DEFORM Benefits

- Quality improvement

- Optimization and saving in the design

- Improvement of production

- Enhanced precision

- Flexibility of use

- Reduction of calculation times

- Reduction of production rejects

- Saves money

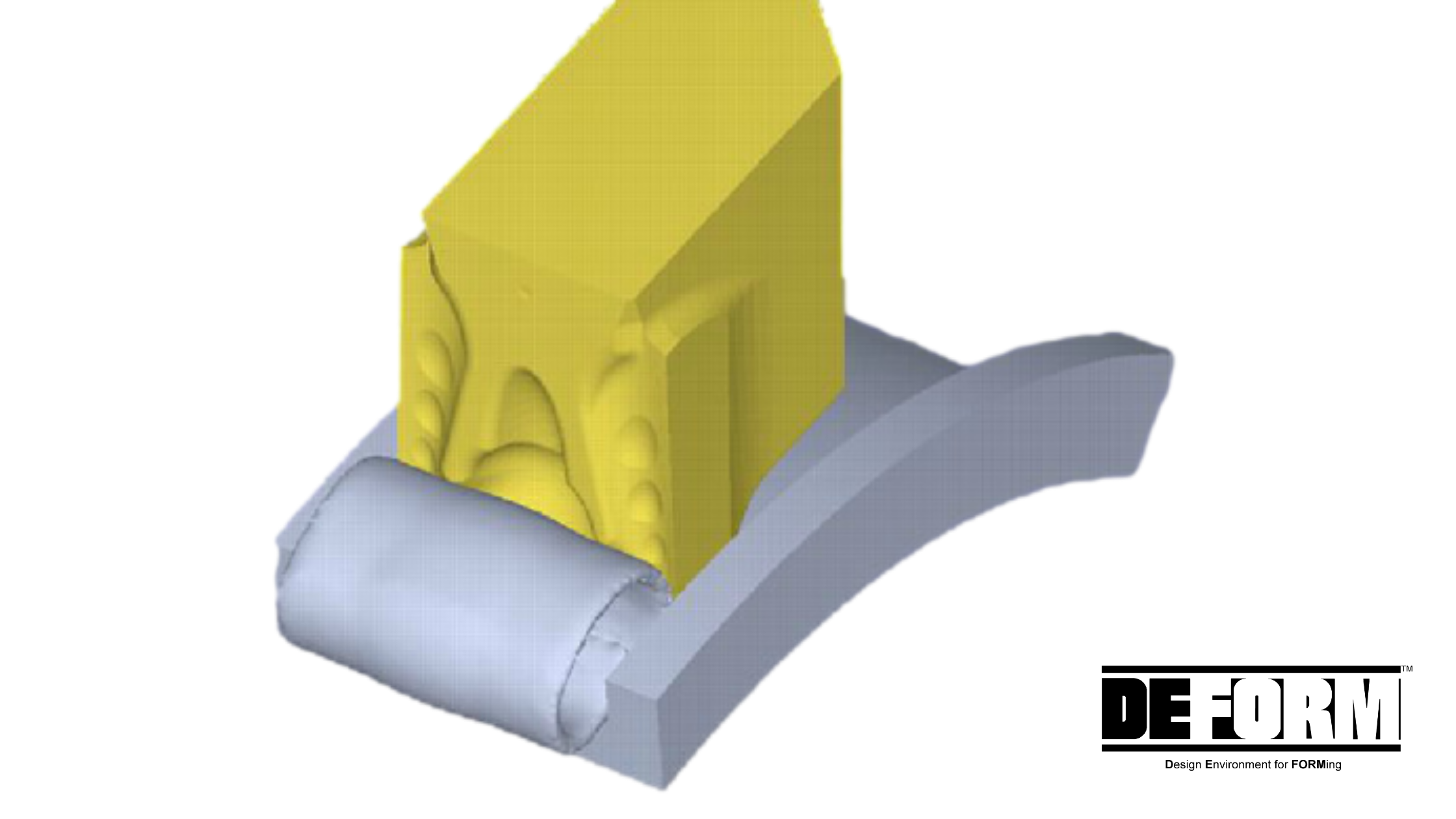

Machining of Turning: What it is

Turning Simulation: How it works

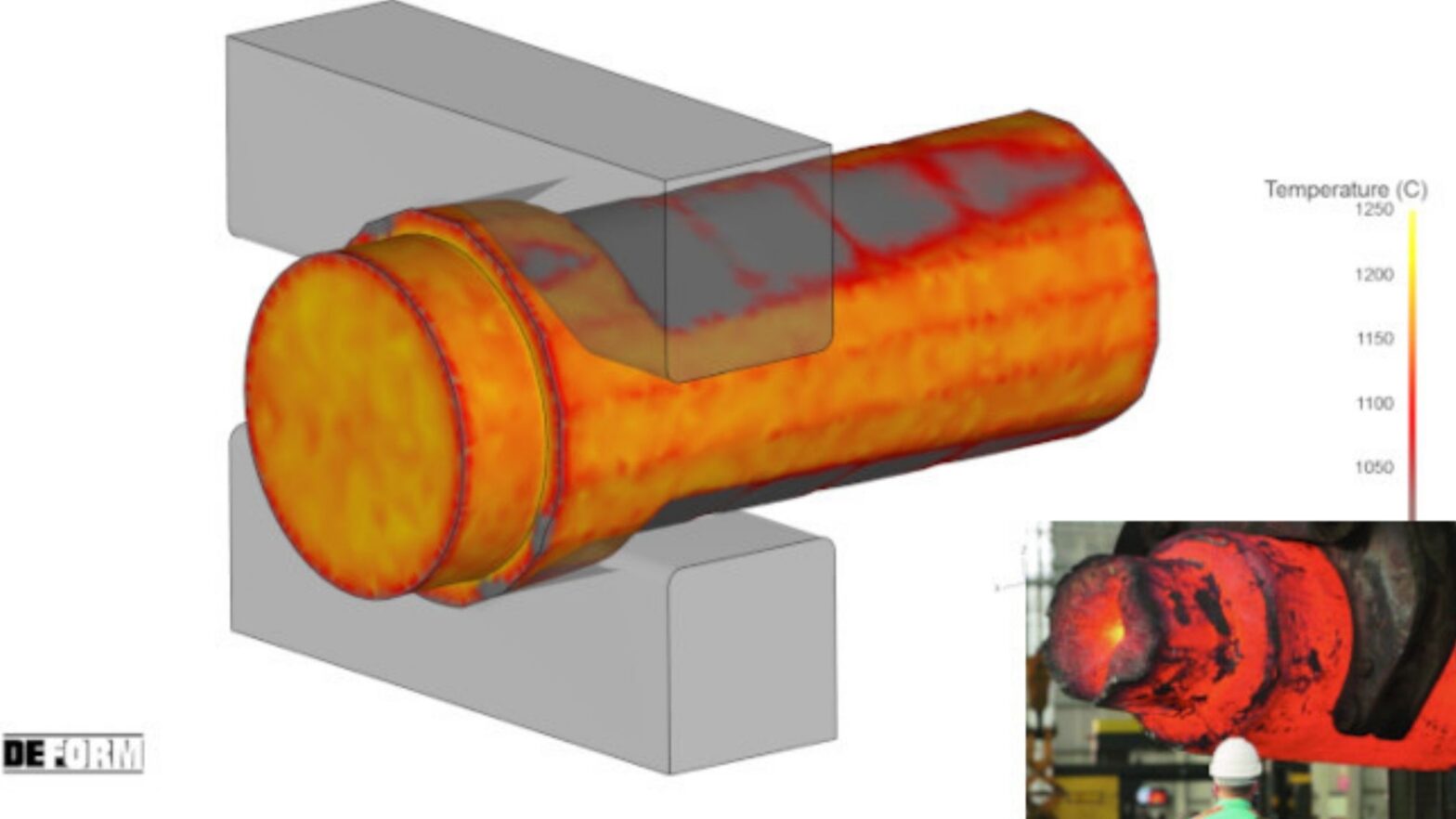

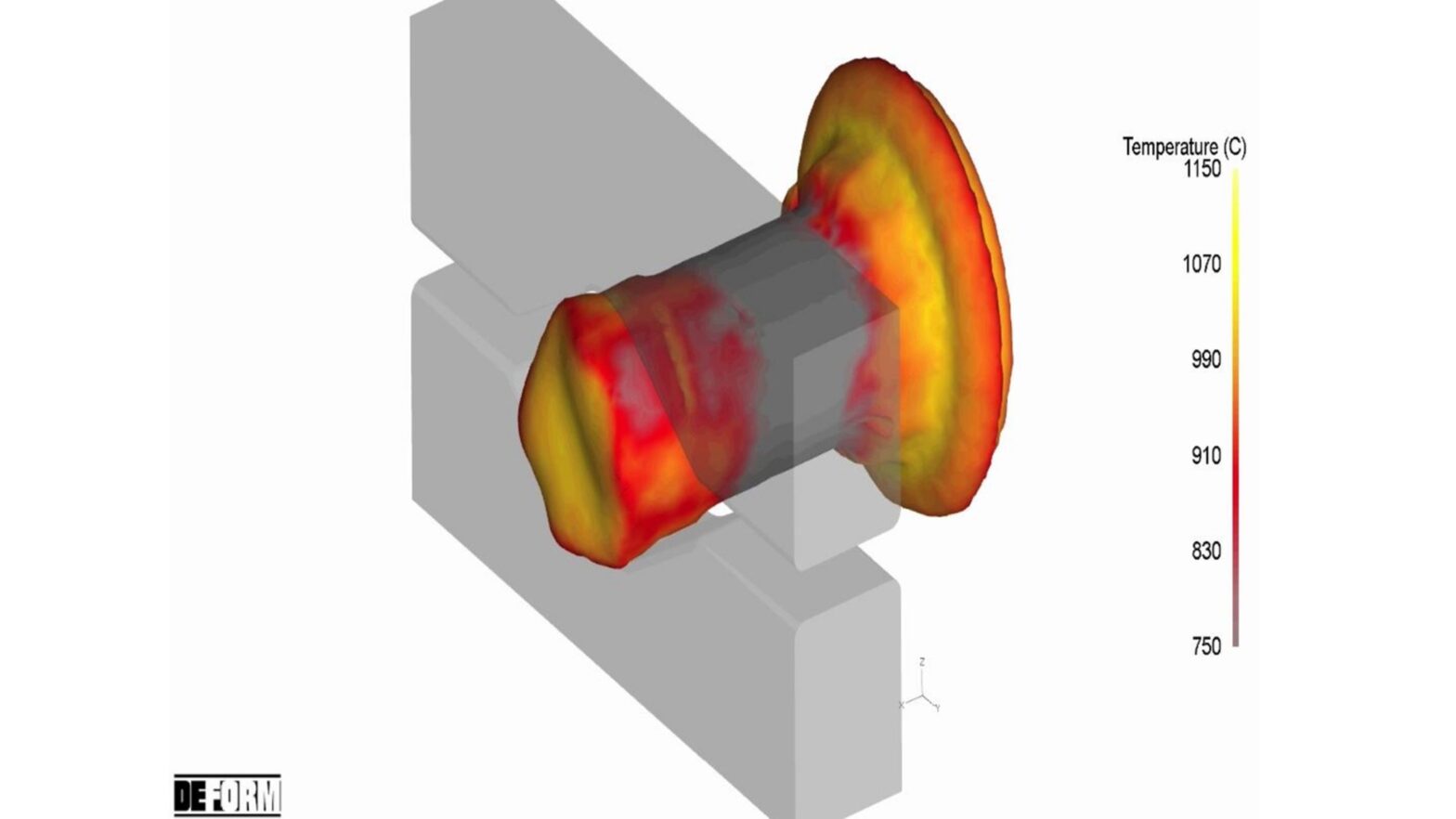

Turning simulation to verify possible skin phase transformations in the areas processed by the tool due to local thermal excess.

This process can be anticipated thanks to DEFORM turning simulation software, a powerful process simulation system designed to analyse the complete mechanical processing flow.

While DEFORM supplies sophisticated analysis functions, the graphical interface is intuitive and easy to learn. A specific template simplifies the routine turning, drilling, boring and milling simulation setup. For more complex processes, the standard interface provides considerable flexibility in configuration of the problem.

The software integrates the production of raw material, forming, heat treatment and machining, predicting the shape of the swarf, the force of the cuts, the temperature of the tool and of the workplace, the wear of tools and residual stresses. In fact distortion, resulting from the residual stress of the whole of the part, can be modelled.

DEFORM automatically calculates deformation and heat treatment in an integrated simulation environment and with a material database, supplied by the Scientific Forming Technologies Corporation (SFTC), of over 250 materials. The software allows you to reduce machine downtime, increase productivity, quickly and efficiently program the lathe and minimise collisions and production failures.

What customers say about DEFORM:

DEFORM Turning simulation software is American and has been optimised to be reliable, quick and easy.

- EXCELLENT AGREEMENT OF “SOFTWARE RESULTS” WITH “REALITY” DEFORM is the most widely used cold forming simulation software in the world

- SAMPLING IMMEDIATELY POSITIVEThe simulation makes it possible to identify defects obtained during forming, to understand their causes and therefore to undertake the right corrective actions

- STARTING TIMES REDUCED TO A MINIMUM The press setting was already tested in simulation. The real sampling will dispose of the machine setup card already defined.