DEFORM Benefits

- Greater mechanical strength

- Resistance to corrosion

- Less residual stresses

Heat Treatments of Soaking and Aging: What it is

The solution Soaking and Aging process is a heat treatment by precipitation mainly dedicated to aluminum and nickel alloys and austenitic stainless steel. The component is heated at high temperatures so as to guarantee full solubilization of the alloy elements within the metal matrix. This is followed by quick cooling of the component, called hardening, with the purpose of keeping the precipitates finely diffused in the component even at room temperature when this microstructure would be unstable.

Solution Soaking and Aging eliminate structural alterations caused by previous processes.

Soaking and Aging simulation: How it works

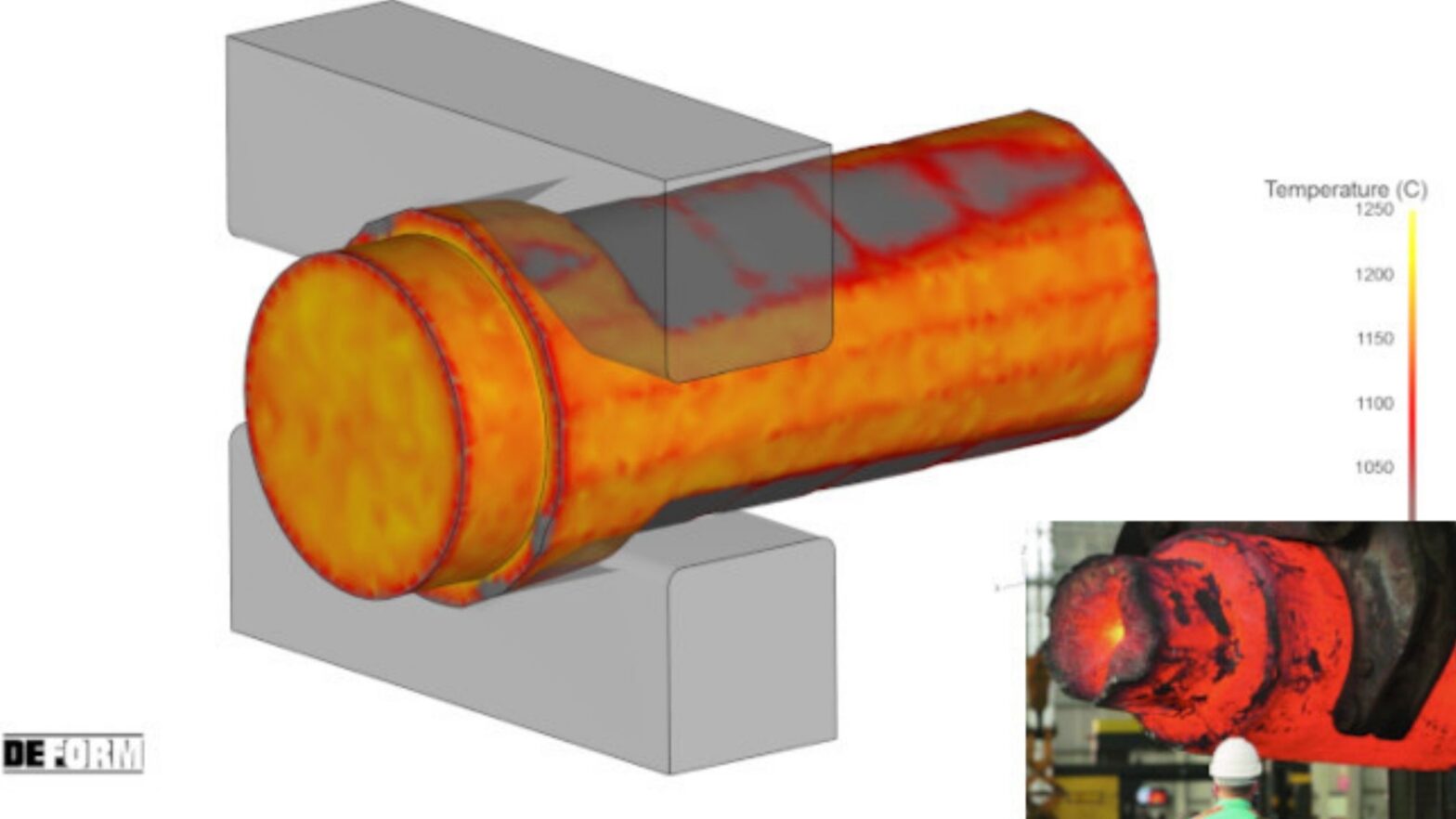

DEFORM, Soaking and Aging heat treatment simulation software, manufactured by the American SFTC – Scientific Forming Technologies Corporation, is capable of predictably simulating the entire solution treatment and aging process in its different types, on computer.

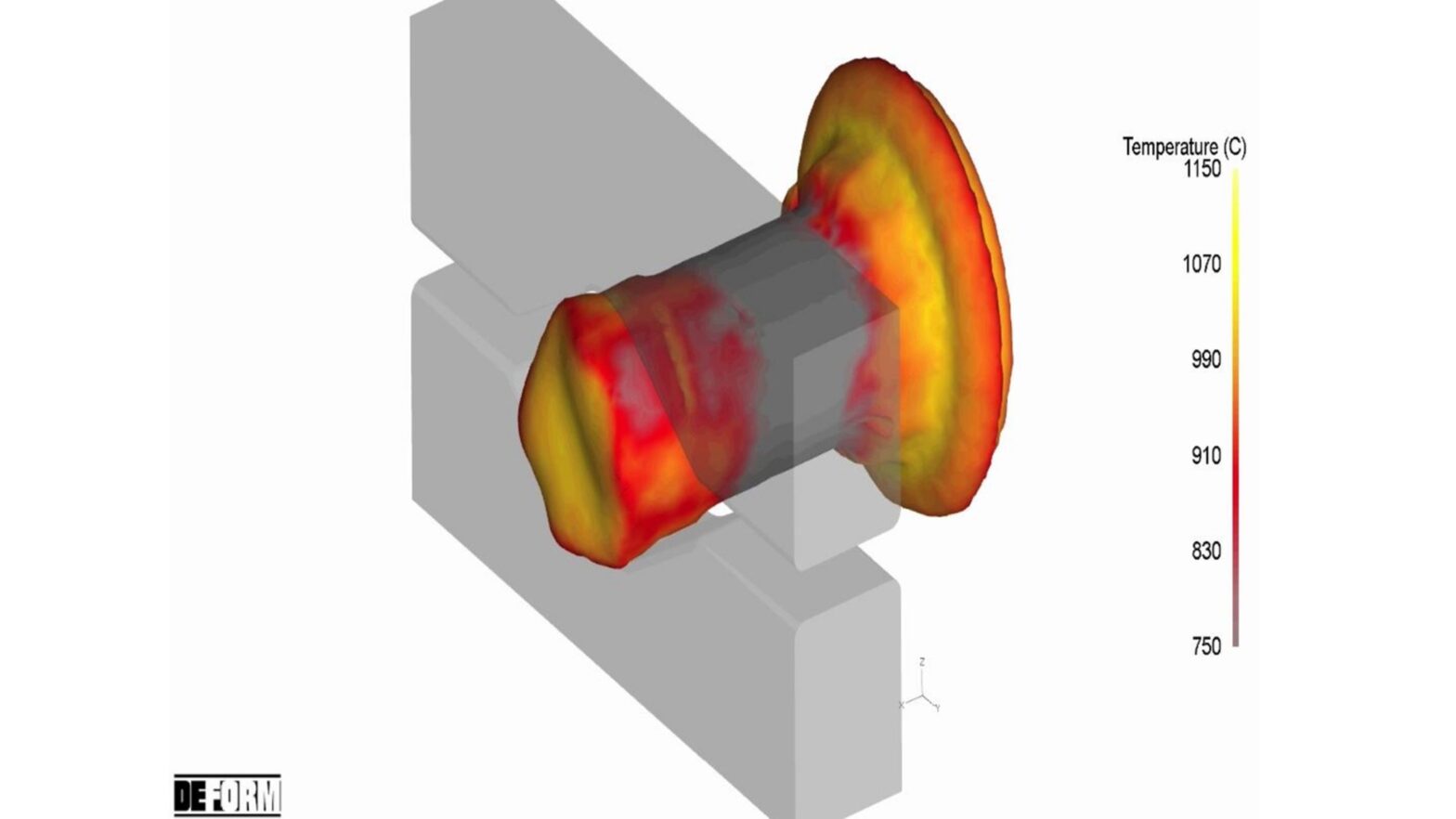

The setting of the soaking and aging heat treatment simulation starts by determining the process parameters: heating temperatures and times, hardening means, switch off duration, times and temperatures of the aging phase.

Following the simulation with DEFORM, you will able to see the outcome of the component after the simulated heat treatment cycle.

The best performance of the component is achieved through simulation of the soaking and aging heat treatments using DEFORM software.

What customers say about DEFORM:

DEFORM soaking and aging simulation software is American and has been optimised to be reliable, quick and easy.

- EXCELLENT AGREEMENT OF “SOFTWARE RESULTS” WITH “REALITY” DEFORM is the most widely used cold forming simulation software in the world

- SAMPLING IMMEDIATELY POSITIVEThe simulation makes it possible to identify defects obtained during forming, to understand their causes and therefore to undertake the right corrective actions

For the purchase, hire or a DEMO of the software or if you want to take advantage of a simulation service specially-made by our technical department, write or call us at +39 030 3365383