DEFORM Benefits:

- Quality improvement

- Optimization and saving in the design

- Improvement of production

- Enhanced precision

- Flexibility of use

- Reduction of calculation times

- Reduction of production rejects

- Saves money

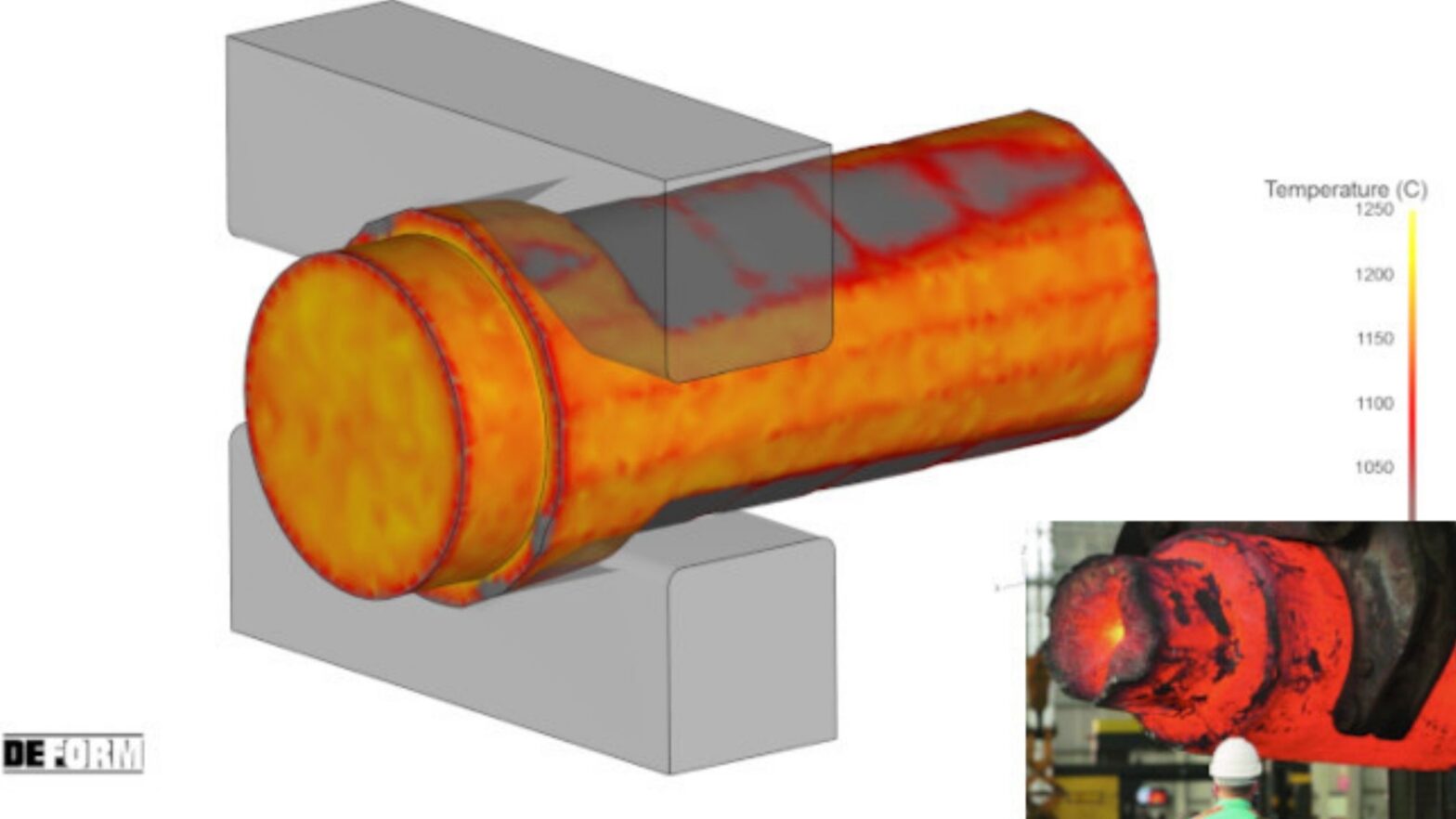

Heat Treatments of Quenching and Tempering: What it is

Quenching and Tempering is a heat treatment used to obtain high hardness/strength of steel. It consists of austenitizing, hardening and tempering, so as to maintain a predominantly martensitic or bainitic structure. Tempering is aimed at reducing the stressing status of the material obtained during hardening.

Heat Treatment simulation: Quenching and Tempering

Success story: gear shaft – Centro Tecnologico Arti e Mestieri

Quenching and Tempering simulation: How it works

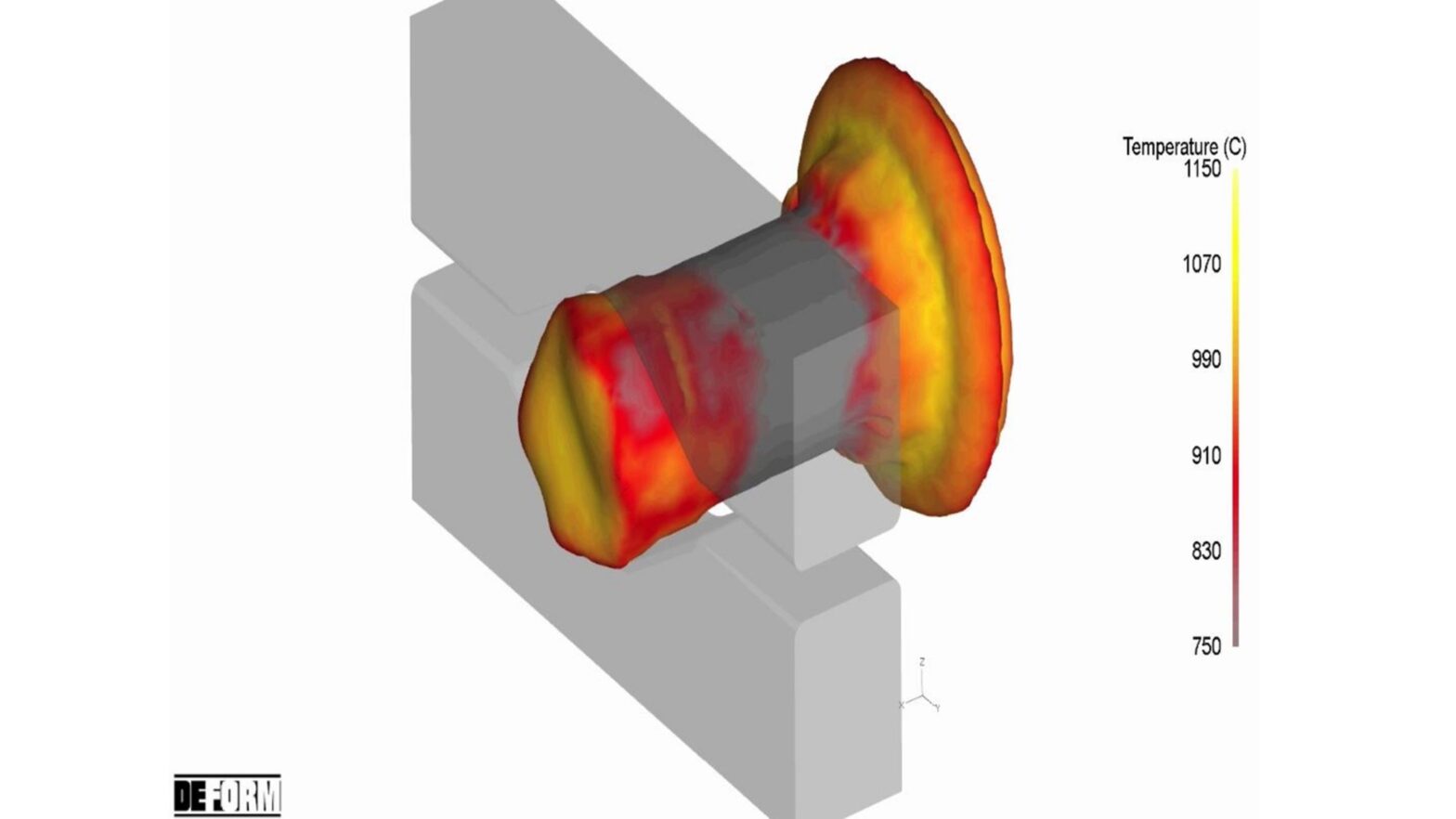

Simulation of all heat treatment methods according to times and temperatures. Phase transformations, martensite quantification, stresses, volume trend, swelling of the grain.

The heat treatment simulation assesses the events that take place during a thermal process, predicting deformations, residual stresses, hardnesses and distribution of metallurgic structures obtained both in the hardening stage and in the areas involved by any carburising.

Microstructure: martensite percentage after hardening in oil

DEFORM simulation software is an aid in heat treatment to calculate the mechanical properties (YTS, UTS, E% and HB) in the entire range – from T4 through T6 and T7 – based on Mg variations and aging parameters for A356/357 in most commonly poured aluminum.

The thermal solver can calculate the flow of heat taking into account conduction, convection and radiation. The release of heat associated to phase changes, such as solidification and transformation of solid phase, is described by an enthalpic formulation.

Final hardness distribution from surface to core.

The DEFORM simulator software, a powerful finite elements modelling system, can simulate heat treatment processes. The system predicts the thermal, mechanical and metallurgic responses of parts during heat treatment. It can predict distortion of heat treatment, hardening and residual stresses.

Final distribution of residual stresses.

The system can also give information on transformation of the phase and volume fraction of the phase. A variety of materials can be simulated, from steel to carbon, aluminum, titanium and nickel-based alloys. Typical heat treatment processes include: – normalising – austenitizing– carburising – solution treatments– hardening – tempering – aging – stress relieving.

Two approaches for the microstructural evolution of modelling during the thermomechanical process are implemented in DEFORM.

What customers say about DEFORM:

- EXCELLENT AGREEMENT OF “SOFTWARE RESULTS” WITH “REALITY” DEFORM is the most widely used cold forming simulation software in the world

- SAMPLING IMMEDIATELY POSITIVEThe simulation makes it possible to identify defects obtained during forming, to understand their causes and therefore to undertake the right corrective actions

For the purchase, hire or a DEMO of the software or if you want to take advantage of a simulation service specially-made by our technical department, write or call us at +39 030 3365383