DEFORM Benefits

- Reduction of prototype production and physical tests

- Elimination of rejects and reduction of defects

- Elimination of samplings

- Less time in development of new components

- Less time in producing new or already existing components

- Lower design and production costs

- Reduction of material waste

- Better understanding of the component before being designed

- Elimination of defects

- Better component quality

- Longer duration of tools and mould

Sheet Metal Forming: What it is

Sheet metal forming is a forming process to obtain products with three-dimensional shapes starting from a flat semi-finished product, usually metal sheets obtained through cold rolling. Sheet metal forming makes use of different materials: stainless steel, copper, brass, aluminum. The sheet metal forming process deforms the material beyond its elastic limit by applying forces in the sheet metal plane, without exceeding the breaking limit.

Transformation by plastic deformation of the sheet metal is carried out by using tools generally called punch and die. Based on the type of product to be made, the process requires the use of several accessory tools capable of restraining and controlling the motion of the sheet metal during its deformation. This all entails a variety of critical features depending on costs, times and machining waste.

Success story NICRO SPA: Cold deep drawn radiant tube. Sheet metal forming simulation with DEFORM to eliminate cracks, wrinkles and reduce the number of stations.

Sheet Metal Forming Simulation: How it works

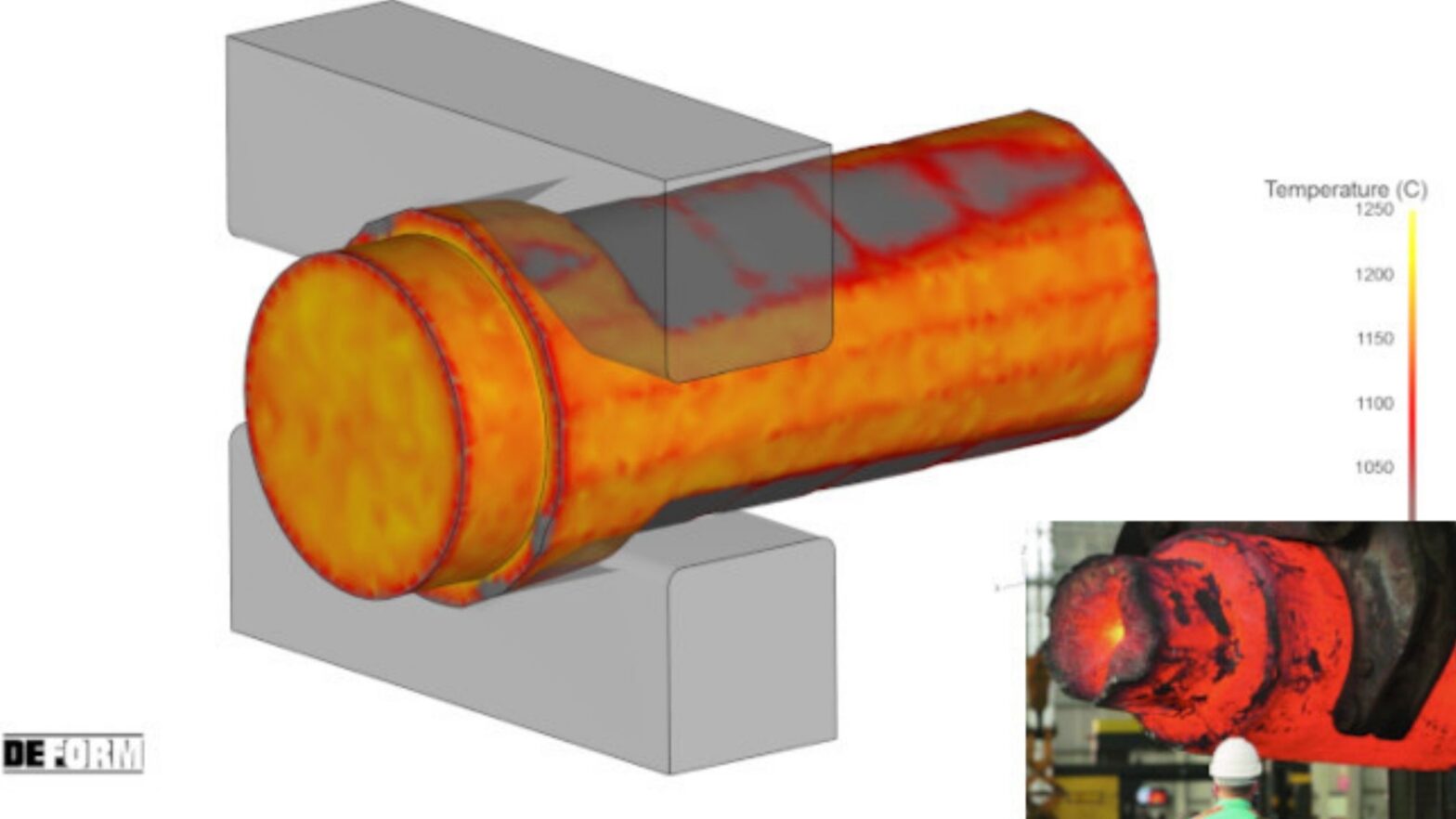

To address these criticalities and the market requirement of reducing times, costs, defects and waste, the DEFORM process simulation software, of the American SFTC – Scientific Forming Technology Corporation, comes into play.

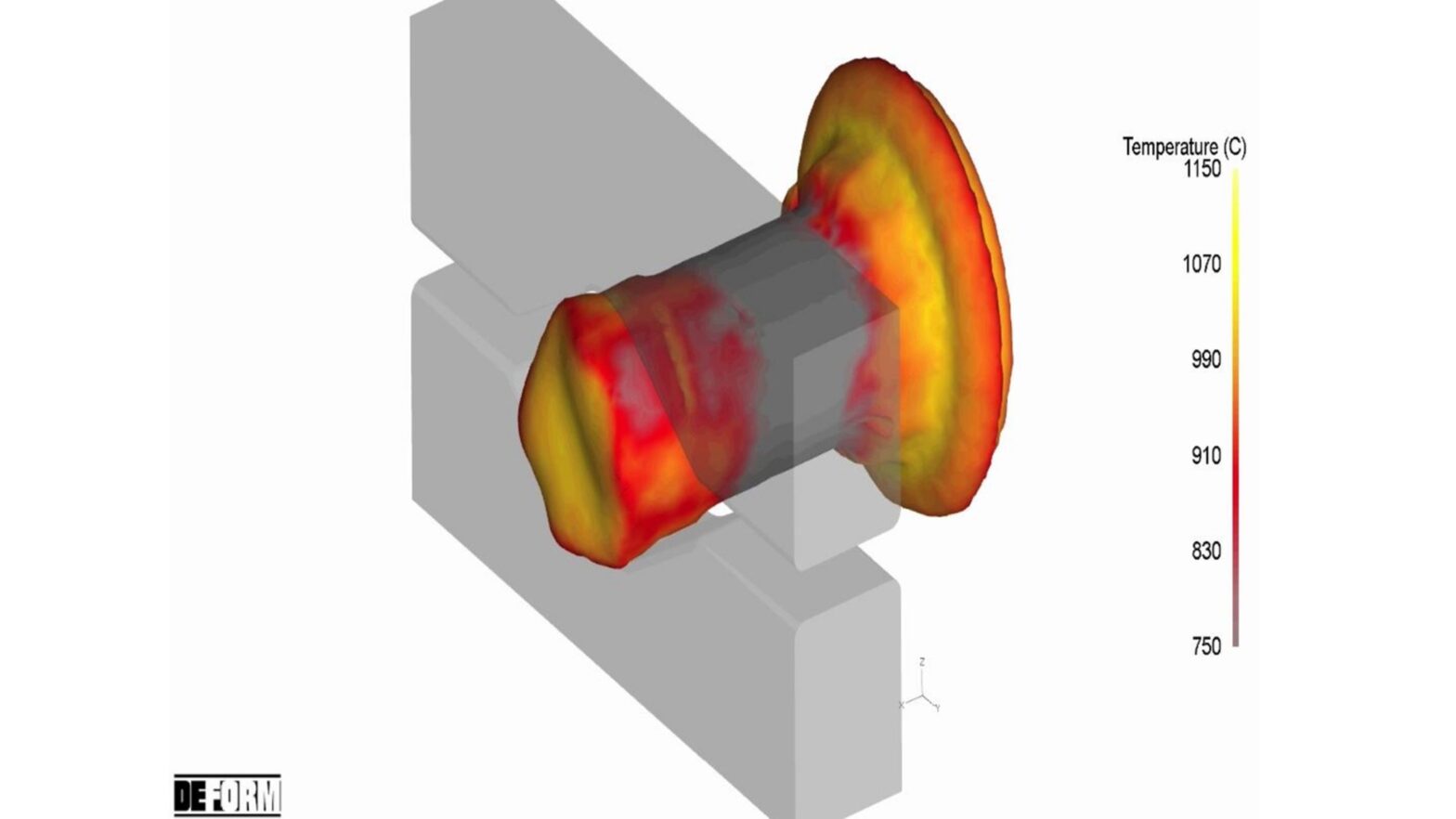

DEFORM Sheet metal forming simulation can analyse and streamline the process variables to obtain quality finished components without typical defects such as creases or fractures.

The simulation software allows you to predictably discover and analyse errors and issues as early as the design stage: compute stresses and efforts in the sheet metal, its springback after removing the load; the stability of the mould through the stress analysis and studies focused on the wear rate of the equipment.

By entering the parameters of the actual model in the DEFORM sheet metal forming simulation software, such as component geometry, the properties of the material and the strength of the press, the simulation results with DEFORM will be realistic. This allows the designer and process engineer to already predict during the design stage how to adjust process parameters to achieve ideal and quality results free of defects, wear and excessive rejects.

DEFORM, through sheet metal forming simulation, is a tool dedicated to production and is therefore simple to use. The technical operator, the quality department and the technical department will use simulation daily to address problems with the workpiece. DEFORM can also be used in parallel by the Research & Development department to understand and develop new products. The software is designed to work on desktop PC or workstation and is a complete, easy and fast application.

Ecotre Valente offers solutions to metallurgic and quality problems together with its partner PentaP Srl of Bergamo: www.pentap.it

• PentaP is the Otto Bihler Maschinenfabrik GmbH & Co. KG partner in Italy for the provision of CAD bNX software training, support and formation solutions.

• PentaP simulates operations with DEFORM for all Otto Bihler Maschinenfabrik GmbH & Co. KG press or equipment mould designs already guaranteeing conformity of the results on a design level.

In the automotive, electronic and medical industries, the level of excellence currently demanded of these products requires features, both of the product and equipment, driven ever more to guarantee compliant results.

These components are made with presses of up to 1,500 strokes/min and with progressive dies made with extremely efficient materials and technologies.

The DEFORM simulation software of the production process, already at the initial stage of an industrialization process, makes it possible to assess the feasibility and quality of the results.

Assessing the deformation conditions, with equal process parameters, makes it possible to determine which is the most suitable solution to best achieve each individual operation, also highlighting the accumulation of stress on the component.

The operations in sequence are then further optimised to limit temperature and wear of all the involved tools.

The thirty-year experience with this type of product and the intuition provided every day in the delicate design stage, are supported by the bending process simulation with DEFORM software, which, through numerical values and clear and easy results, makes it possible to immediately verify the effectiveness of the new solutions proposed.

What customers say about DEFORM:

- EXCELLENT AGREEMENT OF “SOFTWARE RESULTS” WITH “REALITY” DEFORM is the most widely used cold forming simulation software in the world

- SAMPLING IMMEDIATELY POSITIVEThe simulation makes it possible to identify defects obtained during forming, to understand their causes and therefore to undertake the right corrective actions

- STARTING TIMES REDUCED TO A MINIMUM The press setting was already tested in simulation. The real sampling will dispose of the machine setup card already defined.

- CERTAIN RAW MATERIAL PROCUREMENTThe DEFORM forging simulation makes it possible to assess different extruded item diameters and therefore to immediately identify the diameter for each code

- REQUIRED PRESS DEFINITION DEFORM indicates the required tonnage for each workstation and therefore indicates which machine is necessary for the process. Planning of samplings and production

- LONGER MOULD DURATION Tool wear known and reduced thanks to modified mould mechanics. Mould damage phenomena eliminated because expected and therefore taken care of in simulation

For the purchase, hire or a DEMO of the software or if you want to take advantage of a simulation service specially-made by our technical department, write or call us at +39 030 3365383