DEFORM Benefits

- Quality improvement

- Optimization and saving in the design

- Improvement of production

- Enhanced precision

- Flexibility of use

- Reduction of calculation times

- Reduction of production rejects

- Saves money

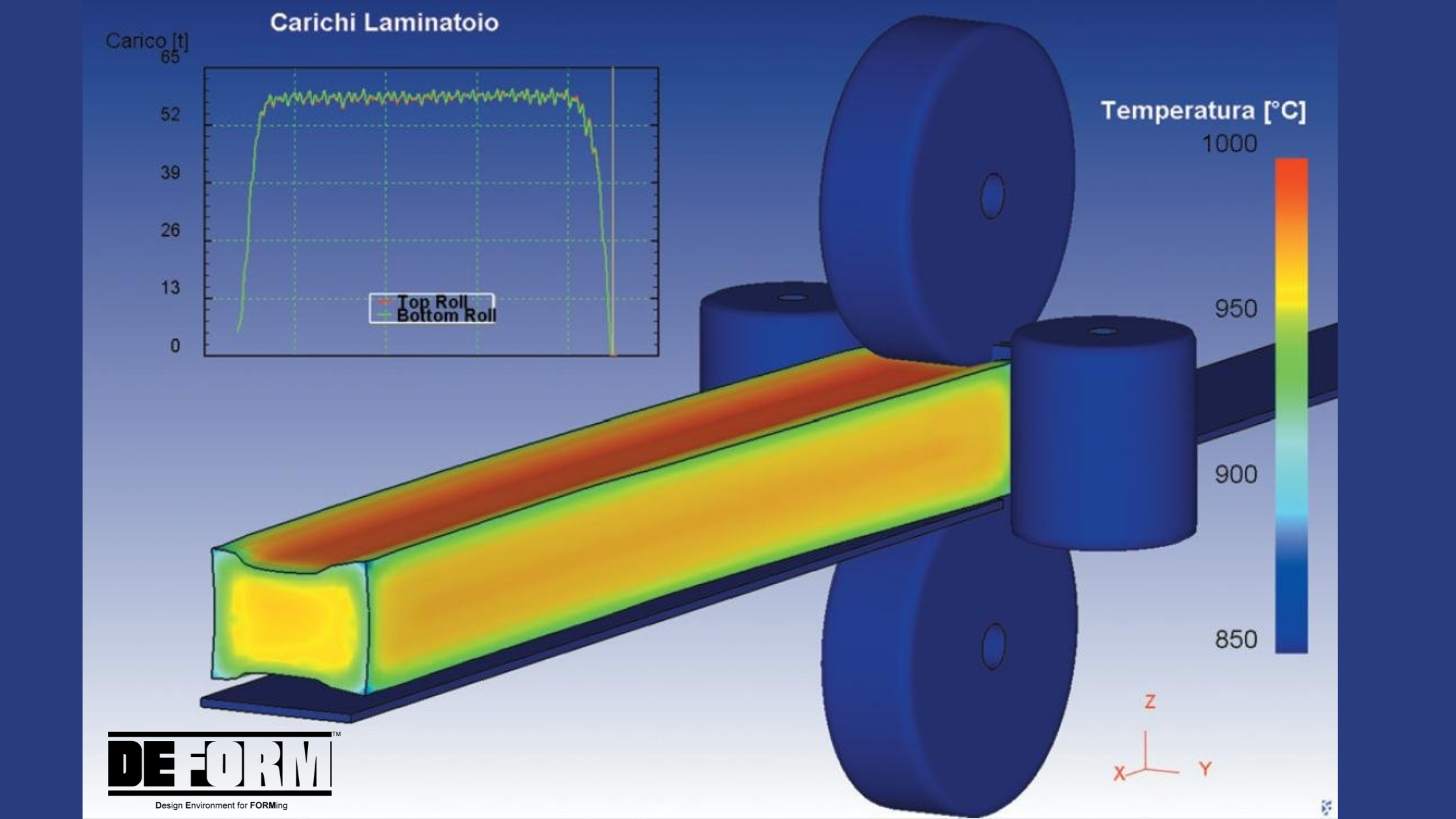

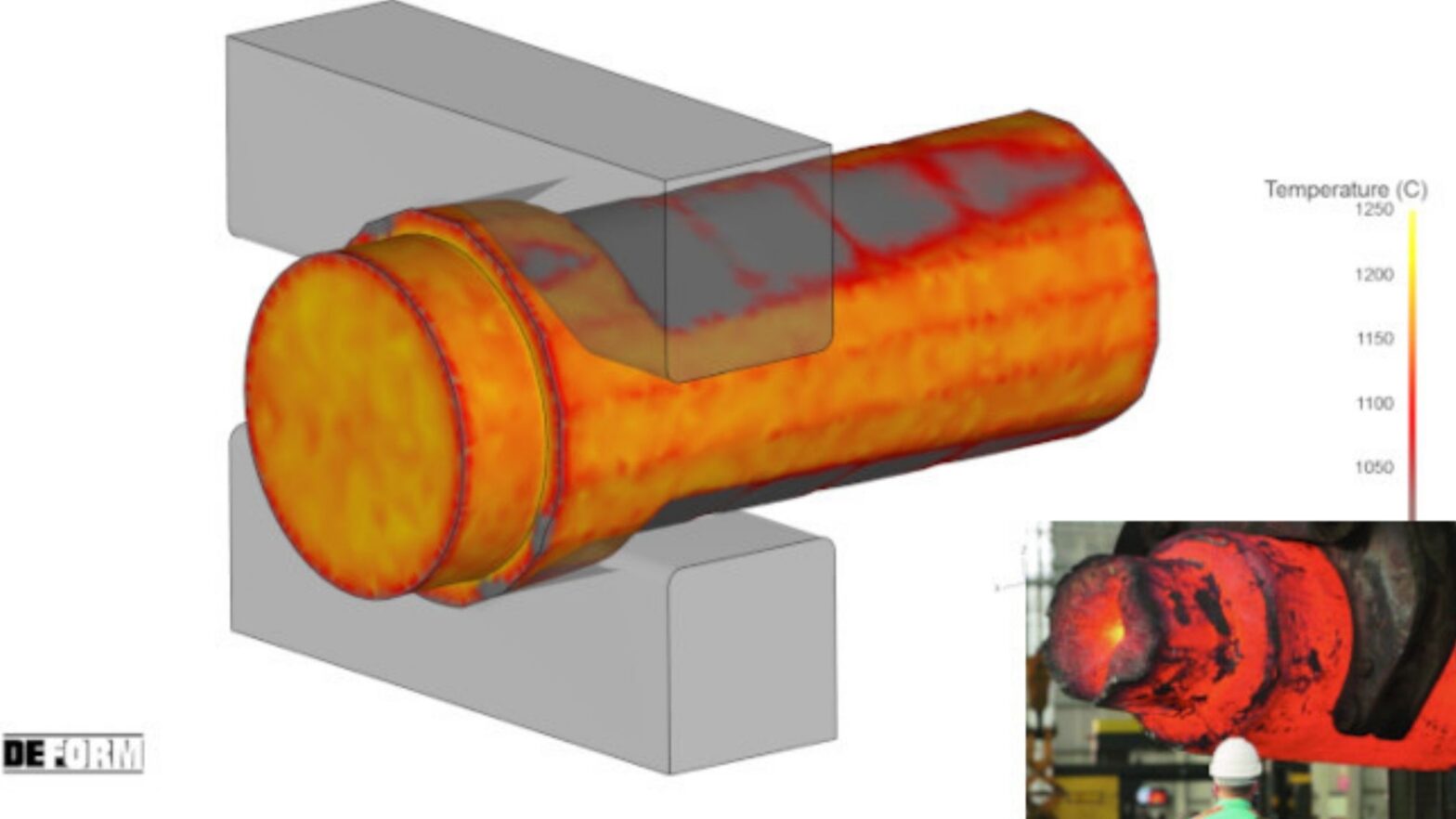

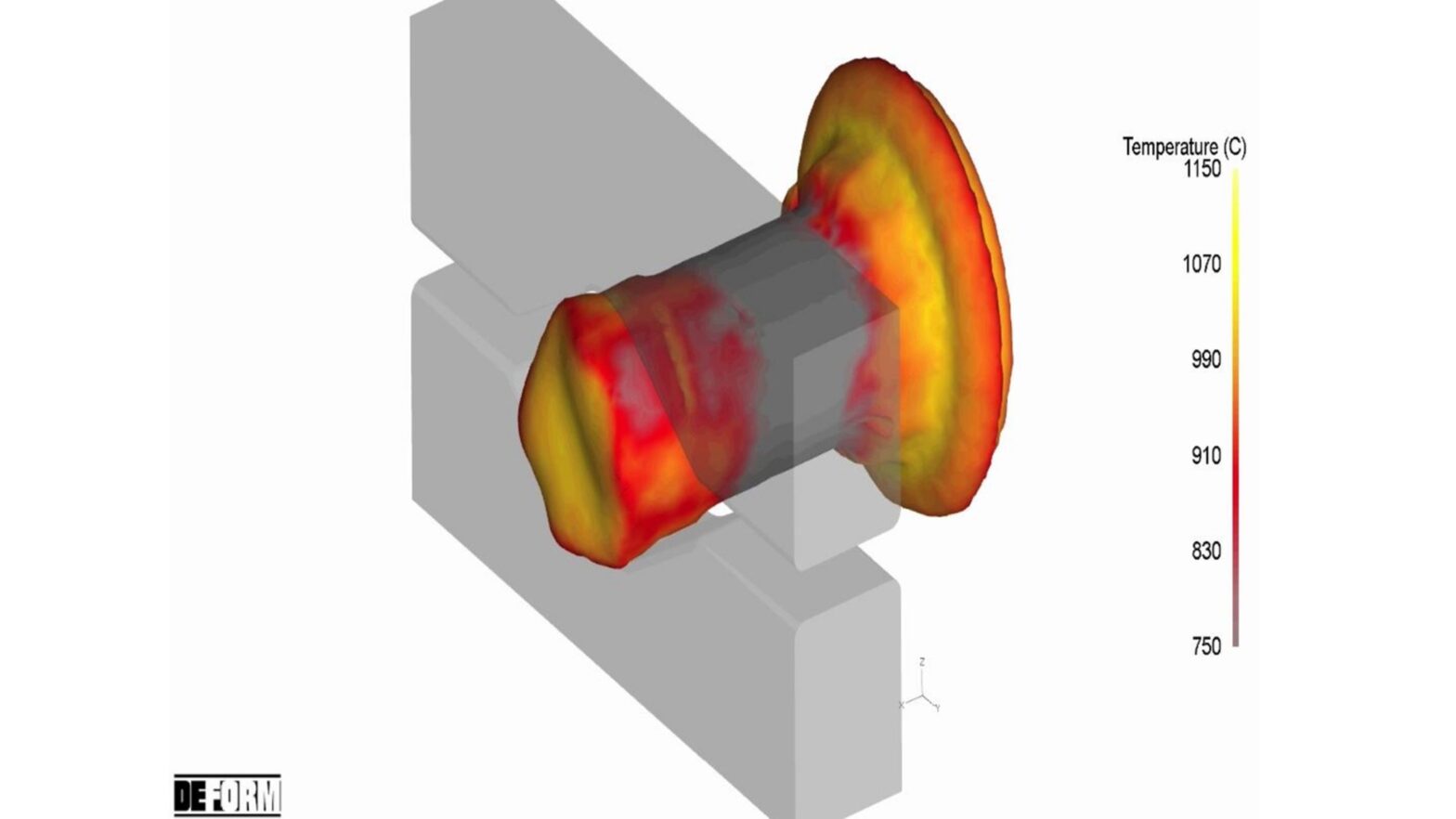

Shape Rolling of metals: What it is

Shape Rolling is a plastic deformation process through which the material passes between rotating cylinders (rollers), smooth or shaped, that exert a crushing action thus reducing the cross-section, accompanied by elongation of the piece. The process can be carried out either hot or cold, normally with several passes between the rollers so as to achieve progressive deformation until the desired section of the laminate is reached.

Shape Rolling Simulation: How it works

Simulation of all shape rolling processes both on continuous and reversible trains and Mannesman process.

DEFORM shape rolling simulation software allows you to re-create the filling of gauges, loads, torques and motor power.

Improvements can include the capability of predicting the thermal profile, the grain size, the recrystallization and phase transformation through several shape rolling operations.

Lastly, optimization techniques can be used to improve the design of the cross-section, to minimise shape rolling stress and to predict the number of times necessary, as well as to avoid potential defects before production trials. DEFORM uses the ALE method to reduce calculation times, without sacrificing precision.

DEFORM is a tool dedicated to production and is therefore simple to use. The technical operator, the quality department and the technical department will use simulation daily to address problems with the workpiece. DEFORM can also be used in parallel by the Research & Development department for new products. DEFORM software is designed to work on desktop PC or workstation.

The Americans, manufacturers of DEFORM, came up with a complete, simple and fast software.

What customers say about DEFORM:

DEFORM shape rolling simulation software is American and has been optimised to be reliable, quick and easy.

- EXCELLENT AGREEMENT OF “SOFTWARE RESULTS” WITH “REALITY” DEFORM is the most widely used cold forming simulation software in the world

- SAMPLING IMMEDIATELY POSITIVEThe simulation makes it possible to identify defects obtained during forming, to understand their causes and therefore to undertake the right corrective actions

- STARTING TIMES REDUCED TO A MINIMUM The press setting was already tested in simulation. The real sampling will dispose of the machine setup card already defined.

- REQUIRED PRESS DEFINITION DEFORM indicates the required tonnage for each workstation and therefore indicates which machine is necessary for the process. Planning of samplings and production

- LONGER MOULD DURATION Tool wear known and reduced thanks to modified mould mechanics. Mould damage phenomena eliminated because expected and therefore taken care of in simulation

For the purchase, hire or a DEMO of the software or if you want to take advantage of a simulation service specially-made by our technical department, write or call us at +39 030 3365383