DEFORM Benefits

- Quality improvement

- Optimization and saving in the design

- Improvement of production

- Enhanced precision

- Flexibility of use

- Reduction of calculation times

- Reduction of production rejects

- Saves money

Trimming & Shearing Simulation: What & how it works

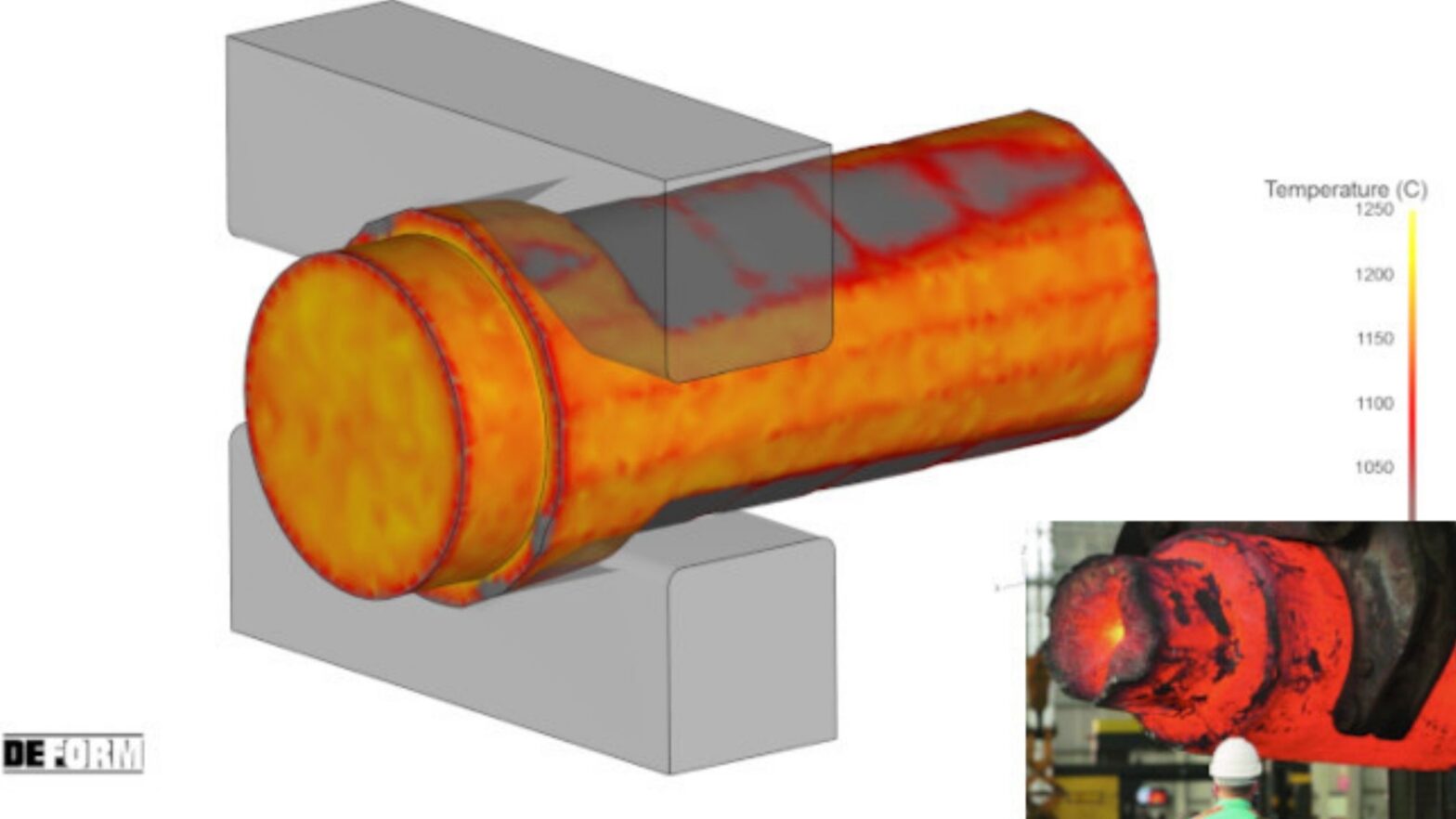

Trimming & shearing is a process consisting the separation a sheet, plate or tubular component by cutting it to get individual components with particular shapes. The process entails having the material undergo high stress, beyond the breakage limit which deforms the material by cutting until a fracture is made. The process requires tools called punch and die and can have even complex and particular shapes.

Trimming & shearing simulation is typically performed downstream, but can jeopardise conformity of the workpiece.

DEFORM software can assess the cutting layout with shears, trimming & shearing a single figure or two figures per stroke and even two mirrored figures per stroke, obtaining an optimal layout in no time. Using trimming & shearing simulation software can considerably reduce both cost estimation errors of materials and the time necessary for the estimations.

Ecotre Valente offers solutions to metallurgic and quality problems together with its partner PentaP Srl of Bergamo: www.pentap.it

• PentaP is the Otto Bihler Maschinenfabrik GmbH & Co. KG partner in Italy for the provision of CAD bNX software training, support and formation solutions.

• PentaP simulates operations with DEFORM for all Otto Bihler Maschinenfabrik GmbH & Co. KG press or equipment mould designs already guaranteeing conformity of the results on a design level.

In the automotive, electronic and medical industries, the level of excellence currently demanded of these products requires features, both of the product and equipment, driven ever more to guarantee compliant results.

These components are made with presses of up to 1,500 strokes/min and with progressive dies made with extremely efficient materials and technologies.

The DEFORM simulation software of the production process, already at the initial stage of an industrialization process, makes it possible to assess the feasibility and quality of the results.

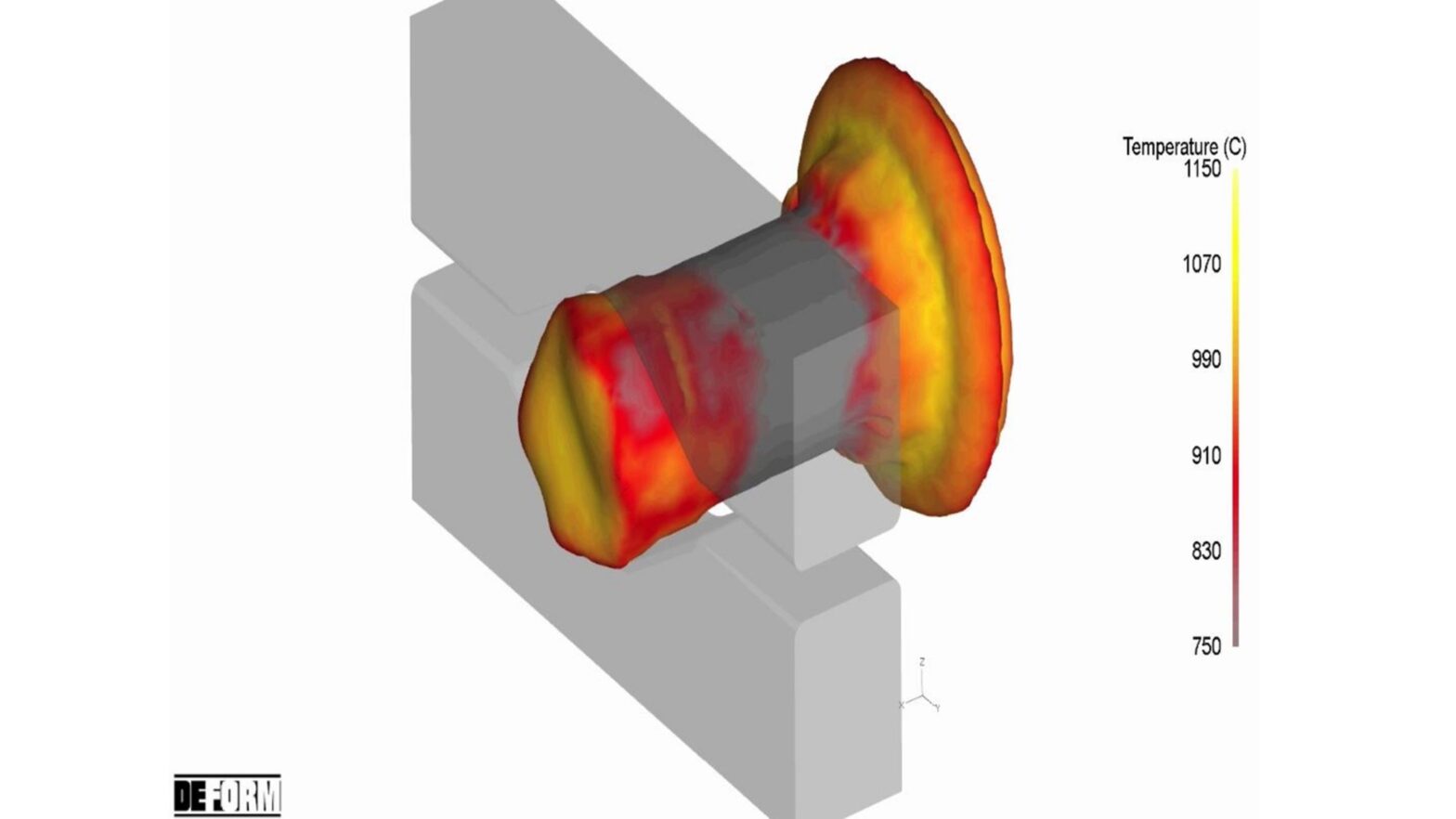

Assessing the deformation conditions, with equal process parameters, makes it possible to determine which is the most suitable solution to best achieve each individual operation, also highlighting the accumulation of stress on the component.

The operations in sequence are then further optimised to limit temperature and wear of all the involved tools.

The thirty-year experience with this type of product and the intuition provided every day in the delicate design stage, are supported by the bending process simulation with DEFORM software, which, through numerical values and clear and easy results, makes it possible to immediately verify the effectiveness of the new solutions proposed.

What customers say about DEFORM:

- EXCELLENT AGREEMENT OF “SOFTWARE RESULTS” WITH “REALITY” DEFORM is the most widely used forming simulation software in the world

- SAMPLING IMMEDIATELY POSITIVEThe simulation makes it possible to identify defects obtained during forming, to understand their causes and therefore to undertake the right corrective actions

- STARTING TIMES REDUCED TO A MINIMUM The press setting was already tested in simulation. The real sampling will dispose of the machine setup card already defined.

- CERTAIN RAW MATERIAL PROCUREMENTThe DEFORM forming simulation makes it possible to assess different extruded item diameters and therefore to immediately identify the diameter for each code

- REQUIRED PRESS DEFINITION DEFORM indicates the required tonnage for each workstation and therefore indicates which machine is necessary for the process. Planning of samplings and production

- LONGER MOULD DURATION Tool wear known and reduced thanks to modified mould mechanics. Mould damage phenomena eliminated because expected and therefore taken care of in simulation

For the purchase, hire or a DEMO of the software or if you want to take advantage of a simulation service specially-made by our technical department, write or call us at +39 030 3365383