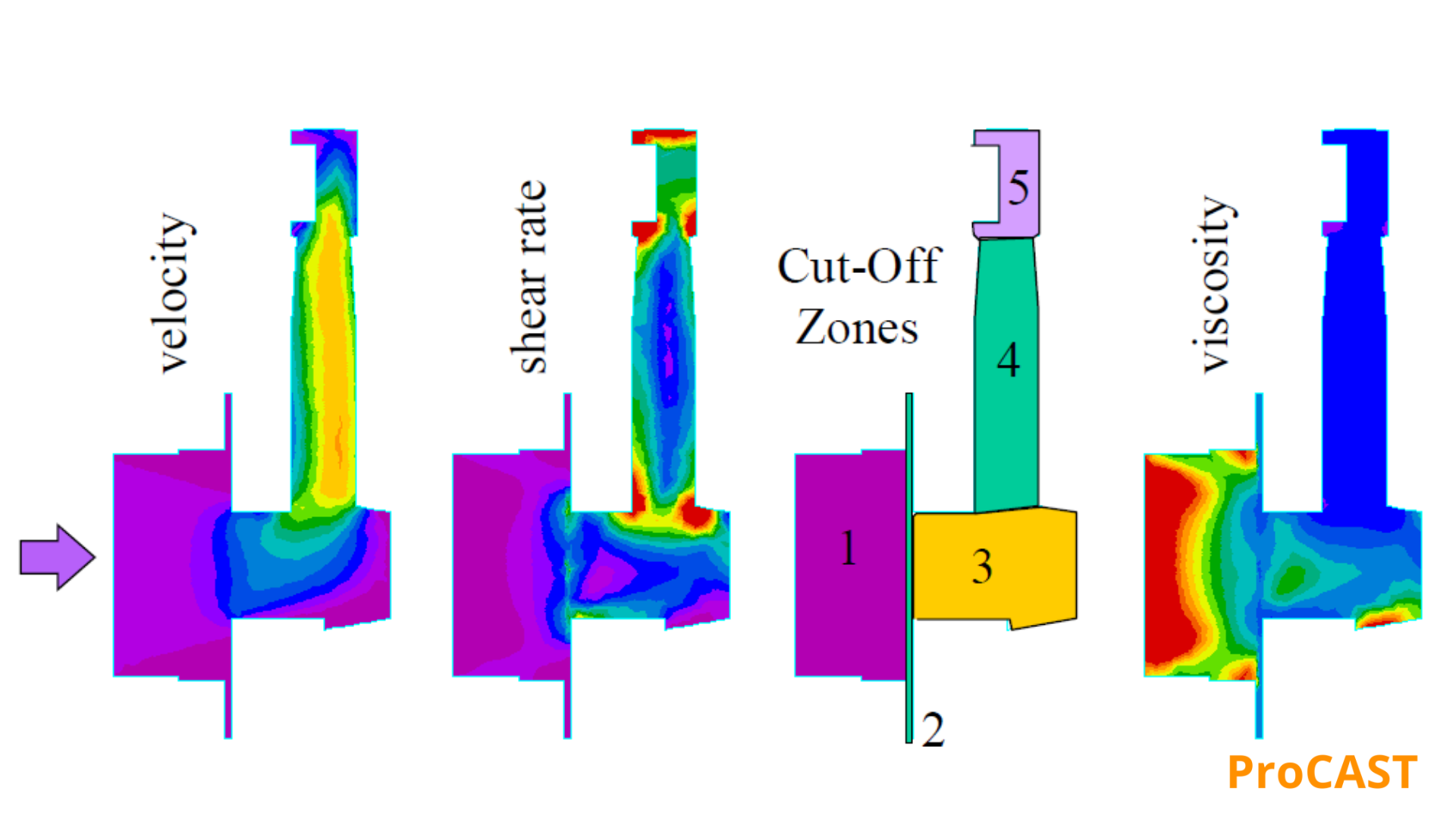

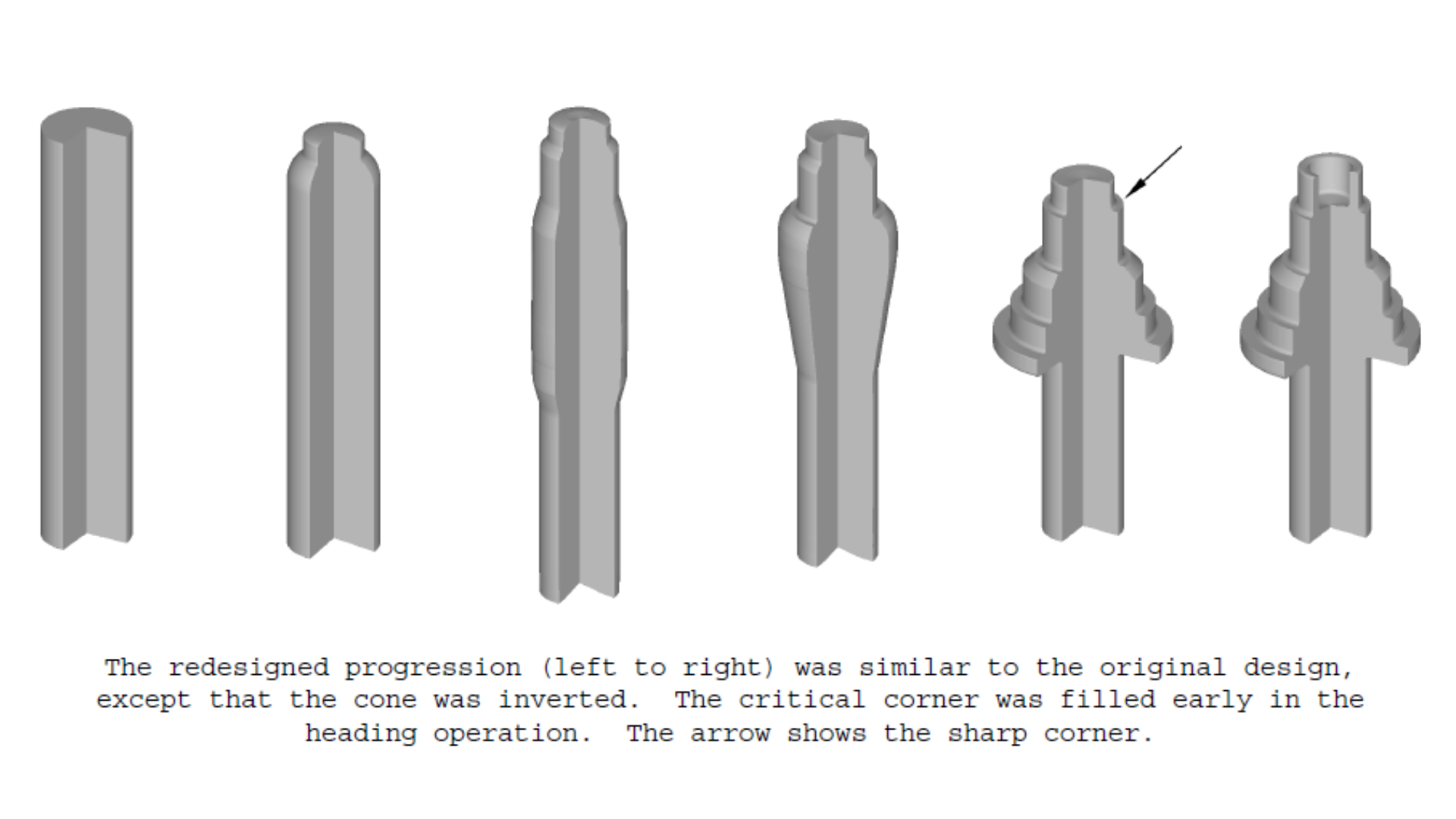

Using DEFORM™, the OSU/ERC team was able to design a progressive die sequence to make the cupped part in 10 stations. While an extra station was required in this example, the methodology was shown to be sound.

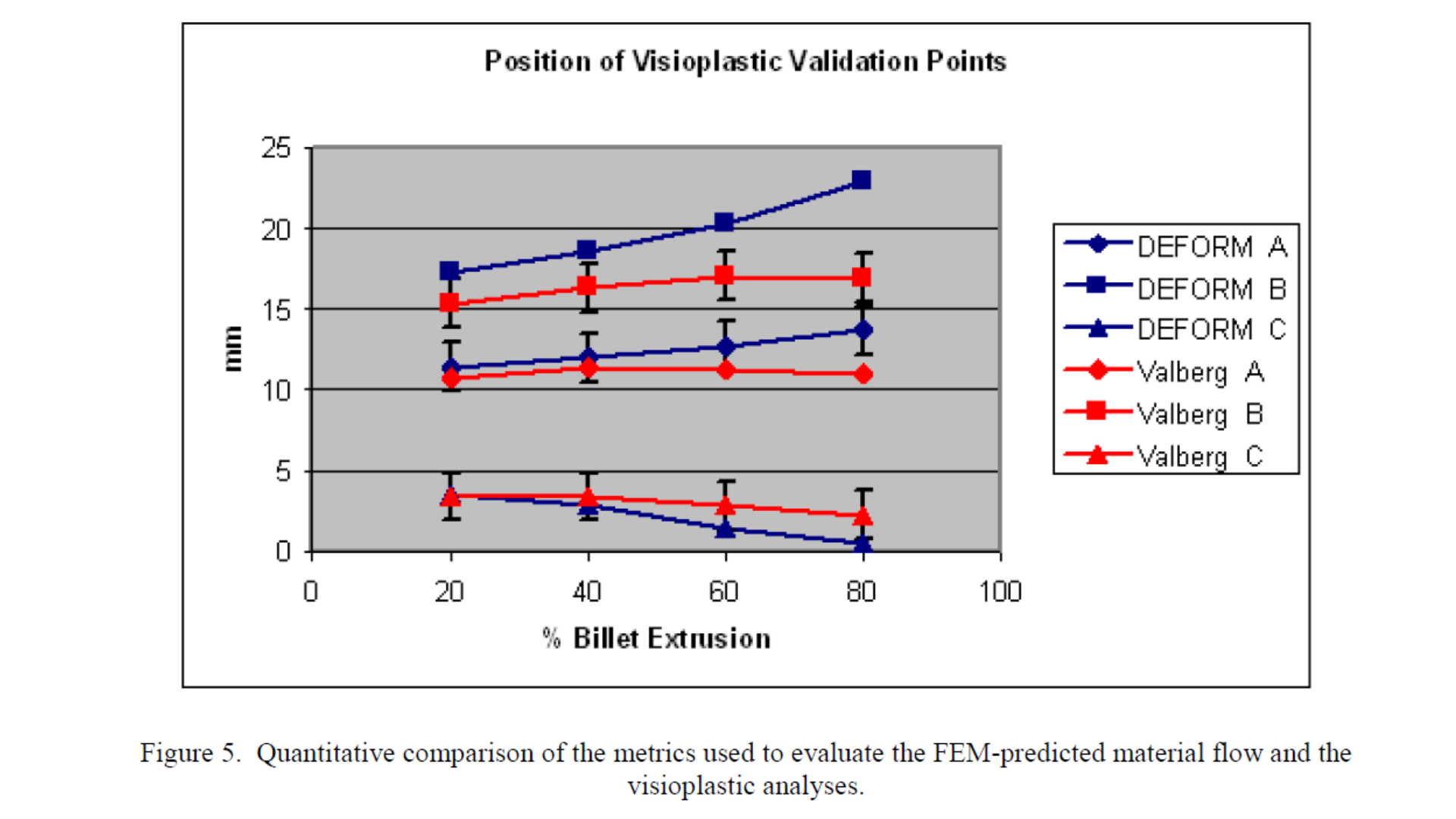

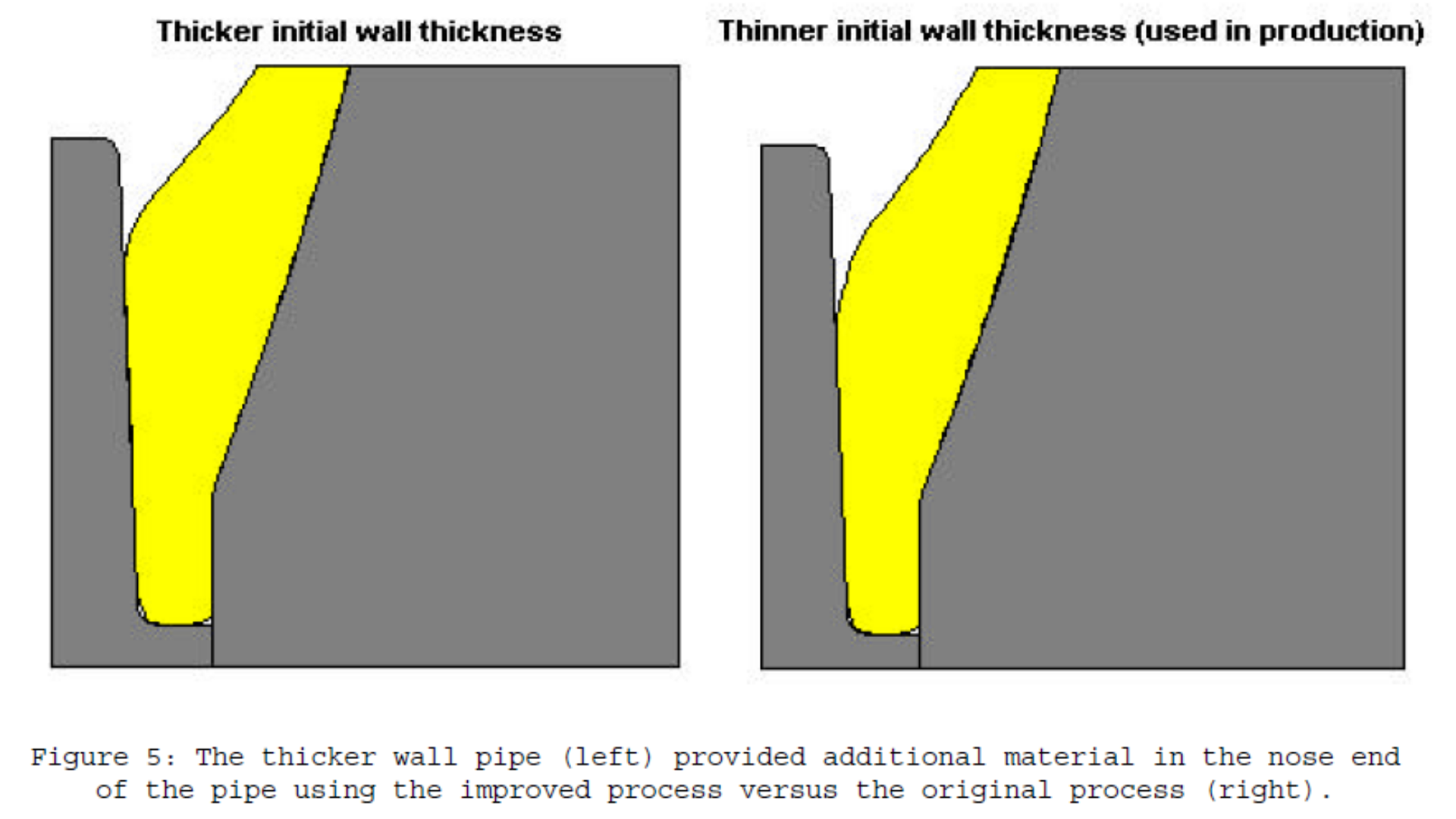

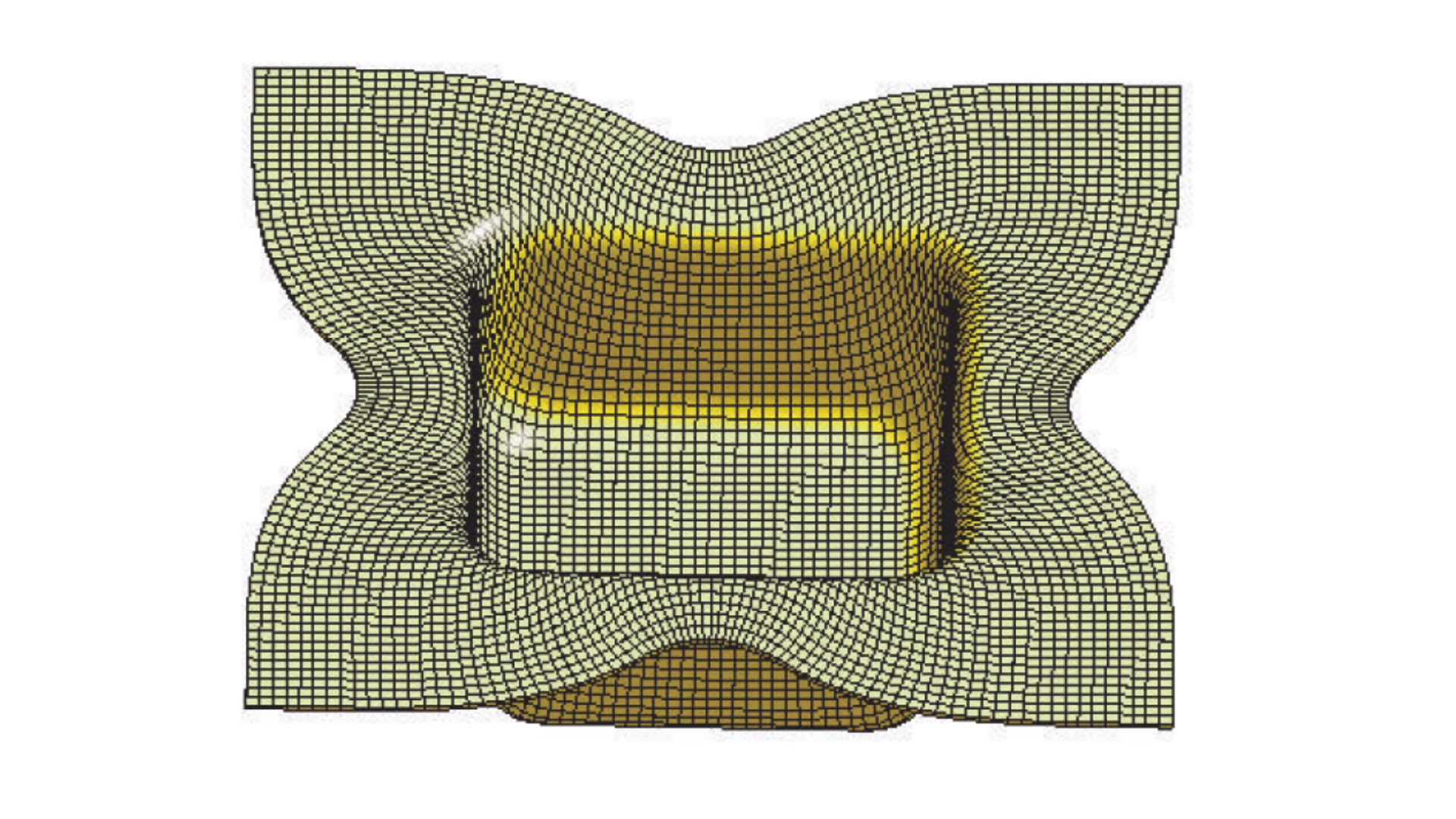

Using this methodology with experienced designers should result in fewer operations. Figure 4 shows the comparison between the emperical design and the design conducted using FEM. It can be noted that the FEM designed progression exhibits reductions that are more consistent from one station to the next. More aggressive wall thinning limits in the early stations could have been used.

This example illustrates how DEFORM™ is capable of optimizing a progressive die sequence.