DEFORM Benefits

- Quality improvement

- Optimization and saving in the design

- Improvement of production

- Enhanced precision

- Flexibility of use

- Reduction of calculation times

- Reduction of production rejects

- Saves money

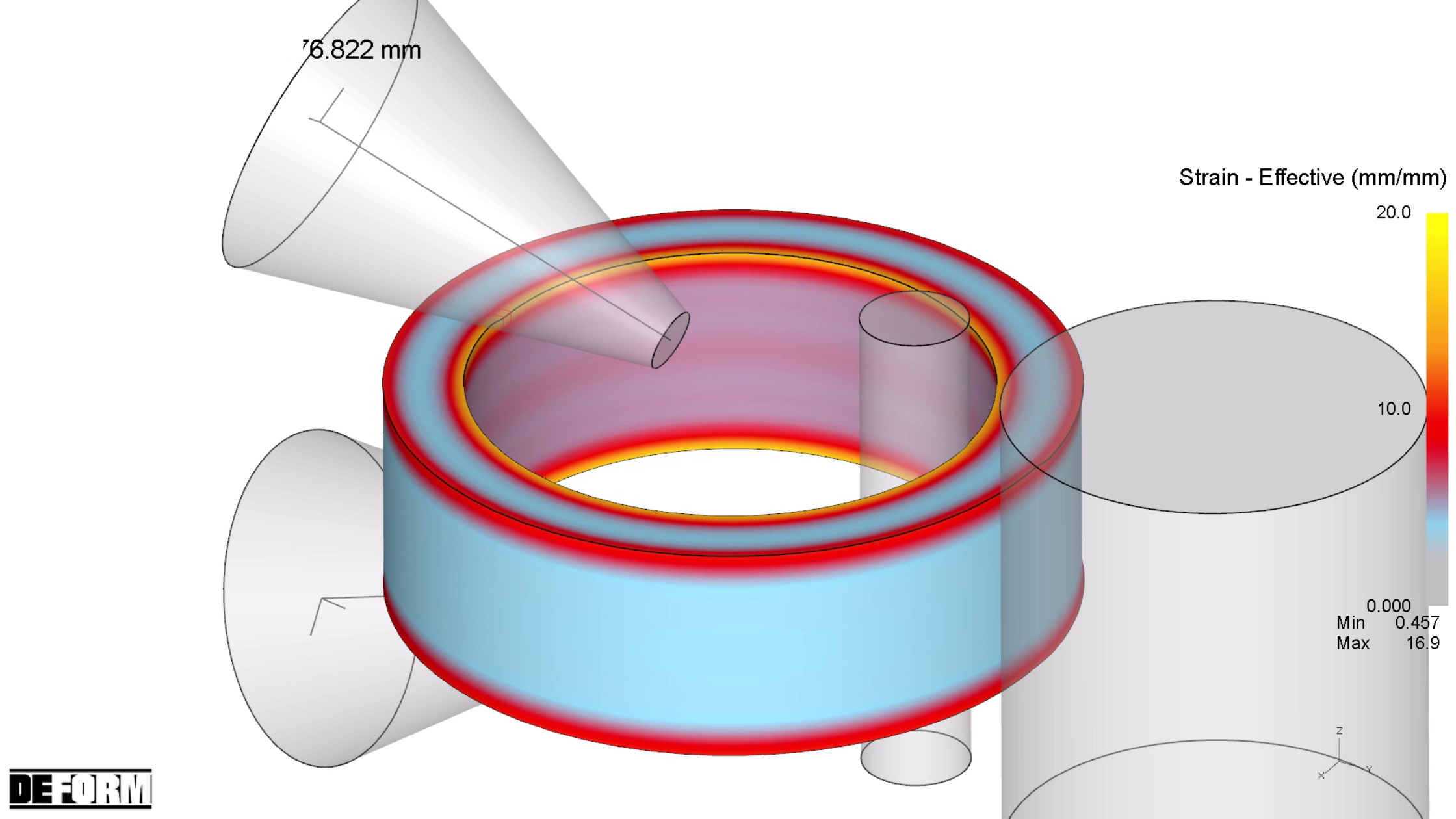

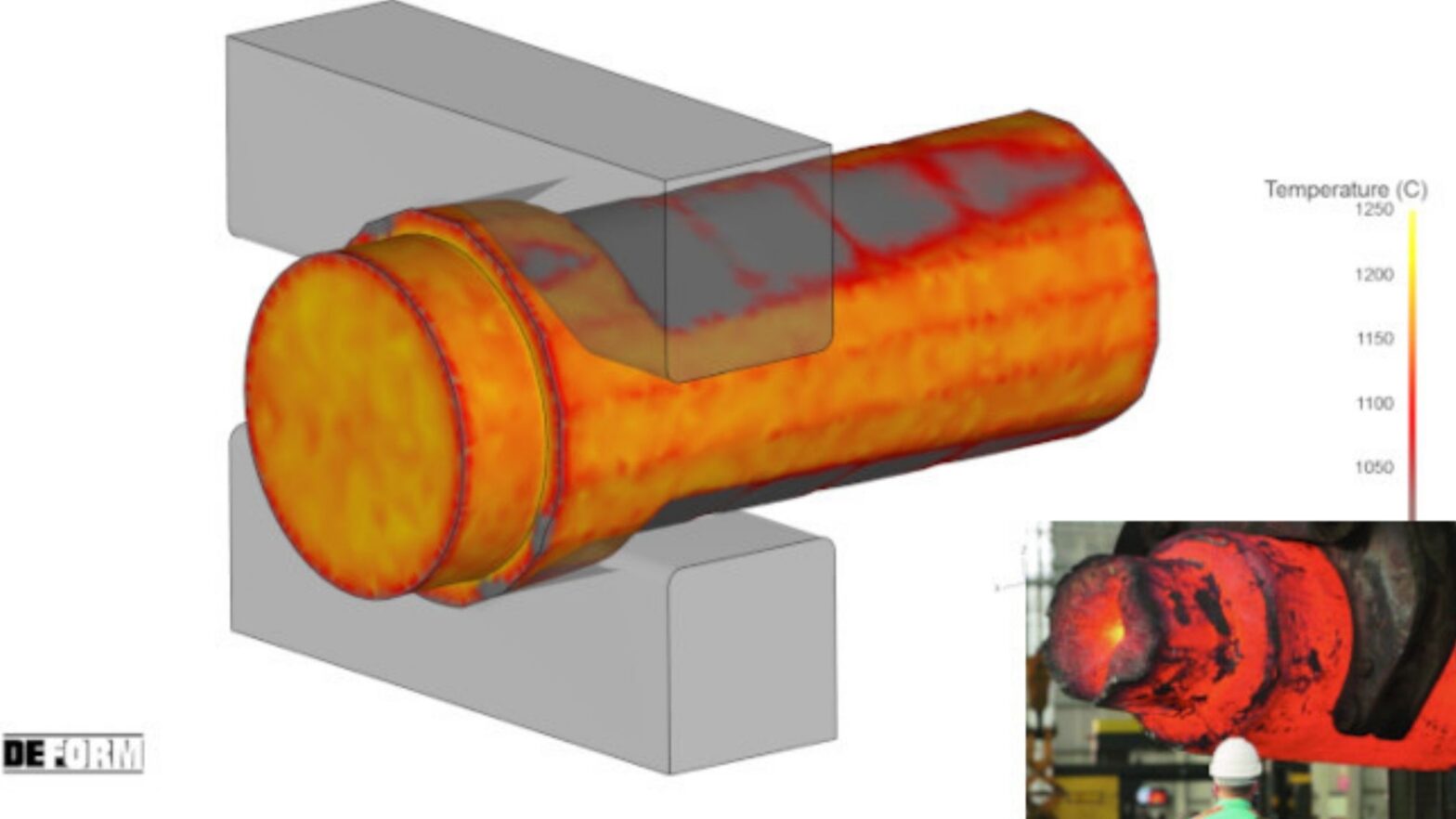

Ring Rolling of metals: What it is

The Ring Rolling process is a machining method in which a very thick ring, placed between two groups of rollers, is deformed in a ring with a greater diameter and smaller section. The thickness is reduced by approaching the rings while rotating. The main products made are large sealing rings for turbines and for bearings with very low tolerances and a favourable arrangement of grains thus improving the mechanical properties.

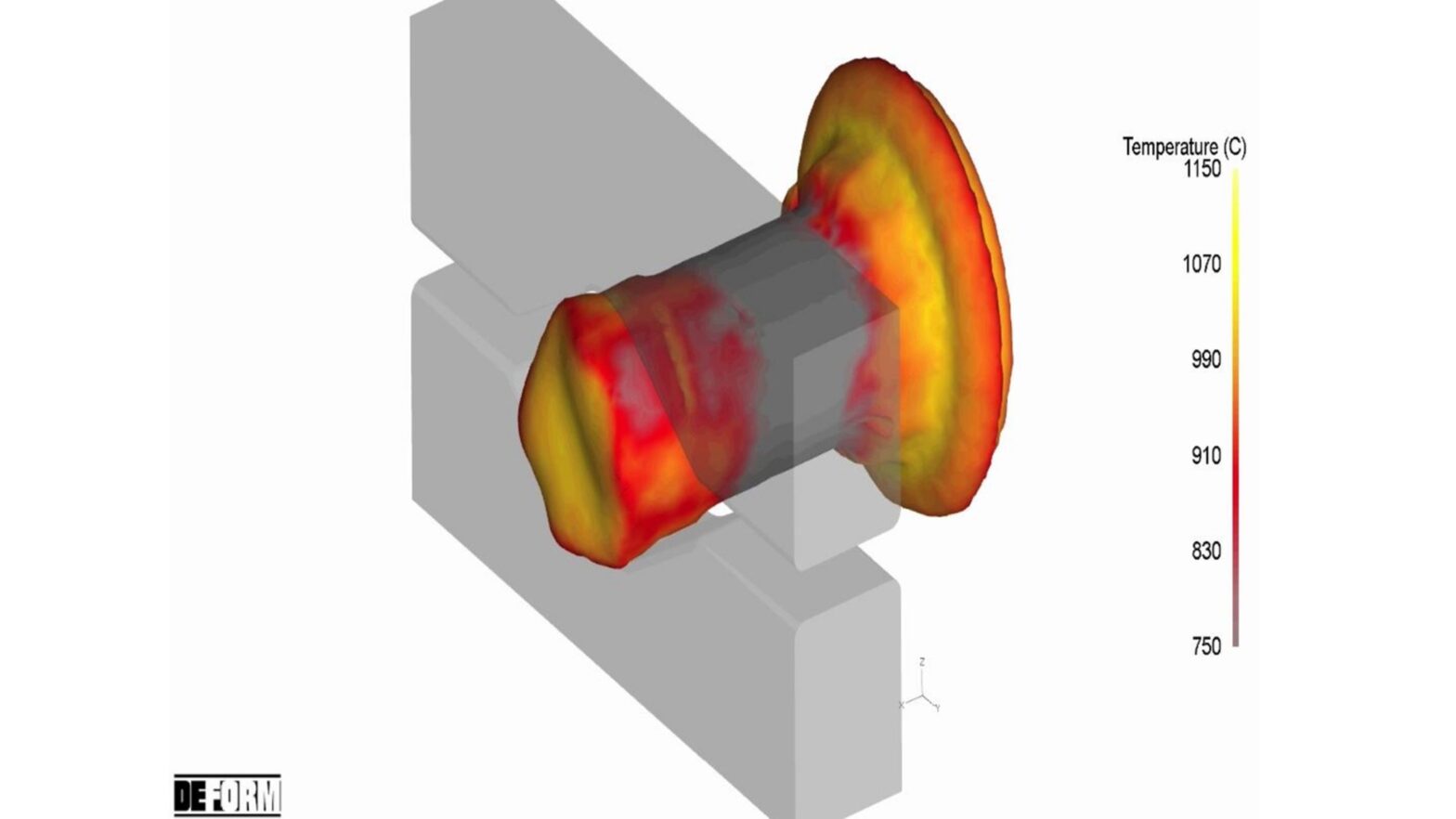

Ring Rolling Simulation: How it works

Simulation of ring rolling to preview times and forces required to make the ring.

The Ring Rolling system of DEFORM was specifically developed with the mesh design, update, FEM motor, contact and simulation control optimised for ring rolling.

Unlike many ring rolling simulation solutions, “artificial” hypotheses are reduced to a minimum. The software is capable of showing the increase in local mesh density in the deformation areas. SFTC, Scientific Forming Technologies Corporation, developed an efficient and accurate simulation system specifically designed for ring rolling.

The solver uses a mix of implicit Langragiane and ALE technologies. A brick mesh (hex), used in the FEM motor, is optimised to refine the mesh in the deformation and contact areas.

What customers say about DEFORM:

- EXCELLENT AGREEMENT OF “SOFTWARE RESULTS” WITH “REALITY” DEFORM is the most widely used cold forming simulation software in the world

- SAMPLING IMMEDIATELY POSITIVEThe simulation makes it possible to identify defects obtained during forming, to understand their causes and therefore to undertake the right corrective actions

- STARTING TIMES REDUCED TO A MINIMUM The press setting was already tested in simulation. The real sampling will dispose of the machine setup card already defined.

- CERTAIN RAW MATERIAL PROCUREMENTThe DEFORM deforming simulation makes it possible to assess different extruded item diameters and therefore to immediately identify the diameter for each code

- REQUIRED PRESS DEFINITION DEFORM indicates the required tonnage for each workstation and therefore indicates which machine is necessary for the process. Planning of samplings and production

- LONGER MOULD DURATION Tool wear known and reduced thanks to modified mould mechanics. Mould damage phenomena eliminated because expected and therefore taken care of in simulation

For the purchase, hire or a DEMO of the software or if you want to take advantage of a simulation service specially-made by our technical department, write or call us at +39 030 3365383